BST-GFL31 User Manual

1

Catalog

1. ABOUT BST-GFL31

........................................................................................................................................ 2

1.1 BST-GFL31 Brief Information?............................................................................................................... 2

1.2 BST-GFL31 Main Functions................................................................................................................... 2

1.2.1 Ground Fault Location................................................................................................................. 2

1.2.2 Frequency Spectrum Analysis ..................................................................................................... 2

1.2.3 Oscilloscope ................................................................................................................................ 2

1.3 Features ................................................................................................................................................. 2

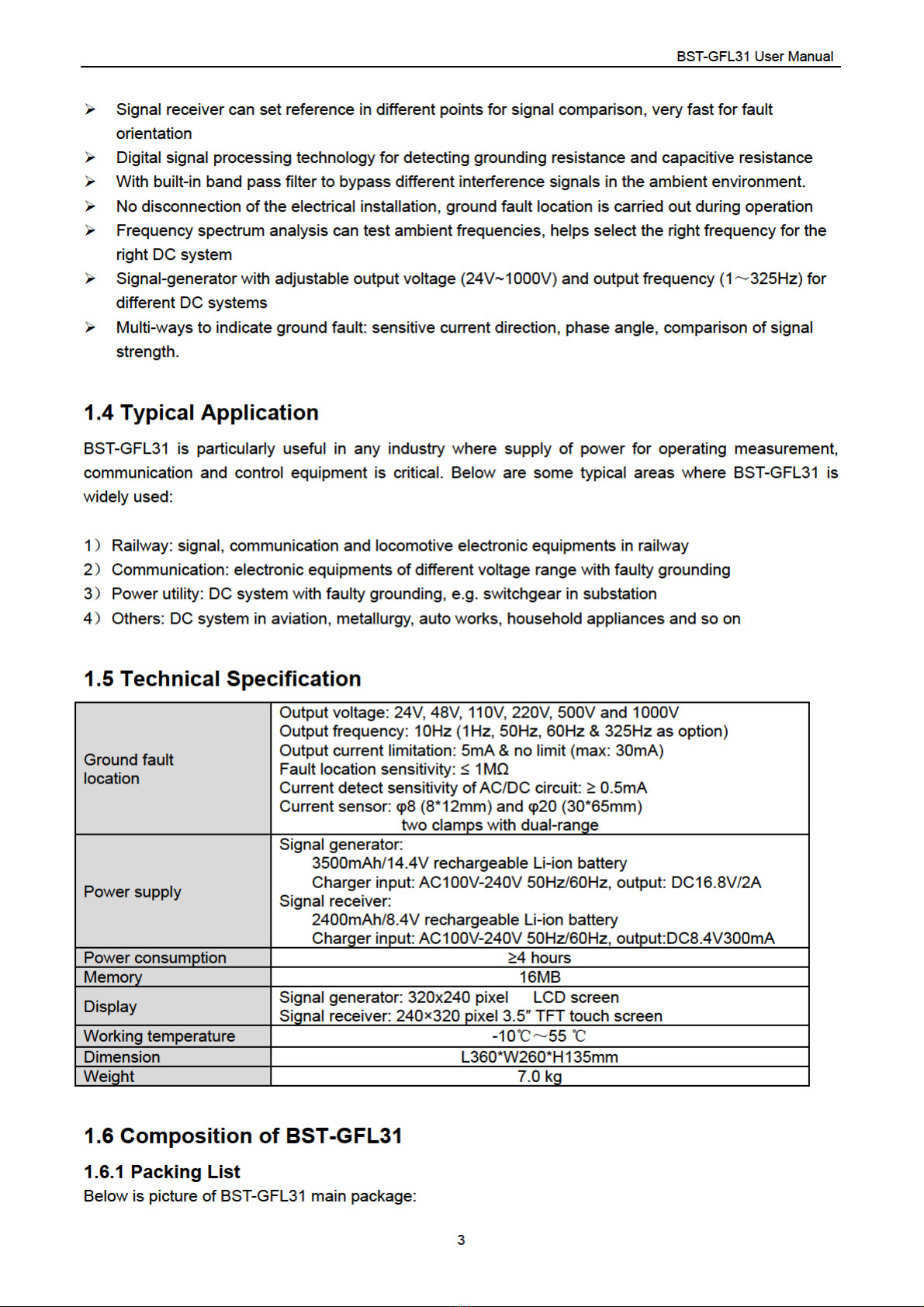

1.4 Typical Application.................................................................................................................................. 3

