BestPack MSD 22 User manual

MODEL MSD22

SEMI-AUTOMATIC UNIFORM CARTON SEALER

Version 1.9

OPERATION AND PARTS MANUAL

READ ALL INSTRUCTIONS BEFORE OPERATINGTHIS MACHINE

YOUR ONE SOURCE

Manual Sidedrive Dual Mast Carton Sealer (MSD)

OperationManual

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer(MSD)

2

TableofContents

TABLE OF CONTENTS

Our Commitment 3

Safety 4

OWNER’SSAFETYRESPONSIBILITY 4

SAFETYPROCEDURES 5

EQUIPMENTSAFETY 6

Machine Overview 8

MACHINEDESCRIPTION&FEATURES 8

MACHINECOMPONENTS 11

MACHINEDIMENSIONS 12

Installation/Setup 14

INSTALLATIONCHECKLIST 14

MACHINEPACKING 14

UNCRATINGPROCEDURES 14

SETUPPROCEDURE 15

Machine Maintenance 17

DAILYPREVENTATIVEMAINTENANCE 18

Troubleshooting 19

Parts Replacement 22

Recommended Spare Parts 23

Drawings and Parts Lists 24

ROLLERBEDASSEMBLY 24

BELTDRIVEASSEMBLY 26

WIDTHDRIVEASSEMBLY 29

MASTASSEMBLY 31

TOPTAPEHEADDRIVEFRAMEASSEMBLY 33

CONTROLPANELDIAGRAM 36

Customer Service Information 38

Warranty 39

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

3

We Value Our Customers

This is the BestPack® Packaging Systems equipment you ordered customized to meet your needs.

This quality machine has been set up and tested successfully in the factory with brand name tapes to

ensure your highest level of satisfaction.

If problems do occur when operating this equipment, please refer to the Troubleshooting section

of this manual for help. If this does not resolve the problem and you need a service call or phone

consultation, reference the Customer Service Section of this manual for contact information.

Remember to lockout all energy sources (i.e. power down and shut off air supply) and release stored

energy prior to servicing or moving the machine to prevent injury.

Replacement Parts, Order Form, Warranty Guidelines, and Warranty Registration

Please take note of the following important items in this manual:

- Recommended replacements parts suggested to keep on hand to minimize downtime

- Troubleshooting section listing the most common causes and simple solutions

- Customer Service Information provided for your support

- Parts Order Form for your convenience

- BestPack® 1-Year Warranty Program and Guidelines

- Warranty Registration Form to activate your warranty

We ask that you fill out the Registration Form provided at the back of this manual and send it in to

activate your warranty.

FUTURE COMMODITIES INTERNATIONAL, INC.

BESTPACK® PACKAGING SYSTEMS

10676 FULTON COURT

RANCHO CUCAMONGA, CA 91730-4848

OurCommitment

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

4

Safety

OWNER’S SAFETY RESPONSIBILITY

Owners and operators of the MSD22 carton sealer are responsible for maintaining an effective

safety program. This program should be consistent with good management practices and meet all

requirements of applicable laws, regulations, and ordinances. Employees must be aware of and

trained to recognize the specific requirements, precautions, and hazards of the sealing machines.

SAFETY AWARENESS

Careful machine operation is the key to safe job performance. Reasonable care and good judgment

in machine operation contribute to operator safety and safety of others. Failure to follow simple safety

rules and precautions may result in an accident. Always be aware of what is going on in the work

area. Recognize hazardous situations before they become an accident.

HAZARD COMMUNICATION STATEMENT AND PRECAUTIONS

Four indicator signal words appear throughout this manual to call your attention to special information,

operating procedures, and safety precautions as described below.

This indicator draws emphasis to special information about

equipment operation and maintenance procedures.

NOTE:

This indicator specifies special instructions or procedures meant

to prevent damage to the equipment, associated components, or

products.

IMPORTANT:

This indicator signals hazards or unsafe practices that could result in

minor personal injury or property damage.

