Bergstrom NITE Kenworth T680 User manual

1

Installation Manual

Kenworth T680

without factory installed heater

For Phoenix Gen 4 units built after 6/26/2017

2390 Blackhawk Road ● Rockford, IL 61109 ● www.nitesystem.com ● 1-866-204-8570

The information contained herein is proprietary to Bergstrom Inc and/or its subsidiaries shall

not be reproduced, copied, or disclosed in whole or in part, or used for manufacture or any

other purpose, without prior written permission of Bergstrom Inc. The only controlled version

is that viewed electronically on the designated Bergstrom intranet site.

2

Table of Contents

1-1

1-2

1-7

1-8

1-9

1-10

2-1

3-1

4-1

5-1

6-1

7-1

Refrigerant Charging

Battery Management

Operating Instructions

Wiring Diagrams

Espar Heater Install

Electrical Installation

Installation Procedures

Tools Required

Before You Start / EPA

Introduction

Unit Exploded View

Warranty / Website

3

1-1

Congratulations. You have chosen

the premier no-idle climate control

system on the market today—the

NITE®Phoenix from Bergstrom.

The NITE Phoenix is a powerful 12V

rechargeable DC system that keeps

sleeper compartments cool in hot

weather and warm in cold weather

(with optional heater) without having to

idle the truck’s engine—and without a

genset. It not only dramatically

reduces fuel burned, it’s also very

environmentally friendly.

Your NITE Phoenix is a self-

contained, hermetically sealed,

compact A/C system that produces

approximately 7,500 BTU/h and has

been quality engineered for years of

reliable service. The system

operates independently from your

truck’s engine using its own deep

cycle batteries that are completely

separated from the truck’s starting

batteries.

The deep cycle batteries used are

the most advanced ever—and will

efficiently power the system for 7 to

9 hours. The batteries are then fully

recharged after just 4 to 6 hours of

driving.

Add it all up, and you have a

revolutionary no-idle system that will

save you money and fuel year after

year—the NITE Phoenix from

Bergstrom.

NOTE:

The NITE Phoenix A/C system is

designed to maintain a comfortable

temperature inside the sleeper

without running the engine.

For optimal comfort, the curtain

between the cab and the sleeper

must be closed when using the unit.

To enhance cooling efficiency during

the day, solar reflectors or curtains

should be placed over windshield and

all windows to block sunlight from

entering the cab and sleeper.

The NITE Phoenix A/C unit will not

pull down a hot sleeper that has

been sitting in the sun without the

factory A/C running. To assist the

NITE Phoenix unit in cooling down

the sleeper, start the engine and run

the factory A/C until desired

temperature is reached. The NITE

Phoenix unit will then maintain a

comfortable temperature depending

on solar load & ambient

temperature.

Introduction

4

Before You Start / EPA

1-2

A typical installation of the NITE Phoenix

generally takes between 8 to 10 hours,

although your particular situation may vary.

This manual contains step-by- step installation

instructions. It is divided into three categories:

●General installation

●Electrical installation

●Heater installation(optional)

There is also a section on how to check your

NITE Phoenix to make sure the installation

was successful, and a section on how to

operate your NITE Phoenix.

If relocation or reinstallation of any pre-

installed equipment is necessary for

installation of the NITE Phoenix equipment -

please refer to the components manufacturer's

instructions or safety guidelines for proper

installation.

Before you start, we highly recommend doing

the following to help make your installation as

easy as possible.

1. Lay out all parts and check to make sure you

have all parts listed on the parts list.

Depending on truck, some hardware may

not be used. If you are missing any parts,

please call 1-866-204-8570.

2. To prevent damage to compressor, keep the

NITE Phoenix unit in an upright position at all

times. If unit is tipped, place back in upright

position for a minimum of 6 hours prior to

running.

3. Check the list of tools needed for installation

and make sure you have all of them. Keep all

tools within easyreach.

4. Look through the whole installation manual to

get an understanding of the order in which

components are installed.

