2/17

目 錄

1、概述.......................................................................................................................... 3

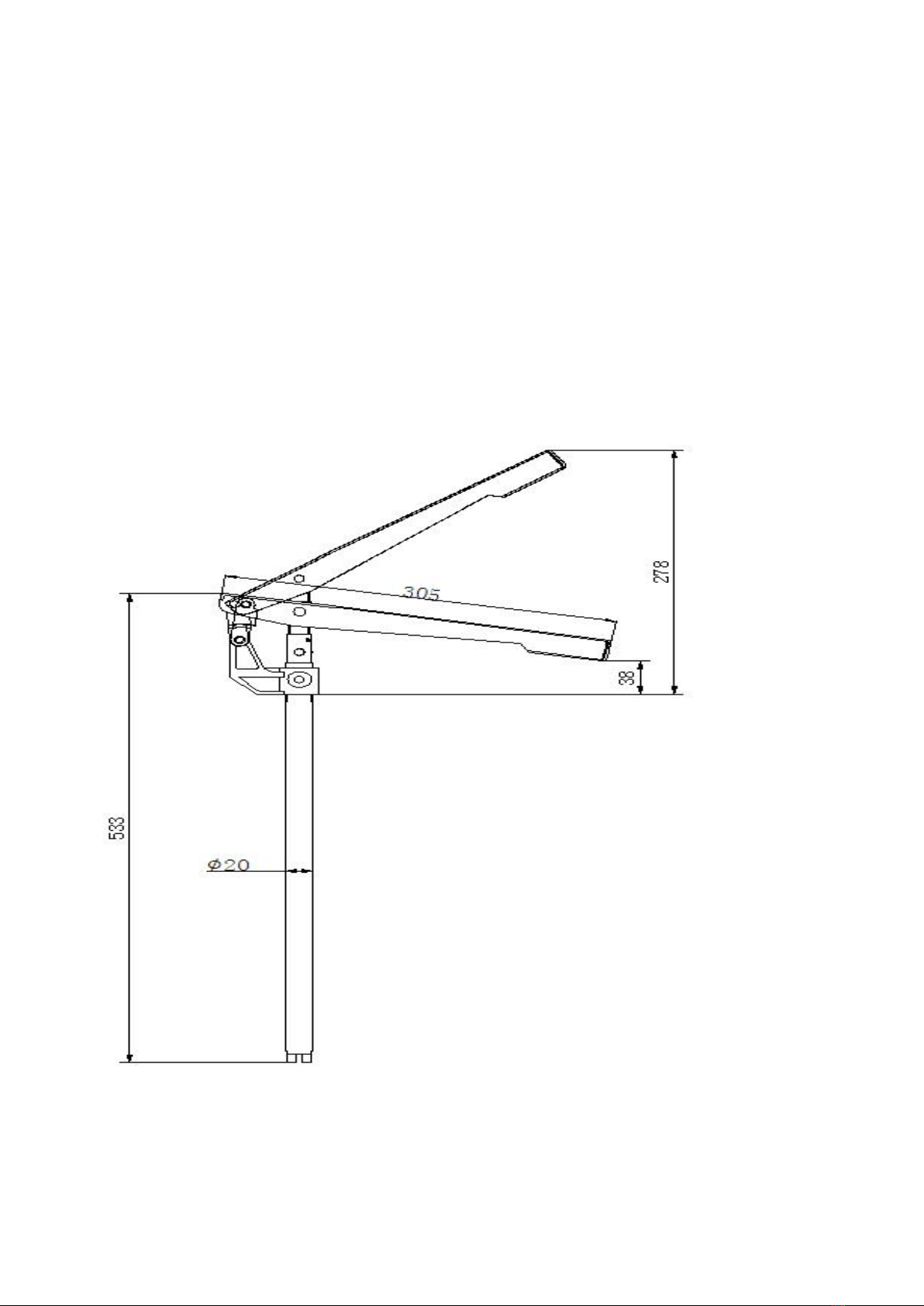

2、外形尺寸及結構部件圖......................................................................................... 3

3、規格型號及技術參數..............................................................................................5

4、使用前的準備工作..................................................................................................5

4.1 用戶按以下步驟自行裝配(如圖二).......................................................................5

4.2 快插接頭的使用......................................................................................................6

4.3 使用、操作方法......................................................................................................6

5保養與維護................................................................................................................7

5.1 油脂使用要求..........................................................................................................7

5.2 維修.......................................................................................................................... 7

6裝箱單........................................................................................................................ 8

7聯繫方式 Contact us.............................................................................................. 17