SCAUTION:

SWARNING:

SDANGER:

To prevent accidental start-up and personal injury during routine

maintenance or when troubleshooting problems, always turn off the

power to the machine first. Then disconnect the machine’s electrical and

compressed air lines from the main supply, and release all stored energy

before commencing work. If the power is not turned off, accidental

startup could result in injury.

This indicator signals hazards or unsafe practices that could result in

severe personal injury or death, if the instructions are not followed.

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

5

SAFETY PROCEDURES

1. Operators should read this manual prior to operating or making any adjustments on the machine.

2. Make sure machine power is turned off during the setup procedure while making adjustments to

the machine. Be careful with the driving direction of the conveyer.

3. Machine should not be washed down or subjected to conditions causing moisture condensation

on components and should be used in a dry, relatively clean environment at 40 to 105 degrees

Fahrenheit with dry boxes.

4. To enhance safety, operators should be alert at all times while operating the machine. When

packing products with toxic powders or chemicals, make sure packing area has good ventilation.

5. Remember to lockout all energy sources (i.e. power down and shut off air supply) and release

stored energy prior to servicing or moving the machine to prevent injury.

CAUTION LABELS

1. This label shows the entry point of the boxes. [Fig 1-1]

2. This label shows the direction of the crank handle. [Fig 1-2]

3. This label shows that that this area contains electrical components. Only authorized personnel

are allowed to access these components. [Fig 1-3]

4. Warning label cautions to keep hands out of this area due to a moving part. [Fig 1-4]

5. Warning label cautions potential electrical shock. Unplug power before servicing the machine.

[Fig 1-5]

6. Warning label cautions to keep hands out of this area because it contains a sharp knife. [Fig 1-6]

Safety

Fig 1-1 Fig 1-2

Fig 1-3 Fig 1-4 Fig 1-5 Fig 1-6

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

6

EQUIPMENT SAFETY

1. Do not alter, deface, or remove factory installed information signs that are attached to the

equipment. If an information sign is damaged, replace it as soon as possible.

2. Never climb or work on equipment while it is operating nor allow anyone else.

3. Inspect all equipment components before each operation shift for damaged parts or parts

suspected of sustaining damage. Repair or replace any damaged or defective components

before starting or operating the equipment.

4. Before starting or operating equipment, perform a walk-around inspection of the workplace and

the equipment. Make sure that no workers, tools, parts, or foreign objects are in, on, under, or

around the equipment.

5. Do not operate equipment if safety gates are not in place. Check safety gates and other safety

devices for proper installation and safe working condition.

6. Before starting equipment make sure that all personnel or visitors know that the equipment is

going to be started.

7. When starting equipment, follow the manufacturer’s recommended starting sequence.

8. Do not allow anyone to start or operate any equipment unless they have been trained in safe

operating procedures.

9. Never leave equipment controls unattended. Either have a qualified operator relieve you or

turn equipment off if you must leave your workstation.

10.When starting up equipment and while equipment is operating, be alert for improper readings,

visual defects, abnormal odors, or unusual noises. These can be an indication of an

equipment problem or warning of a possible hazard. At the onset of any of these conditions,

immediately shut down the machinery following proper shutdown procedures.

11.Do NOT inspect, maintain, adjust, repair, or move the equipment until LOCKOUT procedures

are implemented by trained, authorized personnel in accordance with state and federal laws.

Authorized persons must shut down the power supply, shut down all energy sources, block

moving parts, and release all stored energy to prevent injury.

12.Perform all equipment inspection, maintenance, lubrication, and adjustment procedures with

caution and comply with manufacturer’s recommended procedures.

Safety

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

7

Safety

ELECTRICAL SAFETY

1. Allow only qualified electricians or electronic technicians to work on electrical components or

controls.

2. Always assume that an electrical circuit is “live” until proven otherwise by proper testing

conducted by an authorized person.

3. Repair or replace frayed, cut, broken, or damaged electrical wires, cables, and connectors.

4. Check that electrical ground wires, motor plugs, and power cable connections are properly and

securely connected before starting any equipment.

5. Know all locations of main electrical shut-off boxes in case of an emergency.

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

8

MachineOverview

The BestPack® MSD Semi-Automatic

Uniform Carton Sealer is our most

popular top of the line operator-fed and

adjustable carton sealing machine,

designed to cater to the needs of light-

to-heavy duty uniform carton closure

applications.

