Berthold Uni-Probe LB 491 User manual

JO

7LPH

User’s Manual

ID-No. 38478BA2B

Rev.-No.: 01 27.5.08

Embedded Soft. Rev. 100

Device Description Rev. 03/04 HART

Device Description Rev. 01 PA

Device Description Rev. 01 FF

Process Control detect and identify

Density Measurement

Uni-Probe LB 491

With All Supplements

38478BA2B

1 – 4 27.5.08

Volume 1-7

General Information

Dear customers Thank you very much for purchasing the density measuring system

Uni-Probe LB 491 made by Berthold Technologies GmbH & Co. KG.

The scope of supply also includes this User’s Manual. Be sure to

have this User’s Manual always to hand.

Please read the User’s Manual prior to installation to get acquainted

with the product.

To avoid physical injury and property damage, please observe the

warnings and safety instructions provided in this User’s Manual.

They are identified as follows: DANGER, WARNING, CAUTION or

NOTICE. In Volume 2, "Safety Manuals", you find a summary of all

safety hazards and information how to deal with them.

Indicates an imminently dangerous condition. Failure to fol-

low the instructions will lead to death or serious injury.

Indicates a potentially dangerous condition. Failure to follow the

instructions may lead to death or serious injury.

Indicates a potentially dangerous condition. Failure to follow the

instructions may lead to a slight injury or a medium-degree injury.

Indicates a situation which may cause property damage if the

instructions are not followed.

IMPORTANT

Paragraphs with this symbol provide important information on the

product or how to work with the product.

Tip

Includes application tips and other useful information.

Uni-Probe LB 491

Berthold Technologies GmbH & Co. KG 1 – 5

Volume 1-7

Typographical Conventions

The symbols and typefaces used in this User’s Manual have the

following meaning:

If you do encounter problems despite careful study of the User’s

Manual, please do not hesitate to contact us.

Your Uni-Probe LB 491 team

prompts you to carry out an action.

1, 2, 3, … identifies items in a graphic.

• identifies enumerations.

italic typeface highlights important information.

SMALL CAPS indicate commands or menu items.

38478BA2B

1 – 6 27.5.08

Volume 1-7

Uni-Probe LB 491

Berthold Technologies GmbH & Co. KG 7

Volume 1-7 Table of Contents

Volume 1 Uni-Probe Installation

1General Information.......................................................... 1 – 21

