BestRest Products R11 GS Series User manual

BestRest Products, LLC

http://www.bestrestproducts.com 6908 - 220th St. SW (425) 673-1023

___________________________________________________________________________________________

1

BackRest Installation R11xxGS

“Classic” Model – Stainless Steel Frame

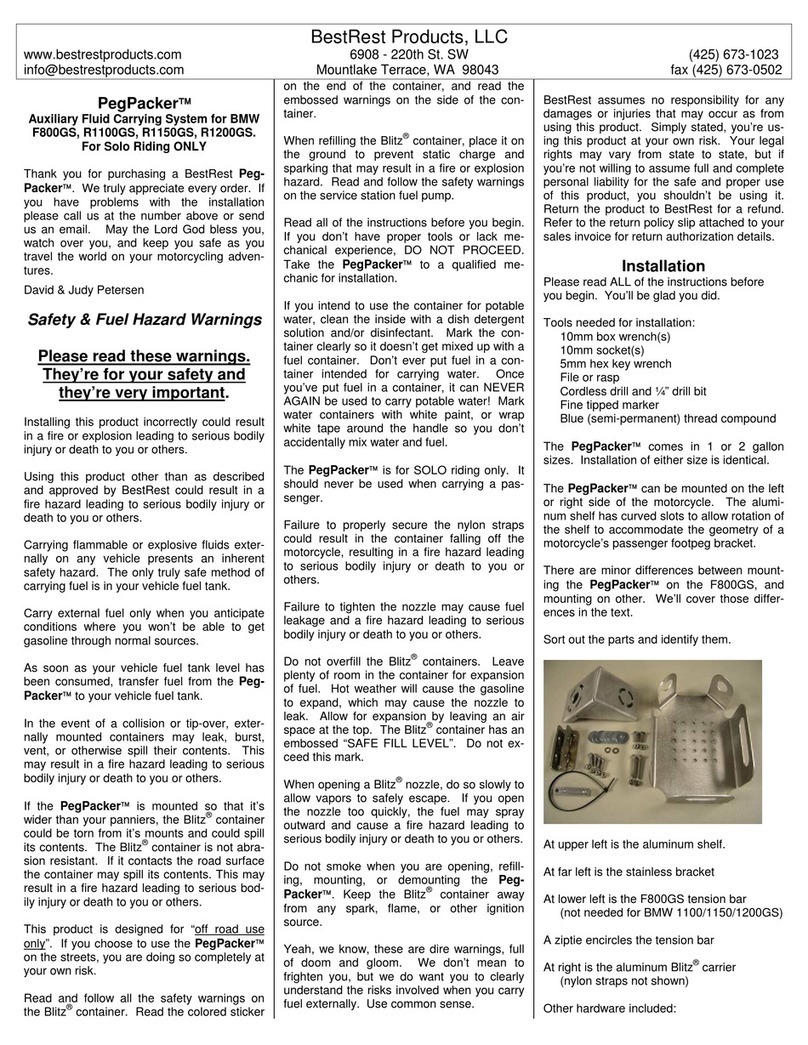

Thank you for purchasing a BestRest

BackRest! We’re confident it’ll improve your

riding comfort and expand your riding

adventures.

If you have problems with installation or

operation of the BackRest please call us at

the number on the letterhead.

Ride safe and God Bless!

David & Judy Petersen

FOR PROPER INSTALLATION &

SAFE OPERATION, PLEASE

READ ALL INSTRUCTIONS

BEFORE STARTING

Unpack the BackRest Assembly and parts

bag from the shipping container. For the

R1100/R1150GS you should have the

following items:

2 - M5 x 12 button head cap screws

2 - M6 x 40 socket head cap screws

2 - M6 x 25 socket head cap screws

2 - M6 nylon locknuts

2 - #10 flat washers (small)

4 - #12 flat washers (large)

2 - 6mm split ring lock washers

1 - Front (long) subframe bar

4 - Rubber grommets

1 - 5 mm hex wrench

Remove the two large ring-pins holding the

BackRest in the folded position by gently

pulling on the rings. These ring-pins have a

detent ball and will “click” as they clear each

hole.

