Bender GFGC-30 Technical specifications

GFGC_D00395_00_D_XXEN/05.2019

GFGC Protection Panel

Universal Ground Fault and Ground Continuity Panel

For 120 VAC to 600 VAC Grounded Systems

BENDER Group

2 GFGC_D00395_00_D_XXEN/05.2019

Ground Fault and Ground Continuity

Protection Panel GFGC

Protection Panel GFGC

Device features

• Universal voltage selection between 120

and 600 V

• Features ground fault detection, ground

integrity monitoring, and power inter-

ruption in case of alarm

• Predefined settings from factory

• 6 mA ground fault trip level

• Inverse time curve for interrupting cir-

cuit on a ground fault

• Adjustable ground continuity trip level

between 0.1 Ω…100 Ω (preset to 3 Ω)

• NEMA 12 painted steel enclosure

• External test and reset buttons

• External LED indication for power and

ground fault/ground integrity alarms

• Internal real-time indications of ground

fault current and ground integrity via

digital displays

Product description

The GFGC series of panels is an all-in-one solution for ground fault detection, ground

continuity monitoring, and power interruption in case of an alarm. Utilizing the latest in

technology, the GFGC panels can detect ground fault currents down to 6 mA without the

problems associated with high sensitivity nuissance tripping. The GFGC unit also verifies

ground connection integrity over a widely adjustable range. The universal voltage selection

allows use of this panel on systems from 120 VAC to 600 VAC. 30 A, 60 A, and 100 A units

are available.

Bender LifeGuard GFGC protection panels are Listed Enclosed Industrial Control Panels

certified to UL 508A.

Ground fault detection: The internal ground fault detector RCMA421H extends the capa-

bility of standard ground fault monitors to detect ground fault current in both AC and DC

systems, as well as through all stages of power conversion, such as with variable frequency

drives. The RCMA421H combines a trip level of 6 mA with protection against nuissance

tripping through operation on an inverse time curve (per UL943, the standard for personnel

protection), as well as exceptional noise filtering.

Open ground detection: The internal ground continuity monitor GM420 adds an additional

layer of protection by continuously monitoring the integrity of the ground conductor

line. A wide adjustable range from 0.1 Ω to 100 Ω ensures the proper level of protection

for nearly every application. In addition, the GM420 monitors for extraneous voltages be-

tween its connection points.

Applications

• Loading docks

• Fueling stations

• Systems requiring frequent user connections/disconnections

Function

The GFGC series of panels is designed to interrupt power to a circuit when either a ground

fault or an open ground is detected. The entire solution is contained inside a NEMA 4

painted steel enclosure. Light indicators as well test/reset buttons on the front of the

enclosure allow for functionality without requiring access inside the panel. Settings are

preset; only a simple internal wiring is required.

When a ground fault is detected, the contactor will trip the main circuit based on an inverse

time curve (per UL943) relative to the preset 6 mA value. The inverse time curve assists in

alleviating potential nuissance tripping issues.

If an open ground is detected, the same contactor will trip the main circuit. The ground

continuity monitor utilizes a ground connection, as well as a field pilot wire connection

on the exterior of the enclosure. This connection is required for proper operation. The

open ground monitor will not allow the contactor to remain pulled in without a proper

field connection.

