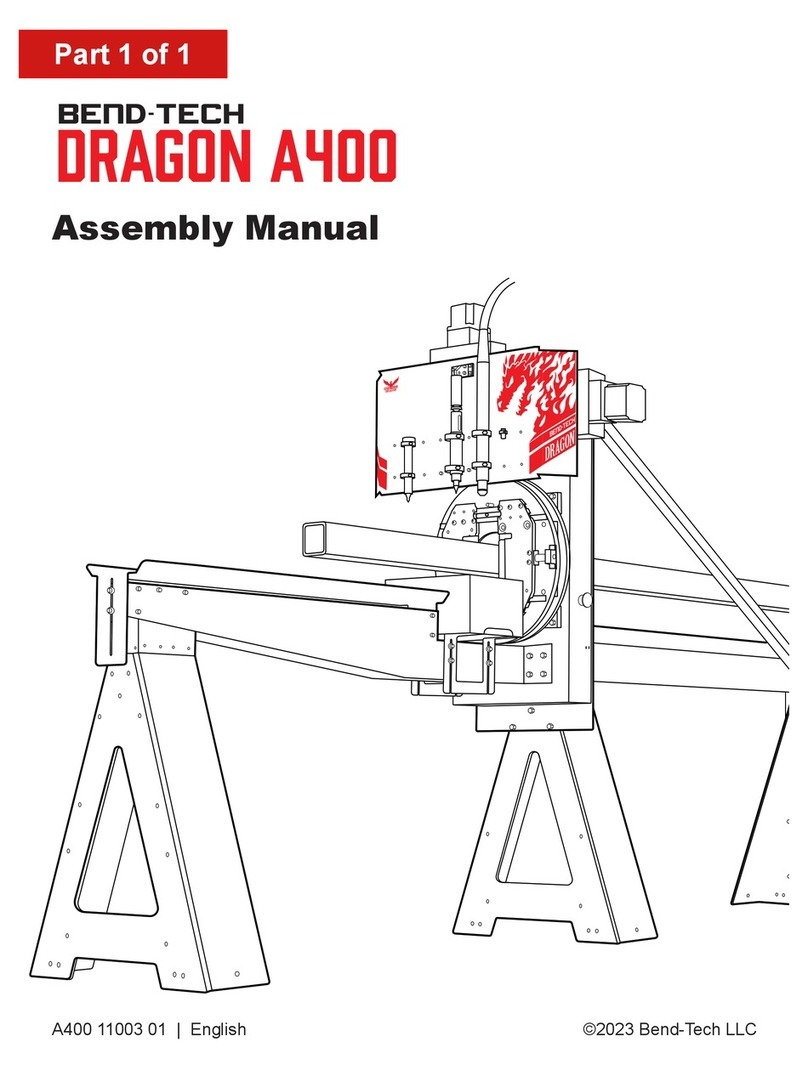

Bend-Tech Dragon A400 Installation guide

Revision 4 | English

A400

Part 1 of 4

Start-Up and Training Manual

Part 1: Safety and Maintenance

©2020 Bend-Tech LLC

ii Bend-Tech Dragon A400

Start-Up and Training Manual

©2020 Bend-Tech LLC

All rights reserved. The information in this manual is subject to change without notice.

Bend-Tech LLC strives to produce the most complete and accurate information regarding

its products. We are constantly working to improve and advance our products to increase

performance, user satisfaction and experience. Bend-Tech LLC assumes no responsibility for

errors or omissions regarding this manual. Bend-Tech LLC assumes no liability for damages

resulting from the use of the information contained in this publication.

iiiBend-Tech Dragon A400 Start-Up and Training Manual

Dragon A400

Start-Up and Training Manual

Revision 4

English

Original Instructions

July 2020

Bend-Tech LLC

729 Prospect Ave.

Osceola, WI 54020 USA

(651) 257-8715

www.bend-tech.com

iv Bend-Tech Dragon A400

Start-Up and Training Manual

Covering Bend-Tech Dragon

Bend-Tech, LLC provides a limited warranty on all new Dragon machines manufactured

directly or under license by Bend-Tech, LLC, and sold by Bend-Tech, LLC or its approved

distributors.

