Safety Instructions: If attachments, accessories, or conguration-modifying components that are

located in the load path affect operation of the lift, affect the lift electrical listing, or affect intended

vehicle accommodation are used on this lift and, if they are not certied for use on this lift, then the

certication of this lift shall become null and void. Contact the participant for information pertaining

to certied attachments, accessories, or conguration-modifying components.

BendPak lifts are supplied with concrete fasteners meeting the criteria as prescribed by ASTM E488/

E488M-18. Lift buyers are responsible for any special regional, structural, and/or seismic anchoring

requirements specied by any other agencies and/or codes such as the Uniform Building Code (UBC)

and/or International Building Code (IBC).

The manufacture, use, sale, or import of this product may be subject to one or more United States

patents, or pending applications, owned by BendPak Inc.

1645 Lemonwood Dr.

Santa Paula, CA USA

www.BendPak.com

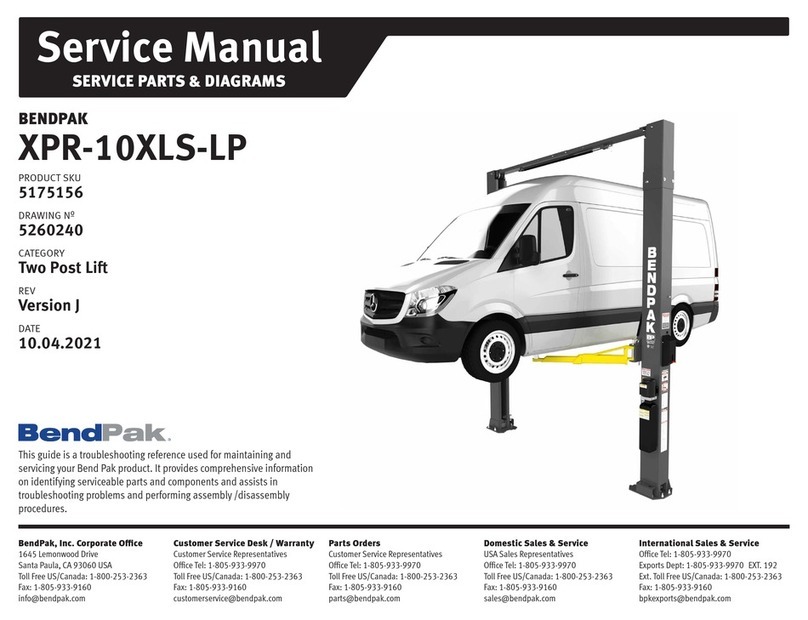

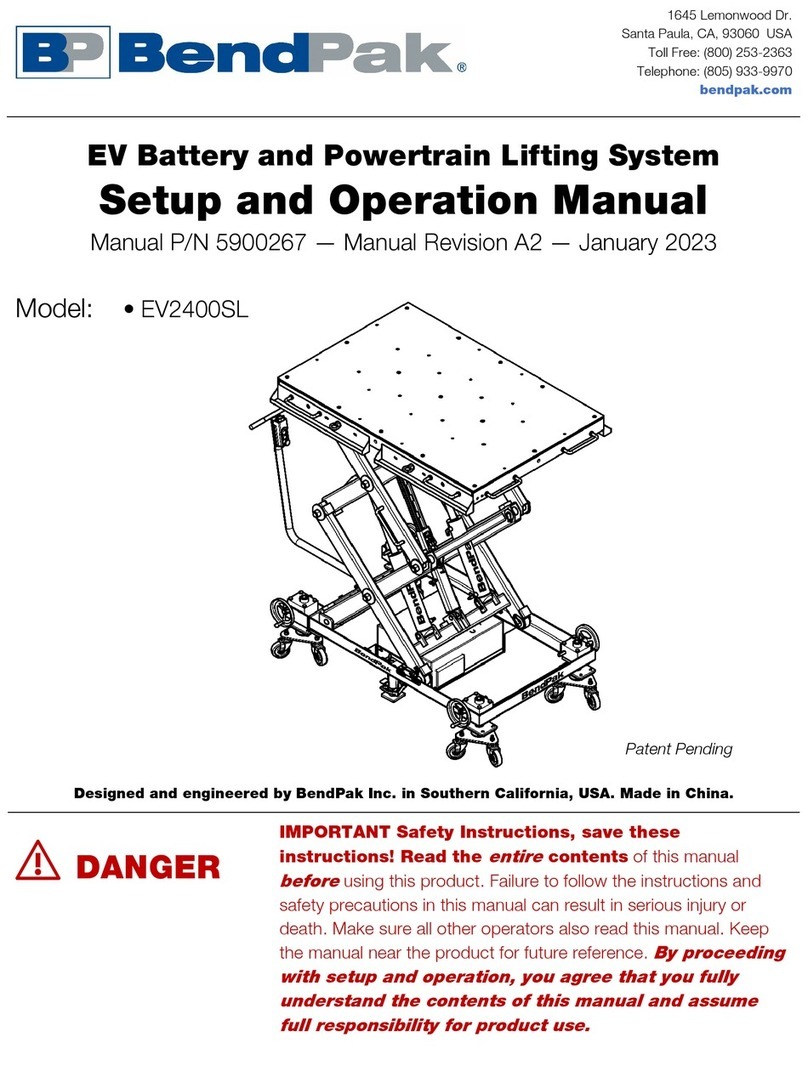

LIFT TYPE: Surface Mount MANUFACTURER: BendPak. See data plate for product details

