10

ENERGY-SAVING DEVICE ESA BASIC

DESCRIPTION

ESA BASIC is a device which has been specially studied, designed and patented to allow for annual energy savings up to

25 kW (indicative value for standard installation).

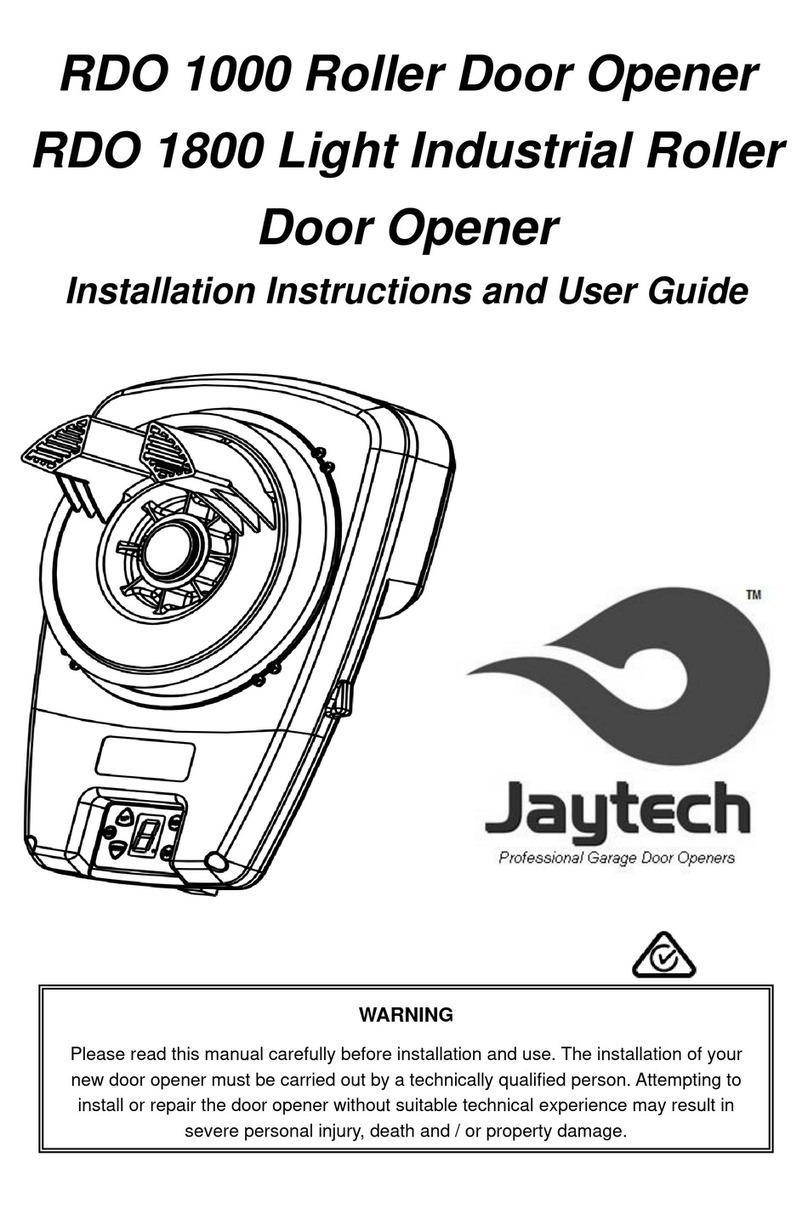

This equipment can be installed onto any new or already existing automatic systems, of any type whatsoever (sliding doors,

swing doors, garage doors, etc.), manufactured by our company or by other producers.

Esa Basic can be also used in systems which are not intended for the automation of doors or gates (e.g. irrigation sprinklers,

etc.). In any case, after installing ESA BASIC, the installer shall be responsible for the checking of the correct operation of

the system.

The manufacturer shall not be deemed responsible for any malfunctions.

OPERATION

Esa Basic must be connected between the mains power supply and the control unit.

