Notices for the User

As of: 02/2009 - 3 -

Table of Contents

Notices for the User ..................................................................................................2

Vehicle Data .........................................................................................................................................2

Preface..................................................................................................................................................2

Instructions for work safety...................................................................................................................................................2

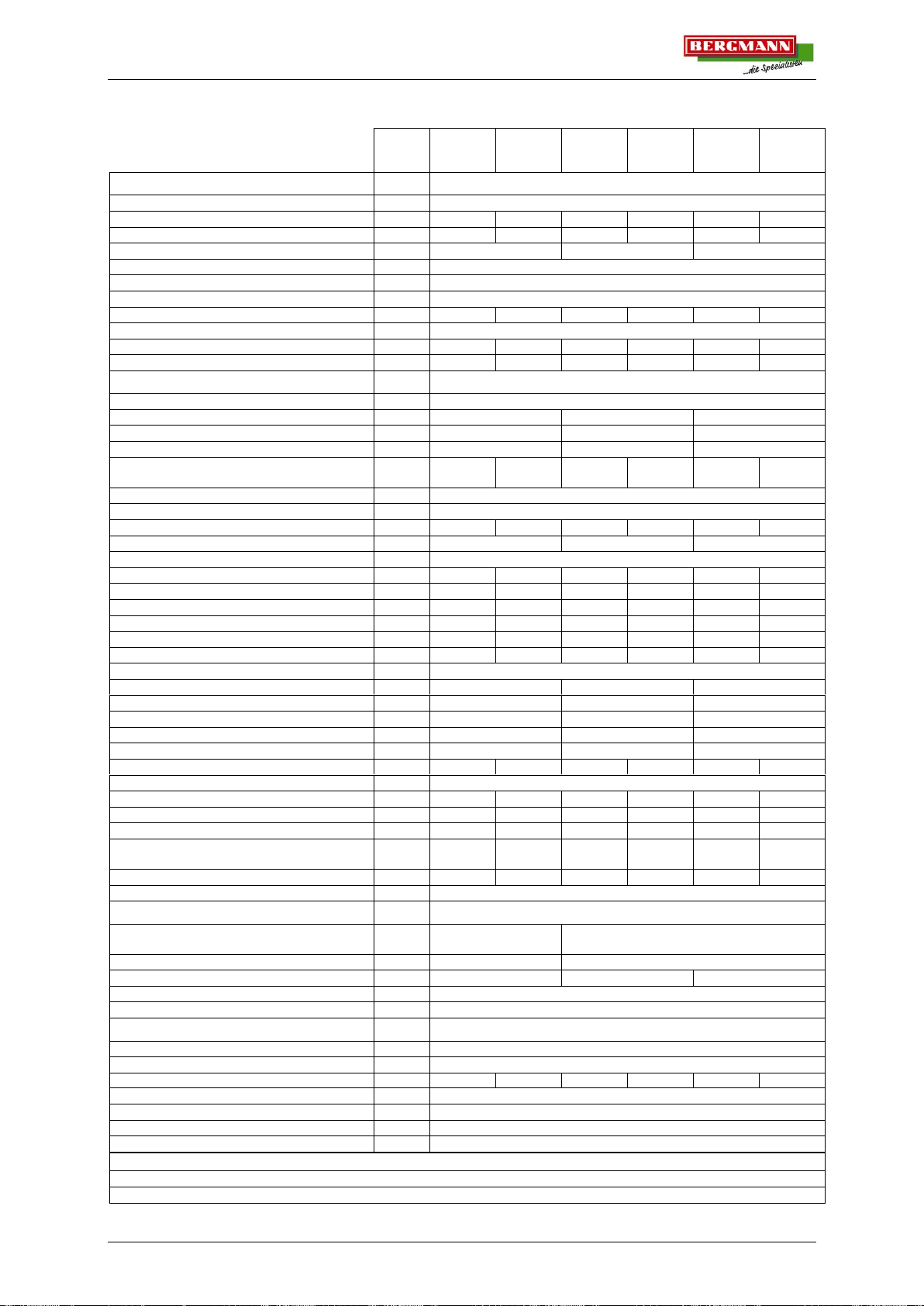

Table of Contents ................................................................................................................................3

Dear customer, ....................................................................................................................................5

Product Liability, Obligation to Inform..............................................................................................5

Product Transfer Instructions............................................................................................................7

General Information ............................................................................................................................8

Intended Use........................................................................................................................................................................8

CE Symbol ...........................................................................................................................................................................8

EC Declaration of Conformity................................................................................................................................................8

Identification Plate................................................................................................................................................................9

Manufacturer........................................................................................................................................9

Technical Data ...................................................................................................................................10

Safety Notice......................................................................................................................................11

Explanation of warning symbols..........................................................................................................................................11

General safety and accident prevention regulations.....................................................................14

Basic rules..........................................................................................................................................................................14

Driving................................................................................................................................................................................15

Road traffic regulations.......................................................................................................................................................15

Coupling, loading, transport................................................................................................................................................15

PTO Shaft Operation..........................................................................................................................................................16

Hydraulic system................................................................................................................................................................16

Brakes and Tires ................................................................................................................................................................17

Maintenance.......................................................................................................................................................................17

Important Information for Vehicle Operation .................................................................................18

Other Hazards....................................................................................................................................................................18

Safety Notice......................................................................................................................................................................18

Initial Start-up and Functions .................................................................................19

Mode of Operation.............................................................................................................................19

Initial Start-up ....................................................................................................................................19

Coupling to the Tractor.....................................................................................................................20

Adjusting the Height of a Drawbar with Mechanical Suspension.........................................................................................20

Parking Equipment............................................................................................................................21

Mechanical Jack Stand.......................................................................................................................................................21

Mechanical Support Jack....................................................................................................................................................22

Hydraulic Jack Stand (optional) ..........................................................................................................................................25

PTO shaft............................................................................................................................................26

Body....................................................................................................................................................28

Cargo Space Access Ladder ..............................................................................................................................................28

Extension Walls (optional) ..................................................................................................................................................28

Scraper Floor .....................................................................................................................................30

Scraper Floor Stop (optional).............................................................................................................................................30

Dosing Wall ........................................................................................................................................31

Installation of the Dosing Wall Extension ............................................................................................................................31

Spreader Unit .....................................................................................................................................32

Design Vehicle Type TSW..................................................................................................................................................32

Design Vehicle Type M.......................................................................................................................................................33

Spread Pattern Limiter (optional) ....................................................................................................33

Lubrication systems..........................................................................................................................34

Automatic Lubrication System for the Milling Unit Drive Chains (optional)...........................................................................34

Automatic Central Lubrication System (Optional)................................................................................................................34

Hydraulic system...............................................................................................................................36

LS Connection (optional)....................................................................................................................................................37

Hydraulic feed drive with manual control .......................................................................................37

Options for Coupling to the Tractor.....................................................................................................................................37

Installation of the Flow Regulator with Knob .......................................................................................................................38

Operation of the Hydraulic Feed Drive During Manual Operation........................................................................................38

Electromagnetic Scraper Floor Adjustment - E- Control Light (optional) ...................................38

Pilot box (optional) ............................................................................................................................39

Adjusting the Rotary Potentiometer in the Pilot box.............................................................................................................40

Comfort Control (optional) ...............................................................................................................41