INSTALLATION MANUAL H5001 HYBRID INVERTER

Rev.1 ©2018 Darfon Electronics Corp. 2| Page

TABLE OF CONTENTS

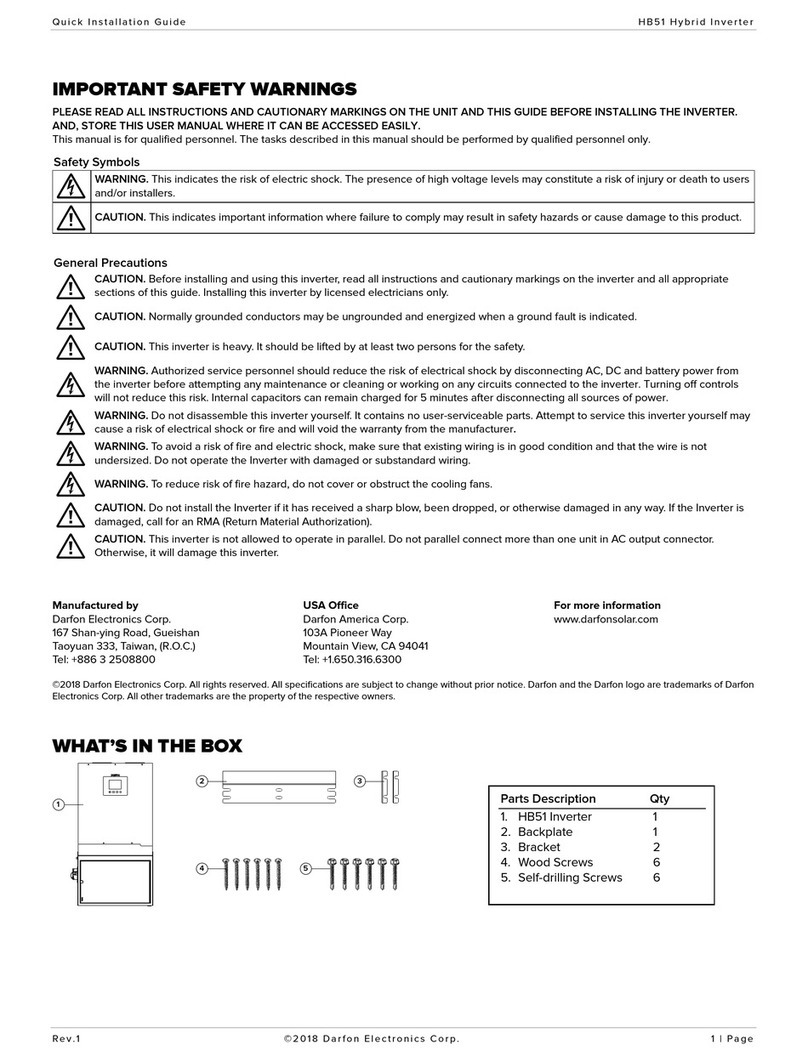

IMPORTANT SAFETY WARNINGS....................................................................................................3

INTRODUCTION ...................................................................................................................................4