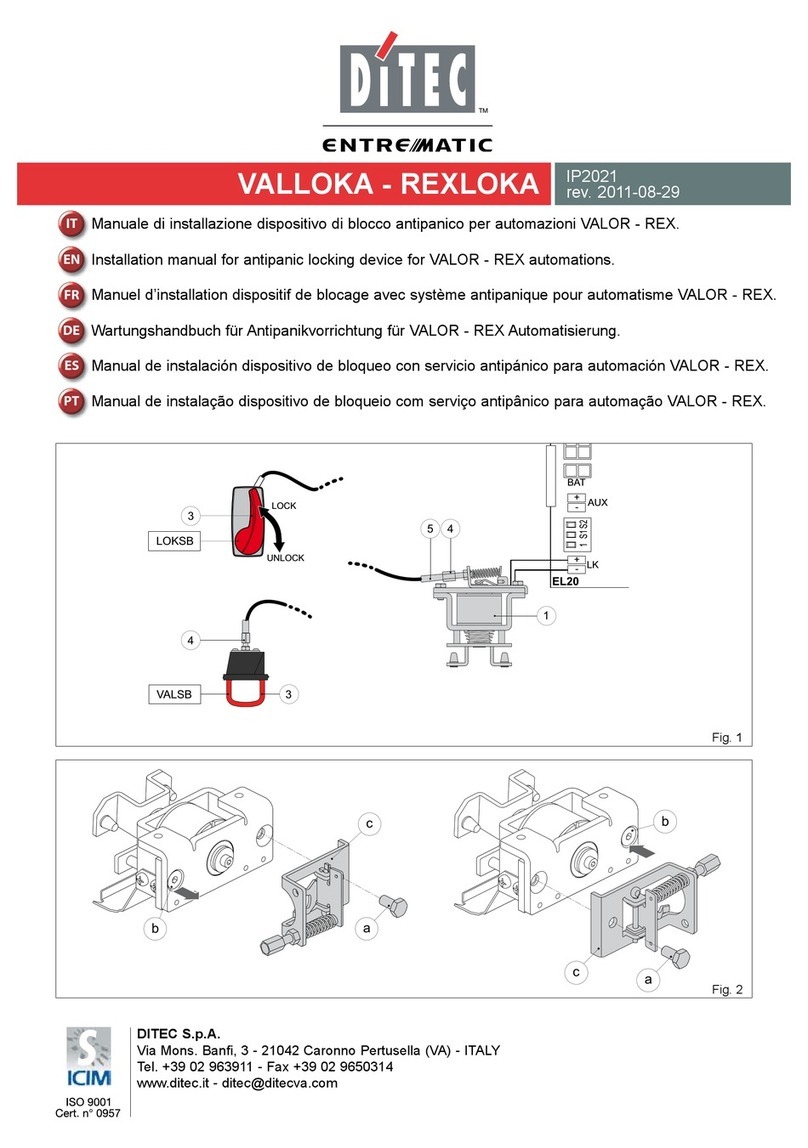

The push-button controls (Step-by-step, STOP, OPEN, CLOSE, SERVICE MAN, PHOT, Etc.) must be disconnected from

the control unit and connected to the ESA BASIC board (see Fig. 2).

The radio receiver codes must be removed from the receiver of the control unit and stored in the incorporated radio re-

ceiver memory (433.92MHz, rolling-code/fixed code/transmitters BYOU series) of the ESA BASIC card (prior check that

the transmitter used are compatible).

The ESA BASIC card keeps the system in “SLEEP” mode for the time it is not used. Energy consumption is therefore

reduced.

Only when the command is sent to the installation, the ESA BASIC card reactivates the system and sends the appropriate

control signal to the control unit. After a presettable time, the system returns to the SLEEP mode.

