Berthold LB 444 User manual

i

OPERATING MANUAL

DENSITY METER LB 444

Table of Contents Page

1. INTRODUCTION....................................................................................................... 1

1.1 Safety Summary .............................................................................................1

1.2 Overview.........................................................................................................2

2. SYSTEM DESCRIPTION..........................................................................................3

2.1 Use and Function............................................................................................3

2.2 The Principle of Measurement........................................................................4

2.3 Measuring Configuration.................................................................................5

2.4 Instrument Description....................................................................................7

Radioactive Source......................................................................................... 7

Shieldings ....................................................................................................... 8

2.4.1.1 Shielding Types LB744............................................................ 8

2.4.1.2 Shieldings for Installation in a Container.................................9

Detector ........................................................................................................11

Evaluation Unit LB 444 .................................................................................12

2.4.1.3 General Description...............................................................12

2.4.1.4 Display...................................................................................13

2.4.1.5 Keypad Function....................................................................13

2.4.1.6 Menu Structure (Flow Chart) ................................................. 14

2.5 Software Functions and System Configuration ............................................15

3. INSTALLATION...................................................................................................... 26

3.1 General Safety Precautions..........................................................................26

3.2 Installation.....................................................................................................27

Installation on Pipelines................................................................................27

Installation in a Container or Tank................................................................ 31

3.3 Installation of Water Cooling.........................................................................33

3.4 Installation of Resistance Thermometer Pt 100............................................35

3.5 Installation of Evaluation Unit .......................................................................35

4. CONNECTIONS...................................................................................................... 36

4.1 Detector ........................................................................................................36

4.2 Evaluation Unit LB 444 .................................................................................37

5. GETTING STARTED..............................................................................................39

5.1 Quick Installation Overview .......................................................................... 39

Getting Started........................................................................................................40

Opening the Radiation Exit Channel............................................................. 40

5.1.1.1 Shielding Container Type LB 744..........................................40

5.1.1.2 Shielding Container for Installation in a Container ................41

Density Meter LB 444 Table of Contents

ii

Calibration and Connection of Pt 100 Resistance Thermometer............................43

Basic Settings............................................................................................... 43

Calibration.....................................................................................................46

5.1.1.3 One-point Calibration.............................................................46

5.1.1.4 Two- and Multi-Point Calibration ...........................................47

5.2 Measurement................................................................................................ 49

5.3 Error Messages............................................................................................. 50

Resetting Error Messages ............................................................................50

Error Messages during Operation.................................................................50

Error Messages during Calibration...............................................................50

Error Messages during Measurement .......................................................... 51

5.4 Starting/Stopping Operation of the System ..................................................52

6. BASICS OF DENSITY MEASUREMENTS............................................................53

6.1 Temperature Compensation.........................................................................53

Temperature Measurement..........................................................................53

Monitoring the Temperature Signal ..............................................................53

Function of Temperature Compensation...................................................... 54

Calculation of the Temperature Coefficients ................................................54

Calculation of the Square Temperature Coefficient......................................56

Reference Temperature................................................................................ 57

Temperature Coefficient Calculation without Table Values..........................57

6.1.1.1 Linear temperature coefficient...............................................57

6.1.1.2 Square Temperature Coefficient ...........................................58

6.2 Calibration Method........................................................................................ 59

Calibration Modes.........................................................................................59

One-Point Calibration ...................................................................................61

Two and Multi-Point Calibration....................................................................64

Correction of Analysis Values.......................................................................65

Checking the Calibration...............................................................................67

6.2.1.1 One-Point Calibration ............................................................67

6.2.1.2 Two-Point Calibration ............................................................ 67

6.2.1.3 Multi-Point Calibration............................................................68

6.3 Interference Radiation Detection..................................................................69

6.4 Automatic Measuring Time Switchover ........................................................ 70

6.5 Measurements of Suspensions and Solutions .............................................71

Measurement................................................................................................ 71

