EWS ES 2050 User manual

Electronic Controllers for water softening units

Instruction Manual

ES 2050

ES 2051

Software version 4.01

CONTENTS

System Description................................................................................................................................. 1

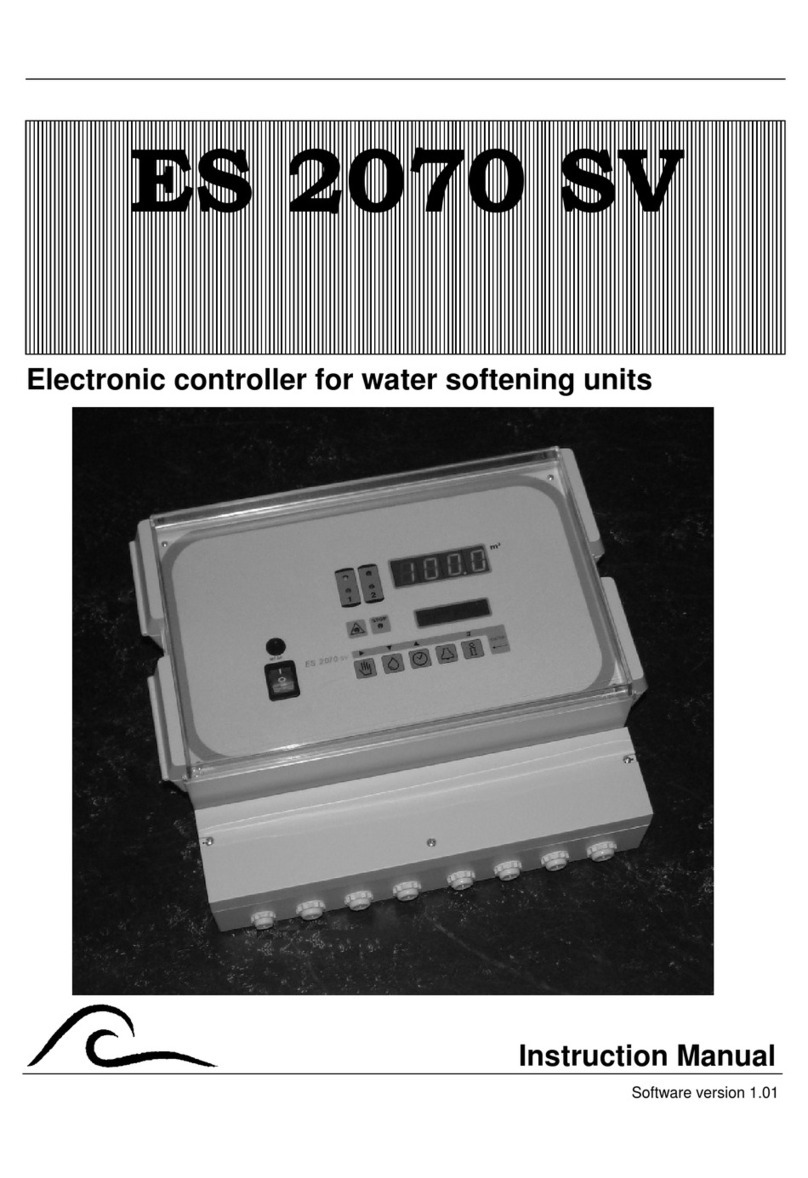

Wall mounted ES 2050, Panel mounted ES 2051 ................................................................................. 2

Status and Regenerationmessages....................................................................................................... 3

LED-display....................................................................................................................................... 3

LED - control lamps........................................................................................................................... 3

LCD - display..................................................................................................................................... 3

Service status............................................................................................................................... 3

Regeneration status..................................................................................................................... 4

Changing and indication of programme values...................................................................................... 5

Hardness of the water supply............................................................................................................ 5

Current Time...................................................................................................................................... 6

Information DISPLAYS...................................................................................................................... 6

Flush period.................................................................................................................................. 6

Regeneration time........................................................................................................................ 6