1.5 Technical Specification ........................................................................................................................... 3

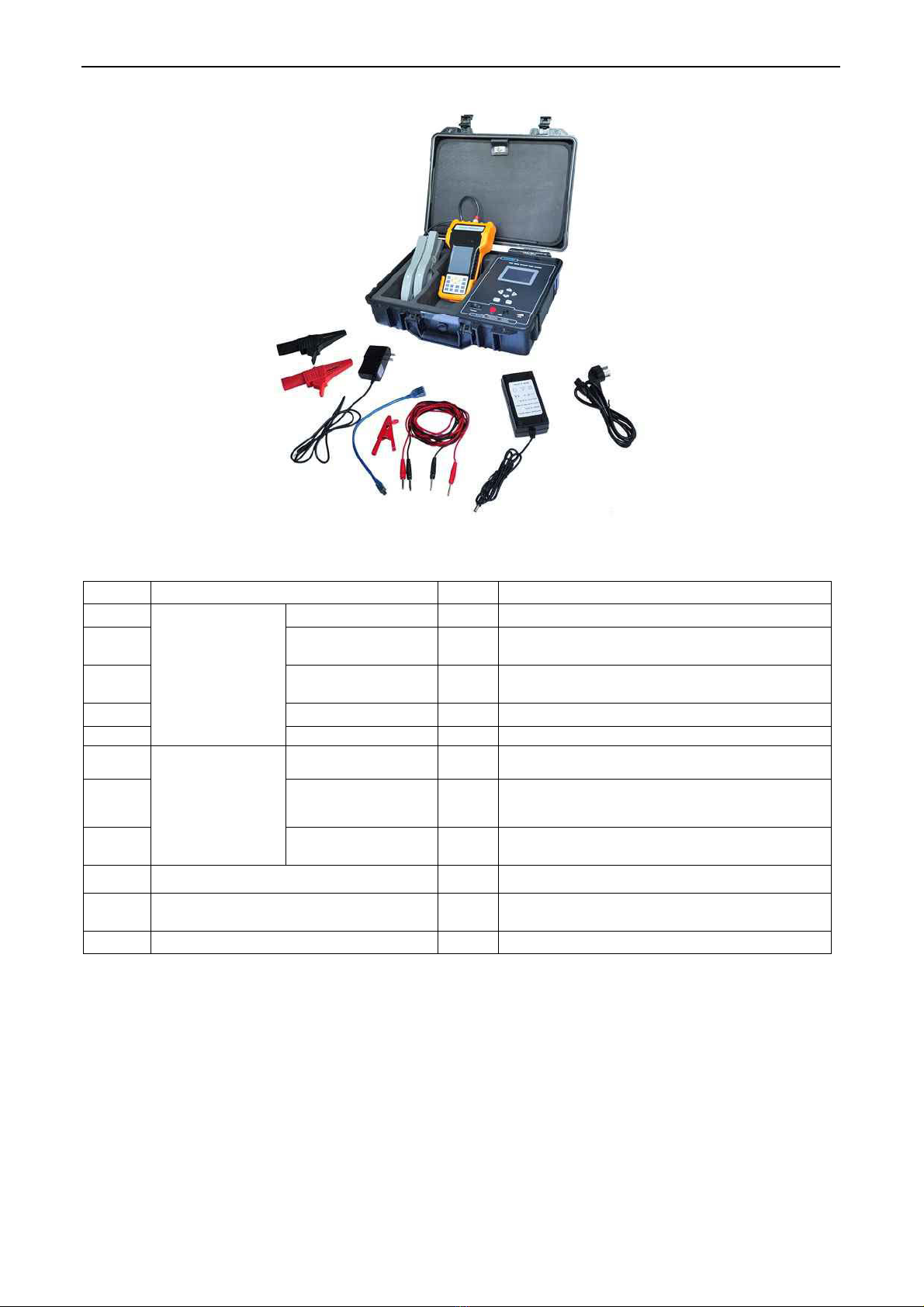

1.6 Composition of BST-GFL31 ................................................................................................................... 3

