not in accordance with the manufacturers

recommendations, codes of practice, or similar standards.

• Air ow through the heater is not in accordance with

the manufacturers technical specications.

• Internal wiring on the heater has been tampered with

or unauthorised service or repairs undertaken.

• The main electrical supply input to the heater has

been interrupted during the heating mode.

• The heater has been subject to and aected by the

ingress of water in any form.

• The heater is not operated at the rating(s) laid down in

the manufacturers technical specications.

• The heater has not been operated or used within the

normal scope of its intended application.

• The manufacturer’s recommended minimum service

requirements have not been complied with

Note (ii)

All warranty claims must contain the following info to enable

processing to take place

• Heater model

• Heater serial number

• Order reference/date of order, together with full

installation details (name and address)

• Details or symptoms of fault

• Installers name and address.

Faulty parts must be returned to the supplier, the address of

which is provided at the rear of this manual.

Any such parts will undergo inspection to verify the claim.

Replacement parts supplied prior to this may be charged, and

a credit supplied upon subsequent validation of the warranty

claim.

Consumable items are specically not included within the

scope of the warranty.

Note (iii)

Notication is required immediately a fault is suspected.

The manufacturer will not accept responsibility for any

additional damage that has been caused, expense incurred, or

consequential loss resulting from any failure of the heater(s).

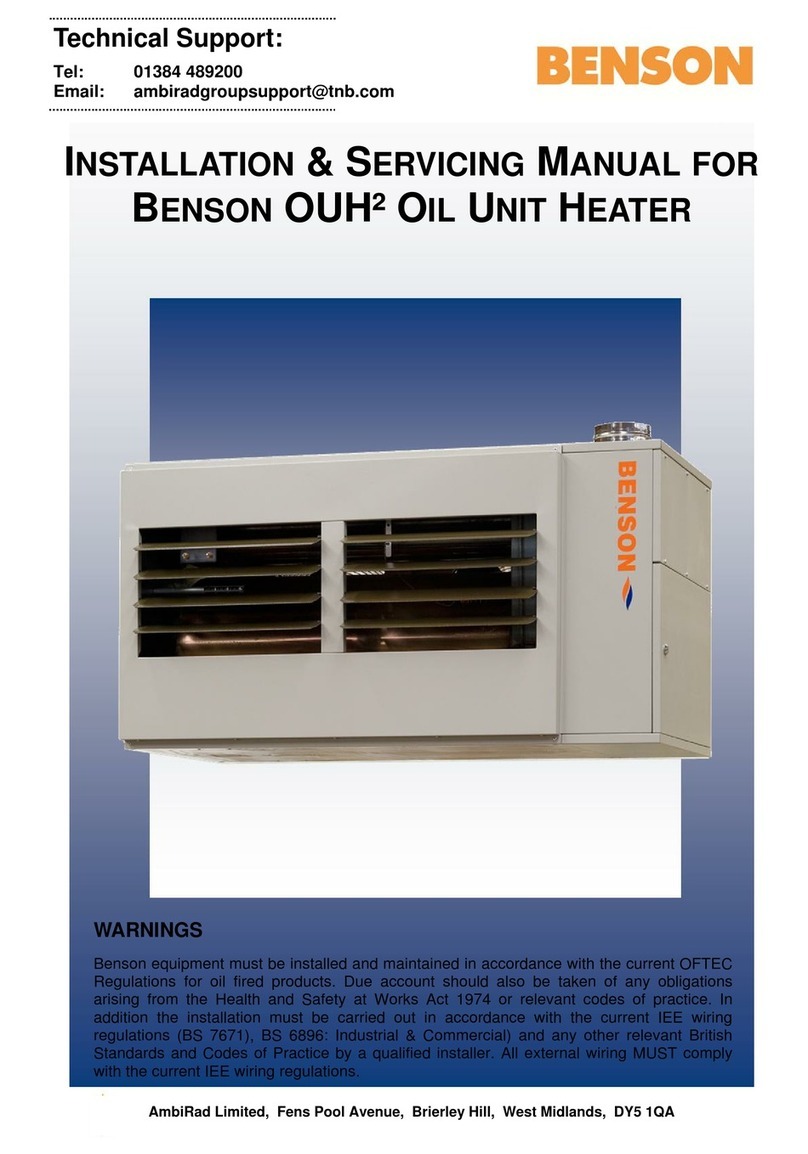

1.7 Health and Safety

The Suspended Oil red Unit Heater range must be

installed in accordance with the current OFTEC regulations for

oil red products Due account should also be taken of any

obligations arising from the Health and Safety at Works Act

1974 or relevant codes of practice. In addition the installation

must be carried out in accordance with the current IEE wiring

regulations (BS 7671), BS 6896: (Industrial & Commercial) and

any other relevant British Standards and Codes of Practice by

a qualied installer. Isolate all electrical supplies to the heater

& controller before proceeding.

For your own safety we recommend the use of safety boots

and leather faced gloves when handling sharp or heavy items.

The use of protective eye wear is also recommended.

Caution

Before using this appliance:

• Check that the voltage indicated on the type plate

corresponds to the mains supply voltage.

• Ensure that the heater has been securely fastened in

its nal mountain position.

UNDER NO CIRCUMSTANCES should any item be placed

on or above any part of the heater, whether the heater is

being used or not.

WARNING: This appliance must be earthed.

1.8 Location / Positioning

Warning

All of the basic criteria must be satised prior to commencing

installation and commissioning, additionally, the Suspended

Oil red Unit Heater must be positioned and installed so as to

comply with all the relevant standards and guide lines (see

section 1.1), as well as meeting national and local re

regulations and insurance criteria, especially if it is proposed

that the heater is to be installed within a special risk area (e.g.

proximity to where petrol engined vehicles are stored or

parked, where cellulose spraying takes place, where

woodworking machinery is operated, etc,).

Indirect heaters must not be located in hazardous areas,

however, it is permissible for the heater to supply air to such

areas.

The heater must not be installed within an environment

where there is a high concentration of chlorides, uorides,

salts, or other aggressive or volatile chemicals/compounds.

Nor should the heater be positioned where the burner could

be adversely aected by high winds or draughts.

The location chosen for the heater must allow for the tting of

an eective ue system.

The location must also allow for adequate clearance for the air

supply, return air circulation, oil supply and electrical supply,

whilst also providing good and safe working access.

Suspended free blowing Unit Heaters are at their most