Warranty Coverage

Each Bend-Tech Dragon machine is warrantied by the manufacturer against defects in material

workmanship for 12-months. The warranty period commences the date the Dragon machine is

installed at the customer’s facility.

Repair or Replacement Only

The Manufacturer’s sole liability, and the Customer’s exclusive remedy under this warranty

shall be limited to repairing or replacing the defective part. Repair or replacement of parts

is at the sole discretion of the manufacturer. The Customer is responsible for warranty parts

installation. Bend-Tech does not provide warranty service labor.

Limits

This warranty does not cover components subject to wear due to normal use of the machine

such as belts, lights, tooling etc. This warranty is void if Bend-Tech LLC has determined any

failure is the result of mishandling, abuse, misuse, improper installation, improper storage,

improper maintenance or unauthorized modication of the machine. The warranty does not

cover damage due to natural disasters, re, ood or other external factors.

Software

Dragon software is covered by a 2-year maintenance plan from the purchase date of the

Dragon A400 machine. After the 2-year maintenance plan is expired, the Customer can

purchase a maintenance plan. A maintenance plan will ensure the customer always has

the newest version of Dragon software. The maintenance plan is critical to keeping Dragon

software updated with the newest capabilities possible, and is critical to the servicing of the

machine. Bend-Tech, LLC will contact the Customer regarding updates to the maintenance

plan within 1-month of expiration. Contact Bend-Tech Support to ensure software is up to date:

Limited Warranty

vBend-Tech Dragon A400 Start-Up and Training Manual

Any questions or concerns regarding this manual can be directed to Bend-Tech, LLC

representatives via the Dragon website, www.bend-tech.com. Click Contact in the menu bar for

communication options and send your comments to the Dragon Customer Service department.

Online Resources

• https://www.youtube.com/user/bendtech2020

• http://www.bend-tech.com/wiki7

• http://www.bend-tech.com

• https://www.facebook.com/2020ssi

• https://www.instagram.com/bend_tech

Customer Service

Congratulations on your purchase of the world’s best CNC plasma tube and pipe cutting

machine, the Dragon A400. Bend-Tech, LLC places great pride in customer satisfaction and it

is our promise to oer you the best support available for your Dragon A400. We recognize that

our support is a key factor in your success.

Contact Us

You can contact Bend-Tech, LLC customer service at 651-257-8715. Our support hours are

mailing address is: Bend-Tech, LLC, 729 Prospect Ave., Osceola, WI 54020, U.S.A..

Customer Satisfaction Commitment

vi Bend-Tech Dragon A400

Start-Up and Training Manual

This manual contains important statements that are called out from the regular text with an

associated signal word: “Danger,” “Warning,” “Caution,” or “Note.” Each of these signal words

is accompanied by its own icon. These signal words and icons indicate the severity of the

condition and the warning. The machine operator should familiarize themselves with these

warnings and read the statements before operating the machine.

Denitions & Examples

Danger

Danger indicates a serious condition that could cause severe injury or death to the operator or

bystanders if the instructions are not followed.

Warning

A Warning indicates there is a possibility for minor injury if the instructions are not followed

correctly.

! Danger !

Exceeding the material weight limit of the Dragon A400 can result in serious injury

to the operator and/or bystanders.

! Warning !

Due to the extreme temperatures that result from the plasma cutting process, parts

cooled in water in the parts catcher can still be extremely hot. Always use caution

when handling newly-cut parts.

Warnings

Example

Example

viiBend-Tech Dragon A400 Start-Up and Training Manual

Caution

Caution warns the operator that minor injury or machine damage could occur if instructions are

not followed. It could also mean that not following directions could aect the overall procedure

being performed.

Note

A Note gives clarication or focuses on information that is critical or unique to an operation.

! Caution !

Exceeding the material weight limit can aect performance and possibly damage

the Dragon A400.

Water Cooling system greatly reduces smoke and vapor emitted by the machine.

Bend-Tech recommends use of the Water Cooling system whenever possible.

Example

Example

viii Bend-Tech Dragon A400

Start-Up and Training Manual

Glossary

Glossary

A400

Indicates machine with 400-lb weight limit.

Axis

A xed reference line used by the Dragon A400.