Calculating the Density of Individual Components.......................................73

6.6 Correcting the Results: Addition and Multiplication......................................75

Additive Constant..........................................................................................75

6.6.2 Multiplication Factor.............................................................................75

7. TECHNICAL DATA ................................................................................................ 77

7.1 Evaluation Unit LB 444 .................................................................................77

7.2 Detector ........................................................................................................79

8. SERVICE INSTRUCTIONS .................................................................................... 81

9. RADIATION PROTECTION ...................................................................................82

9.1 Basics and Guidelines ..................................................................................82

Shielding Installation.....................................................................................85

Point Source Replacement...........................................................................85

9.2 Radiation Dose Calculations......................................................................... 87

9.2.1 Exposure when Installing the Shielding............................................... 88

9.2.2 Exposure when Replacing Point Sources ...........................................88

9.3 Emergency Instructions ................................................................................90

Density Meter LB 444 Table of Contents

iii

10. APPENDIX.............................................................................................................. 91

10.1 Configuration Checklist.................................................................................91

10.2 Parameter Protocol.......................................................................................92

10.3 Absorption Coefficients.................................................................................93

10.4 Temperature Coefficients .............................................................................93

10.5 Density of Water as a Function of the Temperature.....................................96

10.6 Setup Protocol .............................................................................................. 97

10.7 Wiring Diagram...........................................................................................100

10.8 Dimensional Drawings................................................................................101

10.9 Index ............................................................................................................. 105

Density Meter LB 444 List of Figures

iv

List of Figures

Page

Figure 1: Principle of measurement ....................................................................................4

Figure 2: Measuring system mounted on a straight pipeline ..............................................5

Figure 3: Installation on a U-shaped measuring path .........................................................6

Figure 4: Shielding container type LB744...........................................................................8

Figure 5: Shielding for installation in a container ................................................................9

Figure 6: Shutter switch for ex-protected area..................................................................10

Figure 7: Scintillation counter............................................................................................11

Figure 8: Front Panel LB 444............................................................................................12

Figure 9: Softkeys functions.............................................................................................. 13

Figure 10: Live display ......................................................................................................13

Figure 11: Diagram illustrating the hysteresis...................................................................19

Figure 12: Installation on a horizontal pipeline..................................................................27

Figure 13: Outdoor installation.......................................................................................... 28

Figure 14: Installation on S or U-shaped measuring path.................................................29

Figure 15: External installation with shielding and detector..............................................30

Figure 16: Installation in a container .................................................................................31

Figure 17: Installation in a container with horizontal flow..................................................32

Figure 18: Installation in a container with vertical flow......................................................32

Figure 19: Installation of water-cooling .............................................................................33

Figure 20: Required amount of water-cooling...................................................................34

Figure 21: Cable connections at detector .........................................................................36

Figure 22: Terminal connection evaluation unit (rear panel).............................................37

Figure 23: Rear view of shielding container type LB 744..................................................40

Figure 24: Locking mechanism with knurled nut...............................................................41

Figure 25: Locking mechanism with spring pin.................................................................42

Figure 26: Influence of absorption coefficients on one-point calibration...........................63

Figure 27: One-point calibration with additional calibration points....................................63

Figure 28: Example of multi-point calibration....................................................................64

Figure 29: Response.........................................................................................................70

Figure 30: Source holder...................................................................................................86

v

OPERATING MANUAL

DENSITY METER LB 444

Revision History

Revision No. Date Comments

4 3/7/99 USA Version

5 2/15/00 USA Version

Density Meter LB 444 SECTION 1. INTRODUCTION

1

1. INTRODUCTION

1.1 Safety Summary

Electrical Shock Hazard

Disconnect power during installation and before servicing.

Never change the installation or the parameter settings without a

full knowledge of the relevant part of this manual, the connected

controller and the process controlled by this measuring device.