5. Make sure you have good lighting and

enough space to work in.

6. You may want to get an assistant to help

you to reduce the number of times you have

to climb in and out of the cab.

7. Make sure you wear all appropriate safety

equipment

Photo above is representative of kit

1000230792 only.

5

NOTICE - Prior to installation:

Installation, service, and repair of these units should be solicited

only by trained service technicians who are acquainted with

standard service instructions and training material.

All equipment should be installed in accordance with accepted

principles and unit installation instructions. Extreme caution

should be observed when troubleshooting electrical

components. These messages are for your protection and

information. Failure to follow these alerted messages may

cause bodily injuries to yourself and/or others as well as

damages to the specified unit.

Health, Safety, and Environmental Policy

Under any condition Bergstrom Inc. is committed to protecting

the health and safety of all working individuals at or visiting our

site. We strategize, administer, conduct, and supervise our

efforts in agreement with best practice. Hence, we want to

ensure all workers have a clear understanding of their

accountabilities with that of the company.

Environmental Concerns

Public awareness of and education about the benefits of using

green technologies, coupled with energy efficiency, has created

renewed interest within the HVAC industry.

When materials are discarded attempt to reclaim and recycle

them. To preserve our environment, follow appropriate rules

and regulations when disposing of any resources. It is under our

obligation to put in place a series of practices and procedures

that, when taken together, result in an environmental

management system.

Disclaimer of Liability

Descriptions and specifications within this manual were in effect

at the time of production. Models and specifications are subject

to change.

Refer to nitesystem.com for more information, or contact

customer service at 866.204.8570.

1-3

Picture Symbols

Observe all warning and caution notices posted on

equipment and in instructions and/or manuals. Pay

special attention to directives prefixed by symbols and

signals indicated as “Warning”, “Caution”, and “Note”.

Do not disregard any of these alerts.

Warning

This picture symbol with the remark “Warning” refers

to the risk of imminent danger and can be vital to

one’s health. The message will convey what the

hazards are, results when warnings are not heed to,

and/or how to avoid such injury. Under certain

circumstances, failure to comply with these

instructions can cause severe or life-threatening

impairment.

Caution

This picture symbol with the remark “Caution” refers

to a hazardous situation for a person and/or the

product. Failure to comply with these instructions can

cause bodily injuries to yourself and/or others as well

as damage to machinery.

Note

This picture symbol with the remark “Note” contains

information for use and helpful tips to assist an

individual when repairing a specified unit or vehicle.

Before You Start / EPA

6

Precautions for working with HFC134a

(R134a) Refrigerant and Polyvinyl Ether

(PVE) Refrigerant Oil

WARNING

Do not breath A/C refrigerant, oil vapor, or

mist. Exposure may cause irritation to the

eyes, nose, and throat.

Instances where there are accidental system

discharges; ventilate work area before

resuming service.

For additional health and safety information

contact the refrigerant and oil manufactures.

CAUTION

The air conditioning system uses

HFC134a (R134a) refrigerant and

polyvinyl ether (PVE) refrigerant oil,

which are not compatible with CFC-12

(R12) refrigerant, mineral oil, or PAG oil. If

the refrigerants or oils are mixed, the

compressor may fail.

Do not attempt to use R-12 servicing

equipment. Failure to follow this statement

may result in personal injury or equipment

damages.

Use service equipment that is only U.L listed

and certified in which meets the required

standards of SAE J2210 to remove

HFC134a (R134a) from the air condition

system.

Before testing, please authenticate the

HFC134a (R134a) refrigerant in the vehicle

system and recycling equipment / recovery

tank are contaminate free by using a

refrigerant identifier.

Note

All equipment must be serviced by

trained personnel only.

R134a service equipment and/or vehicle air

conditioning systems should not be pressure or

leak tested with compressed air.

Air conditioning system may consist of

R134a fluorescent dye to determine leak

detection. Examine with a high intensity

ultraviolet light system.