Unfold the BestRest. As you do this the Slide

Assemblies in the middle of the BackPlate

will drop down. Align the 5/16” holes at the

ends of the Lower Slide with the holes in the

two upright Rear Posts. Reinsert one of the

5/16” ring-pins thru these four holes to secure

the BackPlate the upright position. Store the

remaining ring-pin in one of the two

remaining storage holes. As you move the

BackPlate thru its full range of motion you

may need to remove the second ring-pin and

relocate it to another storage hole.

See page 3 for information on how to

configure, adjust, and secure your BackRest.

BackRest In Rider’s Position

(Only for R11xxGS)

1. Remove passenger seat and toolkit lid.

Remove the 6mm screw holding the rear of

toolbox. (Fig. 1)

Fig. 1

2. Rotate rear of toolbox upward, then pull

gently rearward (Fig. 2). The front of the

toolbox is held in place by two plastic tabs

that fit into the forward cross frame member.

Fig.2

3. Installation of the Subframe Bar. To hold

the BackRest Assembly onto the motorcycle,

you must install a Subframe Bar (Fig. 3). It

will fasten beneath the cross frame rail, which

is located just in front of recess for the

toolbox. (Fig. 3 shows Subframe Bar next to

the cross frame rail.) Two M5x12 pan head

screws hold this Bar tightly against the

underside of the rail, preventing the Bar from

shifting. The larger 6mm holes are for the

screws that hold the BackRest in place. All

four screws will pass thru the two small slots

in the frame as shown in Fig. 3.

Fig. 3

Special note: The Subframe Bars shown in

these photos are prototypes without the

pressed screw fittings.

Special note: The Subframe Bar is marked

“UP” on one side. Make sure that the Bar is

mounted properly or the pressed screw

fittings may come loose. The fittings should

be on the bottom of the bar.

4. To assist placing the Subframe Bar under

the cross rail, we suggest using a small nylon

ziptie or piece of string. Insert the tie thru the

hole in the Bar and thread the end of the tie

up thru the small slot in the frame (Fig. 4a).

Pull the Subframe bar into place (Fig. 4b).

It’s much easier this way!

Fig. 4a

Fig.4b

5. Once the Subframe Bar is in place

beneath the frame, LOOSELY thread the two

M5x12 flat head screws (with flat washers)

into the Bar (Fig. 5a).

We recommend use of a semi-permanent

thread-locking compound to hold these 5mm

screws. “Blue Thread Lock” will prevent the

screws from coming loose, which would

cause the Subframe Bar to drop or otherwise

move out of alignment. Do NOT use a

permanent (red) thread compound.

Fig. 5a

The two (empty) M6 screw holes must be

equidistant left and right. They must also be

centered fore and aft in the slots (Figs. 5b –

5c). If they’re offset in any axis, adjust the

Subframe Bar as needed. It’s important to

align the bar properly or you’ll have difficulty

inserting and threading the BackRest hold

down screws.

2

Fig. 5b Fig. 5c

Finished installation of the Subframe Bar

should look like Fig. 5d:

Fig. 5d

6. Now that you’ve temporarily fitted the

Subframe Bar, it’s time to mount the

BackRest assembly onto the frame. The

BackRest has “hooks” on the underside,

beneath the black plastic spacer. The hooks

fit into the two large slots shown in Fig. 6a.

Fig. 6a

Fit the hooks into the frame slots, lowering

the BackRest so it’s sitting on the frame, then

slide rearward 3/8” to engage the hooks as

shown in Fig 6b.

