1

®

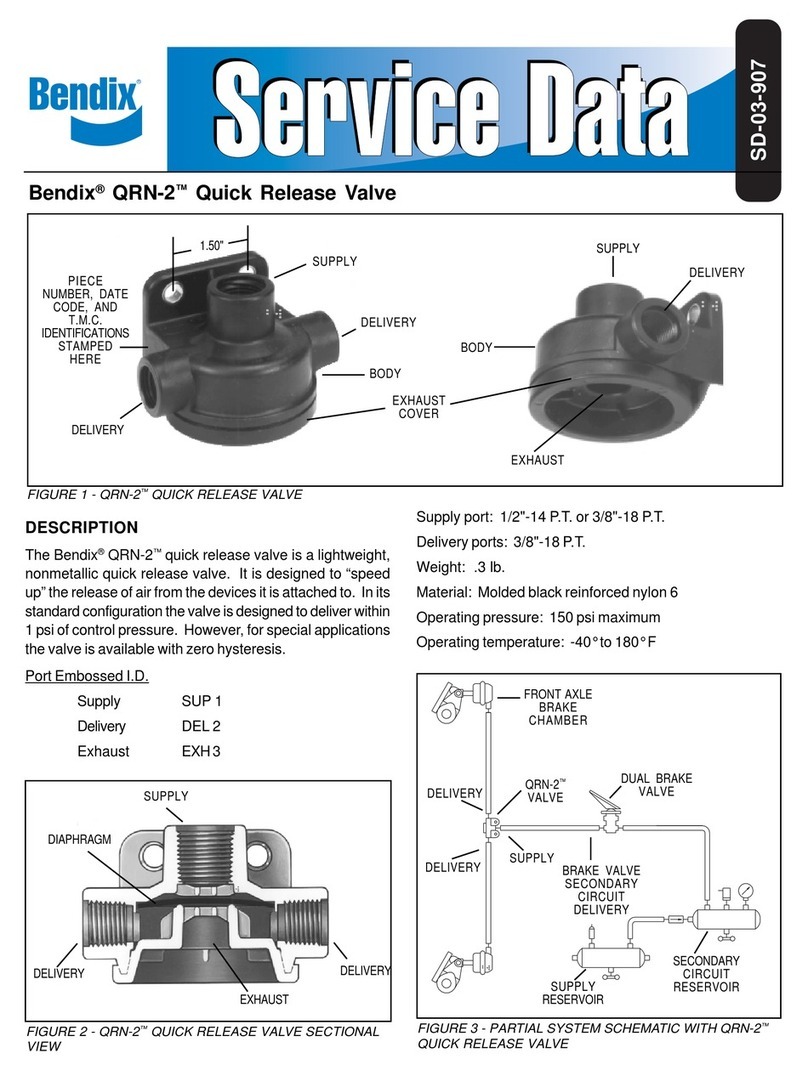

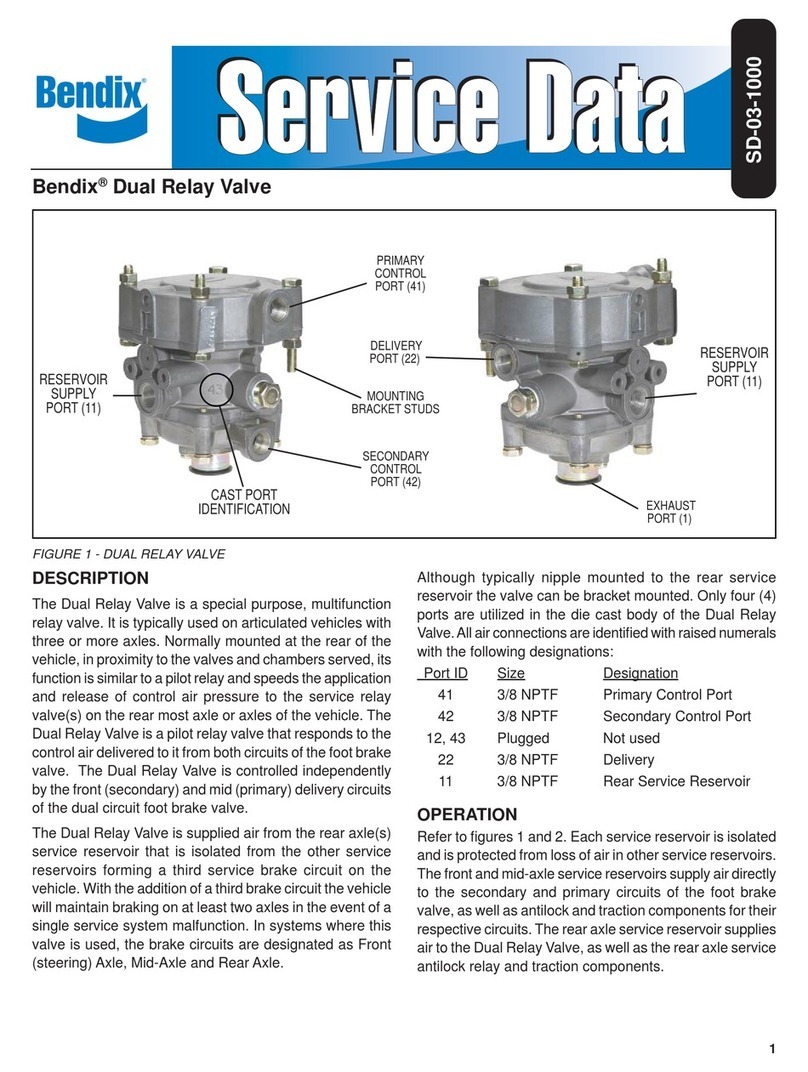

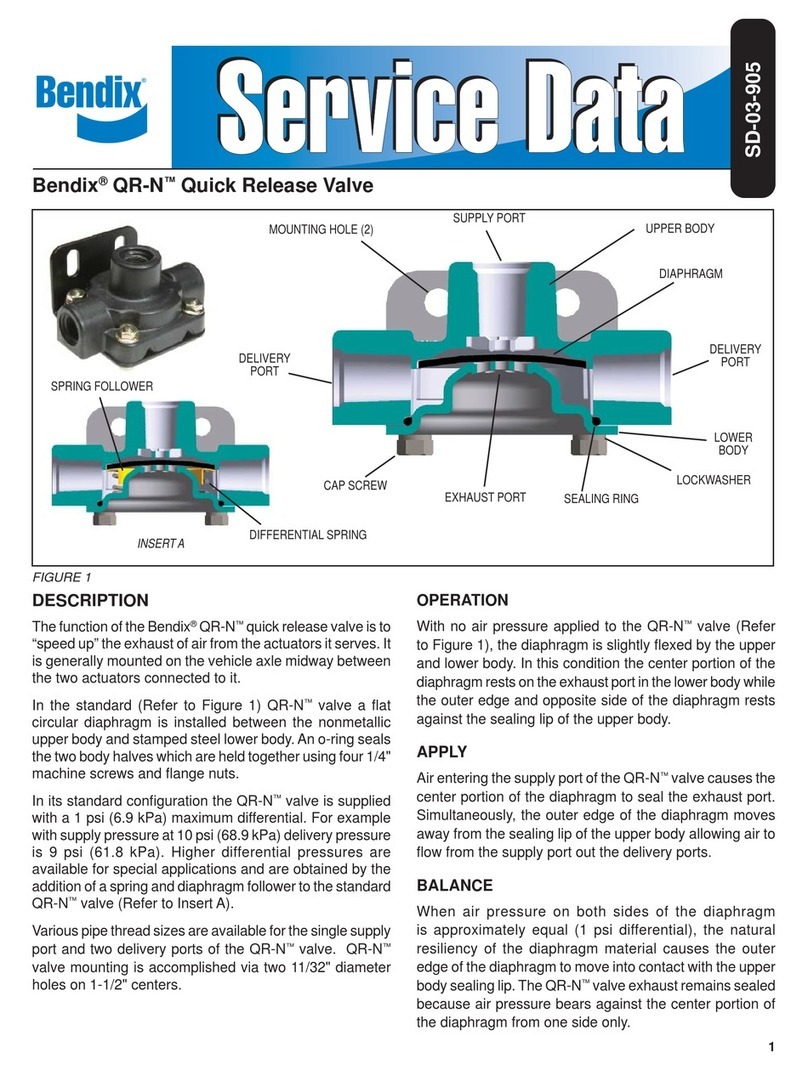

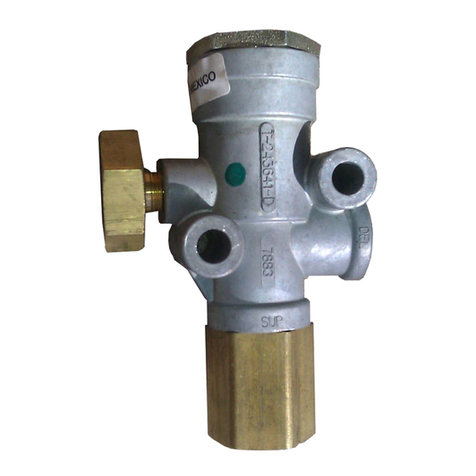

DESCRIPTION

The safety valve protects the air brake system against

excessiveairpressurebuild-up.Thevalveconsistsofaspring

loaded ball valve subjected to reservoir pressure which will

permit air to exhaust reservoir pressure to atmosphere if

reservoirpressure risesabove thevalves pressure setting,

which is determined by the force of the spring.

