Bender LifeGuard LG2 Series User manual

Quickstart EN

LG_D00393_00_Q_XXEN / 12.2020

LifeGuard® LG2-Series

Protection Panels

2

LifeGuard® LG2-Series

LifeGuard® Protection Panels

This document is intended as a reference guide for installing and using a Bender LifeGuard®

LG2-series protection panel. This document includes installation, setup, and usage

instructions.

Only qualified maintenance personnel shall operate or service this equipment. These

instructions should not be viewed as sufficient for those who are not otherwise qualified to

operate or service this equipment. This document is intended to provide accurate

information only. No responsibility is assumed by Bender for any consequences arising

from use of this document.

Use of this document

This quick start applies to standard LifeGuard models with lighted push button front

panels, as pictured above, as well as open panels with no enclosure.

Standard model

Installation

Mounting - NEMA 4X Polycarbonate Enclosure (enclosure code P)

The standard enclosure for LifeGuard protection panels is NEMA 4X polycarbonate. The en-

closure includes mounting feet and separate instructions on wall-mounting the enclosure.

Refer to these instructions for more information. Refer to the figure and table below for

dimensions.

Figure 1 - Dimensions of NEMA 4X polycarbonate enclosure

Table 1: Enclosure dimensions in inches (mm)

LifeGuard® LG2-Series

3

NEMA 4X Stainless Steel Enclosure (enclosure code S Option)

LifeGuard protection panels are available with a NEMA 4X stainless steel enclosure.

The enclosure includes separate instructions for wall-mounting the enclosure. Refer to

those instructions for more information. Dimensions below are in inches (mm.

Type Enclosure A x B x C D x E G x H

Standard 16x12x6 16“ x 12“ x 6“ 14.2“ x 10.2“ 14.5“ x 10.5“

(406 x 305 x 152) (361 x 259) (368 x 267)

If the LifeGuard was purchased without an enclosure (backplate only), consult the following

section “Wiring,” and the section “Backplate Only Models”.

Wiring

I HAZARD

- Disconnect all power before servicing.

OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

- Observe all local, state, and national codes, standards, and regulations.

A professional electrician, licensed in accordance with local laws and regulations, must

perform this installation. The enclosure must be penetrated in order to bring the line and

load conductors to the protective circuit. Bender recommends making these penetrations on

the bottom of the enclosure, and the use of NEMA 4X (minimum) fittings to maintain the

environmental rating of the enclosure. The specifics of the installation will dictate further.

Connect the LifeGuard protection panel in series with the protected circuit. Circuit-conductor

connection varies based on the number of conductors and system voltage. Observe the

following requirements during installation:

• Use copper wire only. For models rated less than 100 A, use 60 °C /140 °F (minimum) rated

conductors. For 100 A models (or for systems where the required 60 °C conductor cannot

be accepted), use conductors rated for 75 °C (167 °F).

• Disconnect switch, branch circuit protection, and/or overload relay must be provided

separately.

4

LifeGuard® LG2-Series

• All active conductors, including the neutral (when used), must be brought into the device

and passed through the current transformer and connected to the line side of the

contactor, as shown in the following diagrams. Standard LifeGuard models are suitable

for 120 to 600-V circuits and are factory-configured for 600 V. For other voltages, relocate

the control-transformer primary tap as required by following the included instructions.

•Connect the load or protected branch circuit to the load side of the contactor.

• Connect the line and load ground (bond) wires to the ground lug on the backplate. Do

not route the ground wire through the current transformer.