Fig. 6b

Once the hooks have been inserted into their

slots and the assembly is moved rearward

3/8”, the M6 holes in the BackRest Carrier

Plate should align with the 6mm holes in the

Subframe Bar you’ve just installed. First time

fitting may be snug; if this occurs, gently tap

the BackRest rearward with a rubber mallet if

necessary. Do not use a steel hammer or

other hard instrument! If you encounter

problems also check to ensure the Subframe

Bar has not shifted out of alignment.

7. If the holes are aligned, insert the M6 x

20mm screws (with lock and flat washers)

into the holes shown in Fig. 7. The screws

should thread easily into the Subframe Bar.

If necessary remove the BackRest and adjust

the Subframe Bar for the best fit, then tighten

the M5 screws holding the Subframe Bar in

place. Replace BackRest and check again

for alignment - this may take a couple tries.

Once you’re satisfied everything is correct,

snugly tighten the small M5 screws, locking

the Subframe Bar in place. Use common

sense and do not over-tighten the screws or

you’ll damage the threaded fittings. The

purpose of these M5 screws is to keep the

Subframe Bar from shifting – there are no

structural requirements involved.

Fig. 7

Note: The Subframe Bar may be left in place

indefinitely; it will not interfere with placement

of the Rider or Passenger seats, or the

toolkit.

8. After you’ve confirmed proper location of

the Subframe Bar, replace the toolkit (Fig. 2,

reverse process). Slide the two front plastic

tabs of the toolkit into their slots in the frame

and tighten the screw at the rear of the

toolbox (Fig. 1). Replace the toolkit lid.

9. Reinstall the BackRest in the Rider’s

Position (Fig 9).

Fig. 9

Remember to fully tighten both two M6x25

screws. Use common sense and do not

over-tighten. These M6 screws should be

checked on a frequent basis to confirm

they’re secure, since they hold the BackRest

in place on the motorcycle.

Removal of the BackRest is easily

accomplished by removing the two M6x20

screws. Slide the BackRest slightly forward

and lift up. You may then place the

Passenger seat back in place if desired.

Note: You can store the M6x25 screws in

their respective holes but you cannot fit the

passenger seat if these screws are in place.