Incorporate our exclusive pop out

pressure sensitive “High Speed” tape

heads with patented tab adjustment, and

the dual (telescopic) masts allow for an

extra 4” carton height extension on the

upper assembly.

MACHINE DESCRIPTION & FEATURES

•Two Side Belts

•Telescopic Mast Design

•Extra 4” Carton Height Adjustment controls conveniently located on both sides of machine

•Adjustable Bed Height 25.3” to 30.00”

•Width/Height Adjustment either side of machine

•Exclusive 4 roller top compression

•Tape Roll Lengths: 1000 yd., 1500 yd., 2000 yd.

•Heavy Duty Frame

•UL Approved Electrical Parts

•Designed for uniform applications

•Capable of Interchanging 2” or 3” Tape Heads

•Electrical ON/OFF box can be mounted on either side of machine

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

9

optional features

• Spare Parts Kit

• High Speed Motor Upgrade (Up to 125 ft./mm.)

• Motorized Height and/or Width Adjustment

• Interlock Safety Gates

• Stainless Steel

machine specifications

• Power Requirements: 110 Volts 60 Hz

• Speed: Up to 40 cartons/minute

• Tape Head: Standard: 2”, Available: 3”

• Shipping Weight: 342 - 550 lbs

MachineOverview

standard features

• Exclusive Pop-out pressure sensitive “high speed” tape

head with patented tab adjustment and noise reduction arm

• Tool Kit

• Operation Manual

- Dual Top & Bottom Side Drive Belts

o Equipped with “V” Guide for positive tracking

and longer belt life

o Idler Rollers behind belts reduce friction

o Changed quickly and easily, reducing

downtime

- Telescopic Mast Design

- Extra 4” carton height adjustment available on upper

assembly

- Adjustable Bed Height 24.5” to 31.25”

- Width/Height Adjustment either side of machine

- Exclusive 4 rollers Top Compression Unit

o Compresses top major flaps together

o Aligns each box for precise tape positioning

o Ensures a tight, secure seal

- Manual Adjusting Dual Side Guides

- Removable/Interchangeable Top/BottomTape Heads

o 2” or 3” tape heads are possible

o Lifts out easily/threads easily; No tools required

o Minimizes downtime due to faster roll changes

o Tape roll lengths: 1000 yd., 1500 yd., 2000 yd.

- Tape Tab Length Adjustment

o Adjusts from 2 3/8” to 3”