1.1 General Safety Precautions ....................................... 1 – 21

1.2 Use and Function...................................................... 1 – 21

1.3 Specific Warnings .....................................................1 – 22

1.4 Radiation Protection Guidelines ................................ 1 – 23

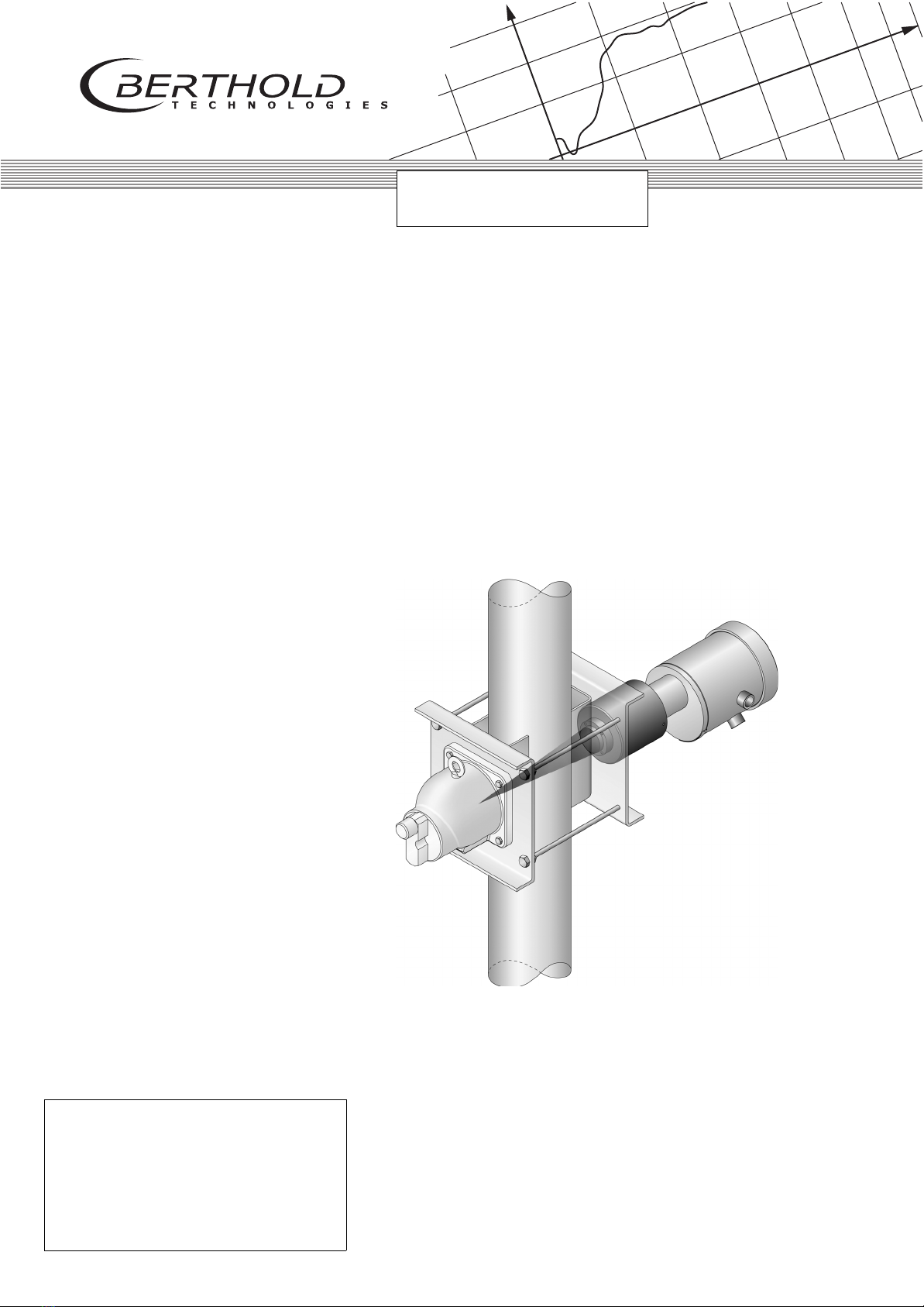

2System Description............................................................ 1 – 25

2.1 Measuring System .................................................... 1 – 25

2.2 Uni-Probe Hardware ................................................. 1 – 27

2.3 Measuring Principle .................................................. 1 – 30

2.4 Basic Measuring Configuration ................................. 1 – 31

2.5 Technical Data .......................................................... 1 – 32

2.6 Detector Code ..........................................................1 – 35

2.7 Uni-Probe LB 491 Nomenclature ............................... 1 – 35

2.8 LB Numerical Code ................................................... 1 – 36

3Installation ........................................................................1 – 37

3.1 Transport to the Installation Site................................1 – 39

3.2 Radioactive Sources .................................................. 1 – 41

3.3 Installation on Pipelines ............................................ 1 – 46

3.4 Installation in a Container .........................................1 – 49

3.5 Detector Protection................................................... 1 – 51

3.6 Installation of Pt100 ................................................. 1 – 53

4Electrical Installation.......................................................... 1 – 55

4.1 Conduits ..................................................................1 – 56

4.2 Terminals .................................................................. 1 – 59

4.3 Switch Setting .......................................................... 1 – 61

4.4 Connecting the Uni-Probe .......................................1 – 63

4.5 Uni-Probe with Ex i Current Output .......................... 1 – 65

4.6 Uni-Probe with Signal Output Profibus PA /

FOUNDATION™Fieldbus (not intrinsically safe)..........1 – 76

4.7 Uni-Probe with Intrinsically Safe Signal Output

Profibus PA / FOUNDATION™Fieldbus.......................1 – 79

5Repair, Maintenance and Service ....................................... 1 – 83

5.1 General Safety Precautions ....................................... 1 – 83

5.2 Visual Inspection of the Uni-Probe ............................ 1 – 85

5.3 Checking the Connection Box ..................................1 – 86

38478BA2B

827.5.08

Table of Contents Volume 1-7

5.4 Trouble Shooting ...................................................... 1 – 87

5.5 Replacing the Complete Uni-Probe .......................... 1 – 89

5.6 Replacing the Electronics Module ............................. 1 – 90

5.7 Replacing the Crystal-Multiplier Assembly................. 1 – 93

5.8 Replacing the Digital Board....................................... 1 – 94

5.9 Replacing the Power Supply Unit .............................. 1 – 96

5.10 Replacing Fuses ........................................................ 1 – 97

5.11 Updating the Embedded Software in the Uni-Probe.. 1 – 98

5.12 Scintillation Detector .............................................. 1 – 103

5.13 Customer Service.................................................... 1 – 106

5.14 Returning Repairs ................................................... 1 – 107

6Certificates ..................................................................... 1 – 109