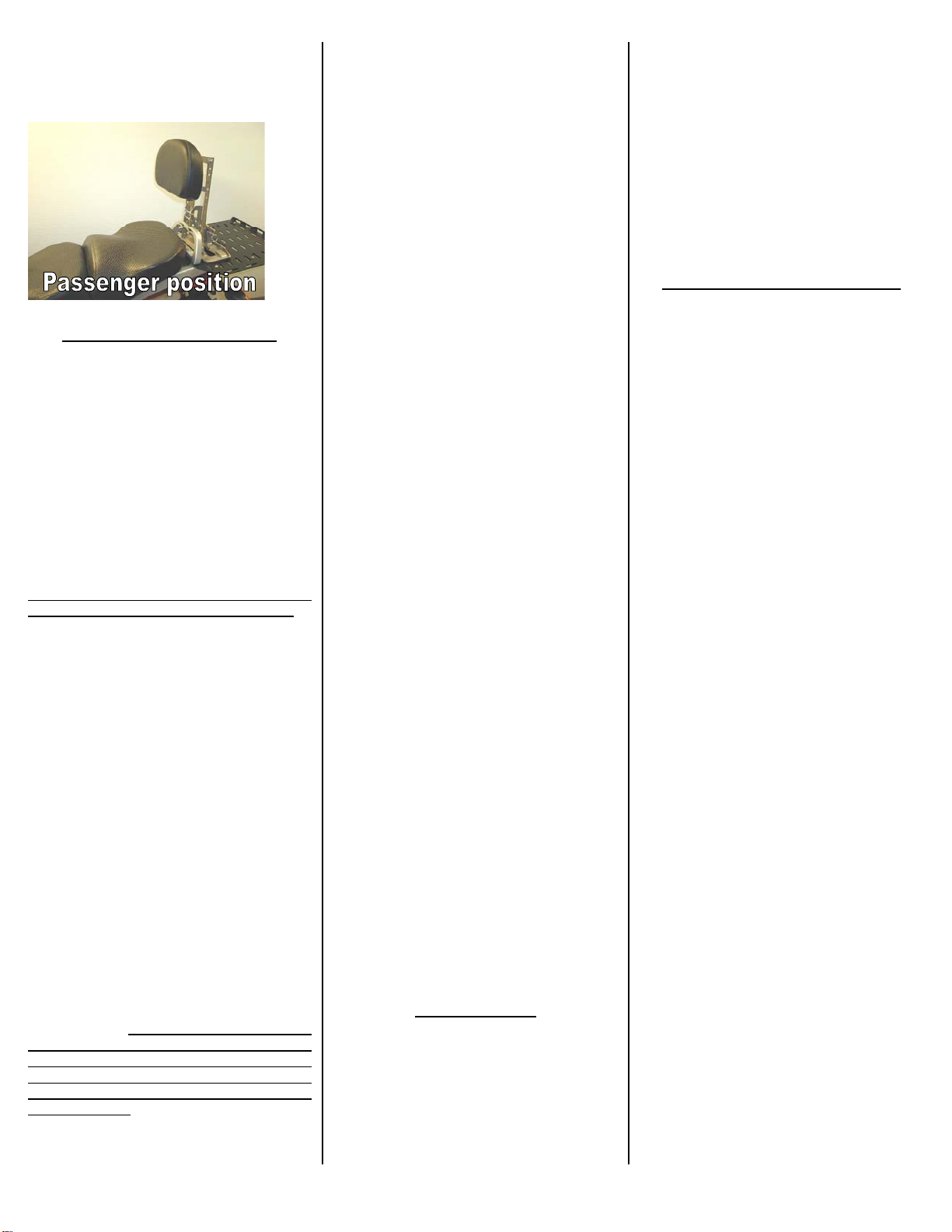

BackRest In

Passenger Position

1. Read the above instructions to familiarize

yourself with BackRest installation in the

Rider Position.

2. Install the BestRest CargoRest according

to instructions, per your specific model.

3. The hooks on the underside of the

BackRest (Fig. 6b) fit into the two square

slots machined in the CargoRest (Fig. 10).

Model C is shown below; Models J and T

have similar hole and slot patterns.

Fig. 10

4. Lower the BackRest onto the CargoRest

and slide the BackRest assembly slightly

rearward so the M6 holes align with the holes

in the CargoRest (Fig. 10). These holes will

also line up with the threads in the Subframe

Bar, beneath the CargoRest. Insert the

M6x40 screws (with lock and flat washers)

and tighten. Use common sense and do not

over-tighten. To provide added strength

and security we’ve included two extra M6

nylon locknuts. While not required, we

recommend attaching them to the bottom

ends of these M6 x 40 screws.

Note: If the stock grab rail prevents the

BackRest from fitting down onto the

CargoRest, change the angle of the

BackPlate. Once in place, readjust to the

desired angle and tighten the screws.

Removal of the BackRest is easily

accomplished by removing the two M6x40

screws. Slide the BackRest slightly forward

and lift up. When the BackRest is not in

place on the CargoRest store the M6x40

screws by threading them down thru the

3

CargoRest and into the Subframe Bar. This

way you’ll never misplace them.

When installed in the passenger position, the

BackRest should look like Fig. 11.

Fig.11

Adjusting The BackRest

The patented BestRest Products BackRest is

infinitely adjustable. As you examine the

various assemblies, you’ll see how easy it is

to adjust the height, angle and pitch for your

comfort and riding style.

Take note of the nylon locknuts fitted to the

ends of the M6 screws that adjust the swing

arms and back pad. The nuts are there to

prevent the screws from vibrating loose and

falling out along the road. The nuts don’t

need to be tightened, and should be left as

they come from the factory.