Additional program....................................................................................................................... 7

Unit capacity................................................................................................................................. 7

Treated water produced............................................................................................................... 7

Inputs............................................................................................................................................ 8

Outputs......................................................................................................................................... 8

Service - Telephone number........................................................................................................ 8

Maintenance................................................................................................................................. 8

Software version........................................................................................................................... 8

Alarms / warnings................................................................................................................................... 9

Programmed capacity exceeded....................................................................................................... 9

Electrical supply failure.................................................................................................................... 10

Refill chemical tank.......................................................................................................................... 10

Await regeneration........................................................................................................................... 11

Pre contact (regeneration pre initiation warning) ............................................................................ 11

Minimum inter regeneration time limit ............................................................................................. 12

Minimum/maximum programmed value exceeded ......................................................................... 12

Message: Maintenance ................................................................................................................... 12

Manual regeneration initiation .............................................................................................................. 13

Remote control ..................................................................................................................................... 14

"water meter" Signal input............................................................................................................... 14

"chemicals low" Signal input............................................................................................................ 14

"await " Signal input......................................................................................................................... 14

"start" Signal input........................................................................................................................... 15

"duty changeover without regeneration" Signal input...................................................................... 15

Special functions................................................................................................................................... 16

Duty changeover without regeneration ........................................................................................... 16

Regeneration of the standby unit .................................................................................................... 16

Regeneration stop............................................................................................................................ 16

Fast program facility........................................................................................................................ 17

Flush ON/OFF................................................................................................................................. 17

Regeneration without counter Reset............................................................................................... 17

Setting and changing of initial values................................................................................................... 18

1. Duty changeover........................................................................................................................ 19

2. Pre service regeneration............................................................................................................ 19

3. Prohibited regeneration period................................................................................................... 20

Start on real time clock............................................................................................................... 21

4. Time controlled regeneration ..................................................................................................... 22

5. Minimum time between regeneration’s ...................................................................................... 23

6. Water meter................................................................................................................................ 24

7. Flow-pulse.................................................................................................................................. 24

8. Incoming water supply hardness................................................................................................ 25

9. Exchange capacity..................................................................................................................... 26

10.Pre regeneration signalling ........................................................................................................ 27

11.Number of valve switching pulses.............................................................................................. 28

12.Electrical control......................................................................................................................... 28

13.Pulse timing................................................................................................................................ 30

14.Regeneration times.................................................................................................................... 31

15.Additional programme

(Regeneration-additional programme, flushing, high pressure pump) ...................................... 32

16.Alarm and warning relay outputs................................................................................................ 35

Capacity exceeded........................................................................................................... 35

Power supply failure......................................................................................................... 35

Refill chemical tank.......................................................................................................... 36

Await regeneration........................................................................................................... 36

17. Input "WAIT".............................................................................................................................. 36

18.“Start” input................................................................................................................................. 37

19.Service........................................................................................................................................ 37

Typical installation diagram.................................................................................................................. 38

Remote monitoring control ................................................................................................................... 38

Typical Electrical wiring diagrams ........................................................................................................ 39

Electrical connection details................................................................................................................. 41

Installation recommendations and commissioning............................................................................... 42

Technical specifications........................................................................................................................ 43

Declaration of conformity...................................................................................................................... 44

ES 2050/51 System Description 1

System Description

The ES 2050 (wall mounted) and ES 2051 (panel mounted) controllers are designed for the monitoring

and control of simplex (single exchange column) and duplex (twin exchange columns) water softener

installations.

Whilst a simplex installation can not provide softened water to service when the exchange column is in

regeneration, a duplex installation is capable of providing treated water from one column whilst the other

is being regenerated. Duplex plants can be operated either in duty/standby mode (one unit in service,

the other either in regeneration or waiting to be called into service), or in parallel mode (both units in

service except when one is regenerating). The regeneration of an exchange column is effected either by

one central control valve or by means of a pilot system controlling individual valves.

