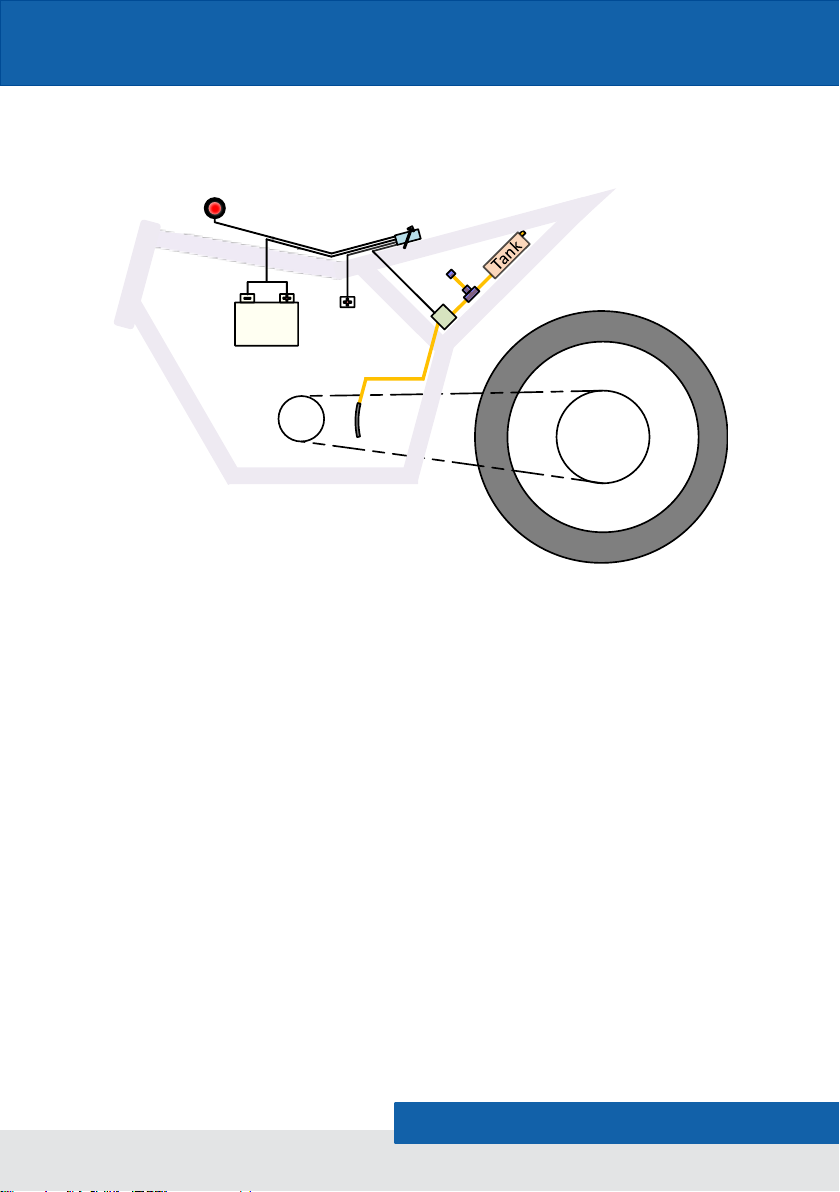

3.4 Rain

While riding inthe rain, lubricity of the chain is wearing off much faster.

By using the integrated rain-mode of the system, the oil flow can be

increased. A quick push on the button of the switch increases the oil

flow by the factor eight of the normal amount. A red LED, integrated

in the switch, indicates if the rain-mode is active. The rain-mode will

be set back to normal by either pushing the button of the switch again

or by turning of the ignition. Also in dusty or dirty environment the rain-

mode can be used to increase the oil flow.

3.5 Flushing

A mode to flush the system can be activated easily. The button of the

switch has to be pushed and held for 4 seconds. If activated, the red

LED will give feedback by flashing fast. This mode opens the

dispensing valve permanently. This can be helpful in the following

situations:

Bleeding the system (see chapter 4.6)

Re-oiling a dry chain fast

Restoring lubricity after a long ride in heavy rain or dirt

Warning: This mode leads to a very high flow of oil. The rear wheel

can be soiled with oil. This is a safety danger. Use this mode with

caution while riding.

3.6 Temperature Influence

The common use of a motorbike lies in a temperature span between

-10°C and +50°C. Beyond these temperatures man and machine

reach the limits of what is bearable.

Within this temperature span, the viscosity of oil changes bythe factor

60. To guarantee a steady oil application on the chain, the control unit

is measuring the outside temperature permanently and adjusts the oil

flow automatically.