Bend-Tech 7X

Machine design software - CAD.

BOB

Breakout Board.

Material Support Lifter

The Material Support Lifter supports

material to reduce sag.

Chuck

Located on the Trolley, the Chuck

holds the material so it can be moved

forward, backward and rotated.

Control Box

Connects Dragon Software Suite

to the Dragon A400.

Coolant Tray

Cools cut parts as they are produced.

Drive Belt

The X Motor uses the Drive Belt to power the

Trolley along the Rail. The Drive Belt is mounted

stationary along the length of the machine.

Drive Belt Pulley

Located on the X Motor, it works in

conjunction with the Drive Belt to

power the Trolley along the Rail.

E-Stop

Emergency stop.

ESS

Ethernet Smooth Stepper (Control Board).

Ethernet

System for connecting multiple

computers via a Local Area Network.

Front Gate

The Gate supports the material at the

front of the machine. It consists of two

sets of self-centering roller jaws.

Gate Lead Screw

Controls operation and adjustment of the Gate.

Interface

Any particular screen display generated

by Bend-Tech software.

Mach3

Machine driver software.

Parts Catcher

The parts catcher is placed at the front of

the machine to catch parts as they are cut.

Rail

The Rail is the main structure of the Dragon

A400. The Trolley rides on the Rail.

Tail

The Tail is located at the opposite end of

the Head of the machine. The Tail arrives

pre-assembled. The X Axis homing sensor,

Drive Belt Adjustment Block and E-Stop

are located at the Tail of the machine.

Toolhead

Operates the Marker, Engraver and Torch.

Trolley

The Trolley rides on the Rail, and carries

the Chuck forward and backward along

the length of the Rail Support Beam.

