2) Select a suitable test method to perform the measurement, the reading

will show on LCD, check the Figure below:

3. Measuring Displacement

1) Press “ D” to enter displacement mode, LCD will show dp-p, 10-500Hz

and mm icons, See the Figure below for details:

2) Select a suitable test method to perform the measurement, the reading

will show on LCD, check the Figure below:

4. Max. Mode

Press MAX button in measuring mode to capture Max. reading, MAX icon

displays simultaneously and the captured Max. reading for the

measurement appears. Repress to disable the function.

5. Data Hold

Press HOLD to enter data hold mode, indicated by HOLD icon on LCD,

and the measured value currently obtained will be frozen. Repress to

disable the function.

6. Backlit Display

Press “ ” button to access backlight mode, indicated by “ ” on LCD,

then LCD will be totally lit up. Repress to exit the function.

7. Record Data

Press “REC” to enter manual recording mode, the Tester shows “DATA”

icon and records currently measured readings. DATA icon disappears in

0.5s. Press REC again to record next data. Long press REC to enter auto

recording mode , DATA flashes on LCD and the Tester will automatically

record the currently measured values at a preset time interval ( See

“ Setting the Menu ” for details ) and exit this function if auto recording

time exceeds 1999 maximum number.

8. Read Data

Press “READ” button in order to read recorded data. LCD shows both

“ ----- ” on reading and No. display zones if the memory is blank. The

Tester will enter measuring mode in 0.5s. If there is any data, the Tester

will automatically display the lasted recorded data and its NO., then press

▼/ ▲to decrease/increase recording No. and view corresponding data;

long press▼/ ▲ to decrease/increase recording No. and view data

quickly; Or press REC button to increment data No. by 100, if recording

No. is less than 100 or you have already go up to No.1999, the Tester will

automatically return to recording No. 1 and its recorded data. Except

buttons mentioned above and “ ” button, other buttons are invalid in

this working mode. Press READ again to exit.

9. Clear Data

Method 1: Press and hold “CLEAR” button while pressing “POWER ” to

turn on the Tester, release “POWER” button, CLR icon will appear on

LCD, indicating the records have already been cleared.

Method 2: Clear data by resetting the Meter to factory default (See

“ Setting the Menu ” for details ).

10. Setting the Menu

Press “MENU” button to enter the menu, it defaults to USB0 item which

keeps USB communication disabled, then press “▲/▼” to change to

USB1 which indicates the communication is enabled. USB icon shows on

LCD under this setup. If READ button is pressed down under menu setup

mode, USB1 icon flashes and data in the memory will be transferred to

PC, with the transfer completed, press ENTER to save and go into next

menu option --- APO setup. APO1 is to enable auto power off function,

indicated by “ ” icon on LCD. Press “▲/▼” to change to APO0 to

disable the function or repress to return to APO1. Finally press ENTER to

save and enter next menu option—Time Interval for auto recording, LCD

★ Measurement with use of short probe is applicable for both high-and

low-frequency vibration.

★ Measurement with use of long-probe is applicable for only low-frequency

vibration. Please use the short probe when measuring acceleration at a

frequency>1kHz.

★ The Tester will turn off automatically after 10 minutes’ inactivity.

Notes:

X. Maintenance

1) Working Environment: BST-VM04 is a precision vibration tester, which

should be protected from any shock, impact, moisture, strong

electromagnetic field, oil and dust.

2) Replacing and Maintaining the battery

a. When low battery indicator “ ” shows, please replace the battery

timely.

b. To avoid any battery leakage or serious damage to the Tester, please

take out the battery if not in use for a long time.

3) Do not attempt to disassemble the Tester to alter its circuits randomly.

4) Cleaning the Casing: Clean the tester surface with soft cloth dampened

with little water; Alcoholic or solvent is not allowed , for it may cause

corrosive damage to the LCD.

XI. Warranty

1) Please refer to Warranty Card for detailed warranty terms

2) The Warranty doesn’t apply to any damage caused by unauthorized

disassembly and misuse from users, self-alteration on warranty card and

absence of purchase proof.