Specified labels on unit will identify systems

that contain fluorescent dye.

1-4

Note

The air conditioning system is designed only for

certain polyvinyl ether (PVE) refrigerant oil for

HFC134a (R134a) A/C systems and HFC134a

(R134a) components. The only recommended oil for

this particular system is Idemitsu FVC68D PVE oil.

The PVE oil is very hygroscopic, meaning it absorbs

water. Without appropriate sealing, the oil will become

moisture saturated and should not be used.

Note

Follow the handling procedures listed below:

Only use the specified FVC68D PVE oil from a

sealed container.

After use, immediately reseal containers of oil.

To avoid contamination, do not return oil to

original container once it has been dispensed.

Additionally, never combine oil with other

refrigerant oils.

Do not allow PVE oil to come in contact with

styrofoam parts. In such occurrences, damage

may result.

Do not allow PVE oil in contact with vehicle

paint. In such occurrences, damage may result.

In order to diminish the amount of moisture that

enters the system, any connection in the

refrigerant loop that is open must be closed as

soon as possible.

.

It is recommended for components that are

replaced to have dust caps left in place until the

component is ready to be installed in the

refrigerant loop.

Once components are removed from the

refrigerant loop they should have dust caps in

place as soon as possible in order to limit and

minimize moisture intrusion.

Before You Start / EPA

7

Important Safety Notices

Before proceeding please read and understand all safety

precautions and warnings. The list as follows contains the

general safety provisions that must be followed.

Work areas should be dry, well lit, ventilated, and free of

clutter such as loose tools, parts, ignition sources and

hazardous substances. All personnel must be aware of

hazardous conditions that can coexist.

Wear protective shoes when working. Opened toed

shoes are not allowed.

Rotating parts can cause cuts, mutilation, or

strangulation. Be alert at all times when operating

machinery.

When working, do not wear loose-fitting or torn clothing.

Additionally, do not wear jewelry. These are hazards

that may cause personal injury.

Before beginning any repairs, disconnect the battery

(negative [-] cable) from both battery boxes and

discharge any capacitors.

To prevent accidental engine starting disconnect the air

starting motor, if equipped.

To prevent personal injury or harm to the specified unit

place a “do not operate” tag in the operator’s

compartment or on the controls.

Before operating, allow the engine to cool.

Always use blocks or proper stands to support the

vehicle or vehicle components before executing service

repairs. It is important that one does not operate on

anything that is supported only by lifting jacks or a hoist.

To reduce the probability of personal injury, use a hoist

or get assistance when lifting components that weigh 23

kg [50 lbs.] or more. Make certain all lifting devices such

as chains, hooks, or slings are in good condition and are

of the correct load capacity. Furthermore, all lifting

devices must be positioned correctly. When needed,

always use a spreader bar. Also, lifting hooks must not

be side-loaded.

1-5

When handling corrosion inhibitors and lubricating

oils avoid exposure to eyes and repeated contact

to skin for they may contain alkali. In case of

contact, immediately wash skin with soap and

water. When cases are severe, please contact a

physician. Store toxic products and substances

out of reach of children.

Naptha and Methyl Ethyl Ketone (MEK) are

flammable and hazardous materials and must be

used with attentiveness. Follow manufacture

guidelines to ensure safety when handling

materials. Store toxic products and substances

out of reach of children.

When operating on a vehicle be attentive and

cautious for hot parts on systems that have been

turned off, exhaust gas flow, and hot fluids in lines,

tubs, and compartments. Direct contact to skin

may cause severe burns.

Always use tools that are in good working

condition. Service technicians must be trained and

have proper understanding on how to use the tools

before administering service.

When replacing items use the same and/or

equivalent fastener part number at all times.

Conversely, do not use a fastener of reduced

quality if replacement is needed.

To prevent bodily injury or harm do not perform

any repairs when impaired, fatigued or after

consuming alcohol or drugs that can impair one’s

functioning.

