Bettcher AirMax Mach 3 Installation guide

AirMax Mach 3 Maintenance Overview

A I R M A X

™

Click Here

for Video

Click Here

for Video

Large Hex

Wrench

#184128

Spanner

Wrench

#184134

Top Plate

Removal Clamp

(2 Required)

#184255

Cup

Assembly

#184246

Rotor Removal

#

Punch 184254

Gear Teeth

#

Cap 185977

Bearing Tool

#185978

#

Air Motor Maintenance Kit 185975 Additional Maintenance Kit Tools

The Proper Tools

To perform maintenance on the AirMax power unit it is essential to have

the proper Bettcher maintenance tools and lubricants. Proper

maintenance and lubrication will improve tool performance and parts life.

Base Assembly

#185976

T a b l e o f C o n t e n t s

Tools for Power Unit . . . . 1

Proper Lubrication . . . . . . 2

Power Unit Maintenance . . . 3

Power Unit Reassembly . . . 4

Handle Assembly . . . . . . . 5

Head Attachment . . . . . . 6

Pa r t s L i s t . . . . . . . . 7

Lubricants for Air Tools . . . 8

Note: This is an interactive

PDF. Click on the blue

hyperlinks and Video icons

to see additional content.

INTERACTIVE

PDF

Please review Operating Instructions for complete instructions & safety information.

Air motors after 80 hours

of operation without

proper lubrication.

Add Whizard Oil

to exhaust ports

™

AirMax Mach 3 Lubrication

Proper lubrication improves both performance and parts life.

Lubrication

Proper lubrication of the AirMax™ power unit is an

important part of daily operation. It is essential to maintain a

proper amount of lubrication inside the power unit while the

tool is running. The absence of proper lubricant will destroy

the vanes and cause premature wear on cylinder parts. In

addition, be sure the air pressure and volume are optimal and

the air supply is clean and dry.

Daily Checklist

1. Constant air pressure of 90 psi (6,2 bars).

Do not exceed 100 psi.

2. Air volume is 14 cfm (396 lpm).

3. The filter bowl (on FRL) should be drained and the

lubricator refilled with ®

Bettcher Whizard Food Grade

Multipurpose Oil Whizard Oil ( - Part #103603).

4. Lubrication on FRL is set at three drops per minute.

After Every 80 Hours

1. Completely disassembly the power unit. Disassembly

information on this can be found on the following pages.

2. Lubricate the gear head by injecting ™ high Max-Z-Lube

performance grease into Gear Head Assembly. See Figure 2

on this page. Max-Z-Lube Part #184282.

®

3. Lubricate air motor with Whizard Oil through the exhaust

ports. See Image Directly Below.

Inspect the seal plate for nicks, dents

or wear. Inspect the O-Ring seal for

cracks or cuts. Replace if damaged.

Re-grease gear head using Max-Z-Lube

grease every 80 hours. The new grease

will push out the old, dirty grease.

Part #184282

2

1

Max-Z-Lube Lubricant

is a high performance

lubricant that provides

valuable protection for

moving parts. This super

slick formula provides

optimum protection from

friction, oxidation and

high temperatures. This is

the best lubricant for your

®

AirMax motor.

Order Part #184282.

The AirMax™ Mach 3 motor delivers

high levels of torque over a wide range

of speeds. To keep the motor operating at peak

efficiency, it should be cleaned and inspected after every

80 hours of usage.

As long as there is no performance loss, most of the

inspection of the air motor can be done without disas-

sembly. However, if the operator mentions a loss in

power, use the following procedure. For complete instruc-

tions refer to the AirMax™ Mach 3 Operating Instructions.

