5

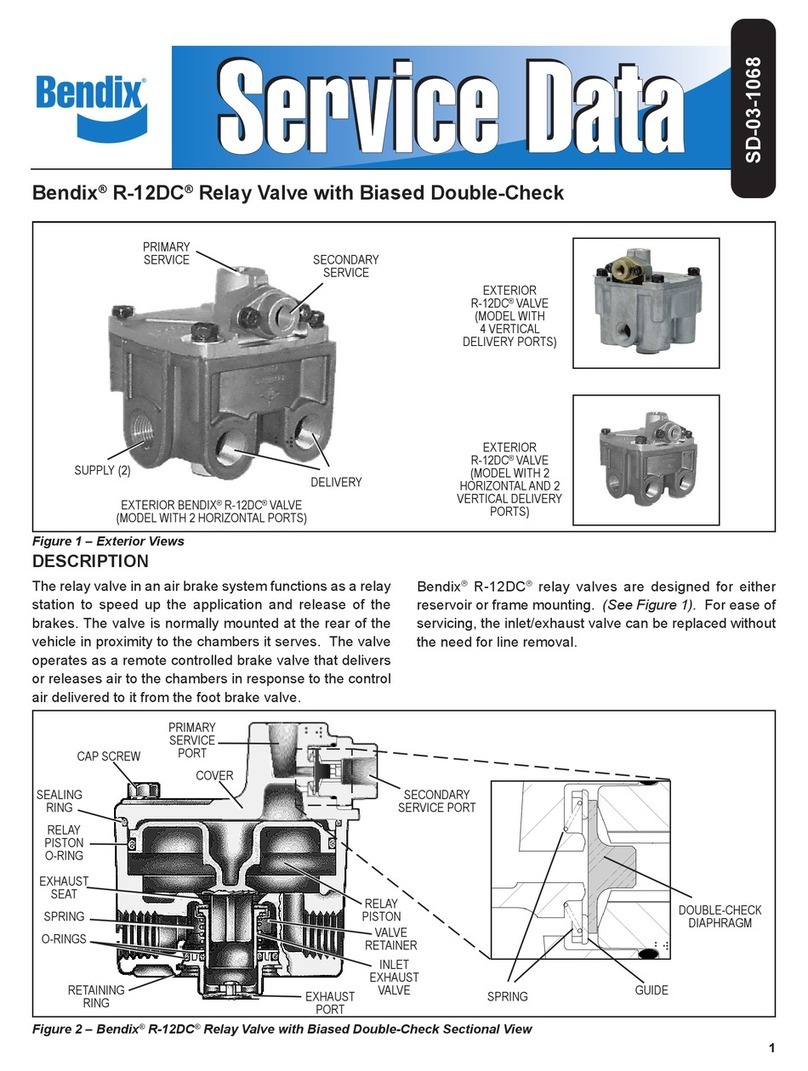

5. Removepiston(9)fromthebody(10)andretainforreuse.

6. Removeanddiscardo-ring(8)frompiston (9).

7. Depressandholdtheexhaustcover assembly (16) and

remove and discard retaining ring (17) from the valve

body (10).

8. Slowly release the holding force on the exhaust cover

assembly (16) to relax the spring.

9. Removeanddiscardthe following parts:

a. Exhaust cover assembly (16)

b. O-rings (14 & 15)

c. Spring (13)

d. Inletexhaustvalve(11)

e. Retainer (12)

CLEANING AND INSPECTION

1. Wash all metal parts in mineral spirits and dry them

thoroughly.

(Note: When servicing the R-12DC™valve, all springs

and all rubber parts should be replaced.)

2. Inspect all metal parts for deterioration and wear, as

evidenced by scratches, scoring and corrosion.

3. Inspect the exhaust valve seat on the relay piston for

nicks and scratches which could cause excessive

leakage.

4. Inspect the inlet valve seat in the body for scratches

and nicks, which could cause excessive leakage.

5. Inspectthecheck valveseatin theR-12DC™valvecover

and make sure all internal air passages in this area are

open and clean and free of nicks and scratches.

6. Replaceallpartsnotconsideredserviceableduringthese

inspections and all springs and rubber parts. Use only

genuine Bendix replacement parts, available from any

authorized Bendix parts outlet.

ASSEMBLY

Note:Alltorquespecifiedinthismanualareassemblytorque

and can be expected to fall off slightly after assembly. Do

notre-torque afterinitialassemblytorquefall. Forassembly,

handwrenches are recommended.

Priortoassembly, lubricate all o-rings, o-ring boresandany

sliding surface with a silicone lubricant equivalent to Dow

Corning#10.

Washallremainingpartsinmineralspiritsanddrythoroughly.

Using the lubricant provided in this kit, lightly lubricate all

o-rings,o-ring grooves, body boresany sliding surfaces.

1. Install o-rings (14 & 15) in the exhaust cover assembly

(16).

2. Install o-ring (8) on piston (9).

3. Installsealing ring (7) on cover(1).

4. Installretainer(12) on inletexhaustvalve(11) andinsert

both in the body (10).

5. Install spring (13) in the body (10).

6. Install exhaust cover assembly (16) in the body (10).

Depress and hold the exhaust cover assembly in the

body.

7. Install retaining ring (17) in the body (10). Make certain

the retaining ring is completely seated in the groove in

the body.

8. Install piston (9) in body (10).

9. Installo-ring(5)ondoublecheck cover (6), installspring

(2), guide (3) and double check diaphragm (4) in cover

(1). Install cover (1) and torque torx head screws to

80-100 in. lbs.

10. Referringto themarks madeduringdisassembly, install

cover(1).

11. Install the mounting bracket (not shown) on the cover

(1).

12. Installthe fourcap screwsin thecover (1)and torqueto

80-100inchpounds.

13. TestthevalveasoutlinedintheOperationalandLeakage

Test section before returning the valve to service.

INSTALLATION

1. Clean air lines.

2. Inspect all lines and/or hoses for damage and replace

as necessary.

3. Install valve and tighten mounting bolts.

4. Connect air lines to valve (plug any unused ports).

5. Testvalveasoutlinedin OperationalandLeakageTests.

OPERATIONAL AND LEAKAGE TEST

1. Chock the wheels, fully charge air brake system and

adjust the brakes.

2. Make several brake applications and check for prompt

application and release at each wheel.

3. Checkforinletvalveando-ringleakage. Makethischeck

withtheservice brakes released. Coat the exhaust port

andtheareaaroundtheretainingringwithasoapsolution;

a 1” bubble in 3 seconds leakage is permitted.

4. Checkfor exhaust valve leakage. Make this check with

the service brakes fully applied. Coat the outside of

the valve where the cover joins the body to check for

seal ring leakage; no leakage is permitted.

If the valves do not function as described above, or if

leakage is excessive, it is recommended that the valves

be replaced with new or remanufactured units or repaired

withgenuineBendixparts,availableatanyauthorizedBendix

parts outlet.

GENERAL SAFETY GUIDELINES