1.6.1 Packing List ................................................................................................................................. 3

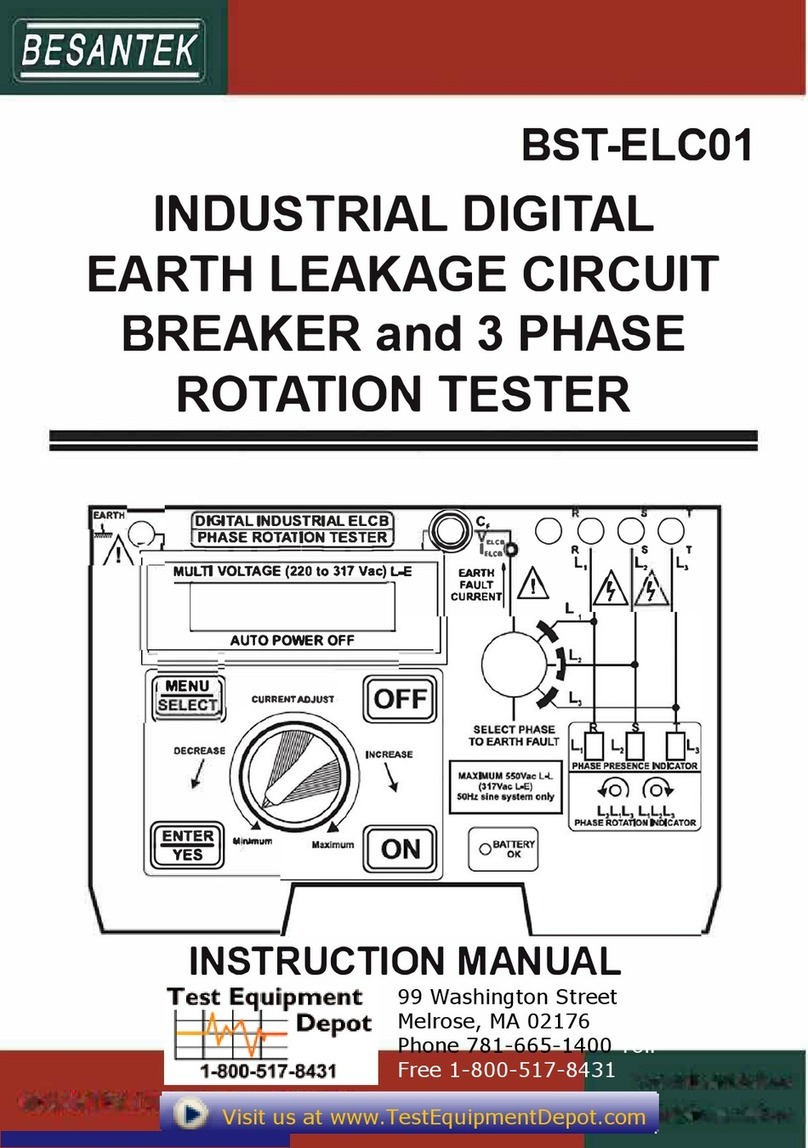

1.6.2 BST-GFL31 Main Body ............................................................................................................... 4