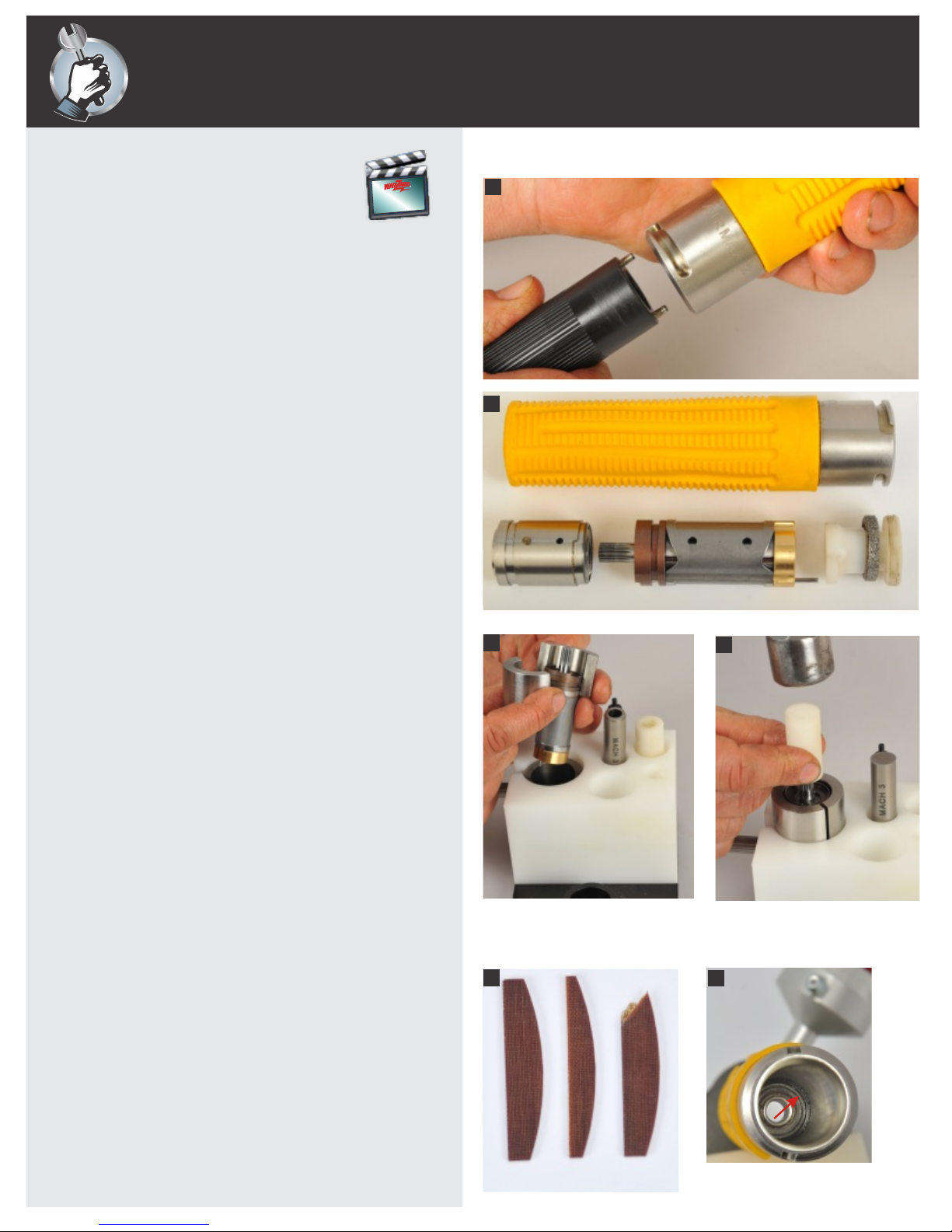

Air Motor Disassembly

1. Tool and Maintenance Kit #185975 is required to

dissemble a Mach 3 trimmer.

2. Unscrew retainer using the spanner wrench. Note:

This is a left-hand thread and must be turned right

(clockwise) to unscrew. Slide components out of

handle. If parts don't slide out easily, tap the handle

lightly against a plastic block to dislodge.

3. Separate the motor from the gear head and adapter.

4. Place the upper bearing plate removal clamps around

the upper bearing as shown in Figure 3.

5. Using a hammer and plastic sleeve, tap the gear teeth

cap until the rotor is free from the upper bearing

plate. Figure 4. Remove the upper bearing and

cylinder.

6. Remove vanes from the rotor and inspect for

chipped or broken tips, grooves and vane height.

Replace vanes with grooves more that .010" (.25

mm) deep or with a height less than .195" (.5 mm).

Next, inspect the rotor for cracked, broken teeth, or

excessive wear.

Inspect

¨Clean buildup out of inlet and exhaust ports

¨Check gear teeth for cracks or damage. Worn teeth

are indicated by rounded or pointed tops

¨Inspect guide pin to verify it is not bent

¨Check the cylinder interior for grooves

¨Replace any parts that are damaged or worn

¨Check vanes as shown in Figure 5

¨Verify the O-Ring is inplace inside handle Figure 6

Place air motor in bearing plate assembly tool and

tap to remove.

™

AirMax Mach 3 Power Unit Maintenance

Maintenance tips that improve both performance and tool life

Gear Head Mach 3 Air Motor Adapter, Muffler

Retainer

2

34

New Worn Broken Make sure O-Ring

is seated.

56

Note:

Left-hand thread

1

Click Here

for Video

Click Here

for Video

Reassembly

Oil is the lifeblood of any motor. Not only does it lubricate

moving parts, it dissipates heat and prevents corrosion.

The quality of oil is equally important … too little, too thin

or too thick will either reduce performance or motor life.