o No additional parts required

o Changes can be made in minutes

- Tape Tension Adjustment Knob

o Prevents tape overrun

o Provides a more consistent tape application

- Tension Optimizing Arm

o Smooth, consistent unwind

o Minimizes unwind noise

o Reduces the amount of tension adjustment

required for optimum performance

o Capable of running all adhesives

o Reduces possibility of tape stretching and

breaking

- Brush Wipe Down System

o Positively wipes tape overlap to bottom side of

box and is removable

- Designed for Uniform Applications

- Heavy Duty Frame; UL Approved Electrical Parts

- Electrical ON/OFF box can be mounted on either side

of machine

major features

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

10

series comparison table

* All specifications capable of customization

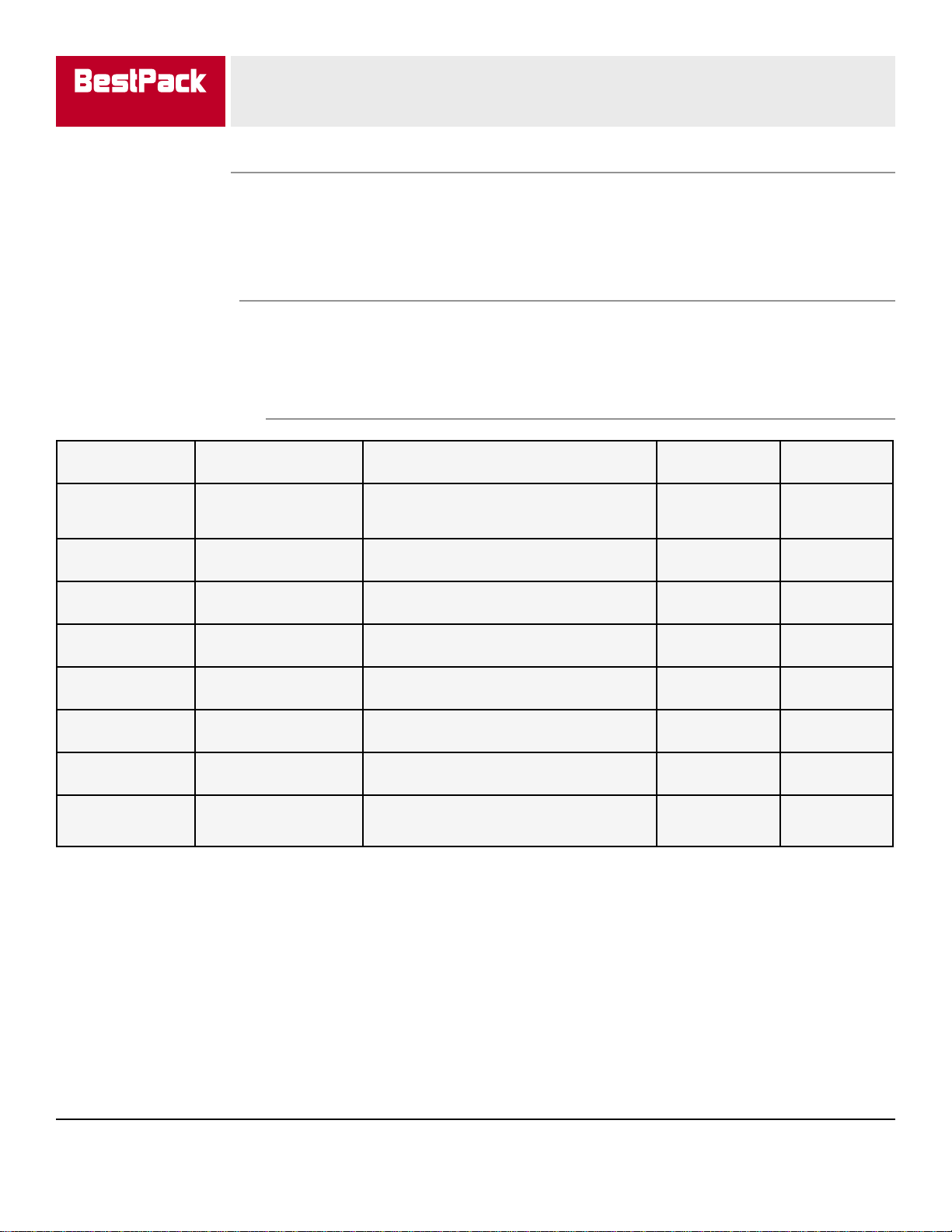

Model Machine Size Carton Range Cartons/Min. Shipping

Weight (lbs.)

MS 20-2

2”TapeHead 39.4” x 28.5” x 35.0” (6.0”-U) x (4.25”** - 20.5”) Up to 40 263

MS 20-3

3”TapeHead 39.4” x 28.5” x 35.0” (6.0”-U) x (5.25”** - 20.5”) Up to 40 263

MSD 22-2

2”TapeHead 39.4” x 32.8” x 55.5” (6.0”-U) x (4.25”** - 20.5”) x (3.25”- 20.5”) Up to40 342

MSD 22-3

3”TapeHead 39.4” x 32.8” x 55.5” (6.0”-U) x (5.25”** - 20.5”) x (3.25”-20.5”) Upto40 342

MSD 23-2

2”TapeHead 46.3” x 36.0” x 65.5” (6.0”-U) x (4.25”** - 20.5”) x (3.9”-30.0”) Up to40 390

MSD 23-3

3“TapeHead 46.3” x 36.0” x 65.5” (6.0”-U) x (5.25”**-20.5”) x (3.9”-30.0”) Upto 40 390

MSD32-2

2”TapeHead 39.4” x 43.8” x 55.5” (6.0”-U) x (4.5”-30.0”) x (3.9”-20.5”) Up to25 550

MSD32-3

3”TapeHead 39.4” x 43.8” x 55.5” (6.0”-U) x (5.5”-30.0”) x (3.9”-20.5”) Up to25 550

carton specifications

Style: 1 Piece, Regular Slotted Container (RSC)

Construction: 125 to 300 Single or Double Wall

Content Weight: 4 lb. to 95 lb.