Universal Voltage 120…600 V

for Grounded AC Systems

Device adjustability and preset values

Type Adjustability Preset defaults

Ground fault, trip value 6 mA, xed 6 mA

Ground fault, time delay Inverse time curve Inverse time curve

Open ground, trip value 0.1…100 Ω3 Ω

Open ground, time delay 0…99 s 0 s

Ground Fault and Ground Continuity – Protection Panel GFGC

GFGC_D00395_00_D_XXEN/05.2019 3

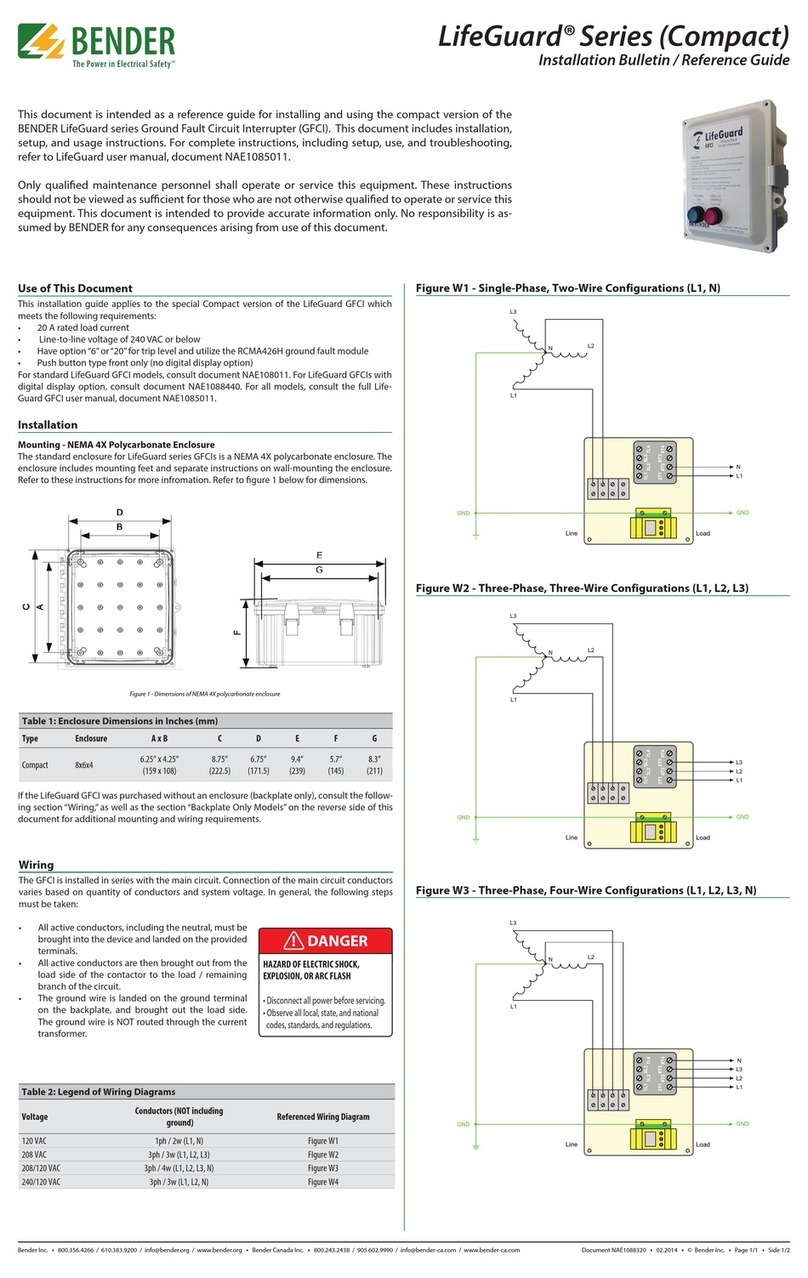

Procedure for wiring GFGC assembly into system

• Locate the wiring diagram specific to the line voltage. Be sure

to select the voltage and phase type specific to the point at

where the GFGC panel is connecting.

• Connect the incoming lines to the contactor, being sure to have

all phases going through the WN-35BS current transformer (in-

cluding the neutral if one exists). Order of conductors is im-

portant.

When connecting to the contactor, placement of the neutral is

important. Connect the outgoing lines in the same manner.

Do not pass the ground conductor through the current

transformer or connect it to the contactor!

• Connect the incoming and outgoing ground wires to the

ground lug.

• Locate the control transformer. Terminal 1 (“Com. H2”) should

already be connected. Connect it if it is not.

• Connect the other wire to the terminal specific to the line volt-

age being protected. For instance, if the system is a 208/120 V

system, and the GFGC assembly is connected on the 208 V por-

tion of the circuit, connect the wire to the terminal labeled

“208.”

• Connect the ground pilot wire clamp to the connector on the

outside of the enclosure.

GFGC enclosure front (drawing not to scale)

Operation

The green POWER ON lamp illuminates when power is available to the load.

The red CIRCUIT TRIPPED lamp illuminates when power is removed from the load.

If unit has tripped, clear the fault and press Reset to resume operation.

Ground Fault Test

Unit must be tested at least once per month or before each use.

Press Test for >2 seconds. Unit must trip.