Adjustments to the BackRest should never be

attempted when operating the motorcycle. If

adjustments are needed, come to a complete

stop, turn off the ignition and secure the

motorcycle against tipping or falling. Make

any required adjustments, then tighten all

screws, fittings and fasteners. Quick release

ring-pins must be fully inserted and locked in

place. Before resuming travel, inspect

carefully to ensure all parts are in place and

properly secured.

To change the angle of BackRest:

1. Loosen the two M6 screws located

on the Upper Slide, allowing it to

move over the top of the Lower

Slide. This sliding movement results

in a change of the BackPlate angle.

2. Adjust the angle as needed and re-

tighten all screws.

The Upper and Lower Slides are screwed

together in the most common setting. If you

require more range of movement, remove the

nylon locknuts and M6 screws and replace

them in two of the five holes found on the

Lower Slide. Note – Always install BOTH

M6 screws and tighten securely! Do NOT

rely on one screw to hold the Upper and

Lower Slide in place. Failure to use both

screws may result in unexpected movement

of the BackRest!

To change the angle or height of the

BackPad:

1. Loosen the eight M6 screws holding

the four SwingArms, adjust as

needed, and tighten.

2. Note that as the BackPad is moved

thru its arc of rotation the pad moves

up/down as well as forward/back,

always staying parallel to the

BackPlate.

To change the elevation of the BackPad:

1. Remove the eight M6 screws,

locknuts, and four SwingArms.

2. Move the BackPad up/down along

the BackPlate to the required height.

Replace the M6 screws and

locknuts and tighten securely.

Changing the four SwingArms from their

factory setting (parallelogram) to a trapezoid

allows the BackPad to change pitch as it

rotates in its arc of motion. You can

experiment with these settings to get exactly

the configuration you require.

To store your BackRest horizontally:

1. To lower the Backrest, pull both

ring-pins and allow the BackPlate to

fold rearward.

2. As you do so, lift the Slide

Assemblies until they’re parallel with

the BackPlate. The 5/16” holes in

the BackPlate Angle will align with

holes in the two Rear Posts.

3. Insert a ring-pin thru all four holes,

locking the BackPlate in a horizontal

position.

4. Insert the other ring-pin into the

holes in the Upper Slide and the

BackPlate Angle. This will lock the

Slides in a horizontal position and

keeps them from damaging the top

of your toolkit.

5. If the top of the BackPad hits the

BMW grab rail when the BackRest is

folded, loosen the SwingArms and

move the BackPad slightly forward.

You can strap duffels and other gear over a

folded BackRest, however it is NOT designed

to handle the weight of a Passenger.

Excessive loading will void any warrantees.

Do not remove or adjust the spring circlip or

clevis pin holding the Upper and Lower Slide

Assemblies to the BackPlate Angles.

Helpful Hints:

Lanyard – Later production models come with

a stainless steel lanyard connecting the two

ring-pins. If yours does not have a lanyard,

make one from nylon cord or other line to

prevent loss of the ring-pins. Tie one end

thru a hole in the BackRest, pass the cord

thru one ring-pin and tie the cord to the

second ring-pin. Adjust the length of the

lanyard as needed – we’re found a 12” cord

is the best size.

Hex wrench storage - We’ve provided a set of

storage holes for your hex wrench, so it’s

always available to adjust or remove the

BackRest. Look for two small holes drilled

near the bottom of the Rear Posts. Pass

your hex wrench thru these holes and slide

the rubber grommets onto the wrench, two on

each end. This effectively locks the wrench in

place until needed. The grommets are NOT

meant to fit into the holes of the posts.

Caring For Your BackRest:

The BackRest assembly and the mounting

hardware are made from high quality

stainless steel. While not completely ‘rust-

proof’, they exhibit excellent corrosion

resistant qualities. To further protect the

finish we recommend a light coating of paste

wax or silicone protectant.

Wash the BackRest with a solution of mild

detergent and water. Use common sense, so

water does not penetrate the seams and

saturate the padding of the BackPad. A

plastic bag over the BackPad helps prevent

this.