This measuring device utilizes radioactive sources. Strict compli-

ance to the rules of Radiation Protection and regulations governing

the use of radioactive sources is mandatory.

Installation, dismantling, relocation, maintenance or testing involv-

ing the radioactive source or its shielding, may ONLY be performed

by persons specifically licensed by the US Nuclear Regulatory

Commission or an Agreement State.

GENERAL WARNINGS

SPECIFIC WARNINGS

SPECIFIC CAUTIONS

Density Meter LB 444 SECTION 1. INTRODUCTION

2

1.2 Overview

The Density Meter LB 444 is designed for density measurements of liquids, sus-

pensions, pulps and bulk materials. The measurement may be made directly in-

line or in a product container or tank.

The density measuring system LB 444 utilizes the radiometric measurement

method, i.e. the attenuation of Gamma radiation passing through the product

being measured.

In order to obtain the optimum measurement effect at a minimum source activity,

the measurement geometry is optimized for the specific measuring location and

the source is designed accordingly. The installation details and the source and

detector design are specified when preparing the quotation, and documented by

drawings, sketches and descriptions. To ensure the proper function of the

measurement, it is therefore important to observe these documents closely

when installing the shielding with the source and positioning the detectors.

Radiometric measuring systems utilize radioactive substances which are

manufactured in compliance with regulations and which are protected by suit-

able shieldings. When handled properly, no hazard to persons due to normal

operation of the device exists.

The hardware and software of the LB 444 system makes it easy to adapt the

system to a variety of measurement geometries and measuring tasks. There-

fore, the settings and parameters of the measuring instrument must be defined

with care for each specific measuring task when commissioning the system. Im-

portant parameters may not easily be changed once the system is operational.

The system should commissioned and set-up only by persons who are familiar

with the instrument. Therefore, all users should read these operating instructions

carefully. In addition, we recommend documenting all settings in a setup proto-

col (see Appendix).

This instruction manual describes several measuring configurations and instru-

ment versions. The optimum system configuration is selected for each measur-

ing task during the planning stage. Therefore, the specific project documentation

must be used to configure the system.

Before starting any work, please read this operating manual carefully!

Density Meter LB 444 SECTION 2. SYSTEM DESCRIPTION

3

2. SYSTEM DESCRIPTION

2.1 Use and Function

The radiometric density measuring system can be used to measure the density

of

•liquids

•suspensions

•pulps and

•bulk goods.

The measurement can made directly in-line or in a tank or container. Pressure

and viscosity fluctuations or the flow rate of the product does not affect meas-

urement accuracy.

Special instrument configurations and calculations allow the measuring system

to be tailored to the local needs and conditions of the product being measured:

a) Instrument configuration (Operating modes)

•Density measurement without temperature compensation (TC)

•Density measurement with temperature compensation via Pt 100

•Density measurement with temperature compensation via current input

•Suspension measurement with any carrier liquid

Solids density and liquid density are known

With or without TC

•Suspension measurement with water as carrier liquid

- Solids density is known

- with water temperature compensation

♦the density of the water and

♦the solids concentration

are used for temperature compensation

•Mass flow measurement without TC

•Mass flow measurement with TC via Pt 100

b) Special configuration

•Back-scatter measurement

c) Selection of measurement mode

•Continuous measurement

•Discontinuous measurement

- Batch operation via keyboard (press <run> button)

- Batch operation via digital input

Density Meter LB 444 SECTION 2. SYSTEM DESCRIPTION

4

2.2 The Principle of Measurement

The density measurement is based on the irradiation method. It utilizes the

physical law of the attenuation of gamma radiation passing through the product

being measured. The resulting measurement effect is the ratio I/I0between the

un-attenuated radiation I0and the radiation I which is attenuated by the product

being measured. The remaining radiation picked up by the detector (scintillation

counter) represents the density of the product being measured. Figure 1 illus-

trates the principle of measurement. The radiation is attenuated according to the

following formula:

I = I0 * e - µ' * ρ* d

I = Radiation picked up by the detector

I0= Un-attenuated radiation

µ= Mass attenuation coefficient (absorption coefficient) in cm2/g

ρ= Density of the absorbing material in g/cm3

d = Thickness of the absorbing material in cm

Source Detector

ρ

ρρ

ρI

d

I0

Figure 1: Principle of measurement

The intensity of the radiation picked up by the detector is also dependent on the

distance between source and detector. As in the case of light, the function in-

volved is a square function, i.e. doubling the distance reduces the radiation in-

tensity to ¼ if all other conditions remain the same.