According to several states and federal agencies

within the United States of America it has been

evident that used engine oil can be carcinogenic,

causing reproductive toxicity. That being said,

avoid inhalation of vapors, ingestion, and

prolonged contact with used engine oil.

Be mindful that liquefied petroleum gas is denser

than air and can accumulate near the floor, in

slumps, and low-lying area.

Close the manual fuel valves prior to performing

maintenance and repairs and when storing the

vehicle inside.

California Proposition 65 Warning –Diesel engine

exhaust and some of its constituents are known to the

state of California to cause cancer, birth defects, and

other reproductive harm. To request more information

regarding the chemical exposures that are the basis of

the warning, contact the manufacture of the product.

WARNING

Ill-advised practices, negligence, and/or

ignoring warning signs may cause death,

personal injury, equipment or property

damages.

Before You Start / EPA

8

1-6

Before You Start / EPA

9

1-7

Cardboard Template Layout

Unit Exploded View

10

1-8

TO REGISTER YOUR NEW SYSTEM

OR FILE A WARRANTY CLAIM

FOLLOW LINK LISTED BELOW.

https://warranty.bergstrominc.com

For technical manuals or service parts

go to

https://us.bergstrominc.com/eproduct-systems/

Email us at

parts@bergstrominc.com

Or call the - NITE LINE

1-866-204-8570

Warranty / Website

WARRANTY

11

1-9

1) Drill Bit Set

2) Hole saws (1″, 1-5/8″, 2″, 2-1/2″, 4-1/2″ and 4-3/4″)

3) Electric/Air Drill

4) Screwdrivers/Assorted Bits (Flat Head & Phillips Head)

5) Impact Gun

6) Air saw/Jigsaw (Cutting Sheet metal)