MachineOverview

operating conditions

• Use in a dry, relatively clean environment at 40° to 105° Fahrenheit (5 to 40 Celsius) with dry boxes.

• Machine should not be washed down or subjected to conditions causing moisture condensation on

components and should be used in a dry, relatively clean environment at 40 to 105 degrees Fahrenheit

with dry boxes.

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

11

MajorComponents

MAJOR COMPONENTS

BOTTOM

TAPE HEAD

MAST ASSEMBLY

UPPER TAPE HEAD

WIDTH ASSEMBLY

ROLLER BED ASSEMBLY

BELT DRIVE

ASSEMBLY

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

12

MACHINE DIMENSIONS

Dimensions

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

13

ElectricalDiagram

ELECTRICAL DIAGRAM

FUSE 10A

SR

S

R

MS1

1

23

MOTOR

MOTOR

MB

4

C16UF250VAC

C16UF250VAC

POWER LAMP

R

R

STOP START

MS1

78MS1

4-6A

9S

TERMINAL:

AC110 V 12 3124RS

MA MB POWER

W:MANUALS/ELECDIAMSD

1

2

MA

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

14

Installation/Setup

INSTALLATION CHECKLIST

Power: 1PH 110/220vac 50/60Hz or 3PH 220VAC 50/60Hz

Voltage fluctuation range: 95% - 105%

Temperature: 40 degrees to 105 degrees Fahrenheit

Relative humidity: 30% to 80% RH

Noise Level: 70 DECIBELS

MACHINE PACKING

The machine is secured on a pallet, wrapped with bubble wrap, covered with double wall corrugated

box, then secured onto the pallet with two plastic straps.

UNCRATING PROCEDURES

1. Position the crate in a large, uncluttered area to unpack the machine.

2. Lift and remove the corrugated box.

3. Remove the bubble wrap.

4. Remove the shipping anchors on the four legs.

5. Lift the machine from the pallet using properly rated cord.

6. If the casters are attached, the machine can be moved manually and rolled to the proper

location.

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

15

Installation/Setup

SETUP PROCEDURE

It is important that the MSD22 series be setup and operated with the product prior to being subjected

to the production environment where time for setup, adjustment, and operator training is usually

limited.

CAUTION: Make sure machine power is turned off. Be careful with the driving direction of the

conveyer.