Assuming a constant distance between source and detector and a fixed meas-

uring path, the radiation picked up by the detector is only dependent on the den-

sity of the material to be measured.

NO contamination of the product being measured or of the pipeline wall by

gamma radiation is possible. (Physics).

Density Meter LB 444 SECTION 2. SYSTEM DESCRIPTION

5

2.3 Measuring Configuration

To cover a desired measurement range continuously, a configuration must be

realized where the dimensions of source and detector cover a measuring field of

equal size. The different options available to accomplish this are described be-

low.

The specific arrangement chosen depends on the measurement range and on

the geometry resulting from the measuring task. Moreover, construction factors

and customer-specific requirements may have an effect on the instrument se-

lection. The specific choices and selections are made during the planning stage

and must be implemented during assembly and commissioning.

A measuring system for density, concentration and mass flow measurements

typically comprises the following components:

a) Radioactive source

b) Shielding container

c) Detector

d) Evaluation unit LB 444

e) Mounting device

f) Connection cable

g) Resistance thermometer Pt 100 (option)

h) Cooling jacket for detector (option)

Detector power and output signals use a common two-wire cable connected

between detector and evaluation unit.

Different configurations and mounting devices may be required, depending on

the measurement tasks, the condition of the product being measured and the

pipe or container.

“Fehler! Verweisquelle konnte nicht gefunden werden.Shows a basic setup

in a pipeline with Pt-100 resistance-thermometer and a 90°-mounting device for

density, concentration and mass-flow measurement.

Figure 2: Measuring system mounted on a straight pipeline

enter

clear run

BERTHOLD

Shielding

Container

Pipeline

Evaluation unit

Detector

Pt 100

Density Meter LB 444 SECTION 2. SYSTEM DESCRIPTION

6

45° and 30° mounting devices are available to extend the measuring path (see

enclosed Technical Information LB 444).

The detector-source arrangement may vary depending on the measuring path. If

measuring paths have the shape of a U or S the shielding must be installed at

the top, the detector at the bottom, as shown in Figure 3.

RADIOACTIVE

Figure 3: Installation on a U-shaped measuring path

The system may have to be installed on external supports when the heat insu-

lating material of the pipeline does not allow safe installation (e.g. glass and rock

wool) or when strong vibrations are likely to damage the detector. For further

explanation see section 3. INSTALLATION.

For all installations, precautions must be taken to prevent persons reach-

ing into the active beam.

Measurements in Containers

Density or concentration measurements can also be carried out in a tank or

container and for this purpose, the source in a shielding is installed into a pro-

tection pipe inside the container (see 0 Installation in a Container).

Density Meter LB 444 SECTION 2. SYSTEM DESCRIPTION

7

2.4 Instrument Description

Radioactive Source

Radioactive sources for industrial applications are always „encapsulated radio-

active substances“ which are tightly welded into a sturdy stainless steel capsule,

so that the radioactive substance cannot leak out. Contamination is therefore not

possible. Moreover activation of the product being measured by the source used

is also not possible. (Laws of Physics).

The following point-shaped Gamma sources can be used for these measuring

configurations. 241Am, 60Co, 137Cs, 244Cm, 85Kr, 90Sr.