While it’s OK to leave the BackRest exposed

to the elements for short periods, we strongly

suggest protecting your investment with a

tarpaulin or other covering, or park your bike

inside, away from acid rain and UV rays.

Occasionally lubricate the main hinge point of

the BackRest, using a lightweight, non-

penetrating oil. Do not lubricate other contact

points since they rely on friction to hold the

angle you’ve set.

Do not use penetrating agents or solvents

since they may attack the thread locking

compounds used in assembly. Solvents may

also affect the nylon inserts on the locknuts

and or the nylon spacer on the bottom of the

BackRest.

Do not attempt to loosen the small M4 screws

that connect the BackRest subassemblies.

These are secured at the factory with a

permanent thread-locking compound. In the

unlikely event they come loose, retighten

them, using a permanent thread compound.

The finish on the BestRest is obtained with a

random orbit sander and 150 grit aluminum

oxide abrasives. You can touchup your

BackRest with fine sandpaper or ScotchBrite

pads. DO NOT USE STEEL WOOL, since it

will ‘infect’ the stainless steel surfaces with

iron oxides, causing rust to form. If rusting

does occur, sand the affected areas gently to

remove any rust spots, then apply a coat of

wax, silicone, or other quality protectant.

4

Safety Inspections and

Consumer Warnings

Do not proceed with installation unless you

are qualified to complete the installation in a

safe fashion and as described herein. Do not

use these products unless you have read all

of the instructions and understand how these

products work and what limitations, if any,

they may have. Failure to read and follow

these instructions could result in serious

bodily injury or death!

It is the Consumer's responsibility to inspect

all screws, fasteners and fittings on a daily

basis, tighten or replace them as necessary,

and to regularly inspect the entire BestRest

System for signs of missing parts, excessive

wear, metal fatigue, or imminent failure.

Should any of these be observed the

BestRest System should be removed from

the motorcycle and not used until inspected

and repaired by BestRest Products.

It is the responsibility of the Consumer to

evaluate the suitability of these products for

personal use. Consumers must evaluate

whether these products meet their needs and

whether these products can be mounted and

used in a safe fashion. The Consumer

accepts full and complete responsibility for

selection of products and for mounting and

maintenance of these products. The

Consumer agrees to follow and abide by any

and all instructions, recommendations,

warnings, or other information supplied or

published by BestRest Products, LLC.

BestRest Products, LLC, it's employees,

agents, and owners assume no liability of any

kind whatsoever for property damage,

personal injury or other losses resulting from

the Consumer’s failure to properly install or

maintain these products, for unauthorized

modifications of any kind, for use of

unauthorized parts (including bushings,

screws, pins, or other fasteners), or for

misuse of any BestRest Product in a fashion

not intended by BestRest or described as a

suggested application in BestRest literature.

Because installation of these products is

done by others outside our control, we cannot

assume any liability or responsibility

whatsoever for improper or unsafe installation

or items installed contrary to the latest

published instructions, that are improperly

secured or maintained, that are improperly

tightened or otherwise secured, or which are

otherwise improper fitted to the motorcycle.

Only authorized BestRest replacement parts

(assemblies, screws, fasteners or fittings)

shall be used when mounting or installing any

BestRest products. Authorized replacement

parts may be purchased only from BestRest

Products. Parts from other sources or

vendors are not covered under warrantee

and will void any Consumer claims against

BestRest or others. Any use, modifications,

or applications of any BestRest Product,

other than those authorized by us in writing,

are specifically prohibited.

BestRest, BestRest System, BestRest-GS,

BestRest Products, BackRest, and

CargoRest, BackPad, designs and logos are

all trademarks of BestRest Products, LLC.

The BestRest System is registered and

patented with the US Patent and Trademark

Office. Please respect our Trademark,

Copyright and Patent rights.

Rev. 05/15/03

©2003 BestRest Products LLC

This manual suits for next models

2

Other BestRest Products Motorcycle Accessories manuals