Regeneration is usually initiated after a measured volume of water has passed through the plant, this

volume is automatically calculated when the exchange capacity and the feed water hardness are

programmed into the controller. Alternatively the regeneration cycle may also be initiated either, after a

predetermined time period, or, by the operation of an external contact e.g. hardness monitoring

equipment, or, push button, or, based on the real time clock. Because, particularly with simplex plants,

there can be periods of the day when regeneration would be undesirable, e.g. periods of high demand,

the control can be programmed so that regeneration cannot take place between certain times. When this

postponed regeneration facility is in use, any initiation signal is stored and a display indicates the earliest

time at which the already initiated regeneration cycle may commence.

An external contact may be used to:

a) inhibit or abort a regeneration cycle

b) open or close the service valve.

In order to prevent microbiological degradation of the unit due to prolonged periods of non operation, the

stand-by unit of a duplex water softener installation can be regenerated immediately prior to being put

into service.

A minimum time interval between successive regeneration cycles may be set, thus allowing brine

systems to recover between regeneration’s, if necessary.

Five volt free relay contacts are available for control of valves, pumps, lamps, etc. or can be used for

remote monitoring.

1. Additional programme relay (programmable):

a) available before, during or after part of the regeneration cycle.

b) can be used to open a dump valve flushing the plant to drain each time a pre-set

volume of treated water has been produced.

c) allows control of a valve or pump during the regeneration or service.

2. Regeneration relay:

Contact available during the regeneration cycle.

3. Flow pulse relay (programmable):

a) repeats the contact of the water meter for remote monitoring of water use.

b) used to control the fill valve of the chemical tank.

4. Warning relay:

Programmable warning contact.

5. Alarm relay:

Programmable fault contact.

ES 2050/51 Wall mounted ES 2050 2

Panel mounted ES 2051

Wall mounted ES 2050

1 Service unit 1 8 Position cursor 15 Numerical input

2 Regeneration unit1 9 Supply water hardness 16 Programming

3 Alarms 10 Next program 17 service unit 2

4 Warnings 11 Real Time 18 LED Display

5 Fuse 12 Previous program 19 Regeneration unit 2

6 Main switch 13 Unlock 20 LCD display

7 Regeneration start 14 Information

Panel mounted ES 2051

ES 2050/51 Status and regeneration messages 3

Status and Regeneration messages

LED - display.

m³

Whilst a unit is in service the LED - display indicates the remaining volume of water which can be

softened before the next regeneration will be required.

When operating without a water meter, i.e. in time control, the display usually shows the full capacity

between regeneration’s.

During the regeneration of a simplex plant the display will read " 0 m3".

If the maximum value of 9999 is exceeded the LED display will show the text "OFL" as long as the value

is to high.

NB! There is an additional "decimal point" in the bottom right hand corner of the display. This flashes

when flushing has been commenced (see step 15 in the basic programme.

LED - control lamps

Coloured lamps are used to give the most important status indications.:-

Unit 1 in service (green)

Unit2 in service (green)

Unit 1 in regeneration (yellow)

Unit 2 in regeneration (yellow)

Message (red)

Fault (red)

Additional information is provided by the LCD display

LCD - display.

Service status.

The first line of the LCD display indicates the actual condition of the plant, e.g. unit 1 in service.

Usually during the service cycle the following information is given by the second line of the LCD:

The left hand part of the line shows the incoming water hardness which has been programmed

into the unit.

The current time is displayed on the right.

Service unit 1

200mg/l 17:00

ES 2050/51 Status and regeneration messages 4

However some operating regimes will produce alternative messages :-

Either:

When operating with the control set to prohibit regeneration between certain times (section 3 of the

programming instructions), if regeneration is required it will be postponed and the initiation signal

stored until the end of the prohibited period, the second line of the display will show the time at

which the unit will commence regeneration and the current time.

or:

If the control has been set to initiate a regeneration after a fixed time interval the second line of the

display will show the number of hours remaining until regeneration will take place and the current

time.

or:

The control can be programmed to give a signal, e.g. for a bleed valve, each time a predetermined

volume of water has been supplied. When this output is active the second line of the display shows

the remaining signal duration.