6.1 ATEX Certificate ..................................................... 1 – 109

6.2 FM Certificate......................................................... 1 – 121

6.3 CSA Certificate....................................................... 1 – 122

6.4 EG Declaration of Conformity................................. 1 – 124

7Screw Fittings and Accessories ........................................ 1 – 125

7.1 ATEX Cable Screw Fittings ...................................... 1 – 125

7.2 ATEX-Adapter (Ex d IIC) for Screwed Cable Glands . 1 – 127

7.3 Dummy Plug........................................................... 1 – 127

7.4 Material Safety Data Sheet for Lubricant OKS 217 .. 1 – 128

8Technical Drawings ......................................................... 1 – 131

8.1 Point Detector with Frontal Irradiation .................... 1 – 131

8.2 Point Detector with Lateral Irradiation..................... 1 – 132

8.3 Point Detector Mounting Clamps............................ 1 – 133

8.4 Sunscreen............................................................... 1 – 133

8.5 Point Detector Installation on a Container............... 1 – 134

8.6 Holder Mounted on Uni-Probe................................ 1 – 134

8.7 Instructions for Installation of the Water Cooling .... 1 – 135

8.8 Required Amount of Cooling Water for Point

Detector ................................................................. 1 – 135

8.9 Point Source Shielding LB 744X .............................. 1 – 136

Uni-Probe LB 491

Berthold Technologies GmbH & Co. KG 9

Volume 1-7 Table of Contents

Volume 2 Safety Manuals

1Safety Instructions...........................................................2 – 153

2Transport and Assembly ..................................................2 – 157

3Radiation Protection........................................................ 2 – 159

3.1 General Information and Guidelines ....................... 2 – 159

3.2 Mounting the Shielding .......................................... 2 – 161

3.3 Safety Measures .....................................................2 – 164

3.4 Protection against Theft.......................................... 2 – 164

3.5 Accidents, Loss, Damage, Fire, Theft ....................... 2 – 165

3.6 Shielding and Source .............................................. 2 – 167

3.7 Leak Test ................................................................ 2 – 169

4Source Replacement ....................................................... 2 – 171

4.1 Point Source Replacement ...................................... 2 – 171

4.2 Radiation Exposure during Source Replacement ......2 – 174

5Source Disposal............................................................... 2 – 175

6Safety Instructions for the Types of Protection

ATEX / FM / CSA .............................................................2 – 179

6.1 Overview Ex-Versions.............................................. 2 – 181

6.2 Type of Protection ATEX.......................................... 2 – 182

6.3 Type of Protection FM/CSA .....................................2 – 183

38478BA2B

10 27.5.08

Table of Contents Volume 1-7

Volume 3 HART®Communicator User Interface

1General Information on the HART®Communicator......... 3 – 189

1.1 Connection, Power On and Power Off of the

HART®Communicator ........................................... 3 – 189

1.2 Working with the HART®Communicator ............... 3 – 190

2Menu Structure............................................................... 3 – 191