The following isotopes are primarily used for density measurements:

a) 60Co has a relatively high energy of 1.17 and 1.33 MeV, respectively. It is

used for density measurements when measuring distances are very long

and/or the radiation has to pass through very thick pipe or vessel walls. Its

half-life period is 5.27 years.

b) 137Cs is the isotope most frequently used for density measurements. Its

energy of 0.660 MeV is sufficient to penetrate commonly used pipe and

container walls. Due to the lower energy, the measuring effect is better

than with Co-60. Also, the shielding costs for a Cs-137 source are lower

than for a Co-60 source. The half-life period of Cs-137 is approx. 30

years.*

*According to NBS, half-life is defined as “Time for the activity of any particular

radioisotope to be reduced to half its initial value”.

Please note the Radiation Protection Guidelines in Section 9.

Density Meter LB 444 SECTION 2. SYSTEM DESCRIPTION

8

Shieldings Except for a few special cases, the source is firmly installed into the working

shielding which includes a radiation exit channel to release the active beam to-

wards the detector. The active beam can be shielded during transport and in-

stallation, and when performing service work. This is accomplished by a shutter

mechanism.

The operation of the shutter mechanism and shielding function must be checked

every six months!

2.4.1.1 Shielding Types LB744

Shieldings with manually operated lock

The shielding consists of a cast iron or stainless steel outer shell filled with lead,

except for an exit port blocked by a lead filled moveable shutter. The shutter

mechanism consists of a rotatable lead filled cup connected to the outside of the

housing by means of a shaft, secured to a handle. The lead filling of the cup has

a cylindrical hole. At one distinct and defined position of the handle, the hole and

source holder is aligned, allowing the radioactive beam to reach outside via a

steel cover plate.

This is the “on” position of the device. At all other shaft positions, the beam exit

is blocked by the lead in the cup. The handle, which indicates the open or closed

condition of the shutter, can be secured in the closed position. The handle in

both the open and closed positions prevents access to the source holder.