Regeneration status.

The first line of the LCD display indicates the actual condition of the plant, e.g. unit 1 in regeneration.

The second line of the LCD display shows, the regeneration step or phase in progress, the time

remaining in the step and indicates, when an additional routine has been selected (section 15 of the

programming instructions), whether the output is active. "-" indicates active "l" indicates inactive. If

"Step: 0" is displayed it means that the additional routine will operate before regeneration can

commence, similarly "Step: 6" indicates that the additional routine is continuing beyond the end of the

regeneration cycle. If required the duration and remainder of the additional routine can be displayed

briefly by pressing the INFO key (see page 6).

Service unit 1

Reg18:00 17:00

Service unit 1

Reg 72h 17:00

Service unit 1

Flush-time 20s

Regen. unit 1

Phase : 2 15 Min.-

ES 2050/51 Changing and indication of program values 5

Changing and indication

of programme values.

The most important programme values can be recalled and, changed if required, by pressing a key.

Hardness of the water supply.

Press the "Hardness" key, indicated by the symbol , to display the supply water hardness.

Should it be necessary to change the programmed value; the arrow key "8" may be used to move the

flashing cursor to the digit to be changed, and the Number key "#" to make the change.

A desired unit of hardness measurement may be selected (section 8 of the programming instructions),

the following are available :-

Hardness units Programmable range

°D

°F

°E

mg/l CaCO3

gpg

German hardness degrees

French hardness degrees

English hardness degrees

Milligrams per litre as CaCO3

Grains per gallon

2 - 99

4 - 199

2 - 99

40 - 1990

2 - 99

The controller automatically recalculates the capacity between regeneration’s using the new value, at the

initiation of the next regeneration cycle, as follows :-

If the resulting value exceeds the maximum value of the LED display (9999 m3) "maximum value

exceeded" will appear in the display.

Important Note! If a hard water blending by pass is used so that the water meter indicates the blended

water capacity, it is essential to subtract the final, blended, water hardness from the value to be inserted.

Example:

supply water hardness = 300 mg/l CaCO3, blended water hardness = 120 mg/l CaCO3

Thus a value of 180 mg/l CaCO3(300 mg/l CaCO3- 120 mg/l CaCO3) must be programmed into the

control.

Water hardness:

220mg/l

Column capacity [ grms CaCO3/m3of resin x m3of resin] =Softened Water Capacity [m3]

Supply Water Hardness [mg/l ~ CaCO3]

ES 2050/51 Changing and indication of program values 6

Current Time.

Press the "Time" key indicated by the symbol , to display the current time.

Should it be necessary to change the programmed value; the arrow key "8" may be used to move the

flashing cursor to the digit to be changed, and the Number key "#" to make the change.

Information DISPLAYS.

The "INFORMATION" key makes it possible to retrieve information, e.g. values from memory. Each time

the "INFORMATION" key indicated by the symbol , is pressed a different piece of information is

displayed :-

Flush period.

The programmed volume between successive flush signals, the volume remaining to the next flush

signal and the duration of the flush signal are displayed.

Regeneration time .

The duration of a complete regeneration cycle and the possible additional time which could be

programmed in are displayed.

Regeneration restrictions.

NoReg 16:00-18:00 if the control has been set to prohibit regeneration between certain times (section 3

of the programming instructions), this part of the display shows the time between which regeneration is

prohibited. Otherwise the display will read : NoReg---.

Current Time

Mo 16:48

Flushing

500l 350l 20s

Regen.time [min]

Σ125 rest 15

NoReg16:00-18:00

IntRg72 MinRg4

ES 2050/51 Changing and indication of program values 7

IntRg 72 if the control has been set to initiate regeneration after a programmed time interval (section 4 of

the programming instructions), this part of the display shows programmed time interval in hours.

Otherwise the display will read : IntRg -.