2.1 Information on the Menu Structure ........................ 3 – 191

2.2 Menu Overview ...................................................... 3 – 192

2.3 Start Menu ............................................................. 3 – 194

2.4 LIVE DISPLAY .......................................................... 3 – 195

2.5 PROBE RAW DATA.................................................. 3 – 196

2.6 VIEW PARAMETERS ................................................ 3 – 196

2.7 PROCESS VARIABLES .............................................. 3 – 197

2.8 SHOW CAL. DATA .................................................. 3 – 198

2.9 STATUS / ERROR LOG ............................................. 3 – 199

2.10 SHOW ERROR LOG................................................. 3 – 200

2.11 REVIEW .................................................................. 3 – 201

2.12 ACCESS TO SETUP.................................................. 3 – 203

2.13 ENTER PASSWORD ................................................. 3 – 204

2.14 SETUP..................................................................... 3 – 205

2.15 CONFIGURATION.................................................... 3 – 205

2.16 GENERAL DATA ...................................................... 3 – 206

2.17 SYSTEM PARAMETER.............................................. 3 – 207

2.18 MEASURE PARAMETER........................................... 3 – 208

2.19 DAMPING DATA ..................................................... 3 – 209

2.20 RAD. INTERFERENCE............................................... 3 – 211

2.21 PULSE RATE LIMITS ................................................. 3 – 212

2.22 TEMP. COMPENSATION .......................................... 3 – 213

2.23 SUSPENSION MEAS. ............................................... 3 – 213

2.24 CALIBRATION I/O.................................................... 3 – 214

2.25 CALIBRATION ......................................................... 3 – 214

2.26 CAL. DATA ............................................................. 3 – 215

2.27 ENTER CAL. DATA .................................................. 3 – 216

2.28 ADJUST CURVE ...................................................... 3 – 217

2.29 SAVE & LOAD CURVE............................................. 3 – 218

2.30 INPUT / OUTPUT ..................................................... 3 – 218

2.31 CURRENT I/O .......................................................... 3 – 218

2.32 COUT1 (PV)............................................................ 3 – 219

Uni-Probe LB 491

Berthold Technologies GmbH & Co. KG 11

Volume 1-7 Table of Contents

2.33 CIN1 (TEMP) ...........................................................3 – 220

2.34 DIGITAL OUT CONFIG............................................. 3 – 221

2.35 DIGITAL INPUTS ......................................................3 – 222

2.36 SERVICE ................................................................. 3 – 222

2.37 TEST CALCULATION................................................3 – 223

2.38 I/O Test ................................................................... 3 – 224

2.39 STATUS DIG. INPUT.................................................3 – 224

2.40 DIG. OUTPUT TEST ................................................. 3 – 224

2.41 CURRENT I/O TEST..................................................3 – 225

2.42 ANALOG OUTPUT 1 ............................................... 3 – 225

2.43 ANALOG INPUT 1/2 ................................................ 3 – 226

2.44 ADJUST Pt100 ........................................................ 3 – 226

2.45 PROBE SETTINGS ....................................................3 – 226

2.46 HV SETTINGS.......................................................... 3 – 227

2.47 PLATEAU ................................................................ 3 – 228

2.48 HART®INTERFACE..................................................3 – 229

3Getting Started via the HART®Communicator ................ 3 – 231

3.1 Steps for Getting Started ........................................ 3 – 231

3.2 Setup Protocol ........................................................ 3 – 232

3.3 Calibration Values................................................... 3 – 234

4Calibration...................................................................... 3 – 235

4.1 Preparing Calibration .............................................. 3 – 235

4.2 Measure Background.............................................. 3 – 242

4.3 Operation Modes for Calibration ............................3 – 245

4.4 Two- and Multi-Point Calibration ............................3 – 248

4.5 One-Point Calibration ............................................. 3 – 253

4.6 Suspension Calibration ...........................................3 – 257

4.7 Temperature Compensation....................................3 – 262

4.8 Correcting the Measured Values ............................. 3 – 267

5Functional Processes .......................................................3 – 269

5.1 Plateau Measurement ............................................. 3 – 269

5.2 Changing the Uni-Probe Password.......................... 3 – 271

6Explanations ................................................................... 3 – 273

6.1 Background ............................................................ 3 – 273

6.2 Radiation Interference Detection............................. 3 – 275

6.3 Reading-in Pulse Rates............................................ 3 – 278

6.4 Calibration Modes ..................................................3 – 280

38478BA2B

12 27.5.08

Table of Contents Volume 1-7

6.5 Measurement of Suspensions ................................. 3 – 286

6.6 Software Versions................................................... 3 – 291

7Tables ............................................................................. 3 – 297

7.1 Absorption coefficients........................................... 3 – 297

7.2 Temperature coefficients......................................... 3 – 298

7.3 Density of Water as a Function of the Temperature . 3 – 300

8Error Handling ................................................................ 3 – 301