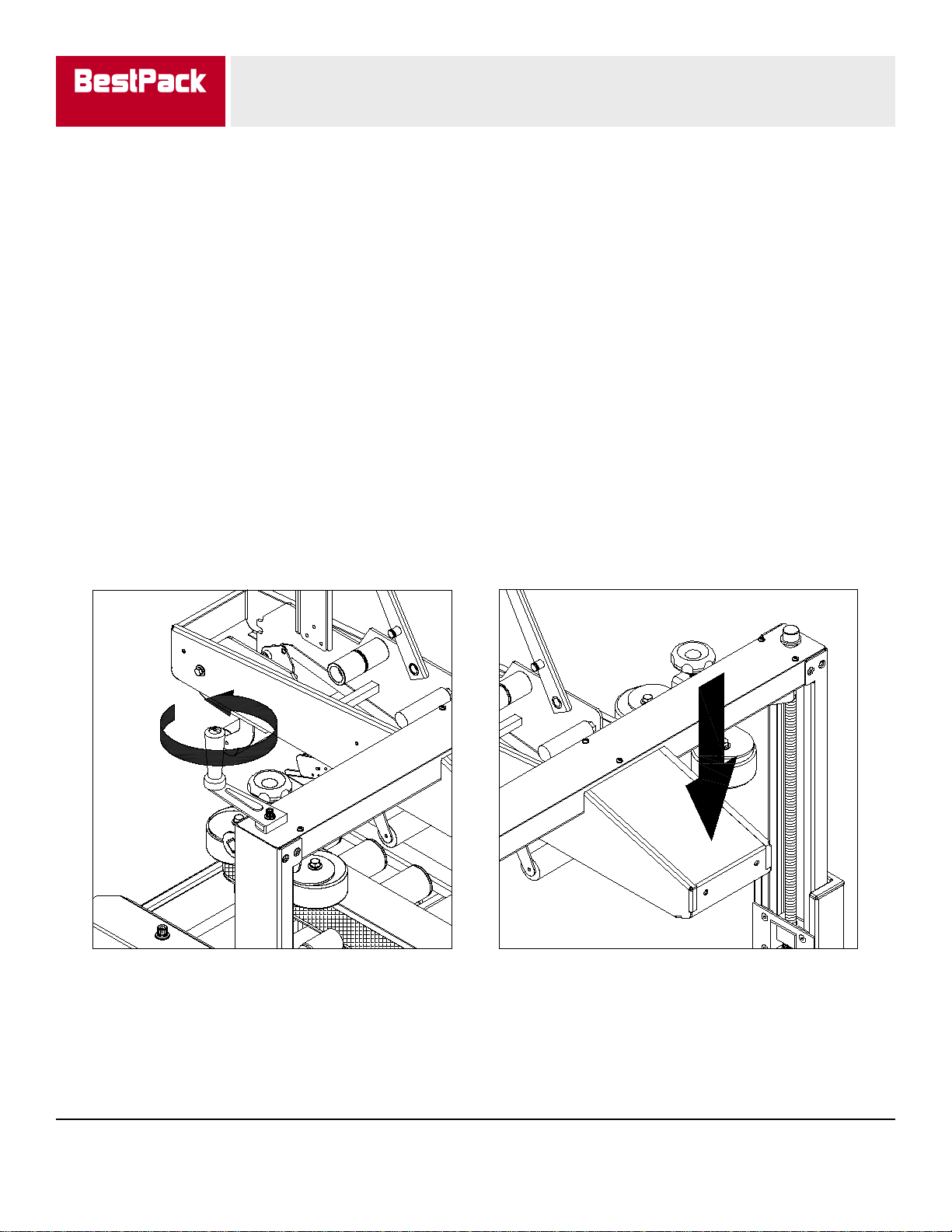

HEIGHT ADJUSTMENT: Once both tape heads are loaded with tape, the upper tape head can

be positioned for the box height being sealed by means of the height adjustment crank. Turn (H)

clockwise to decrease height or counter-clockwise to increase height. [Fig 2-1]

BOX SIZE SETUP: Place a closed box under the top drive frame. Lower the frame until all flaps are

fully closed. Align the box top flap center seam with the center of the frame. [Fig 2-2]

FIGURE 2-1 FIGURE 2-2

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

16

Installation/Setup

WIDTH ADJUSTMENT CRANK: Turn the handle (W) clockwise for narrow and smaller packages;

turn the handle counter-clockwise for wider and larger packages. [Fig 2-3]

COMPRESSION ROLLERS: Adjust the compression rollers against the top edge of the box and

tighten the knobs to secure them in the operating position. [Fig 2-4]

FRAME ADJUSTMENT: Turn electrical switch to the “ON” position to start the drive belts. Move the

box forward under the top tape head frame until taken away by the drive belts. If the box is hard to

move or is crushed, raise the frame slightly to decrease pressure. If the box movement is erratic or

stops under the frame, lower the frame slightly to add more pressure between the box and the drive

belts.

FIGURE 2-3 FIGURE 2-4

CAUTION: If drive belts are allowed to slip on

the box. Excessive belt wear will occur.

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

17

MachineMaintenance

LUBRICATION

It is important to lubricate all moving parts on the machine to keep it in top operating condition.

Lubricate the following areas with grease or oil (as indicated) every two months.