ixBend-Tech Dragon A400 Start-Up and Training Manual

Contents

Contents

Limited Warranty .....................iv

Customer Service.................... v

Customer Satisfaction

Commitment............................. v

Warnings ..................................vi

Glossary ..................................viii

Contents................................... x

01

Safety....................................... 13

1.1 General Safety Notes ........... 13

1.2 Safety Procedures .............. 14

1.2.1 Personal Protective Equipment

(PPE) ........................ 14

1.3 Recommended PPE for Operating the

Dragon A400 ..................... 14

1.3.1 Ultraviolet Eye Protection .... 14

1.3.2 Footwear ................. 15

1.3.3 Heat-Resistant Gloves....... 15

1.3.4 General Eye Protection ...... 15

1.3.5 Hearing Protection.......... 15

1.3.6 Breather Mask or Ventilation

System ....................... 15

1.4 Operational Safety .............. 16

1.4.1 Guards................... 16

1.4.2 Machine Walkthrough ....... 16

1.4.3 Machine Operational Movement16

1.4.4 Material Securing........... 16

1.5 Pinch Points ................... 17

1.6 Recommended Safety Guidelines .. 17

1.7 Modications To The Machine ..... 18

1.7.1 Unauthorized Modications ... 18

1.7.2 Factory Parts Kits and Updates 18

1.8 Emergency Stops (E-Stops). . . . . . . 19

1.8.1 E-Stop Overview ........... 19

1.8.2 Control Screen E-Stop....... 20

1.9 Electrical Servicing.............. 20

1.9.1 Power Down Before Servicing. 20

1.10 Material Weight ............... 20

1.10.1 Weight Limit.............. 20

1.11 Material Length................ 21

1.11.1 Material Support Lift........ 21

1.12 Plasma Torch ................. 21

1.12.1 Torch Overview ........... 21

1.12.2 Ultraviolet Light ........... 22

1.12.3 Heat .................... 22

1.12.4 Gloves .................. 22

1.12.5 Fumes .................. 22

1.13 Other Safety Information ........ 23

1.14 More Information .............. 23

xBend-Tech Dragon A400

Start-Up and Training Manual

Contents

02

Maintenance............................ 25

2.1 Dragon A400 Maintenance Overview 25

2.2 Daily Maintenance .............. 25

2.2.1 Clean Gate. . . . . . . . . . . . . . . . 25

2.2.2 Clean Rail ................ 26

2.2.3 Water Level ............... 26

2.2.4 Part Catcher. . . . . . . . . . . . . . . 26

2.2.5 Air Pressure ............... 26

2.2.6 Work Area ................ 26

2.2.7 Plasma System ............ 26

2.3 Weekly or Every 40 Hours ........ 26

2.3.1 Grease and Oil Buildup ...... 26

2.3.2 Electronic Connections ...... 27

2.3.3 Trolley And Related ......... 27

2.3.4 Drive Belt ................. 27

2.4 Monthly or 150 Hours............ 27

2.4.1 Fasteners................. 27

2.4.2 Cooling System ............ 27

2.4.3 Eccentric Bearings.......... 27

2.4.4 E-Stop ................... 28

2.5 Quarterly or 500 Hours. . . . . . . . . . . 28

2.5.1 Coolant Screens ........... 28

2.5.2 Pillow Block Bearings ....... 28

2.5.3 Comprehensive Cleaning .... 28

2.5.4 Actuators and Lead Screws... 28

2.6 Bi-Annually or 1000 Hours ........ 28

2.6.1 Chuck. . . . . . . . . . . . . . . . . . . . 28

2.6.2 Level and Straightness ...... 29

2.7 Annually or 2000 Hours .......... 29

2.7.1 Backlash ................. 29

11Bend-Tech Dragon A400 Start-Up and Training Manual

Safety

01

01

Safety

1.1 General Safety Notes

Read all warnings, cautions and instructions before operating the machine.

Each company has dierent processes. Always act in accordance with Environmental Health

& Safety (EHS) standards set in place regarding the facility in which the Dragon A400 is being

operated.

Follow basic safety precautions to reduce the risk of injury or mechanical damage. CNC metal

working machines such as the Dragon A400 introduce hazards such as moving parts, rotating

work, belts, pulleys, high voltage electricity, sparks, heat, noise and compressed air. It is the

responsibility of the Operator to take appropriate safety measures regarding the potential

hazards of this machine, and not the responsibility of Bend-Tech, LLC.

Maintaining cleanliness of the machine is important during normal use as well as prior to and

after servicing the machine. Cleaning procedures may require Personal Protective Equipment

(PPE) beyond the scope of daily operation procedures of the machine.

Read the Start-Up and Training manual in its entirety to ensure safe and ecient operation of

the Dragon A400 machine.

This manual is a reference guide for operation of the Dragon A400 and is not a comprehensive

source of operation or training information. A complete training course and support can be

requested from Bend-Tech, LLC, www.bend-tech.com.

12 Bend-Tech Dragon A400

Start-Up and Training Manual

Safety

01

1.2 Safety Procedures

1.2.1 Personal Protective Equipment (PPE)

Metalworking and metalworking operations can be dangerous. Using the proper PPE is

important in avoiding injuries that can result from sparks, heat, noise, smoke and vapor,

dropped objects and ultraviolet light. Consult local safety codes before operating the machine.

Before any personnel work on or near the machine, it is important to read this manual and fully

understand the safe operation of the machine. Contact Bend-Tech, LLC with any questions or

concerns regarding the safe operation of the Dragon A400.

1.3 Recommended PPE for Operating the Dragon A400

1.3.1 Ultraviolet Eye Protection

Safety glasses with the proper shade based on amperage of the Torch are required for

operation of the machine. It is important the Operator and anyone observing the machine

wear welder’s glasses or a welder’s mask, or the machine be surrounded by a welding curtain.

Refer to Occupational Safety and Health Administration (OSHA) standards to determine proper

safety glass shading and/or welding curtain for the cutting torch amperage being used.

! Caution !

The Dragon A400 should only be operated by authorized and trained personnel. The

Operator should always act in accordance with the Dragon A400 Start-Up and Training

safety procedures and machine instructions for safe operation of this machine. Failure to

follow these guidelines may pose a hazard to personnel and the machine.

! Danger !

The cutting torch emits ultraviolet light. Looking directly at the plasma stream can

damage human retinas.

13Bend-Tech Dragon A400 Start-Up and Training Manual

Safety

01

1.3.2 Footwear

The Dragon A400 is a metal working machine and metal materials can be extremely heavy.