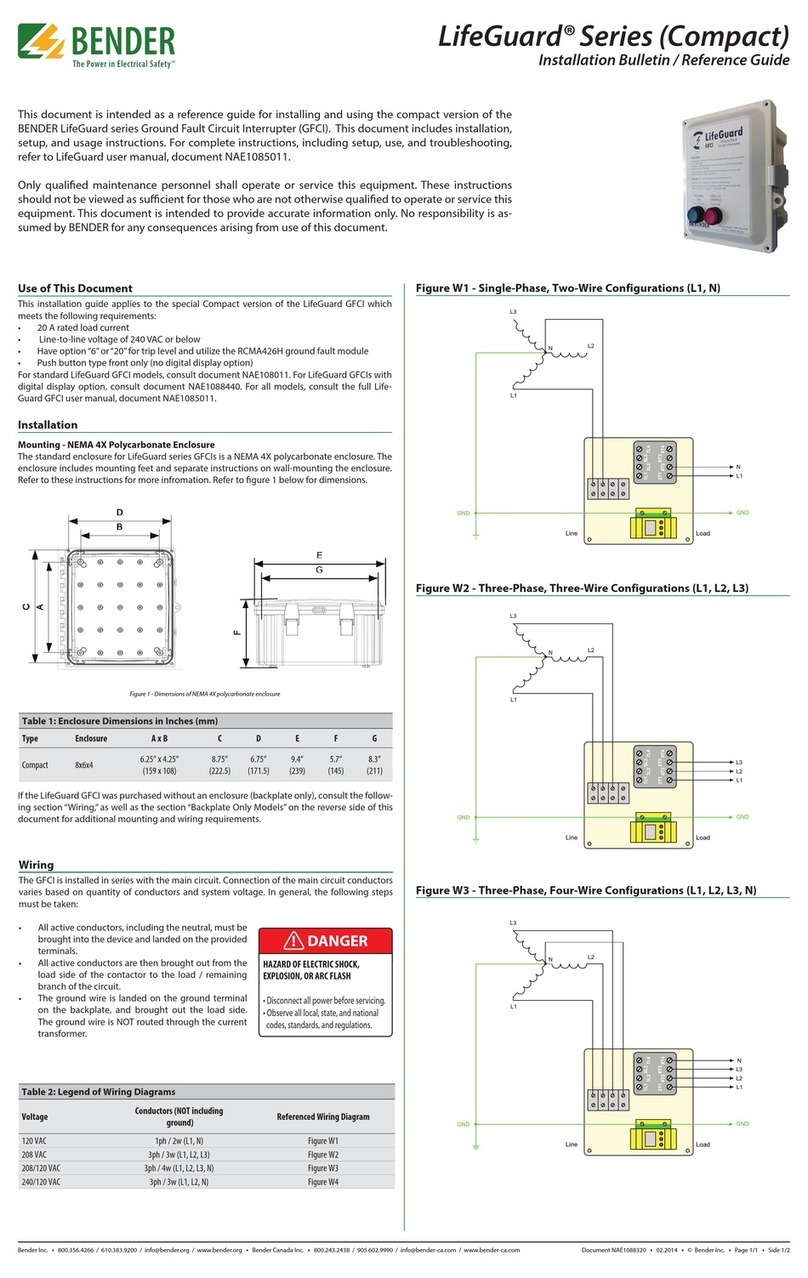

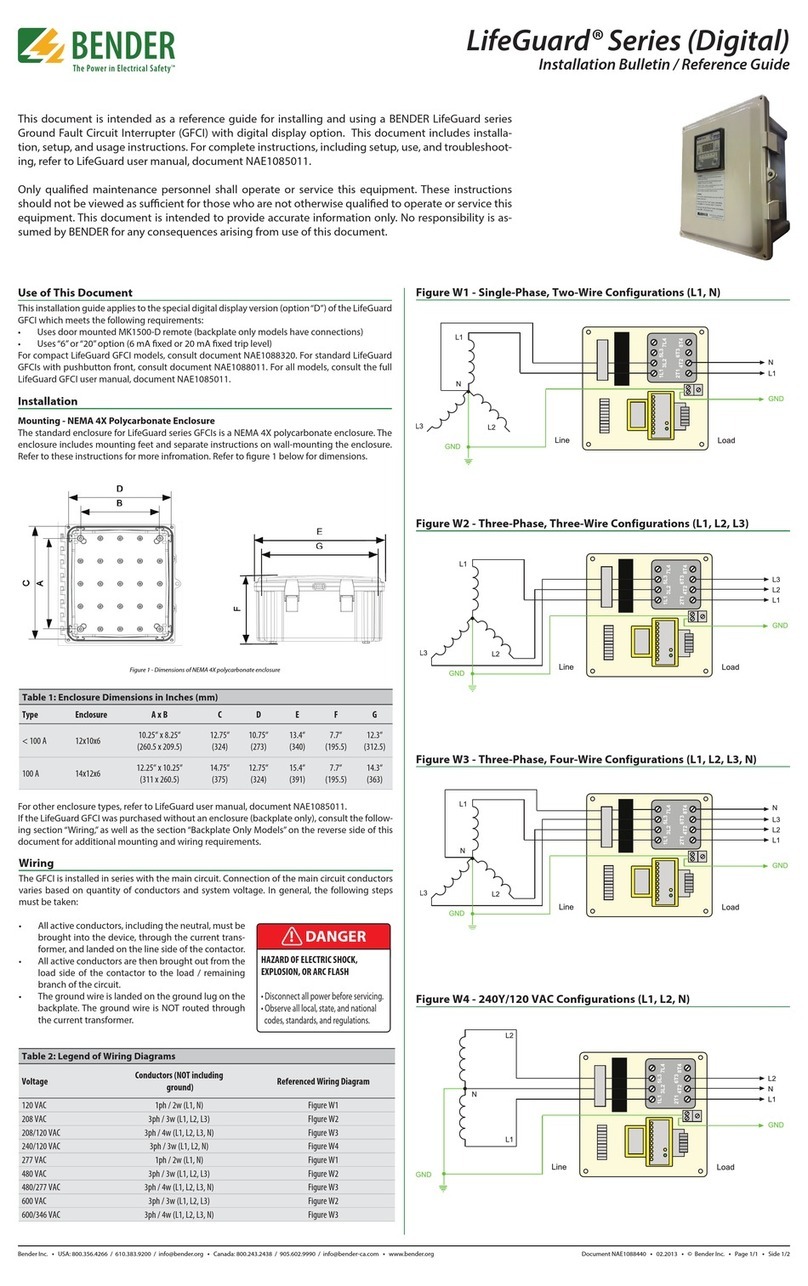

Voltage Conductors (not including ground) Referenced Wiring Diagram

120 VAC 1ph / 2w (L1, N) Figure W1

208 VAC 3ph / 3w (L1, L2, L3) Figure W2

208/120 VAC 3ph / 4w (L1, L2, L3, N) Figure W3

240/120 VAC 1ph / 3w (L1, L2, N) Figure W4

480 VAC 3ph / 3w (L1, L2, L3) Figure W2

480/277 VAC 3ph / 4w (L1, L2, L3, N) Figure W3

600 VAC 3ph / 3w (L1, L2, L3) Figure W2

600/347 VAC 3ph / 4w (L1, L2, L3, N) Figure W3

Figure W1 -

Single-Phase, Two-Wire

Congurations (L1, N)

Figure W2 -

Three-Phase, Three-Wire

Congurations (L1, L2, L3)

7L4

5L3

3L2

1L1

8T4

6T3

4T2

2T1

L1

L2

L3

N

Line Load

GND

Note 1

L1

N

GND

CT

600

480

277

240

208

120

CPT

7L4

5L3

3L2

1L1

8T4

6T3

4T2

2T1

L1

L2

L3

N

Line Load

GND

Note 1

Note 2

L1

L3

L2

GND

CT

600

480

277

240

208

120

CPT

LifeGuard® LG2-Series

5

Figure W3 -

Three-Phase, Four-Wire

Congurations (L1, L2,

L3, N)

FigureW4 - Single-Phase

120/240 V Congurations

(L1, L2, N)

Note 1:Disconnect switch, branch circuit protection and/or overload relay must be provided

separately. Note 2: Three-phase three-wire supplies can be solidly or resistance grounded.

This section applies to LifeGuard models purchased without an enclosure and on a

backplate only. Refer to instructions below for additional requirements for installation and

wiring. Backplate-only models must be installed in a suitable enclosure.

Mounting - Backplate Only

Refer to the figure below for dimensions. The unit must be mounted in a location sufficient

to protect live electrical equipment. Use four #10 screws for mounting. It should be placed

X inches away from other equipment. This vertical clearance X (minimum depth of

enclosure, measured from the installed backplate) of the backplate is:

7L4

5L3

3L2

1L1

8T4

6T3

4T2

2T1

Note 1

Note 1

B

D

A

C

CT

Type A x B C x D

< 100 A 8.25“ x 10.25

(210 x 260)

8.88“ x 10.88“

(225 x 276)

100 A 12.25“ x 14.25“

(311 x 362)

12.88“ x 14.88“

(327 x 378)

• 6” (152 mm) for models less than 100 A

• 8” (203 mm) for 100 A models.

The mounting hole diameter is 1/4“ (6.4 mm).