Cover plate Moveable shutter Shell Lock

Pb

Radiation Position Radiation Source Locking

exit channel "closed" source holder lever

Figure 4: Shielding container type LB744

Density Meter LB 444 SECTION 2. SYSTEM DESCRIPTION

9

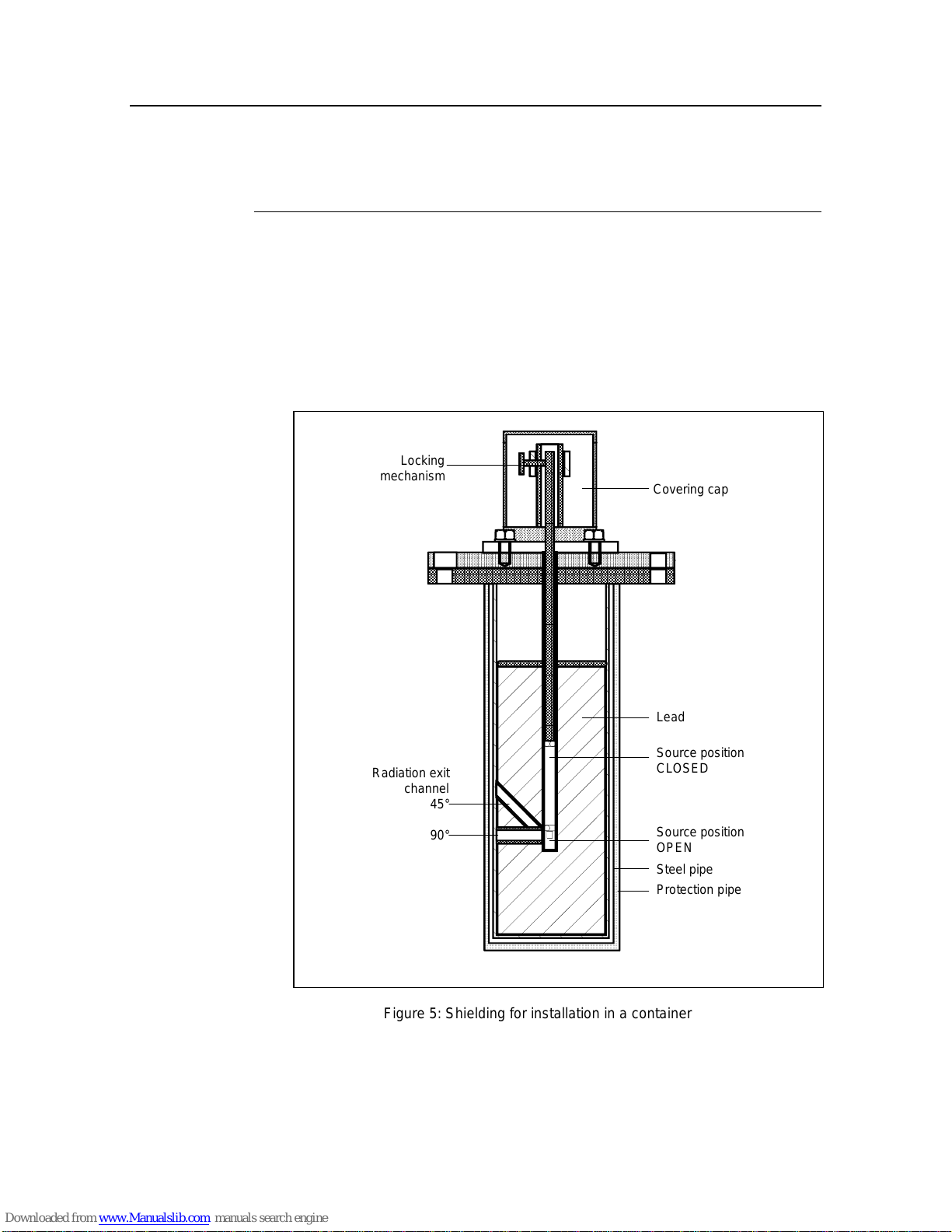

2.4.1.2 Shieldings for Installation in a Container

Shieldings with manually operated lock

The shielding consists of a lead-filled steel pipe, with a guide tube for the radio-

active source installed in the center. The radiation exit channel is located in an

angle of 90° or 45° to the longitudinal axis.

After taking off the covering cap which is secured by a lock you may open the

knurled screw and, using the stay bar, move the radioactive source forward

(OPEN) or back (CLOSED).

Locking

mechanism Covering cap

Lead

Source position

CLOSED

Steel pipe

Protection pipe

Source position

OPEN

Radiation exit

channel

45°

90°

Figure 5: Shielding for installation in a container

Density Meter LB 444 SECTION 2. SYSTEM DESCRIPTION

10

Shutter switches signal the position of the sources.

Two versions are available:

a) Version for use in areas not endangered of explosion:

2 Reed contacts max. 250 V, 40 VA

1 x for OPEN, 1 x for CLOSED.

b) Version for use in the areas endangered of explosion:

1 proximity switch for position CLOSED.

It has to be connected to an inherently safe power supply.

Closed

Open

Switch flag

Cover cap

Connection for

pressurized air electr. signal

OPEN/CLOSED

Proximity

switch

Figure 6: Shutter switch for ex-protected area

See the drawings that are part of the documentation for detailed information on

the construction and function of the shielding type used.

Density Meter LB 444 SECTION 2. SYSTEM DESCRIPTION

11

Detector

Scintillation counters are used as detectors, since only these detector systems

provide the required high sensitivity to Gamma radiation and the radiation field

does not limit their service life.

The detector comprises

•a sodium iodide crystal doped with Thallium

•a photomultiplier

•an electronics unit.

The built-in microprocessor tracks the configuration, counts the pulse rates,

controls the high voltage, measures the temperature of the probe and an exter-

nal Pt 100, transfers data and performs calibration and control functions.

+

−

AMPLIFIERRADIATION

LIGHT FLASH

SCINTILLATOR DYNODES

PHOTO CATHODE

.