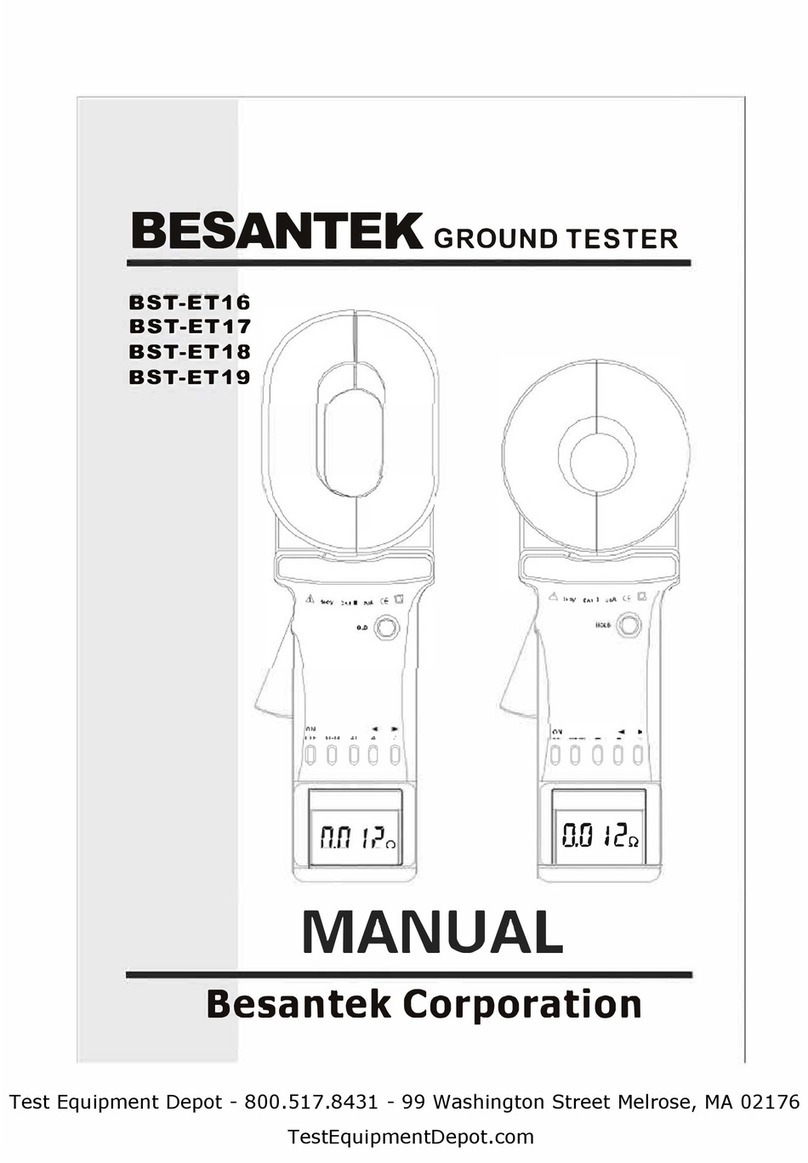

1.6.3 Signal Receiver ........................................................................................................................... 5

1.7 Basic Concepts ...................................................................................................................................... 6

1.7.1 About Faulty Grounding............................................................................................................... 6

1.7.2 Wire Mix-connection.................................................................................................................... 7

1.7.3 Short circuit.................................................................................................................................. 8

1.7.4 Current leakage ........................................................................................................................... 8

1.7.5 Tracing of Current Signal............................................................................................................. 8

2. MAIN OPERATION OF BST-GFL31 ............................................................................................................... 8

2.1 General Steps for Fault Location ........................................................................................................... 8

2.2 Operation Preparation............................................................................................................................ 9

2.3 Wire connection with DC System........................................................................................................... 9

2.4 Set Generator Output Signal................................................................................................................ 10

2.4.1 Measurement of Circuit ............................................................................................................. 10

2.4.2 Output Signal Adjustment.......................................................................................................... 11

2.4.3 Output Signal to Circuit for Fault Location ................................................................................ 12

2.4.4 Return Circuit for Fault Location................................................................................................ 13

2.5 Signal Tracing with Signal Receiver..................................................................................................... 13

2.5.1 Frequency Synchronization....................................................................................................... 13

2.5.2 Set Signal Reference ................................................................................................................ 14

2.5.3 How to Locate Ground Fault? ................................................................................................... 17

2.6 Some Tips for Ground Fault Location .................................................................................................. 18

2.6.1 Multiple Setting of Signal Reference ......................................................................................... 18

2.6.2 Gross searching ........................................................................................................................ 20

2.6.3 Use more than one signal receiver............................................................................................ 20

2.7 Signal Changes in Earth Fault Circuit .................................................................................................. 20

2.8 Location for Other Ways of Fault ......................................................................................................... 21

2.8.1 Wire Mix-connection.................................................................................................................. 21

2.8.2 Short-circuit Fault Location........................................................................................................ 22

2.9 About Distributed Capacitance............................................................................................................. 22

3. OTHER SETTINGS OF GENERATOR AND RECEIVER ............................................................................. 23