OPERATION

Toillustratetheoperationofthesafetyvalve,weshallassume

that the governor cutout pressure is set at 125 psi.Asafety

valve with a setting of 150 psi could then be used. Should

system pressure rise to approximately 150 psi air pressure

would force the ball valve off its seat, and allow reservoir

pressure to vent to atmosphere through the exhaust port in

the spring cage.

When reservoir pressure decreases sufficiently, the spring

force will seat the ball check valve, sealing off reservoir

pressure.This wouldoccur atapproximately135psiforthe

150psivalve.Itisimportanttonotethatthedesiredpressure

setting of the safety valve is determined by the governor

cutout pressure. The opening and closing pressures of the

safety valve should always be in excess of governor cutout

pressure setting. The pressure setting is stamped on the

lowerwrench flatofthevalve.

Normally, the safety valve remains inoperative and only

functionsiffor anyreasonreservoirpressure risesabovethe

settingof thevalve. Constant“poppingoff”orexhaustingof

thesafetyvalvecanbecausedbyafaultysafetyvalve,faulty

governor, faulty compressor unloading mechanism, or a

combination of any of the preceding.

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performinganyintrusivemaintenanceprocedures.Awarranty

maybe voidedif intrusivemaintenance isperformed during

thewarranty period.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuableguide indeterminingthe bestmaintenance interval

for air brake system components.At a minimum, the safety

valveshouldbe inspectedevery6monthsor1500operating

hours, whichever comes first, for proper operation. Should

the safety valve not meet the elements of the operational

testsnotedinthisdocument,furtherinvestigationandservice

ofthe valvemay berequired.

OPERATING AND LEAKAGE CHECKS

OPERATING TEST: With air pressure in the system, pull

theexposed endof thevalvestemremovingthe springload

fromtheballcheckvalve.Airshouldexhaustfromthevalve’s

exhaust port. Release the stem, the air flow should stop.

Failure of valve to pass operating test would indicate the

valve should be disassembled, cleaned and rebuilt. (See

“Disassembly and Assembly” section). If adjustment is

necessary, see “Adjustment” section.

LEAKAGE CHECK: Coat the exhaust port with soap

solution.Aleakage ofa 1”bubble in5 secondsis permitted.

Excessiveleakage indicatesdirt invalve,faultyballvalve or

seat. Valve should be disassembled, cleaned and rebuilt.

(See “Disassembly and Assembly” section).

REMOVING AND INSTALLING

REMOVING

1. Block wheels or otherwise secure vehicle and drain

reservoirs.

2. Usingwrenchflatclosesttoreservoir,unscrewvalvefrom

reservoir.

INSTALLING

Safety valve should be installed in same reservoir that

compressor discharge line is connected to. Install in a

convenient location in a top port of the reservoir. If safety

valveisinstalledhorizontally,exhaustportshouldpointdown,

stemof thevalve shouldfacerearofvehicle.

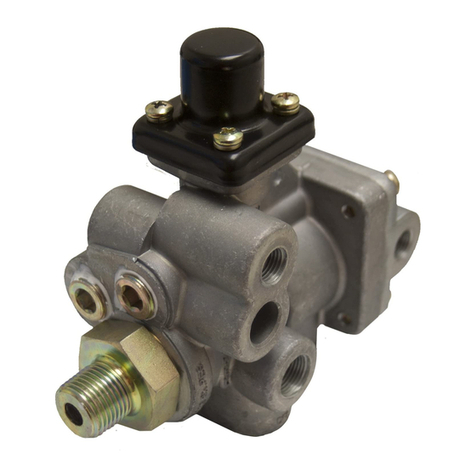

PRESSURE

SETTING

150 PSI

EXHAUST

PORT

ST-3™

VALVE

ST-1™

VALVE

SD-03-1901

Bendix®ST-1™& ST-3™Safety Valve