.

.

Figure 7: Scintillation counter

The scintillator converts the incidence of Gamma into light flashes.

The flashes of light are converted into electrical signals in a photomultiplier,

which is optically coupled, to the detector. To achieve a very high accuracy and

a high long-term stability, the integrated processor automatically adjusts the op-

timum operating point of the photomultiplier, monitors the limit values, and

stores all detector-specific data. Power is supplied via 2-wire technique; all

measured data and information is transmitted between detector and the evalua-

tion unit at the same time.

The detector probe is mounted in a sturdy stainless steel housing which pro-

tects the instrument against normal environmental stress.

To ensure reliable operation and a long service life, the detector probe

must not be subject to heavy mechanical stress or vibrations.

Cooling must be provided for ambient temperatures above 50°C. (see sec-

tion 3.3 Installation of Water Cooling).

For more information see: Technical Information LB 444.

Density Meter LB 444 SECTION 2. SYSTEM DESCRIPTION

12

Evaluation Unit LB 444

2.4.1.3 General Description

The evaluation electronics is designed as a 19" module in the format 3 HE, 21

TE. It includes the microprocessor-controlled evaluation electronics and the

power supply. A 32-bit microprocessor with menu-structured software specially

designed for density measurements is used for signal processing.

The six foil keys on the front panel are used to operate the instrument.

•Three keys work as soft-keys which allow user-guided definition of all in-

strument settings and input of the required parameters.

•Three more keys serve as function keys.

The illuminated display field on the front panel shows the relevant instrument

function on four lines. The front panel also includes an RS 232 interface.

enter

clear run

LCD display

BERTHOLD

Softkeys

Funktion keys

..

..

..

..

..

..

EG&G Berthold

LB 444 V 1.00

Density - Meter

more

Figure 8: Front Panel LB 444

The terminal strip on the instrument rear panel includes all terminals for power

for the detector and for the analog and digital output signals. The current output

is isolated and the built-in relays for max.-min.-indication and for error messages

include an isolated contact.

The system automatically corrects for the decrease of source activity with age.

System malfunctions are signaled by error messages.

The calibration data is stored in a FLASH memory and saved during loss of

power.

Density Meter LB 444 SECTION 2. SYSTEM DESCRIPTION

13

2.4.1.4 Display

The illuminated display field of the instrument comprises 4 lines; the first three

lines show the menu titles, the currently selected parameters or the current

measurement value. The bottom line shows the current function of the softkey

button located below or, when a measurement is running, the status “run“.

2.4.1.5 Keypad Function

The Density Meter is operated via the softkeys and function keys de-

scribed below; which select the desired operating level within a menu

structure in order to select a function or enter parameters. The menu

guidance is illustrated in the quick overview of the menu structure

(see next page) and from tables (see Appendix).

Softkeys

Softkeys are used to select different menu groups and operating lev-

els within the menu structure. Depending on the current position in

the menu structure, functions are assigned to these keys, as shown

on the display above the respective key.

<sk1>and

<sk2> switch to the indicated menu (Figure 9 a).

<more> switch to the next menu group.

<done> shows the end of the menu and takes you back to the

menu group.

<^^^> text: scrolls through the various selection options (Figure

9 b)

numerical values: increments the number marked by the

cursor by 1.

<!!!

!!!!!!

!!!> moves the cursor to the left and at the end of the input

field again to the start position (Figure 9 c).

<+> and

<-> scrolls forward / back in the submenus (Figure 9 d).

Figure 9: Softkeys functions

Function Keys

<enter> accepts the entry and moves the cursor to the next input

field or toggles between two input fields.

<clear> clears the numerical value.