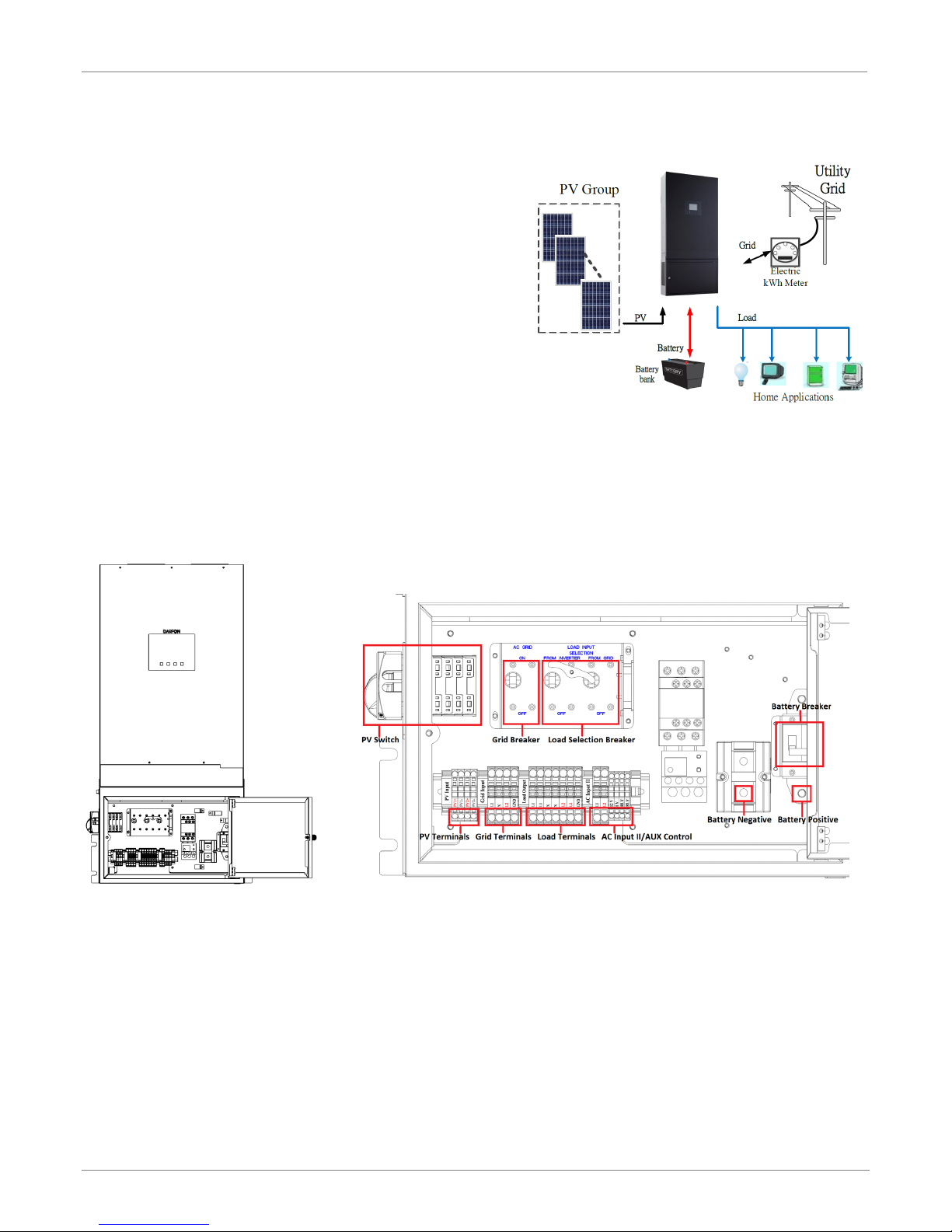

Product Overview................................................................................................................................ 4

MOUNTING THE INVERTER...............................................................................................................5

Installing the Inverter onto the Wall ............................................................................................... 5

PV MODULE (DC) CONNECTION .....................................................................................................6

Connecting the PV Arrays ................................................................................................................ 6

GRID (UTILITY) CONNECTION ..........................................................................................................7

Connecting to the Grid/Utility ...........................................................................................................7

BATTERY CONNECTION AND CHARGING REQUIREMENTS....................................................8

Connecting the Batteries .................................................................................................................. 8

Battery Charging Requirements...................................................................................................... 9

LOAD (AC OUTPUT) CONNECTION ...............................................................................................11

Connecting to the Load.....................................................................................................................11

OPERATION AND DISPLAY PANEL ...............................................................................................12

Display Panel Overview....................................................................................................................12

Starting the System............................................................................................................................12

Stopping the System .........................................................................................................................12

LCD Screen – Icons and Pages .....................................................................................................13

Mode Rule Definition.........................................................................................................................14

System Settings ..................................................................................................................................15

Warning and Fault Definition........................................................................................................... 17

GENERATOR [OPTIONAL] ................................................................................................................19

Generator Sizing.................................................................................................................................19

Automatic Start Generator...............................................................................................................19

Generator Application Schematic..................................................................................................19

CONFIGURING THE HARDWARE ..................................................................................................20

Connecting to the hardware ..........................................................................................................20

USE APPLICATION SOFTWARE MODIFIES PARAMETERS..................................................... 22

Preparation..........................................................................................................................................22

Connecting to the application software and modifies parameters .....................................22

Parameters setting tables ...............................................................................................................25

MAINTENANCE & CLEANING........................................................................................................ 26.

Wiring Diagram ..................................................................................................................................26

SPECIFICATIONS .............................................................................................................................. 27

GRID SUPPORT PARAMERTERS ................................................................................................... 28

5-YEAR LIMITED WARRANTY ........................................................................................................ 30