Use only ®

Whizard Food Grade Multipurpose Lubricating

Oil ®

Part #103603 (Whizard Oil ) as a high quality, long-

lasting lubricant that will protect your trimmer investment.

Lubricate and Reassemble Air Motor

1. Saturate vanes with before assembly.

®

Whizard Oil

2. Insert the vanes with the curved side toward the

rotor center.

3. Slide the cylinder over the rotor and add a small amount

of around the top of the rotor assembly.

®

Whizard Oil

Note: The alignment pin in the bearing plate inserts

into the alignment hole in the cylinder. Make sure the

exhaust notches line up.

4. The upper bearing plate is installed by first inserting the

alignment pin of the lower bearing plate into the

alignment hole in the base of the assembly tool fixture.

5. Place the upper bearing plate onto the cylinder and then

the bearing. Using a hammer and the bearing tool, tap

the bearing tool until the bearing plate is fully seated on

the cylinder.

6. The air motor is now assembled and the shaft should

rotate freely.

®

Add a small amount of Whizard Oil and then place in

the maintenance tool block.

Saturate vanes and insert in rotor, curved side

towards rotor.

Mach 3 Air Motor — Reassembly

3

1

4

5

2

Using the bearing tool and hammer, tap bearing onto

cylinder. Make sure notches are aligned (note circle).

Assembled

Motor

• Use one FRL for each trimmer.

• Constant 90 psi (6,2 bars) at a

volume of 14 cfm (396 lpm).

• Filter bowls should be drained

and lubricator refilled daily.

• Oil should be set for three drops

®

per minute of Whizard Oil for

proper lubrication and protection.