Figure 10: Live display

sk1: general

sk2: operating

sk1 sk2 more

a)

Product select

[extern/intern]

^^^ done

intern

b)

time constant

more

value: 20.000

←

←←

←←

←←

←←

←←

←

∧∧∧

∧∧∧∧∧∧

∧∧∧

c)

HV (500): 112 cps

+ - exit

HV (560): 116 cps

HV (620): 122 cps

d)

LB 444

Density = 1.5g/cm³

+ - RUN more

<run> starts or ends a measurement or leads directly back to

the display and at the start of a measurement automati-

cally changes to the measurement value display.

Density Meter LB 444 SECTION 2. SYSTEM DESCRIPTION

14

2.4.1.6 Menu Structure (Flow Chart)

The flow chart below shows in a simplified way the menu structure for parameter

input and operation. With <more> you select the various menu groups and from

there you get to the respective menu with <sk1> or <sk2>. Within the menu you

get to the individual windows with <more> and at the end of the menu you get

back to the menu group with <done>. For a complete overview of the menu

structure see the appendix to this manual.

↓

↓

↓

Parameter

Isotope

Time Constant

Rapid Switch-Over

Rad. Interference

Maximum Rate

Minimum Rate

Product Data

Product Selection

Curr. output Limits

Current outp. error

Relay 2 + 3 Setup

Solids density

↓↓

sk2

sk1 more

Productselect

↓sk2

sk1 more

Service menu ↓

Pt100 Adj./Plateau

Test calculation

HV Setting/Status

Adj. Current Out

↓↓

↓

sk2

Calibrate

Countrate

Massflow display

Density display

Integr. M.

Flow

sk1 more

Product Selection

Calculate

Cal. Mode

Resuls

Data Input

↓↓

Oper. Mode

Mass flow

Config Instrument

Density / TC

Password

Date & Time

System/ Version

Language

General Data

sk2sk1 more

Error Mode

Print Parameter

Factory Setting

Rad./Backscatter

Interfaces

Liquid density

HV Detector

Live Display

Unit

Range Input

Flow

Counter Interval

Massflow

Density Meter LB 444 SECTION 2. SYSTEM DESCRIPTION

15

2.5 Software Functions and System Configuration

The factory settings are listed in the Configuration Checklist in the Appendix.

Enter the final operating settings in this list. Please remember that the entry in all

operating levels is made with the <^^^> key and the new value is accepted with

<enter>.

General Data

Password: One may enter a number comprising up to 6 digits. Upon confirmation with <en-

ter>, the system is protected against unauthorized manipulation of the parame-

ters. All parameters can still be viewed, however. The password protection is

canceled when you enter the correct numerical value and confirm your entry

with <enter>.

Date: Enter the current date in the format TT.MM.YY. The correct date is important for

automatic correction of the activity decay of the source.

Time: Enter the current time in the format HH.MM. Time deviations have hardly any

effect on the correction of the activity decay; checking the time can help to check

the instrument function.

System/Version:

Display of instrument type and software program version.

Language: You can choose German, English or French as dialog language by pressing the

<^^^> key.

Print Parameter:

A printer with serial interface can be connected on the front panel. All parame-

ters can be printed for documentation. The printout in the appendix shows an

example. A PC may also be connected and the data transferred to the computer

and processed there using a terminal program.

Factory Setting:

All parameters can be reset to the factory setting with <sk1>. However, a meas-

urement with this data only is not possible.

The current calibration data is lost when the instrument is reset!

Table of contents

Other Berthold Measuring Instrument manuals

Berthold

Berthold BTwave LB 571-02 User manual

Berthold

Berthold Duo Xpert LB 478 MPLM User manual

Berthold

Berthold DUO XPERT LB 470RID User manual

Berthold

Berthold InlineSENS Duo Series User manual

Berthold

Berthold DuoXpert LB 476 Level+ User manual

Berthold

Berthold MicroPolar LB 566 User manual

Berthold

Berthold LB 134 User manual

Berthold

Berthold LB 444 K-40 User manual

Berthold

Berthold Uni-Probe LB 491 User manual

Berthold

Berthold castxpert LB 452 User manual