7) Torx Head (T20-T25) Bit Set

8) Metric Wrenches

9) SAE Wrenches

10) 1/4″, 3/8″ Drive Ratchets

11) SAE Socket Set

12) Metric Socket Set

13) Wire Cutters

14) Terminal Crimpers

15) Wire Strippers

16) Razor Knife

17) Electrical Tape

18) Cable Cutters

19) #4 Professional Grade Cable Crimpers

20) Cable Strippers

21) Work Light

22) Torque Wrench up to 50 in/lb

23) U-barrel Crimper

24) Pop Rivet Gun

25) Deutsch Crimpers

Tools Required

12

1-10

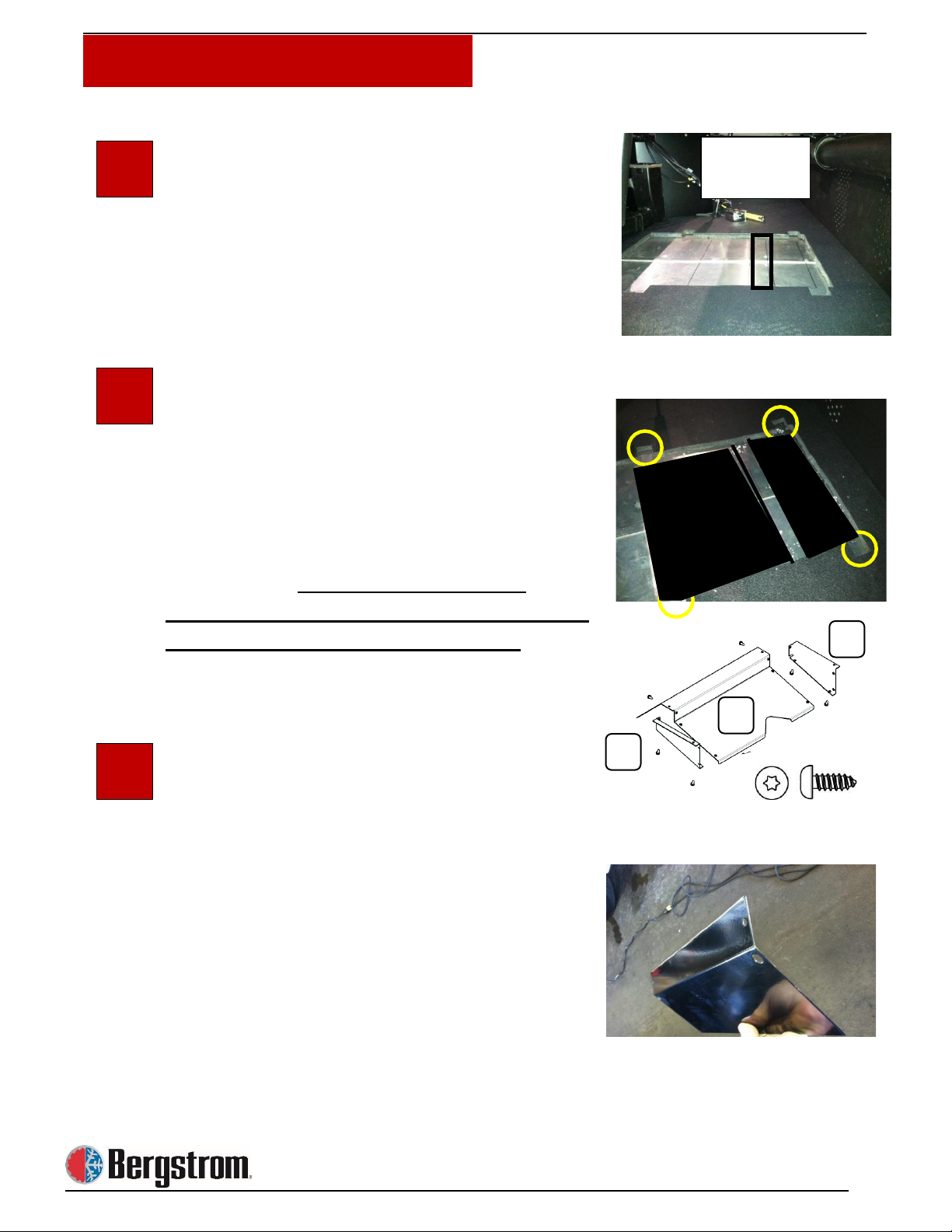

Installation Procedures

37”

4.5”

