4

INSTALLATION

Inspection And Storage:

Immediately upon receipt of shipment, inspect and

check shipping manifest and report to the Transportation

Company’s local agent any damage or shortage.

If the unit is received sometime before it can be used, it

should be inspected, recrated and stored in a dry location.

Location of Unit:

The unit should be mounted in a location where it can be

easily assessible for inspection and maintenance.

Mounting of Base:

Drill and insert six 1/2-13 x 2” (min. length) concrete

anchors into floor. Level base using leveling wedges or

shims and then securely attach base to mounting surface.

If noise level is a factor, the base plate may be filled with

grout through the access hole to reduce vibration and

noise.

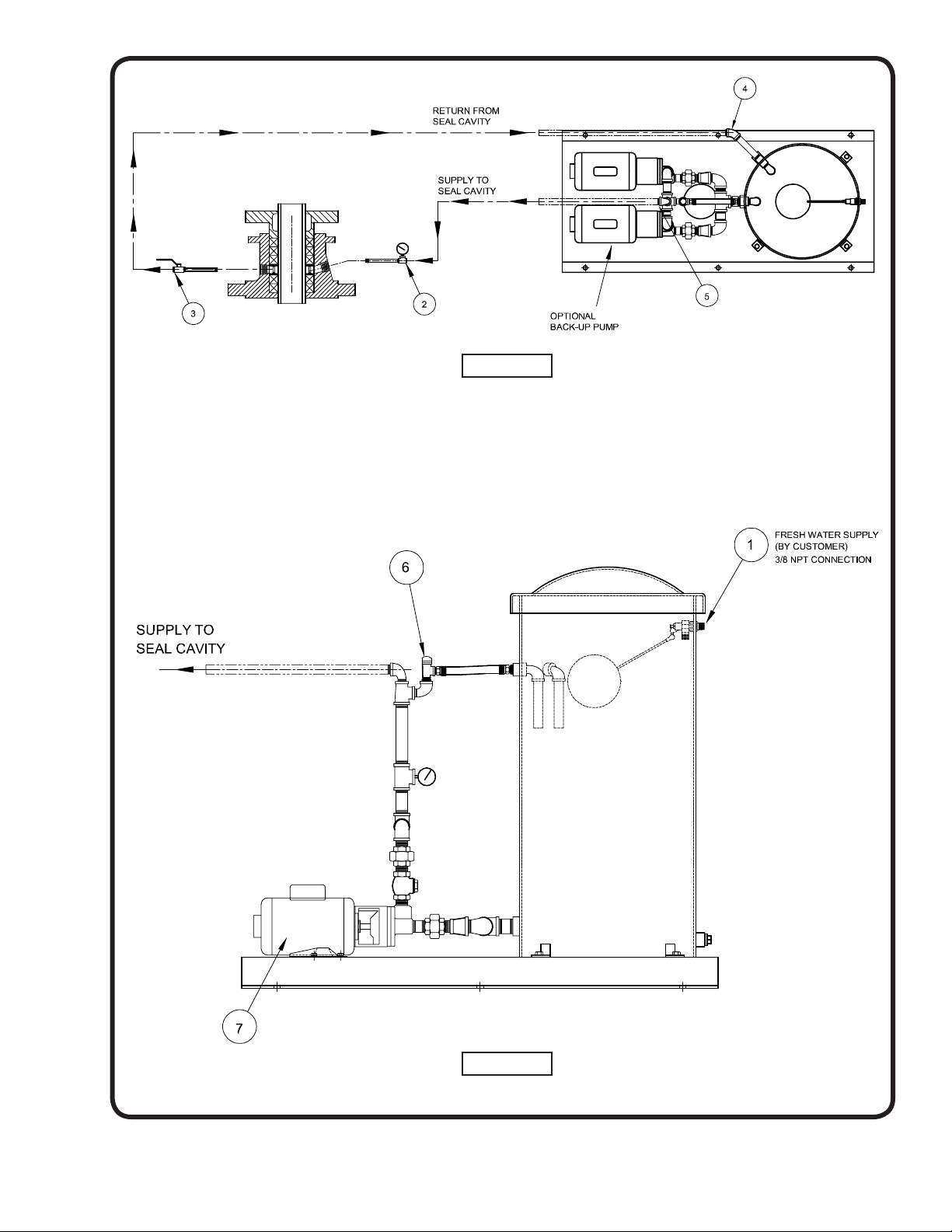

Piping:

Connect fresh water supply to the 3/8” NPT connection

of the float assembly (Figure “B” Pos. 1). Using a suitable

pipe sealer, install item (44) and item (7) pipe nipple/

pressure gauge combination (Figure “A” Pos.2) onto one

side of the packing area (seal cavity) of the dry pit pump.

Next install item (44) and item (6) pipe nipple shut off valve

combination (Figure “A” Pos. 3) on the other side. Install

piping to connect supply water (Figure “A” Pos. 5) from

the pressurized system to the seal cavity (Figure “A” Pos.

2) and return piping from seal cavity (Figure “A” Pos. 3)

to the pressurized system (Figure “A” Pos. 4). NOTE: ALL

pipe joints must be capable of containing 125 psi water

pressure without leaking.

WARNING! BURKS Turbine Pumps are of the

positive displacement type. When the pump

is operating, liquid will be delivered to the

discharge side of the pump. If the discharge

line is blocked or closed, pressure will build

up until the motor stalls, a pump part breaks

or the piping burst. To prevent the possibility

of equipment damage or personal injury, a

pressure relieving device of adequate size

must be incorporated in the discharge side of

the system.

Electrical:

Connect motor control circuit (380 volts, three phase,

50Hz.) to the electric motor junction box (Figure “B” Pos.

7).

WARNING! Failure to connect the motor frame

to the power supply equipment grounding

conductor by using the grounding cord,

green screw or green wire provided may

result in serious electrical shock. All electrical

connections are to be be made by a qualified

electrician.

All pumps with three phase motors MUST be installed

with a magnetic starter which provides 3-leg protection for

motor. Failure to use correct starter will void warranty.

Start the motor and check rotation of the shaft. Be sure

it operates in the direction indicated by the arrow on the

pump casing or frame, as serious damage can result if the

pump is operated in the wrong direction.

Adjusting Supply Pressure:

Allow fresh water supply to fill holding tank to proper

level, start pump and allow for all air to be purged out of

the system. Set the ball valve (Figure “A” Pos.3) so the

pressure gauge shows dry pit operating pressure + 10%.

NOTE: Pressure relief valve (Figure “B” Pos.6) is

factory set and must not be re-adjusted.

Operating Checks:

Open gate valve in discharge line wide open.

Check the pump and piping to assure there are no leaks.

Check and record pressure gauge reading for future

reference.

Check and record voltage, amperage per phase.

MAINTENANCE

Lubrication:

No lubrication is required for the liquid end of any BURKS

turbine pump. Motors are equipped with ball bearings

which are grease-packed and sealed at the factory. No

additional lubrication is required. Base-mounted pumps

have ball bearings in the Power Frame Assembly which

are grease-packed at the factory and have provisions for

re-lubrication as required. Use Chevron SR1 grease, or

equal. For continuous operation, lubricate annually. For

intermittent operation, lubricate every two years. DO NOT

over-lubricate.

Shaft Seal:

The mechanical shaft seal should be replaced if water is

noticed around the motor shaft. Remove case and impeller

and, using two screw drivers to pry on each side, remove

seal stationary seat. Clean seat area of frame, install new

stationary seat with ceramic surface facing out toward

impeller and slide new rotating element over shaft sleeve

with hard carbon surface against ceramic seat. Be sure to

keep all surfaces clean. Lubricating seal parts with water

will help the installation of the seal. Reinstall impeller and

pump case.

Stuffing Box:

Pumps equipped with a stuffing box depend upon a small

amount of water leakage for packing lubrication. Drain

sump below the stuffing box is provided with a 1/4” pipe

tapping for attaching a drain pipe if desired. Stuffing

box should be tightened with pump running. A finger

tight adjustment is generally sufficient. When installing

additional packing, the joints of successive packing pieces

should be staggered to give the best results.