LUBRICATE THE FOLLOWING:

1. Chain drive mechanism for width adjustment. GREASE [Fig 3-2]

2. Spindle screw mechanism for width adjustment. GREASE [Fig 3-2]

3. Chain drive mechanism for height adjustment. GREASE [Fig 3-1]

4. Spindle screw mechanism for height adjustment. GREASE [Fig 3-1]

5. Sprocket for spindle screw mechanism for width adjustment. OIL [Fig 3-2]

GREASE

POINTS

INDICATED GREASE POINTS

3

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

18

DAILY PREVENTATIVE MAINTENANCE

MachineMaintenance

Two-Minute Maintenance (after every shift)

In order to maintain your BestPack®carton sealer in top operating condition, please take two minutes

after every shift change to perform the following maintenance procedure.

1. Clean the Machine

a. Blow the machine down with dry air paying special attention to all moving parts.

2. Clean the Blade

a. Wipe down the cutting blades with a clean rag making sure to remove any glue and

plastic film that may have adhered to the blade.

(i) For stubborn accumulation, spray some solvent; i.e., WD-40 or Zylene, onto a

rag to wipe the blade clean.

CAUTION ! Do NOT get WD-40 on the rubber rollers. Do NOT

use any hard objects to scrape accumulation from the

blade as it could damage the blade.

b. Wipe a thin layer of Vaseline onto the blade as your last cleaning step.

3. Water Reservoir (applicable if the machine uses air)

a. If your carton sealer uses air, check for moisture build-up in the water reservoir.

b. If there is water in the reservoir, bleed off any moisture that has accumulated in the

water reservoir of the air regulator by pushing the button located at the bottom of the

glass container on the main regulator.

IMPORTANT SAFETY REMINDER! Remember to lockout all energy sources (i.e. power down and

shut off air supply) and release stored energy prior to servicing or moving the machine to prevent

injury

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

19

Troubleshooting

TROUBLESHOOTING

Review SETUP PROCEDURE to ensure setup is correct. If correct, the troubleshooting chart below

lists possible problems, causes, corrections, and reference guide.

PROBLEM POSSIBLE CAUSES CORRECTION

1. Drive belts do not

convey boxes Narrow boxes

Check machine specifications. Boxes

are narrower than recommended causing

slippage and premature belt wear.

Worn drive belts Replace drive belts

Top flap compression rollers

in too tight Readjust compression rollers

Top tape head does not

apply enough pressure

Adjust the box height adjustment with the

crank

2. Drive belts do not

turn

Worn bearings, gears, or

driving shaft Replace ball bearing, gears, or driving shaft

Drive belt tension too loose Adjust belt tension screw

Electrical disconnect Check power and electrical plug

Motor not running Check the fuse, capacitor, and setting of

thermal relay

3. Drive belts break Worn belt Replace belt

4. Light boxes tip

back on exit

Top drive frame down too

far Carefully adjust top drive frame

5. Squeaking noise

as boxes pass

through machine

Dry compression rollers Lubricate compression rollers

Driving pulleys Lubricate plastic and aluminum pulleys and

replace, if defective

* Denotes to reference your tape head manual

YOUR ONE SOURCE

ManualSidedriveDualMastCartonSealer (MSD)

20

Troubleshooting

PROBLEM POSSIBLE CAUSE CORRECTION

6. Tape not centered

on box Tape drum not centered Reposition tape drum *

Top compression rollers not

aligned with the tape head

Align the left and right compression roller to

the tape head *

Box flaps not of equal

length

Check box specifications and adjust

accordingly

7. Blade does not cut

tape, or tape end is

jagged or shredded

Blade is dull and/or has

broken teeth Replace blade *

Tape tension is insufficient Increase tape tension by adjusting the

mandrel wheel *

Adhesive has build-up on

blade Clean and adjust the blade *

Blade not positioned

properly

Check that the blade is bottomed out against

the mounting bolts *

Blade is dirty Clean blade and lubricate the oiler pad on the

blade guard *

Blade in backwards Mount the blade so that the beveled edge is

away from the entrance end of the head *

Blade spring guard Replace the defective spring

TROUBLESHOOTING (cont’d)

This manual suits for next models

8

Table of contents

Other BestPack Food Saver manuals