8.1 Device Response to Errors....................................... 3 – 301

8.2 Error Handling Modes............................................. 3 – 302

8.3 Corrective Action.................................................... 3 – 302

8.4 Reset ...................................................................... 3 – 304

8.5 Operation Modes during Measurement .................. 3 – 304

8.6 Error Reset.............................................................. 3 – 305

8.7 Fault Current .......................................................... 3 – 306

9Setup Protocol ................................................................ 3 – 309

9.1 Parameter List......................................................... 3 – 309

9.2 Calibration Values................................................... 3 – 311

Uni-Probe LB 491

Berthold Technologies GmbH & Co. KG 13

Volume 1-7 Table of Contents

Volume 4 PACTware™User Interface FDT/DTM

1PC Connection to the Uni-Probe ..................................... 4 – 317

2Installing and Working with DTM ....................................4 – 319

2.1 Requirements ......................................................... 4 – 319

2.2 FDT Container ........................................................ 4 – 319

2.3 DTM Communication Software...............................4 – 320

38478BA2B

14 27.5.08

Table of Contents Volume 1-7

Volume 5 SIMATIC PDM User Interface HART®

1PC Connection to the Uni-Probe ..................................... 5 – 329

2General Information on SIMATIC PDM ............................ 5 – 331

2.1 Hardware Requirements ......................................... 5 – 332

2.2 Fifo Buffer .............................................................. 5 – 332

3Getting Started with SIMATIC PDM................................. 5 – 335

3.1 First Steps............................................................... 5 – 335

3.2 Installing SIMATIC PDM .......................................... 5 – 335

3.3 Installing the Uni-Probe LB 491 Device Description.. 5 – 339

3.4 Project Setup .......................................................... 5 – 340

3.5 Starting SIMATIC PDM............................................ 5 – 344

4Menu Overview .............................................................. 5 – 345

4.1 FILE Menu .............................................................. 5 – 346

4.2 DEVICE Menu......................................................... 5 – 359

4.3 VIEW Menu ............................................................ 5 – 394

4.4 OPTIONS Menu ...................................................... 5 – 400

4.5 HELP Menu............................................................. 5 – 406

5Calibration with SIMATIC PDM........................................ 5 – 407

5.1 Preparing Calibration.............................................. 5 – 407

5.2 Measure Background.............................................. 5 – 412

5.3 Operation Modes for Calibration ............................ 5 – 414

5.4 Two- and Multi-Point Calibration ............................ 5 – 416

5.5 One-Point Calibration ............................................. 5 – 420

5.6 Suspension Calibration ........................................... 5 – 423

6Functional Processes ....................................................... 5 – 425

6.1 Plateau Measurement............................................. 5 – 425

6.2 Changing the Uni-Probe Password.......................... 5 – 428

7Explanations ................................................................... 5 – 431

7.1 Background............................................................ 5 – 431

7.2 Radiation Interference Detection............................. 5 – 433

7.3 Reading-in Count Rates .......................................... 5 – 436

7.4 Calibration Modes .................................................. 5 – 438

7.5 Measurement of Suspensions ................................. 5 – 444

Uni-Probe LB 491

Berthold Technologies GmbH & Co. KG 15

Volume 1-7 Table of Contents

8Error Handling ................................................................ 5 – 449

8.1 Device Response to Errors .......................................5 – 449

8.2 Error Handling Modes............................................. 5 – 450

8.3 Corrective Action....................................................5 – 451

8.4 Reset ...................................................................... 5 – 452

8.5 Operation Modes during Measurement .................. 5 – 453

8.6 Error Reset.............................................................. 5 – 453

8.7 Fault Current .......................................................... 5 – 454

9Working with SIMATIC PDM ...........................................5 – 457

9.1 Starting SIMATIC PDM ............................................ 5 – 457

9.2 The SIMATIC PDM Main Window ...........................5 – 458

9.3 Device Icons in SIMATIC PDM ................................. 5 – 461

38478BA2B

16 27.5.08

Table of Contents Volume 1-7

Volume 6 SIMATIC PDM User Interface Profibus PA

1Process Operation ........................................................... 6 – 467

1.1 Important Information on the Operation................. 6 – 467

1.2 Alternative Operation via HART®............................ 6 – 467

1.3 System Overview .................................................... 6 – 468

2Installation / Program Start.............................................. 6 – 469

2.1 Installing the Device Description (DD)...................... 6 – 469

2.2 Starting SIMATIC PDM............................................ 6 – 470

3Device-specific Menus..................................................... 6 – 471