POWER: Electric/Hydraulic INSTALLATION: See manual or contact factory

Do Not Remove Engineered by BendPak Inc., USA Made in China

PN 5905940

(Yellow color in file represents what should be clear PET material and SHOULD NOT print as Yellow ink.)

MD-6XP Product Decal Positioning

A

C D

B

MD-6XP_BendPak_Cylinder_Decal.pdf:

Material: Clear Adhesive PET

Size: 16”W x 3”H

Thickness: 4 Mil

Finish: Matte Overlaminate (No gloss)

Ink: U.V. protected, Opaque White

Print Process: Silk Screen, 85 line-screen (Yellow color in file represents what should be

clear PET material and SHOULD NOT print as Yellow ink. White area in file represents

Opaque White ink.)

Lamination: Clear laminate non-glare medium matte over-laminate (No gloss) for abrasion,

chemical and ultra violet protection.

Warning_Operation_Inst_Label_5905577.pdf:

Size: 3.5”W x 8.25”H

Material: 4 Mil. Permanent White Adhesive Vinyl

Thickness: 4 Mil

Ink: U.V. protected CMYK 2/C Process

Finish: Matte Overlaminate (No gloss)

Print Process: Offset Lithography - 200 line-screen or 300

p.p.i. for digital

Lamination: Clear laminate non-glare medium matte over-

laminate (No gloss) for abrasion, chemical and ultra violet

protection.

Warning_Drive_Car_Over_Label_5905576.pdf:

Size: 3.5”W x 11”H

Material: 4 Mil. Permanent White Adhesive Vinyl

Thickness: 4 Mil

Ink: U.V. protected CMYK 2/C Process

Finish: Matte Overlaminate (No gloss)

Print Process: Offset Lithography - 200 line-screen or 300 p.p.i. for digital

Lamination: Clear laminate non-glare medium matte over-laminate (No gloss) for abra-

sion, chemical and ultra violet protection.

Product_Data_Label_5905940-New.pdf:

Size: 4.5”W x 2.3”H

Material: 4 Mil. Permanent White Adhesive Vinyl

Thickness: 4 Mil

Ink: U.V. protected CMYK 2/C Process

Finish: Matte Overlaminate (No gloss)

Print Process: Offset Lithography - 200 line-screen or 300

p.p.i. for digital

Lamination: Clear laminate non-glare medium matte

over-laminate (No gloss) for abrasion, chemical and ultra

violet protection.

PN 5905577

PN 5905576

PN 5905940

PN 5905204

Clear PET material and

SHOULD NOT print as Yellow

TO PLACE ORDER

Visit www.bendpak.com

or dial 1-800-253-2363

Monday - Friday

6 a.m. - 4:30 p.m. PST

WARNING

!

WARNING

!

Maximum Lifting Capacity

6,000 lbs. / 2722 kg

FAILURE TO READ AND UNDERSTAND THE FOLLOWING WARNINGS MAY

RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE.

KEEP HANDS AND FEET AWAY FROM MOVING PARTS.

Read and understand entire contents of operation manual and

warnings below before operating this equipment.

Before raising a vehicle, make sure there is at least 1 inch of clearance

between the lift and the vehicle. The MD-6XP requires space between

the ground and your vehicle to build up enough force to raise vehicle.

It cannot raise a full load from a completely flat starting position.

WARNING

!

USE PROPER ADAPTERS

Do not attempt to lift trucks or other frame type vehicles with

standard rubber contact pads. NEVER use lift with missing

or damaged rubber contact pads. ALWAYS REPLACE rubber

contact pads when worn or damaged. Contact BendPak or your

BendPak dealer for product information.