When unit trips a self test sequence starts. Wait >10 seconds.

Press Reset for >1 second. Unit should reset, restoring power to the load.

Ground Connection Monitor

Connect a pilot lead to the powered-equipment

ground and the connection located on the bottom of this enclosure. Loss

of this connection will cause loss of load power and the OPEN GROUND lamp to light.

Technical support: 1-800-356-4266

E-mail: [email protected]

Push To Reset

POWER

ON

CIRCUIT

TRIPPED

OPEN

GROUND

GROUND FAULT

GROUND CHECK

GFGC

Push To Test

Push To Test Lamp

1 - Power ON light/Reset pushbutton

Light illuminates when power is received to the device and not

in an alarm state.

Pushing the button for > 1 second resets the device.

(Must wait for test to complete!)

2 - Circuit tripped light/Test pushbutton

Light illuminates when the circuit has been tripped due to a

ground fault.

Pushing the button for > 2 seconds runs a test on the ground

fault detection unit.

3 - Open ground light/Light test pushbutton

Light illuminates when the ground continuity monitor has

detected an open ground.

Pushing the button runs a test on the open ground light.

1 2 3

Ground Fault and Ground Continuity – Protection Panel GFGC

4 GFGC_D00395_00_D_XXEN/05.2019

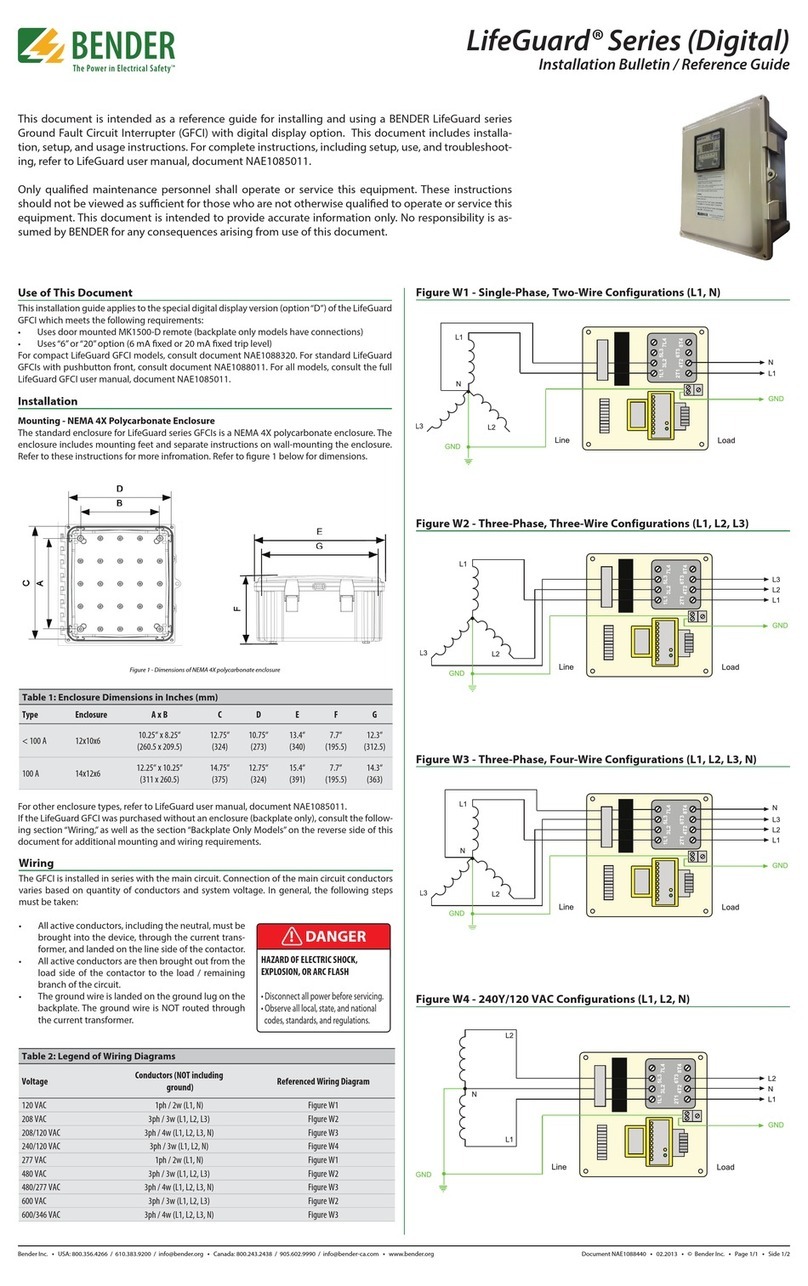

Wiring diagrams

120 V, single phase, with N (L, N)

208/120 V, three-phase, with N (L1, L2, L3, N)