A piece of dropped material could cause injury to the Operator or observers. Also, the Torch

emits sparks and possibly hot torch slag. It is highly recommended that the Operator wear

safety shoes or boots while operating the Dragon A400.

1.3.3 Heat-Resistant Gloves

Parts produced by the Dragon A400 will be extremely hot and could cause severe burns if not

handled properly. It is recommended that the Operator wear heat-resistant gloves when

handling parts produced by the Dragon A400.

1.3.4 General Eye Protection

The Dragon A400 will emit sparks, plasma dust and slag during operation. Anyone operating or

observing the machine should wear the appropriate eye protection.

1.3.5 Hearing Protection

While the Dragon A400 is relatively quiet, it is recommended that the Operator wear hearing

protection as specied per the facility safety requirements.

1.3.6 Breather Mask or Ventilation System

Plasma dust and debris is toxic, and inhalation can cause respiratory diculties or other

complications. It is recommended that the Operator and any observers wear a breathing mask,

or that the shop be equipped with an eective ventilation system for safe operation of the

Dragon A400.

! Warning !

Due to the extreme temperatures that result from the plasma cutting process, parts

cooled in water in the parts catcher can still be extremely hot. Always use caution

when handling newly-cut parts.

The Dragon A400 Coolant System greatly reduces smoke and vapor emitted by the

machine. Bend-Tech recommends use of the Coolant System whenever possible. The

Coolant System is especially eective when working with aluminum or stainless steel.

14 Bend-Tech Dragon A400

Start-Up and Training Manual

Safety

01

1.4 Operational Safety

1.4.1 Guards

Do not operate the machine without safety guards in place.

1.4.2 Machine Walkthrough

Perform an inspection walkthrough of the machine before each startup, making sure all

electrical cords and cables that function as part of moving assemblies are secure and

fastened. Ensure all tools are fastened securely. Ensure all E-stop switches are disengaged.

1.4.3 Machine Operational Movement

While a program is running, the Trolley and Toolhead can move rapidly at any time through its

short/long travel feed rate procedures. Operator and bystanders should stay clear of the Trolley

and Toolhead during machine operation.

1.4.4 Material Securing

Assure that any material loaded into the machine is securely fastened in the Chuck and is

snug in the Gate.

! Warning !

The Trolley,Toolhead, and Gate are pinch points. Stay clear during machine

operation.

! Warning !

Improperly secured material may cause injury.

15Bend-Tech Dragon A400 Start-Up and Training Manual

Safety

01

1.5 Pinch Points

Use caution in the area of pinch points. There are many pinch point locations identied on the

Dragon A400 including the Gate assembly, Toolhead, Trolley and Material Support Lift. It is

advised to use caution in these areas and stay clear of them during machine operation.

1.6 Recommended Safety Guidelines

• Keep unauthorized personnel away from the Dragon A400 work area.

• Keep the work area clean and free of debris.

• Stay clear of the machine and any moving parts during machine operation.

• Stay clear of the Toolhead during operation.

• Never operate the machine while under the inuence of alcohol or drugs.

• Wear appropriate PPE at all times while operating the machine.

• Keep ammables away from machine during operation.

• Risk of electric shock - avoid touching exposed wires while machine is powered.

• Always power o machine and disconnect from main power source before servicing

electrical components.

• Do not exceed the machine’s capacities.

• Do not wear loose-tting clothing or jewelry while operating machine.

• Be aware of sharp edges on cut material.

• Avoid handling hot parts.

Toolhead

movement

Front Gate

movement

Material Support

Lift movement

Where the Trolley

contacts the Rail

Chuck

movement

Where the Trolley

contacts the rear bumper

16 Bend-Tech Dragon A400

Start-Up and Training Manual

Safety

01

1.7 Modications To The Machine

1.7.1 Unauthorized Modications

Performing unauthorized modications to the Dragon A400 is not recommended. Bend-Tech,

LLC is not responsible for damage resulting from modications to the Dragon A400.

Unauthorized modications include modications to the machine’s G-code that alter the factory

settings and adversely aect the operation of the machine.

1.7.2 Factory Parts Kits and Updates

Some parts kits and update packages are manufactured and sold by Bend-Tech, LLC.