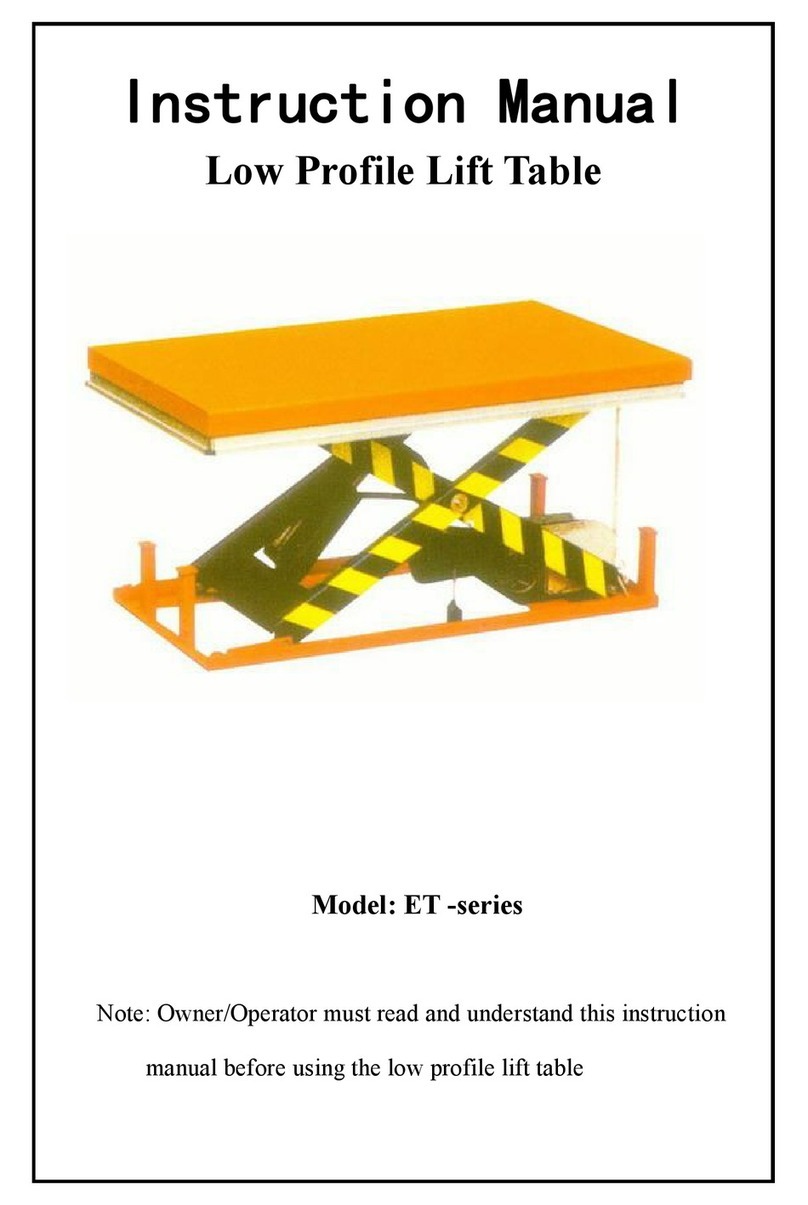

3 Never exceed rated capacity of the lift.

3 Do not operate the lift if any component is defective or worn. If you

find a problem, remove the lift from service and get it repaired.

3 Never operate lift with any person or equipment below it.

3 Drive vehicle completely over lift; make sure vehicle is centered and

stable prior to raising or lowering.

3 Keep a visual line of sight to the lift during operation.

3 Stand clear of the lift during operation.

3 Only leave the lift on the ground or on a locking position.

3 Keep all body parts and other objects away from pinch points during

operation.

3 Only use lift on flat, defect-free concrete.

3 Always use the lift pads that came with your lift. If a lift pad is

missing or damaged, replace it.

3 Visually confirm lift is on locking position before working under or

near lift.

Required for use when lifting

trucks, vans or other frame

vehicles that require additional stability.

FRAME CRADLE

ADAPTERS

SKU# 5215506

PN 5905576

Read and understand all Danger, Warning, and Caution messages

and operation procedures before using lift. Keep hands and feet

away from moving parts. Do not work under or near a raised vehicle

unless the lift is on a locking position.

OPERATION INSTRUCTIONS

Before raising a vehicle, make sure the weight of the vehicle does

not exceed the rated capacity of the lift, that all persons and

obstacles are away from the lift, and that the lift is lowered.

To Raise Lift:

1. Drive vehicle over lift; there must be at least 1 inch of clearance

between vehicle and lift.

2. Raise the lift until the tires are off the ground.

3. Make sure the vehicle is balanced and the pads are in contact with the

vehicle’s lifting points.

4. Raise the lift to just past the desired height.

5. Lower the lift down onto the most recently passed locking position.

Lock Pin needs to firmly rest against Lock Block, as shown in Figure A.

Before lowering a vehicle, make sure the area around and under

the lift is clear of people and obstacles.

To Lower Lift:

1. Raise the lift up for a second or two. This moves the Release Cam into

position so that it can push the Lock Pin over the Lock Block, allowing

the lift to lower, as shown in Figure B.

2. Lower the lift to the ground.

3. Remove all pads, check under the vehicle for obstacles, then drive the

vehicle off the lift.

WARNING

!

LOCKED POSITION

Figure A

LOWERING POSITION

Figure B

WARNING

!

ALWAYS make sure the lift is firmly in a locked position before

working on a raised vehicle.

PN 5905577

Lock Block

Release Cam

Lock Bar

Lock Pin

Lock Block

Release Cam

Lock Bar

Lock Pin