208 V, three-phase, no N (L1, L2, L3)

240/120 V, single-phase, with N (L1, L2, N)

1L1 3L1 5L3 7L4

2T1 4T2 6T3 8T4

123 4 567

H2 Com. 120 V 208 V 240 V 277 V 480 V 600 V

Incoming Lines

Outgoing Lines

WN-35BS CT Contactor

Control Transformer

Always Connected

Connect Here

(120 V)

Pilot Wire Connection

(On exterior of enclosure)

To Clamp

L1 N

1L1 3L1 5L3 7L4

2T1 4T2 6T3 8T4

123 4 567

H2 Com. 120 V 208 V 240 V 277 V 480 V 600 V

Incoming Lines

Outgoing Lines

WN-35BS CT Contactor

Control Transformer

Always Connected

Connect Here

(208 V)

Pilot Wire Connection

(On exterior of enclosure)

To Clamp

L1 L2 L3 N

1L1 3L1 5L3 7L4

2T1 4T2 6T3 8T4

123 4 567

H2 Com. 120 V 208 V 240 V 277 V 480 V 600 V

Incoming Lines

Outgoing Lines

WN-35BS CT Contactor

Control Transformer

Always Connected

Connect Here

(208 V)

Pilot Wire Connection

(On exterior of enclosure)

To Clamp

L1 L2 L3

1L1 3L1 5L3 7L4

2T1 4T2 6T3 8T4

123 4 567

H2 Com. 120 V 208 V 240 V 277 V 480 V 600 V

Incoming Lines

Outgoing Lines

WN-35BS CT Contactor

Control Transformer

Always Connected

Connect Here

(240 V)

Pilot Wire Connection

(On exterior of enclosure)

To Clamp

L1 L2 N

Ground Fault and Ground Continuity – Protection Panel GFGC

GFGC_D00395_00_D_XXEN/05.2019 5

Wiring diagrams

277 V, single-phase, with N (L1, N)

480/277 V, three-phase, with N (L1, L2, L3, N)

480 V, three-phase, no N (L1, L2, L3)

600 V, three-phase, no N (L1, L2, L3)

1L1 3L1 5L3 7L4

2T1 4T2 6T3 8T4

123 4 567

H2 Com. 120 V 208 V 240 V 277 V 480 V 600 V

Incoming Lines

Outgoing Lines

WN-35BS CT Contactor

Control Transformer

Always Connected

Connect Here

(277 V)

Pilot Wire Connection

(On exterior of enclosure)

To Clamp

L1 N

1L1 3L1 5L3 7L4

2T1 4T2 6T3 8T4

123 4 567

H2 Com. 120 V 208 V 240 V 277 V 480 V 600 V

Incoming Lines

Outgoing Lines

WN-35BS CT Contactor

Control Transformer

Always Connected

Connect Here

(480 V)

Pilot Wire Connection

(On exterior of enclosure)

To Clamp

L1 L2 L3 N

1L1 3L1 5L3 7L4

2T1 4T2 6T3 8T4

123 4 567

H2 Com. 120 V 208 V 240 V 277 V 480 V 600 V

Incoming Lines

Outgoing Lines

WN-35BS CT Contactor

Control Transformer

Always Connected

Connect Here

(480 V)

Pilot Wire Connection

(On exterior of enclosure)

To Clamp

L1 L2 L3

1L1 3L1 5L3 7L4

2T1 4T2 6T3 8T4

123 4 567

H2 Com. 120 V 208 V 240 V 277 V 480 V 600 V

Incoming Lines

Outgoing Lines

WN-35BS CT Contactor

Control Transformer

Always Connected

Connect Here

(600 V)

Pilot Wire Connection

(On exterior of enclosure)

To Clamp

L1 L2 L3

Ground Fault and Ground Continuity – Protection Panel GFGC

6 GFGC_D00395_00_D_XXEN/05.2019

Installation troubleshooting tips

• The ground fault alarm trips instantly on a consistent basis.