Customers may choose to install these kits and updates themselves. However, the Customer

should have a thorough understanding of the machine and the service actions being

performed. If a Customer has any doubts regarding their ability to install parts kits or update

packages contact Bend-Tech, LLC for assistance.

! Caution !

Bend-Tech, LLC does not recommend unauthorized modications to the Dragon

A400. Contact Bend-Tech service representatives with any questions regarding

operation or capabilities of the machine.

17Bend-Tech Dragon A400 Start-Up and Training Manual

Safety

01

1.8 Emergency Stops (E-Stops)

1.8.1 E-Stop Overview

There are four external emergency stop (E-stop) buttons located on the Dragon A400 machine.

There is one E-stop on the Tail of the machine, one on the Trolley cover, and one on each side

of the Gate. These four emergency stops completely shut power o to all motors and outputs.

To re-enable the machine after pressing an E-stop, the E-stop must be disengaged and power

to the motors must be initialized by pressing the green light on the Control Box. If the green

light doesn’t initialize, this is an indicator that the E-stop is still engaged. The green light

indicates the motors have power.

E-Stop

Locations

18 Bend-Tech Dragon A400

Start-Up and Training Manual

Safety

01

1.8.2 Control Screen E-Stop

There is an additional emergency stop located on the machine control screen. This E-Stop

doesn’t cut power to any motors or outputs, but will temporarily disable any software that is

being used. This will discontinue any project that is being run, without losing power to the

motor.

1.9 Electrical Servicing

1.9.1 Power Down Before Servicing

Completely power o the Control Box before handling any electrical components. Electrical

components include all motor connections, motor cables, sensors, sensor cables, emergency

stops, laser cable, and Torch cable.

1.10 Material Weight

1.10.1 Weight Limit

Material weight limit for the Dragon A400 should not exceed 400 lbs. This is the maximum

weight of material the Trolley can support while still operating safely. This is also the maximum

weight of material the Drive Belt and Stepper Motor can handle and maintain safe operation.

! Danger !

Do not touch 120VAC components inside the Control Box without rst disconnecting

the machine from its power source.

! Warning !

Never disconnect a Motor Cable with power applied.

19Bend-Tech Dragon A400 Start-Up and Training Manual

Safety

01

1.11 Material Length

1.11.1 Material Support Lift

Some non-rigid materials, or excessively long materials, can sag and cause material to

raise at the Toolhead, introducing the danger of material contacting the Torch or damaging

the Engraver. Material longer than 5 ft. or thinner material may need to be supported by the

Material Support Lift in order to avoid contacting the Torch or damaging the Engraver.

1.12 Plasma Torch

1.12.1 Torch Overview

The Torch and plasma cutting device is a high-voltage system that requires extreme caution

when operating. It is recommended that the Operator read the manual and become familiar

with the hazards of working with the machine before operating it in conjunction with the Dragon

A400.

! Danger !

Exceeding the material weight limit of the Dragon A400 can result in serious injury

to the Operator and/or bystanders.

! Caution !

Exceeding the material weight limit can aect performance and possibly damage

the Dragon A400.

20 Bend-Tech Dragon A400

Start-Up and Training Manual

Safety

01

1.12.2 Ultraviolet Light

The Torch emits extreme ultraviolet light which can damage human retinas. Never look directly

at the cutting process without the appropriate eye protection.

1.12.3 Heat

The Torch will introduce extreme heat into the material during the cutting process. The

Operator should take caution handling freshly-cut parts. Always wear heat resistant gloves

when handling parts after cutting.

1.12.4 Gloves

Always wear insulated gloves when handling Torch consumables. Consumables get extremely

hot during Torch operation. Touching Torch consumables can result in electric shock if the

Torch is not disabled before handling.

1.12.5 Fumes

Some metals, including stainless steel, can emit toxic fumes when cut. Bend-Tech

recommends using a ventilation system with the Dragon A400 or ensure the facility has

adequate ventilation to ensure air quality meets standards and regulations

! Danger !

The plasma arc of the Torch can cause severe injury or even death. Never

approach the Torch while it is activated and operating.

! Warning !

Always wear shade 10 glasses when the Torch is cutting.

Other manuals for Dragon A400

14

Table of contents

Other Bend-Tech Cutter manuals