Floor Support

under truck

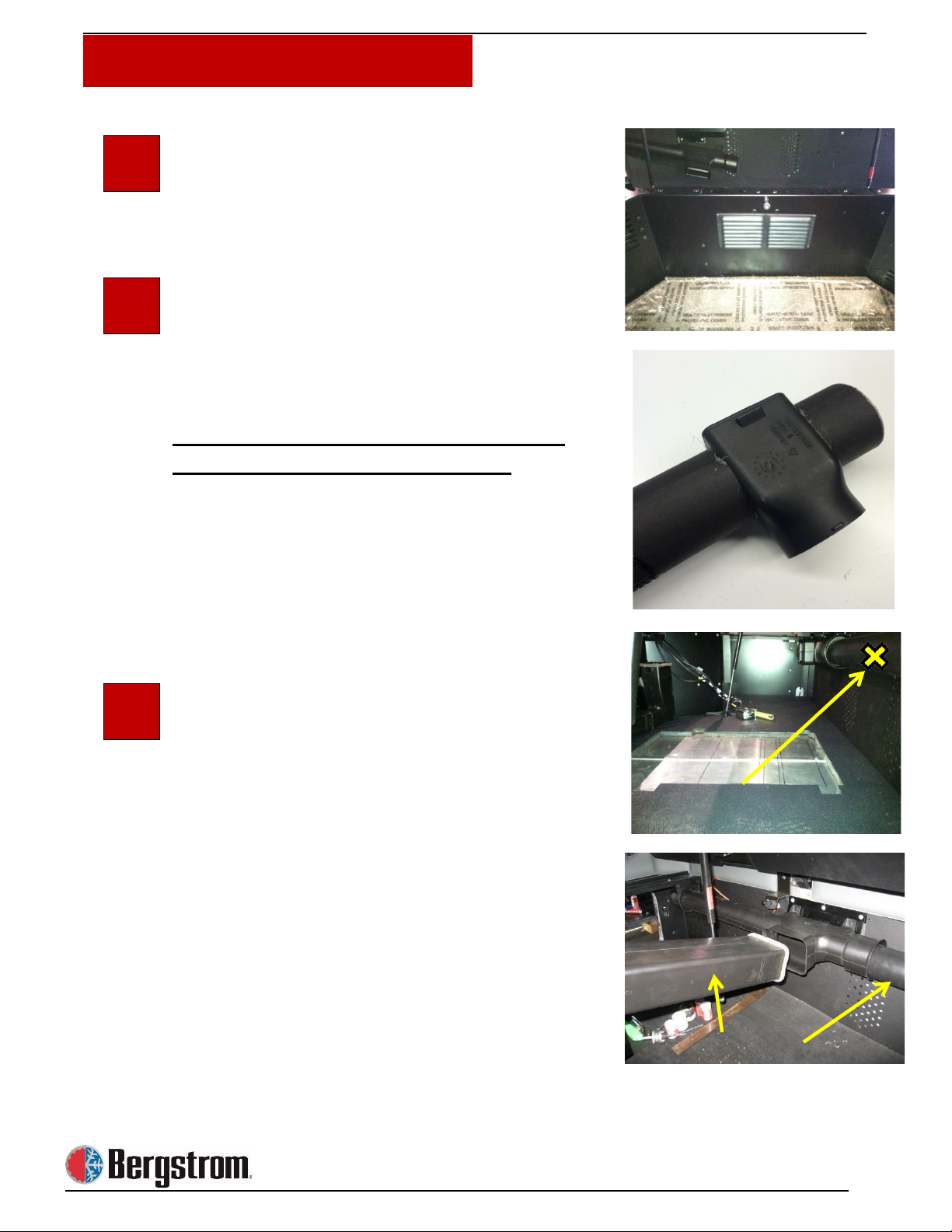

Prepare the Work Area

Start by disconnecting the ground wire from

the starting batteries. Set up your work light

and clear the sleeper compartment of loose

items.

Floor Insulation

Determine approximate location for the

Phoenix unit. Measure 37 inches from the

driver side sleeper door and 4 ½ inches

from the rear wall liner. This will position the

Phoenix unit so the area between the 2

condenser openings will be centered above

the floor cross member. Remove the floor

insulation as shown, exposing the floor of

the sleeper.

Mark Area in Truck Floor to be Cut

Bend or remove the end tabs of the

template and position the template as

shown (see photo). Check under the truck

for any obstructions. Do not cut through

cross members. Mark the rectangular

openings in the template. Openings should

be large enough for the condenser air

bracket to fit inside (see photo step 5). Use

caution not to cut too large. Cross member

flange will be wider than the template

marks! Cut openings to edge of cross

member only.

DO NOT CUT CROSS MEMBER!

(See photo)