XII. Certification

The Vibration Tester complies with:

EN61326-1:2006

Display Update Period

LCD Display

Accuracy

Displacement Range

Velocity Range

Acceleration Range

Vibration Collection

Technical Parameters

10HZ ~ 500HZ

XIII. Technical Specifications

Specifications

Piezoelectric accelerometer

0.01cm/s~19.99cm/s (true valid value)

0.001mm~1.999mm (peak peak value)

(5%+2dgts)

Frequency Range (for Acceleration) 10HZ ~ 10kHZ

Frequency Range (for Velocity) 10HZ ~ 1kHZ

Frequency Range(for Displacement)

Digital; 1999-count

1 second

0.1m/s ~199.9m/s (peak value)

2 2

Low Battery Indicator

Storage Temperature

Working Humidity

Battery Life

Auto Power Off

Backlight Off Time

Working Current

Current Under Sleep Mode

Power 9V alkaline battery

1uA

25mA

Press backlight key to shut off

automatically power off after 10 minutes'

inactivity

20 hours of continuous use

Working Temperature 0 50

20%RH 80%RH

-20 60

Shows when battery voltage<7V

Dimension 166mm X 80mm X 30mm

Weight 395g

Altitude 2000 m

Appendix:

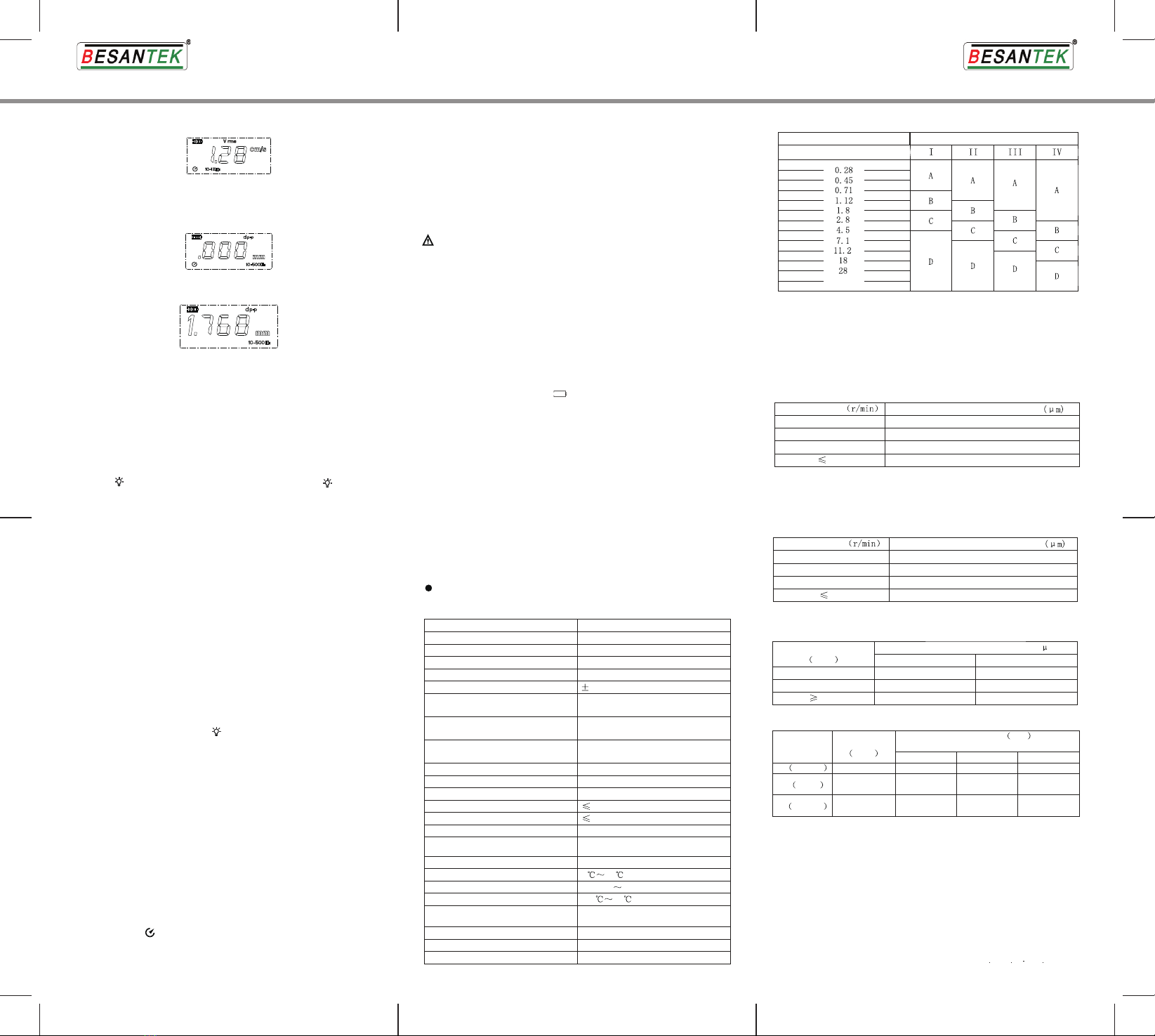

a. Vibration Severity ( IS02372 )

45

Vibration Strength Machinery Category

Vibration velocity Vrms(mm/s)

Note:

(1) I Category: Small Machinery( <15kW); II Category: Medium Machinery

( 15kW~75kW ); III Category: Large Machinery; IV Category: Large

Primary Machinery (the basis ).

(2) A, B, C, D: Vibration Severity. A: Good; B: Satisfactory, C: Unsatisfactory,

D: Unacceptable. The Vrms value should be measured from three axes

of driveshaft.

b. Maximum Vibration Allowed for Machinery with >1 horse power ( NEMA

MG1-12.05)

3000~4000 25.4

1500~2999 38.1

1000~1499 50.8

63.6

Peak-peak displacement amplitude

Rotating speed

999

d. Preformed winding squirrel-cage induction machinery.

Note:

For AC machinery, please use Maximum syn rotation speed; for DC