MinRg 4 if the control has been set to give a minimum period between successive regeneration’s

(section 5 of the programming instructions), this part of the display shows the programmed time interval

in hours.

Otherwise the display will read : MinRg -.

Additional program.

If the additional program has been selected (section 15 of the programming instructions), the selected

start time and the duration of the additional program are displayed, if "Step 0" is displayed the additional

routine will operate before regeneration can commence, similarly "Step: E" indicates that the additional

routine will continue beyond the end of the regeneration cycle. If the program is activated the display

shows how long it has left to run.

If no additional program in has been entered "No additional program" will appear in the display.

Unit capacity.

The calculated capacity between regeneration’s is displayed.

Treated water produced.

The total volume of water which has been treated by the plant.

Warning: This counter can be reset to zero by a service engineer, consult service logs for details of

the value prior to reset.

Additional progr.

Step:2 26 Min.

Unit capacity

150 m3

Treated water

45367 m3

ES 2050/51 Changing and indication of program values 8

Inputs.

Indicates the current status of each input, the inputs are :-

WM = water meter RC = regeneration chemicals WA = wait RS = regeneration start

Inputs WM, WA, and RS are shown as active when the external contacts are closed, RC is active

when the external contact is open. Active states are indicated by "1" after the input reference,

inactive by "0".

Outputs.

Indicates the current status of each output, " l " below an output number indicates an active output," - "

an inactive one.

Service - Telephone number.

To change the telephone number.

Select the digit using the "8" key, the number can then be changed by using either the "6" or "t" key.

Maintenance.

If the automatic maintenance required warning is programmed the pre set maintenance interval is

displayed on left hand side of the second line and the quantity of treated water produced since the last

maintenance visit is displayed on the right hand side of the second line.

Software version

The software is regularly updated in the factory.

Modifications are made in order to adapt the product in accordance technological changes and

customer requests. The display indicates which version of the software is loaded.

Input

WM0 RC0 WA0 RS0

Out123456789AB

|----------

Service

0031 73 443755

Maintenance

500m3 20m3

Software-version

ES2050 9606-2.20

ES 2050/51 Alarms / warnings 9

Alarms / warnings.

When the equipment is operating, various messages may appear in the display, this facility can be used

to drive relay outputs or to give alarms or warnings. The relay positions are indicated by red control

lamps bearing symbols for "Attention" for messages and "Stop" for alarms. The programming of these

functions is described in sections 5, 10,15 and 18 of the programming instructions.

Descriptive text appears in the LCD display, in addition to the fault or warning light indication.

Programmed capacity exceeded.

This message can only be displayed when controlling a duplex plant and appears if the working unit

requires regeneration whilst the off line unit is in regeneration.

Possible causes when the plant is water meter controlled:

Wrongly programmed capacity.

Wrongly programmed incoming hardness.

The water meter is faulty or of the incorrect type.

Excessive demand for water e.g.. a large tank being filled very rapidly.

Possible causes when regeneration is remotely initiated by water analysis equipment signal:

Faulty analytical equipment.

Incorrect operation of analysis unit.

Water analysis equipment too sensitive or giving spurious readings.

Inadequate regeneration of the unit leading to shortfall in capacity.

IMPORTANT! In this condition if regeneration initiation is volume dependent, i.e.. by water meter, the

on-line unit will begin to regenerate as soon as the other unit has finished it's regeneration.

If a salt saturator is being used and there is insufficient brine available for the second regeneration the

second regeneration cycle must be prevented either by switching off the control or by giving a "wait"

input. Once sufficient brine is available the second unit can be allowed to regenerate.

Press the "UNLOCK" key indicated by the symbol , in order to reset the warning or alarm relay. If the

key is pressed a second time, the LCD display will also be reset, providing that the initiation signal is

also no longer present. Then the regeneration of the second unit will not take place.

Installation

exceeded

ES 2050/51 Alarms / warnings 10

Electrical supply failure.

If there is a failure of the power supply no status information will be lost. The control panel "remembers"

the condition it was in when the supply is interrupted.

NB. The current time will be lost and must be re-entered.