1

2

3

13

1-11

Installation Procedures

A

B

A

Do not cut

this area

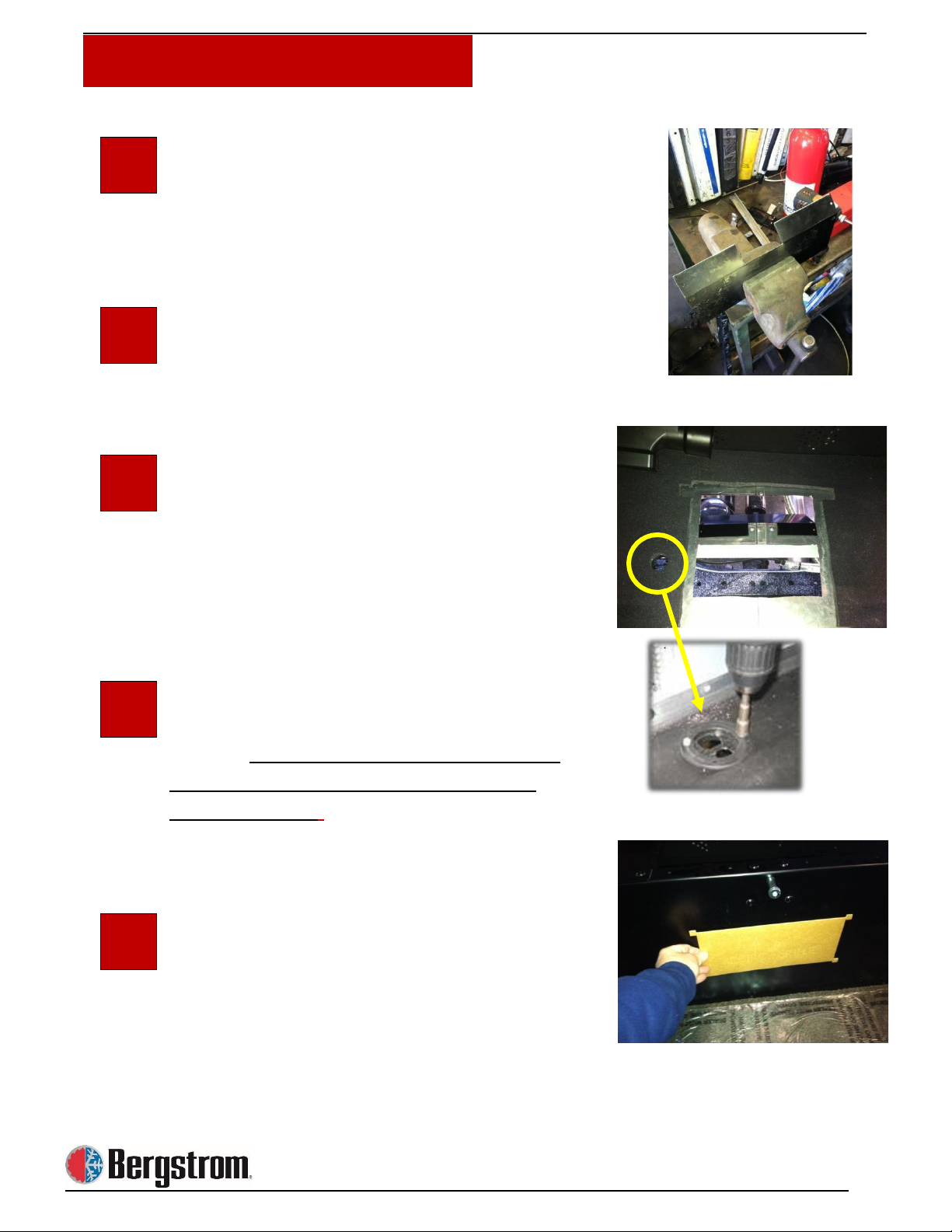

Cut Hole in Truck Floor

Drill starter holes in all four corners of the

area marked for cutting. Note location of

cross members prior to drilling holes. Use

air saw/jigsaw to cut through truck floor.

Position the NITE Phoenix mounting

template, as shown, with the condenser

openings over the holes cut in the truck

floor. Mark 4 mounting feet locations as

indicated in photo. The unit has 8 possible

locations but you will only use 4. Use equal

spacing to provide adequate stability of the

Phoenix unit. Predrilling holes for the

mounting screws will aid in keeping the unit

square with the condenser openings.

Modify Condenser Air Inlet

Sides A will not be used. Cut section B as

shown in the next 2 photos. You will

remove the side that has the notch leaving

the top flat section on the piece to install.

4

5

6

14

1-12

Installation Procedures

Modify Condenser Air Inlet

Measure and notch the flat mounting side of

the deflector so it will sit flat on the truck

floor avoiding the floor seam and rivets.

(See Photo)

Install the Condenser Air Inlet

Place modified deflector in the condenser

opening. Fasten with 1″ x 5/16 head self-

drilling screws.