Near-instant tripping may also indicate a serious ground fault in

the system.

Ensure that the following items are correct:

– The transformer and contactor are wired properly per the

above wiring diagrams based on the voltage being used.

– All phases (including the neutral if one is being used) are going

through the WN-35BS current transformer. Improper wiring

can cause an incorrect reading on the ground fault detector.

– The ground conductor must not pass through the current

transformer.

– There are no neutral-ground bonds downstream of the de-

vice. Having a neutral-ground bond downstream of the de-

vice will activate the grounded neutral protection alarm.

The panel must be reset manually via the door-mounted RESET

button in order to clear the trip.

• The ground fault alarm trips on a consistent basis, but not

instantly.

Ensure all of the above items are correct.

Ensure there are no ground faults on the system. A non-instant

trip is an indication that the total leakage current from many

different sources is adding up to approximately 6 mA. Consult

the manufacturer for more information and technical support.

• The open ground alarm trips on a consistent basis.

Ensure that the following items are correct:

– There is a proper pilot wire connection to the connector on

the outside of the enclosure.

– There is a proper connection between the clamp and the ve-

hicle/object.

– There are no broken ground connections in the system being

protected.

The panel must be reset manually via the door-mounted RESET

button in order to clear the alarm.

Installation troubleshooting tips (continued)

RCMA421H Ground Fault Monitor GM420 Ground Continuity Monitor

The RCMA421H is labeled with “IΔn” in the top right corner.

Possible messages displayed on the screen include:

• “X mA”: The amount of ground fault current (in mA) read by the

device.

• “E 01”: Connection alarm (consult the manufacturer if this alarm

appears).

• “E 02”: Connection alarm (consult the manufacturer if this alarm

appears).

If the RCMA421H has gone into the alarm state, and is not display-

ing an error code, follow these steps to retrieve the mA value:

• Hold the MENU button for > 1.5 s to enter the main menu.

• Press the down-arrow button until “HiS” (history) is reached.

Press the enter/MENU button.

Use this value to assist in determining the source of the ground fault.

If any error codes appear on the unit, consult the manufacturer for

more information.

The GM420 is labeled with “Ω LOOP” in the top right corner.

Possible messages displayed on the screen include:

• “X Ω”: The resistance of the loop in ohms.

• “OL”: Overload alarm (open connection).

If the GM420 goes into the alarm state, a reading of “X Ω” generally

indicates a present, but faulty ground connection. A reading of

“OL” generally indicates a nonexistant ground connection. Use these

values to troubleshoot the ground loop connection.

If any error codes appear on the unit, consult the manufacturer for

more information.

Ground Fault and Ground Continuity – Protection Panel GFGC

GFGC_D00395_00_D_XXEN/05.2019 7

Technical data: Ground fault monitor RCMA421H-D-2 and current transformer WN-35BS

Insulation coordination acc. to IEC 60664-1/IEC 60664-3

Rated insulation voltage AC 250 V

Rated impulse voltage/pollution degree 2.5 kV/3

Protective Separation (reinforced insulation) between (A1, A2) - (k/l, T/R) - (21, 22, 24)