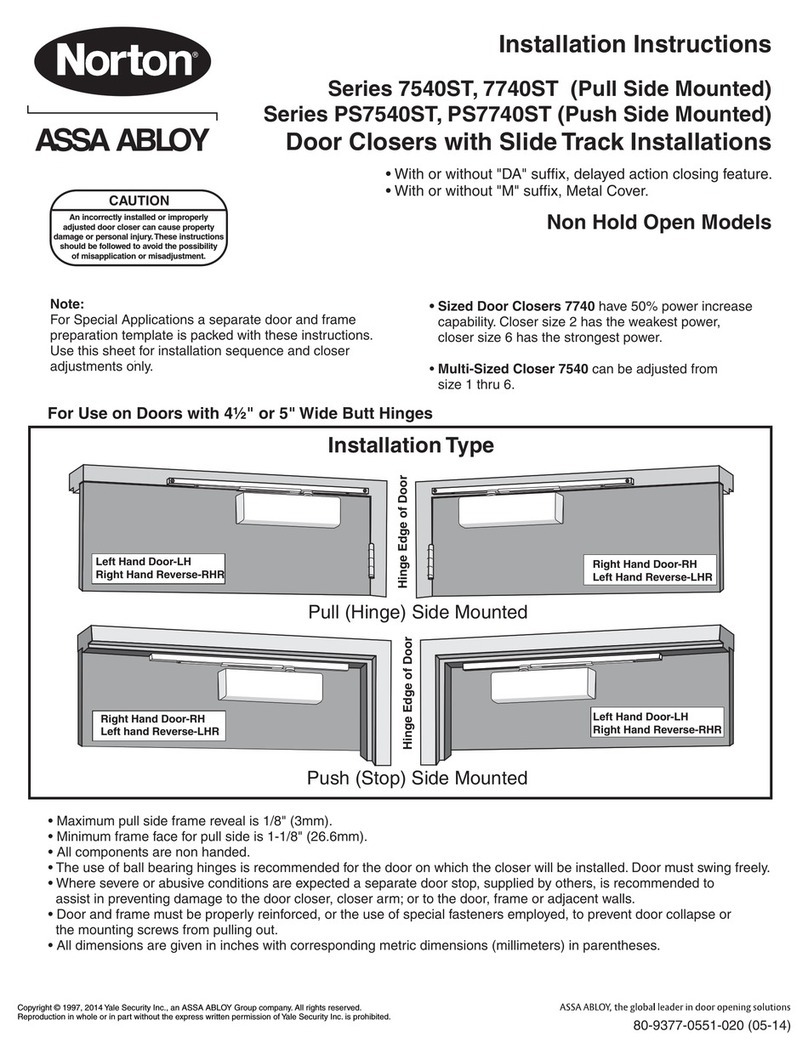

WIRE DIAGRAM

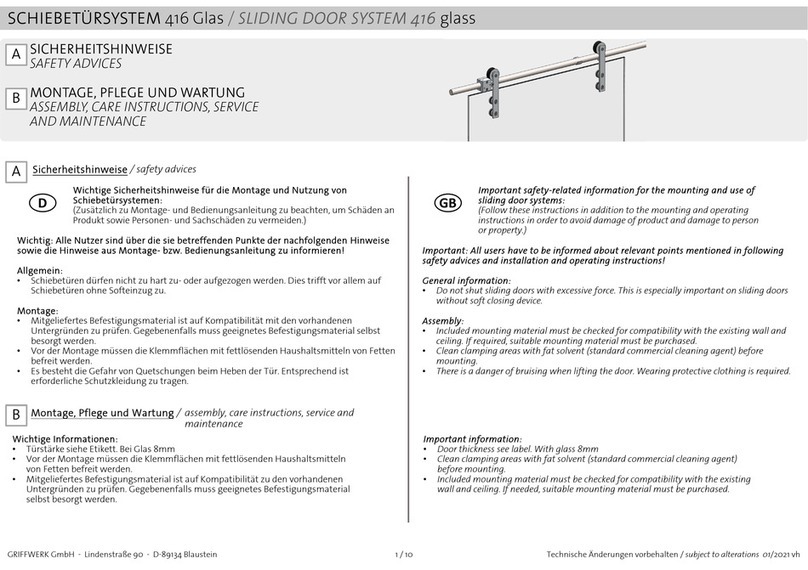

The electric connections shown in Fig. 1 are described in the following table:

Terminals Function Description

1-2 Mains power

supply

Input, mains power supply.

ESA BASIC accepts power supply voltages ranging from 85 to 26 VAC.

3 COM Common to all control inputs.

4-COM IN 1 Input, contact of command 1. It is configurable for NO, NC or IST contact.

It is preset as NO input by default.

5-COM IN 2 Input, command contact 2. Same characteristics as input 1.

6-COM IN 3 Input, command contact 3. Same characteristics as input 1.

7-COM IN 4 Input, command contact 4. Same characteristics as input 1.

8-COM IN 5 Input, command contact 5. Same characteristics as input 1.

9-COM IN 6 Input, command contact 6. Same characteristics as input 1.

1 -11 OUT 1

Output, channel 1. It replicates the status of input 1 or, alternatively, it can be matched

to a radio transmitter.

12-13 OUT 2

Output, channel 2. It replicates the status of input 2 or, alternatively, it can be matched

to a radio transmitter.

14-15 OUT 3

Output, channel 3. It replicates the status of input 3 or, alternatively, it can be matched

to a radio transmitter.

16-17 OUT 4

Output, channel 4. It replicates the status of input 4 or, alternatively, it can be matched

to a radio transmitter.

18-19 OUT 5

Output, channel 5. It replicates the status of input 5.

2 -21 OUT 6

Output, channel 6. It replicates the status of input 6.

22-23 Antenna

Connection of the antenna to the incorporated radio-receiver module

22 SHIELD: Screen / 23 ANT: Control signal.

24-25-26 SLEEP output

Output, power supply of the control unit: 25 Vac/16A maximum. Through this contact,

the control unit is activated or deactivated by ESA BASIC.