Cut Hole for Wiring Grommet

Using a 2″ hole saw, drill a hole for the

wiring grommet. We chose the location next

to the Phoenix where the wiring will drop

through the floor inside the frame rail.

Choose the best location for routing the

cables away from heat and sharp edges.

Install Wiring Grommet

Fasten with 1″ x 5/16 head self-drilling

screws. After wiring is complete, seal all

voids around wires and grommet with

silicone sealant.

NOTE: Silicone sealant not included in

installation kit

Cut Opening for the Recirculation Grill

Using provided template, locate center of

bunk support and mark area to be cut. Cut

and remove marked area. Also if

applicable, mark a location for the 2 ½ inch

round hole for the optional heater duct.

7

8

9

10

11

15

1-13

Installation Procedures

Install Recirculation Air Grill

Using black Phillips head screws provided.

New Duct Adapter Connect the Phoenix

Duct to the OE

Photo to the right shows duct adapter

already cut and ready for installation.

Before removing cross car duct, mark

the location for the duct adapter.

Line up the side of the adapter with the side

of the floor cut out and mark center of

adapter location.

Remove Both OE Duct Sections as

Indicated

12

13

14

16

1-14

Installation Procedures

Cutting the New Duct Adapter

Using the appropriate size hole saw, cut out

each side of the new duct adapter.

Slide Adapter Onto OE Duct

Center it on the X mark made in step 14.

Cut OE Duct Section as shown

Using an air saw, remove the marked

section. Use caution, do not cut too much.

The opening must be inside the adapter

when reinstalled.

Slide the Adapter Onto the OE Duct

Center adapter over the opening. Fasten in

place with self-drilling screws. Seal around

the adapter with silicone.

Reinstall Duct Assembly after Steps 35-

38 –Gravity Door Install

15

17

16

18

19

17

1-15

Installation Procedures

Prepare to Install Unit

Attach Seal Strip to Duct Bracket and

Elbow

Install foam seal around opening of flange

bracket and elbow.

Install the Duct Elbow Mounting Bracket

to the Phoenix unit using #10 X 1/2″ T20

elbow bracket screws.

Now Install One Half of the Elbow

Support Ring

Using elbow flange screws #8 X 3/4″ T20.

Do not completely tighten screws at this

time.

Slide the Elbow Into the Support Ring

facing what will be the back of thetruck and

install the second half.

Once Installed Snug All Screws

20

21

22

23

24

18

1-16

Install Mounting Feet

The Phoenix unit has 8 pre-dimpled

locations. Fasten feet in the 4 locations

matching the predrilled holes from page 13

step 5. Use 1″ x 5/16 hex head self- drilling

screws. Do not install feet where the

case is not dimpled or you will damage

the unit.

Install Phoenix Unit

Now secure the unit using eight 1″ x 5/16

head self-drilling screws.

New adapter replaces the install kit elbow

Prepare to Install the Phoenix Controller

Remove the OE Control Panel

Installation Procedures

25

26

27

28

19

1-17

Installation Procedures

Controller Location

On this model, the location for the controller

is stamped in the back of the OE panel.

Place the controller template in the area to

be cut to make sure the dimensions and

area are ok to cut.

Drill Starter Holes for Air Saw

Cut out marked section.

Attach Control Panel to the Sleeper

Carefully depress the lock and remove the

controller cover.

29

30

31

20

1-18

Installation Procedures

Install the Controller to the Control

Center

Using #10 x ½” T 20 torque head screw

(PN 600129). Do not over tighten.

Install Phoenix Control Harness

Route the controller harness from Phoenix

unit to control center area. Connect harness

to controller.

Install the OE Control Center

Gravity door: The purpose of this door is to

prevent the Phoenix system cool air from

flowing backwards through the OE bunk

unit.

Install the Provided Gravity Door

Modify OE duct.

32

33

34

35

Table of contents

Other Bergstrom Temperature Controllers manuals