IMPORTANT! If the plant is in a regeneration cycle when the power supply fails it is possible for the unit

to become partially exhausted, by the passage of water to drain, if the water supply is maintained during

the power failure.

In this situation the regeneration cycle should be terminated and a new cycle initiated first ensuring

sufficient chemicals are available.

Press the "UNLOCK" key indicated by the symbol , in order to reset the warning or alarm relay and

then reset the current time.

Refill chemical tank.

NOTE: This message can only appear only if there is a "regeneration chemicals" input connected.

Chemicals should be added to the chemical tank.

IMPORTANT! One regeneration cycle will be performed after this message appears. and regeneration

may still be initiated by pressing the "REGENERATION START" key indicated by the symbol .

Press the "UNLOCK" key indicated by the symbol , in order to reset the warning or alarm relay. The

message will then clear when regeneration chemicals are available.

With duplex plant operating in standby mode the standby unit will automatically be brought into service

even though regeneration of the exhausted column cannot take place.

Message

Supply failure

Refill

chemical tank

ES 2050/51 Alarms / warnings 11

Await regeneration.

This message appears during the regeneration cycle only if there is a "Wait" contact, for example a

water pressure switch intended to prevent regeneration when there is insufficient water pressure,

connected.

Press the "UNLOCK" key indicated by the symbol , in order to reset the warning or alarm relay. This

will abort any regeneration cycle which is in progress.

Important Note: If the manual regeneration key indicated by the symbol , is pressed the "Wait" signal

is temporarily neutralised and the regeneration cycle will take place.

The alarm and warning relays and the LCD signals are cleared, as soon as the "wait" signal is removed.

In order to prevent cancellation of the warning before the fault has been cleared it is not possible to

manually reset the message relay.

With duplex installations, operating in standby mode, the stand by unit will be brought on-line if there is a

"wait" signal when a regeneration cycle is initiated.

IMPORTANT If "EURO" is selected at step 12.4 of the programming sequence the outlet (pilot) solenoid

valves will be closed in the service condition.

IMPORTANT Any additional programme (see page 31) will be disabled.

Pre contact (regeneration pre initiation warning).

This message will only be appear, if selected (section 10 of the programming instructions).

Press the "UNLOCK" key indicated by the symbol , in order to reset the display and the alarm relay,

if programmed. If the warning relay is programmed it cannot be cancelled manually. This is to prevent

premature disconnection of, for example, water analysis equipment.

The display and the relay are automatically cancelled when the regeneration cycle is initiated.

Message

Wait

Message

Pre contact

ES 2050/51 Alarms / warnings 12

Minimum inter regeneration time limit.

This message will only appear if a minimum interval between regeneration’s has been programmed

(section 5 of the programming instructions).

Possible causes when the plant is controlled by a water meter:

Wrongly programmed capacity.

Wrongly programmed incoming water hardness.

The water meter is faulty or of the incorrect type.

Excessive demand for water e.g. a large tank being filled rapidly.

Possible causes when activated by an external water analysis equipment signal:

Poor water quality from a column which has been on standby for some time, due to the contra ion effect.

this can be overcome by fitting a flushing valve or circulation pump in the system or by reducing the

sensitivity of the analytical equipment.

IMPORTANT Regeneration is not initiated. This must be done manually, this prevents repeated

regeneration’s due to a malfunction.

Press the "UNLOCK" key indicated by the symbol ,to restore the display and reset the alarm relay, if

programmed.

Maximum programmed value exceeded.

This indicates that the result of the automatic calculation exchange capacity / hardness lies outside the

permissible range (0.1 - 9999). (Section 9 of the programming instructions)

Message: Maintenance.

This message can only appear when the facility for giving an automatic warning that maintenance is due

has been selected in section 18 of the programming sequence.

Press the "Reset" key with the symbol in order to reset the alarm relay, if programmed, and call your

maintenance company. The LCD display can only be cleared by trained personnel.