machinery, select the rotation speed with Max. power; for series-connected

or multipurpose machinery, use the working speed.

c. Maximum Vibration Allowed for Large Induction Machinery ( NEMA MG1-

20.52)

Peak-peak displacement amplitude

Rotating speed

3000 and higher 25.4

1500~2999

999

50.8

1000~1499 63.6

76.2

Two standards above are formulated by National Electrical Manufacturers

Association (NEMA)

50.8 63.6

38.1 50.8

25.4 25.4

Sync rotating speed

720~1499

1500~2999

3000

Peak-peak displacement amplitude ( m)

Plastic support Rigid support

The standard is formulated by American Petroleum Institute.

e. ISO/IS2373 the electric quality standard based on vibration velocity.

80<H<132 132<H<225 225<H<400

Quality grade

600~3600 1.8 2.8 4.5

N Normal

600~1800

1800~3600

0.71

1.12

1.12

1.8

1.8

2.8

600~1800

1800~3600

0.45

0.71

0.71

1.12

1.12

1.8

R Good

S Special

Rotating speed Axis height H mm

maximum vibration velocity rms(mm/s)

r/min

r/min

Grade N limit value recommended in the table is only applicable to common

machinery.

at the moment shows 060, DATA and REC icons, then press “▲/▼” to

increase/decrease the time or long press“▲/▼” to increase/decrease

quickly. The time can be set within 0.5~255 seconds. Finally press

ENTER to save and access next option—factory default, LCD will show

“ DEF? ” ( Pressing ENTER will reset the Tester to factory settings —

USB0, APO1, 60s and clear all recorded data. If with MENU pressed

down, the Tester will go into measurement selected before the menu

setup, or if turning off the Tester when setting the menu, the Tester will

automatically save the setup status, and there is no need to reset after

returning on the Tester ).

** END **

Due to our policy of constant improvement and development, we

reserve the right to change specifications without notice.