Voltage tests to IEC 61010-1 2.21 kV

Supply voltage

Supply voltage USAC/DC 70…300 V

Frequency range of US42…460 Hz

Power consumption ≤ 4.5 VA

Measuring circuit

External measuring current transformer WN-35BS

Rated voltage (current transformer) 2.5 kV

Rated frequency 0…150 Hz

AC/DC measuring range 0…40 mA

Relative percentage error ( 0…20 Hz) -33 %…+100 %

Relative percentage error ( 20…90 Hz) 0…- 33 %

Relative percentage error ( 90…150 Hz) ± 17.5 %

Operating value

Rated ground fault current 6 mA

Time behavior

Operating time tae per UL943 See diagram

Starting delay tOperating time tae + 3.2 s

Display and memory

Display range (measured value) 0…40 mA

Maximum operating error ( 0…20 Hz) -33/+100 %/± 2 digits

Maximum operating error ( 20…90 Hz) 0…20 %/± 2 digits

Maximum operating error (IΔ< 2 mA) ± 7 digits

Measured value memory capacity Measured alarm value set

Switching elements

Number of switching elements 1 SPDT contact

Operating principle, adjustable normally energized operation

Electrical service life under rated operating conditions 10,000 switching cycles

Contact data acc. to IEC 60947-5-1

Utilization category AC-13 AC-14 DC-12 DC-12 DC-12

Rated operational voltage 230 V 230 V 24 V 110 V 220 V

Rated operational current 5 A 3 A 1 A 0.2 A 0.1 A

Minimum contact load 1 mA at AC/DC ≥ 10 V

Fault memory behavior Latching operation

Connections

Connection type specification for Screw terminals

Rigid/flexible conductor sizes AWG 24…12/24…14

Stripped length 0.31…0.35 in (8…9 mm)

Tightening torque 0.36…0.44 ft-lb (0.5…0.6 N-m)

Connection type specification for Push-wire terminals

Rigid/flexible conductor sizes AWG 24…14

Flexible with core end sleeve AWG 24…16

Stripped length 0.39 in (10 mm)

Opening force 11.2 lb (50 N)

Test opening, diameter 0.1 in (2.1 mm)

Environment/EMC

EMC acc. to UL 943

Operating temperature - 31…+ 150 °F (- 35…+ 66 °C)

Climatic class acc. to IEC 60721

Stationary use (IEC 60721-3-3) 3K5 (except condensation and formation of ice)

Transport (IEC 60721-3-2) 2K3 (except condensation and formation of ice)

Long-time storage (IEC 60721-3-1) 1K4 (except condensation and formation of ice)

Classification of mechanical conditions IEC 60721

Stationary use (IEC 60721-3-3) 3M4

Transport (IEC 60721-3-2) 2M2

Long-time storage (IEC 60721-3-1) 1M3

General data

Operating mode continuous duty

Position of normal use display-oriented

Protection class, internal components (IEC 60529) IP30, NEMA 1

Protection class, terminals (IEC 60529) IP20, NEMA 1

Enclosure material polycarbonate

Screw mounting 2 x M4

DIN rail mounting acc. to IEC 60715

Flammability class UL94V-0

Documentation number D00395

Weight:

RCMA421H ≤ 0.33 lb (150 g)

WN-35BS ≤ 0.78 lb (355 g)

Inverse time curve operation (including contactor) per UL943

260220 240200180160140120100806040200

0,01

0,10

1,00

10,00

T/s

I/mA

6; 5,594

30; 0,560

264; 0,0250

Ground Fault and Ground Continuity – Protection Panel GFGC

8 GFGC_D00395_00_D_XXEN/05.2019

Technical data: Ground continuity monitor GM420

Insulation coordination acc. to IEC 60664-1/IEC 60664-3

Rated voltage AC 400 V

Rated impulse voltage/pollution degree 4 kV/3

Protective Separation (reinforced insulation) (A1, A2) - (E, KE) - (11, 12, 14) - (21, 22, 24)

Voltage tests to IEC 61010-1:

(E, KE) - [(A1, A2), (11, 12, 14)] 3.32 kV

(E, KE) - (21, 22, 24) 2.21 kV

(A1, A2) - (11, 12, 14) - (21, 22, 24) 2.21 kV

Supply voltage

Supply voltage USAC/DC 70…300 V

Frequency range of US15…460 Hz

Power consumption ≤ 3.5 VA

Measuring circuit

Loop resistance Rm

Measuring range Rm0…100 Ω

Measuring current ImDC 20 mA

Measuring voltage Um≤ DC 24 V

Extraneous voltage Uf

Measuring range UfAC 0…50 V

Rated frequency fn42…460 Hz

Measuring loop disconnection at Uf≥ 12 V

Measuring loop reconnection ≤ 10 V

Extraneous voltage Uf≤ 440 V

Permissible extraneous DC voltage without measurement influence DC 0 V

Response values

Loop resistance > Alarm 1 0.1…100 Ω

Resolution of setting R= 0…10 Ω0.1 Ω

Resolution of setting R= 10…100 Ω1 Ω

Time behavior

Start-up delay tAdjustable 0…99 s

Response delay ton1/2 Adjustable 0…99 s

Delay on release toff Adjustable 0…99 s

Operating time

tae in case of open loop connection (R > 50 kΩ) ≤ 40 ms

tae in case of closed loop connection (> R) ≤ 500 ms

tae in case of extraneous voltage (> V) and overload (OL) ≤ 100 ms

Response time tan tan = tae + ton1/2

Recovery time tan ≤ 300 ms

Recovery time tab after disconnection for safety reasons ≤ 1 s

Switching elements

Number of switching elements 2 SPDT contacts

Operating principle, adjustable normally energized or de-energized operation

Electrical service life under rated operating conditions 10,000 switching cycles

Contact data acc. to IEC 60947-5-1

Utilization category AC-13 AC-14 DC-12 DC-12 DC-12

Rated operational voltage 230 V 230 V 24 V 110 V 220 V

Rated operational current 5 A 3 A 1 A 0.2 A 0.1 A

Minimum contact load 1 mA at AC/DC ≥ 10 V

Fault memory behavior Latching or non-latching operation

Connections

Connection type specification for Screw terminals

Rigid/flexible conductor sizes AWG 24…12/24…14

Stripped length 0.31…0.35 in (8…9 mm)

Tightening torque 0.36…0.44 ft-lb (0.5…0.6 N-m)

Connection type specification for Push-wire terminals

Rigid/flexible conductor sizes AWG 24…14

Flexible with core end sleeve AWG 24…16

Environment/EMC

EMC IEC 61326

Operating temperature - 13…+ 131 °F (- 25…+ 55 °C )

Climatic class acc. to IEC 60721

Stationary use (IEC 60721-3-3) 3K5 (except condensation and formation of ice)

Transport (IEC 60721-3-2) 2K3 (except condensation and formation of ice)

Long-time storage (IEC 60721-3-1) 1K4 (except condensation and formation of ice)

Classification of mechanical conditions IEC 60721

Stationary use (IEC 60721-3-3) 3M4

Transport (IEC 60721-3-2) 2M2

Long-time storage (IEC 60721-3-1) 1M3

General data

Operating mode continuous duty

Mounting any position

Protection class, internal components (IEC 60529) IP30, NEMA 1

Protection class, terminals (IEC 60529) IP20, NEMA 1

Enclosure material polycarbonate

Screw mounting 2 x M4

DIN rail mounting acc. to IEC 60715

Flammability class UL94V-0

Weight ≤ 0.33 lb (150 g)

Technical data: GFGC panels

System voltage (universal) 120 , 208 , 208/120, 277, 480, 480/277, 600 V

Enclosure rating NEMA 4

Enclosure size, 30 A panel 12" x 12" x 6"

Enclosure size, 60 A and 100 A panel 16" x 12" x 6"

Fuse Rating Class CC Time Delay Fuse, 8/10 A, 600 VAC

Ground fault protection See RCMA421H technical data

Ground continuity protection See GM420 technical data

Ground Fault and Ground Continuity – Protection Panel GFGC

GFGC_D00395_00_D_XXEN/05.2019 9

Dimensions: GFGC-30 enclosure

Dimensions: GFGC-60 and GFGC-100 enclosure

12”

12”

12”

6”

6”

12”

16”

12”

12”

6”

16”

6”

Ordering Information

Load Ampere Rating Mfg. Reference No. Type Ordering Number

30 A LG30-600-120-3/4-4-PA-CH-XSLU GFGC-30 B541300044

60 A LG60-600-120-3/4-4-PA-CH-XSLU GFGC-60 B541300045

100 A LG100-600-120-3/4-4-PA-CH-XSLU GFGC-100 B541300046

GFGC_D00395_00_D_XXEN / 05.2019 / pdf / © Bender GmbH & Co. KG, Germany – subject to change! The specied standards take into account the edition valid until 05.2019 unless otherwise indicated.

USA & Mexico • Exton, PA • 800-356-4266/610-383-9200

Canada • Mississauga, ON • 800-243-2438/905-602-9990

Latin America • Santiago de Chile • +56 2 2933 4211

Your local contact:

This manual suits for next models

5

Table of contents

Other Bender Protection Device manuals