Minimum regene-

ration period

Max display

value exceeded

Maintenance

0031 73 443755

ES 2050/51 Manual regeneration initiation 13

Manual regeneration initiation.

A regeneration may be manually initiated at any time. Press the "REGENERATION INITIATION" key

indicated by the symbol , after 2 seconds regeneration of the on line unit is initiated.

With duplex installations operating in standby mode the stand by unit is brought into

service.

If manual initiation is attempted during a period in which the controller has been

programmed to prohibit regeneration (section 3.1 of the programming instructions)

the time at which regeneration will be initiated will appear with the current time in the

LCD display. In a duplex plant, operating in standby mode, the stand by unit is brought

into service.

If the prohibited time function is already activated the regeneration will initiate, i.e.

the prohibited time function will be overridden.

The counter is reset to the calculated capacity after the regeneration.

If the unit has been set to initiate a regeneration after a fixed time has elapsed,

(section 4.1 of the programming instructions) the interval timer is reset to its

programmed value and restarted.

If a minimum time between regeneration’s has been programmed (section 5.1 of the

programming instructions), the timer will be overridden and reset.

ES 2050/51 Remote control 14

Remote control.

The following functions may be remotely controlled by switch contacts connected to the terminal strip of

the controller :-

"water meter" Signal input.

"Contact head"/"reed" water meters give a pulse each time a fixed volume of water has registered e.g. of

every 100 litres. These pulses are counted by the controller and once the calculated capacity has been

supplied a regeneration is initiated.

The controller cannot accept more than 5 pulses per second.

Receipt of a water meter pulse is indicated by the "*" symbol in the second row of the LCD display.

(See page 3.)

"Chemicals low" Signal input.

This input signal can be used to monitor the chemical tank and prevent regeneration is there are

insufficient chemicals available.

The warning will not immediately prevent a regeneration, because it is assumed that there will be

sufficient chemicals present for one regeneration. By pushing the key "REGENERATION INITIATION"

indicated by the symbol , it will is possible to override the warning and initiate a regeneration.

IMPORTANT! The input signal facility does not monitor the chemical tank until 3 hours after a

regeneration has taken place, however if a regeneration is initiated during this time the chemical tank is

checked. The facility is disabled during regeneration.

"await " Signal input.

This input can be used for either of two different functions (see section 17 of the programming

sequence).

Either: Active during the regeneration

The input signal can be used to hold off or stop a regeneration cycle. The input is active only during a

regeneration cycle.

With duplex installations, when the signal is active, regeneration of an exhausted unit can not be initiated

but, if the plant is operated in standby mode, the stand by unit will be brought on line.

After the "WAIT" signal is cleared the regeneration cycle is commenced or continued.

ES 2050/51 Remote control 15

When "REGENERATION INITIATION" indicated by the symbol , is pressed, the "WAIT" signal will

be suspended for the duration of the regeneration cycle.

When using the fast program key facility, (see special functions page 16) it is possible to step

forward to the next regeneration step.

IMPORTANT If "EURO" is selected at step 12.4 of the programming sequence the outlet (pilot) solenoid

valves will be closed in the service condition.

IMPORTANT Any additional programme (see page 31) will be disabled.

Or: Active during service.

The service valves will open or close in response to the input.

APPLICATION: Treated water storage tank level control.

"start" Signal input.

This input signal can be used to initiate a regeneration of the plant by remote means, e.g. a push button,

or water monitoring equipment. When operating a duplex plant in standby mode the standby unit will be

brought on line. A start-up delay can be set at program step 18.2

If remote initiation is attempted during a period in which the controller has been programmed to prohibit

regeneration (section 3.1 of the programming instructions) the time at which regeneration will be initiated

will appear with the current time in the LCD display. In a duplex plant, operating in standby mode, the

stand by unit is brought into service. Regeneration is not initiated.

If a minimum interval between regeneration’s has been programmed (section 5 of the programming

instructions) if an attempt is made to initiate a regeneration during this interval the "minimum

regeneration time" warning will be displayed. Regeneration will not be initiated, manual initiation will be

required and the alarm must be manually reset. (see page 12.)