3.1 DEVICE Menu......................................................... 6 – 472

3.2 VIEW Menu ............................................................ 6 – 510

4Calibration with SIMATIC PDM........................................ 6 – 519

4.1 Preparing Calibration.............................................. 6 – 519

4.2 Operation Modes for Calibration ............................ 6 – 527

4.3 Two- and Multi-Point Calibration ............................ 6 – 529

4.4 One-Point Calibration ............................................. 6 – 534

4.5 Suspension Calibration ........................................... 6 – 538

5Functional Processes ....................................................... 6 – 541

5.1 Plateau Measurement............................................. 6 – 541

5.2 Define Unit of Measure and Unit for the Function

Blocks..................................................................... 6 – 546

6Explanations ................................................................... 6 – 549

6.1 Background............................................................ 6 – 549

6.2 Radiation Interference Detection............................. 6 – 551

6.3 Reading-in Pulse Rates............................................ 6 – 554

7Error Handling ................................................................ 6 – 557

7.1 Device Response in Case of Errors........................... 6 – 557

7.2 Error Handling Modes............................................. 6 – 558

7.3 Corrective Action.................................................... 6 – 558

7.4 Reset ...................................................................... 6 – 560

7.5 Operation Modes during Measurement .................. 6 – 560

Uni-Probe LB 491

Berthold Technologies GmbH & Co. KG 17

Volume 1-7 Table of Contents

Volume 7 FOUNDATION™Fieldbus User Interface

1Process Operation ........................................................... 7 – 565

1.1 Important Information on the Operation.................7 – 565

2Installation / Program Start .............................................. 7 – 567

2.1 Installing the Device Description..............................7 – 567

2.2 Addressing the Density Meter Uni-Probe LB 491 .....7 – 567

3Parameter Overview........................................................ 7 – 569

3.1 Parameters for the Function Block Resource............7 – 569

3.2 Parameters for the Function Block Transducer .........7 – 570

3.3 Parameters for the Function Blocks Analog Input ....7 – 577

3.4 Parameters for the Function Blocks Analog Output .7 – 577

4Calibration with FOUNDATION™Fieldbus........................ 7 – 579

4.1 Preparing Calibration .............................................. 7 – 579

4.2 Set Background ......................................................7 – 581

4.3 Operation Modes for Calibration ............................7 – 582

4.4 Two- and Multi-Point Calibration ............................7 – 584

4.5 One-Point Calibration ............................................. 7 – 587

4.6 Suspension Calibration ...........................................7 – 589

5Functional Processes .......................................................7 – 591

5.1 Plateau Measurement ............................................. 7 – 591

5.2 Test Calculation (Test Signal Output) .......................7 – 593

5.3 Damping ................................................................7 – 594

5.4 Radiation Interference Detection............................. 7 – 596

5.5 Input Configuration................................................ 7 – 596

5.6 Relay Configuration................................................ 7 – 597

5.7 Defining the Upper/Lower Pulse Rate Limit.............. 7 – 598

5.8 Protecting Parameters against Modification ............7 – 599

5.9 Reading Out the Error Log ...................................... 7 – 599

6Explanations ................................................................... 7 – 601

6.1 Background ............................................................ 7 – 601

6.2 Radiation Interference Detection............................. 7 – 603

6.3 Reading-in Pulse Rates............................................ 7 – 606

7Error Handling ................................................................ 7 – 607

7.1 Device Response in Case of Error ............................7 – 607

7.2 Error Handling Modes............................................. 7 – 608

JO

7LPH

Volume 1 Uni-Probe Installation

38478BA2B

1 – 20 27.5.08

Volume 1

Table of contents

Other Berthold Measuring Instrument manuals

Berthold

Berthold MicroPolar LB 566 User manual

Berthold

Berthold DuoXpert LB 476 Level+ User manual

Berthold

Berthold Duo XPERT LB 470 Level User manual

Berthold

Berthold LB 442 User manual

Berthold

Berthold LB 444 K-40 User manual

Berthold

Berthold Duo Series User manual

Berthold

Berthold LB 9510 User manual

Berthold

Berthold Duo Xpert LB 478 MPLM User manual

Berthold

Berthold LB 444 User manual

Berthold

Berthold BTwave LB 571-02 User manual