Additional requirements - Backplate-Only Models (enclosure type N)

7L4

5L3

3L2

1L1

8T4

6T3

4T2

2T1

L1

L2

L3

N

Line Load

GND

1Note

L1

L3

N

L2

GND

CT

600

480

277

240

208

120

CPT

7L4

5L3

3L2

1L1

8T4

6T3

4T2

2T1

L1

L2

N

Line Load

GND

Note 1

Note 1 L1

L2

N

GND

CT

600

480

277

240

208

120

CPT

6

LifeGuard® LG2-Series

Use - Enclosure Front

Apply Power

To apply power, close the customer-supplied circuit breaker / disconnect on the line side of

the LifeGuard panel. If there are no ground faults present on the system, the green POWER

ON LED will light.

Perform Test (Trip Level Option F)

To perform a test on fixed 6-mA models with trip level option F:

• Push TEST for at least two seconds.

• The unit will trip, the green POWER ON LED will go out, and the red CIRCUIT TRIPPED LED

will illuminate. Power to connected loads will be interrupted.

• An internal self-test will initiate, taking approximately ten seconds.

• Push RESET for at least one second.

• If the internal self-test has completed, the unit will reset, the red CIRCUIT TRIPPED LED

will go out, and the green POWER ON LED will illuminate. Power will be restored to the

load.

Perform Test (Trip Level Option A)

To perform a test on field-adjustable models with trip level option A:

• Push TEST for at least two seconds.

• The unit will trip, the green POWER ON LED will go out, and the red CIRCUIT TRIPPED LED

will illuminate. Power to connected loads will be interrupted.

• Push RESET for at least one second.

• The unit will reset, the red CIRCUIT TRIPPED LED will go out, and the green POWER ON

LED will illuminate. Power will be restored to the load.

green

POWER LED / RESET button:

Illuminates when the panel has power and is not

tripped /

RESET button: Resets the panel if faults have been

cleared (momentary push).

red

TRIPPED LED / TEST button:

Illuminates when tripped /

TEST button: Performs a functional test

(hold for at least 2 seconds).

POWER

ON

Push to Reset

CIRCUIT

TRIPPED

Push to Test

OPERATION

The green POWER ON lamp

illuminates when power is available to the

load.

The red CIRCUIT TRIPPED lamp illumi-

nates when power is removed from the

load..

If the unit trips, clear the fault and press

Reset to resume operation.

TESTING Unit must be tested at least

once per month

Press Test for > 2 seconds.

Unit must trip.

Press Reset for > 1 second.

Unit should reset, restoring power to

the load.

USA & Mexico

800-356-4266

Canada

800-243-2438

Latin America

+56 2 2933 4211

Technical Support:

®

LifeGuard® LG2-Series

7

Canada: Bender Canada Inc.

5810 Ambler Drive, Unit 1

Mississauga, ON L4W 4J5

Toll-Free: 800-243-2438

Phone: 905-602-9990

E-mail: [email protected]

www.bender-ca.com

All rights reserved.

USA: Bender Inc.

420 Eagleview Blvd.

Exton, PA 19341

Toll-Free 800-356-4266

Phone: 610-383-9200

E-mail: info@benderinc.com

www.benderinc.com

12.2020 | All rights reserved.

UL 508A Industrial Control Panels

Approvals

Field Adjustment, Error Codes and troubleshooting

Models with trip level option A have field adjustable ground-fault-current trip level and trip

time. The factory defaults are 30 mA and 0 s. These models have a CTUB101-CTBC35P

current sensor, which has a three-position potentiometer that must be set to the correct

position depending on the RCMA420-D-2 ground-fault-current trip setting. For trip settings

up to 100 mA, the potentiometer must be rotated to the left position (pointing to 8 o’clock)

and for setting above 100 mA the potentiometer must be rotated to the vertical position (12

o’clock).

For details about protection relay settings, error codes, and troubleshooting, please refer

to the respective protection relay technical manuals, available online.

Table of contents

Other Bender Protection Device manuals

Popular Protection Device manuals by other brands

ABB

ABB REL 501-C1 2.5 Technical reference manual

MSA AUER

MSA AUER VAUTEX ELITE 3SL Type 1b ET EN 943-2 manual

cias

cias BF installation manual

Franklin Electric

Franklin Electric submonitor Installation & operation manual

Watershed Innovations

Watershed Innovations HydraBarrier Titan instructions

Ducati

Ducati 96767609B manual