On a simplex plant the input is disabled during regeneration and only becomes available again once the

regeneration is complete and the time entered at program step 18.1 has elapsed.

In double filter systems the input is blocked after the start of regeneration for the time

entered at program step 18.1. Then if a start signal is present the report "system overloaded"

is shown, since evidently both filters are exhausted.

NOTE The time entered at program step 18.1 is also activated after a power loss to allow for

a measuring device to take a new measurement.

NOTE If the controller was programmed for de carbonisation (see text of program step 7),

the blockage times referred to above do not apply. Instead the time from program step 18.1

is activated as a start-up delay for the first sampling in accordance with the time from

program step 18.2. It is assumed that there is a measurement device which shows water

quality directly (pH measurement).

“duty changeover without regeneration” Signal input.

If both the "Regeneration Chemicals" and the "Wait" input are activated (36-37 open and 38-39 closed)

within a period of 1 second the plant will perform the "Duty changeover without regeneration" function.

Once the plant has changed over the contact between 36 and 37 must be restored.

IMPORTANT If this facility is used Step 16.8 and 16.12 of the program must

be set to "N".

ES 2050/51 Special functions 16

Special functions.

These functions should only be used by a trained specialist, ill considered use of these functions will

cause operating problems.

Duty changeover without regeneration.

Press the "UNLOCK" key and the "INFORMATION" key simultaneously. On a duplex plant duty

changeover takes place after 2 seconds delay.

IMPORTANT There are separate counters for each exchange column. If an almost exhausted column is

brought into service, then that unit may require regeneration whilst the other unit is in regeneration. The

"period capacity exceeded" warning will be displayed.

Regeneration of the standby unit.

Press the "TIME" key simultaneously with the "UNLOCK" key . On a duplex plant regeneration of

the stand by unit is initiated after 2 seconds delay.

Regeneration stop.

Press the "REGENERATION INITIATION" key and the "UNLOCK" key simultaneously. The

regeneration in progress will be aborted after 2 seconds and the plant will be return to the normal service

condition.

IMPORTANT Pilot stagers for manifold valves may not have an automatic "return to service" facility

when the control is returned to the service condition, this type of stager will hold the plant in regeneration

mode and will no longer be synchronised with the controller.

IMPORTANT If chemical has been drawn into the plant it will be necessary to rinse the chemicals out

before allowing the plant to supply water to service.

ES 2050/51 Special functions 17

Fast program facility.

Press the "REGENERATION INITIATION" key and the "INFORMATION" key simultaneously,

after 2 seconds delay the internal timer switches from minutes to seconds for the remainder of the

current program step, at the end of the current step the timer returns to normal, the next regeneration

step proceeds normally.

IMPORTANT When cycling through regeneration steps, sufficient time must be allowed between steps

to permit the regeneration control valve to synchronise with the controller.

IMPORTANT If chemical has been drawn into the plant it will be necessary to rinse the chemicals out

before allowing the plant to supply water to service.

Flush ON/OFF.

Press the "Unlock" key , and the "ENTER" key simultaneously.

After 2 seconds delay the flush will commence. If the flush is already in operation, using this key

combination will end the flush period.

Regeneration without counter reset.

For maintenance purposes, it is possible to initiate a regeneration which will not reset the counter or

recalculate the operating capacity.

Press the "HARDNESS" key simultaneously with "UNLOCK" key .

With simplex installations regeneration is initiated without resetting the counter and without recalculation

of the unit capacity.

With duplex installations regeneration of the stand by unit is initiated. If regeneration of the duty unit is

required first initiate duty changeover as described above (see "Duty changeover without

regeneration initiation"). The "Regeneration stop" and "Fast program" facilities are both available, in

this regeneration cycle.

IMPORTANT If chemical has been drawn into the plant it will be necessary to rinse the chemicals out

before allowing the plant to supply water to service.

This manual suits for next models

1

Table of contents

Other EWS Controllers manuals