Performance Tip

Click Here

for Video

Click Here

for Video

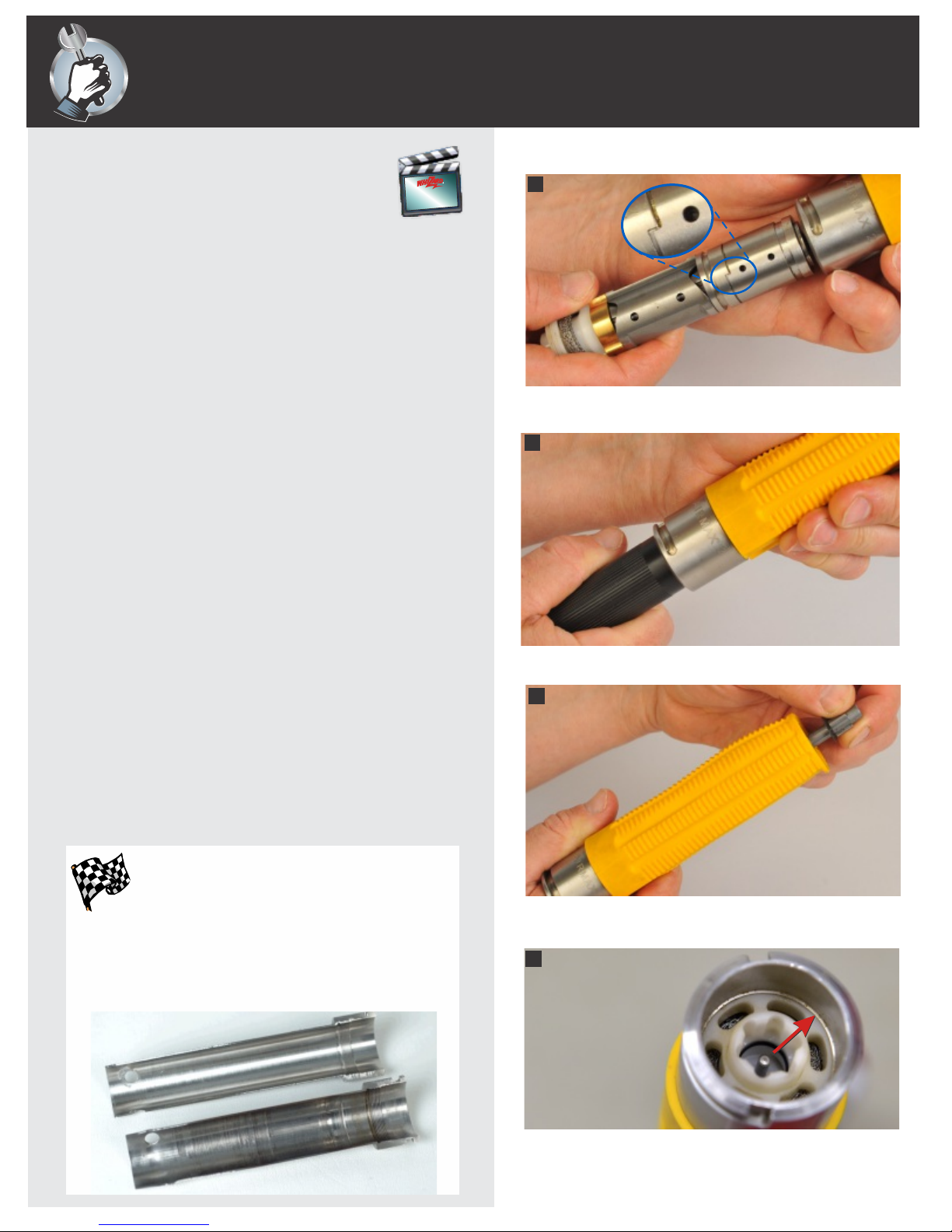

Assembly of the Power Unit

Holding the handle ‘up’ and all the power unit components

together, slide them up into the handle. With all the components

together and the handle in the ‘up’ position, components are less

likely to get misaligned.

Spin and Tighten

To insure power unit components stay aligned when installed into

the handle, use the following procedure:

1. Using the spanner wrench, snug the retainer (Figure 2).

This is a left-hand thread. Counter-clockwise tightens.

2. Place the driver adapter into position and rotate the air

motor back and forth a few times (Figure 3).

3. Snug the retainer again, using the spanner wrench

(Figure 2), then rotate the driver and air motor back and

forth (Figure 3) with the driver adapter.

4. Repeat the process one last time.

5. The drive adapter should turn freely in the power unit.

6. Using the spanner wrench, make sure the retainer is tight after

each days use, as the retainer may loosen with time or usage.

7. When the motor is properly installed one or two threads will

be visible (Figure 4). If there are more threads the O-Ring

may be missing. No threads visible – either Step 1 or 3 was

not done correctly.

Power Unit Alignment & Installation

Align the power components and push up

inside the AirMax™ handle.

Snug the retainer using the spanner wrench.

Using the driver adapter, rotate the air motor

back and forth.

When the air motor is properly installed there

will be one or two threads visible — too many

or no threads means miss installation.

1

3

2

Note:

Left-hand thread

What happens with an

improperly seated power unit ...

An improperly tightened power unit will spin

inside the handle, causing a total loss of power and

damage to the handle. The procedures on this

page will prevent this.

Performance Tip

Cut-a-way

of AirMax™ Handle

Click Here

for Video

Click Here

for Video

4

Attachment and Adjustment

To ensure a proper, comfortable fit, several options

are available for the AirMax™. Select from left- or

right-handed frame configurations, and the thumb

support or spacer ring. The frames are designed with

several notches to allow the most comfortable

position of the handle and thumb support for the

operator.

AirMax™ Mach 3 handles are available in either

yellow or dark blue. The dark blue handle is typically

used with the TrimVac™ for processing cattle over

the age of 30 months.

Step 1

Select the spacer ring or optional thumb supports. If

a spacer ring is used, slide the spacer ring onto the

frame, small end first.

If the thumb support is used, it should be positioned on

the side opposite the grease cup. Align the thumb

support tab with a notch on the frame and slide the

thumb support onto the frame.

Step 2

While holding the AirMax™ frame, align the pin in

the handle with one of the notches on the frame. For

the initial adjustment the short groove on the handle

should be facing up.

Next, let the operator test the assembly. Make

adjustments for the most comfortable fit.

Step 3

Insert the attachment screw in the frame and tighten

firmly using the supplied hex wrench.

Note: Recommended torque:

115-140 lb-in ( 13-16 N-m ).

Thumb Support

Short

Groove

Spacer

Ring

™

AirMax Mach 3 Head Attachment

The operator can choose whether to use the

thumb support or not.

Align the short groove with the notch in the frame.

Secure the Hex Wrench in a vice and turn the trimmer

to the recommended 115 - 140 lb-in of torque.

1

3

2

Never put the AirMax™ handle into a vice,

this will crush the hollow handle.

X

Mach 3 Power Unit and Motor Parts List

#

Cap 184286

Seal Block

#184062

Seal Kit

#184427

Gear Head

Assembly

#185935

Air Motor

Assembly

#185942

Adapter Plate

Assembly

#184047

Muffler

#184388

Retainer

#184049

Upper

Bearing

#185950

Upper

Bearing

Plate Assy

#185948

Cylinder

#185947

Rotor

#185944

Vane Kit

(5 Vanes)

#185790

O-Ring

#122316

O-Ring

#122316

Lower

Bearing

#184046

Lower Bearing

Plate Assy

#184042

(Spacer)

#184043

Complete Air Motor

#185942

#

Complete Power Unit Assembly 185923

#

Handle with O-Ring 185927

AirMax™ Mach 3 – Handle Color Options

Dark blue handle for cattle over 30 months.

#

Complete Power Unit Assembly 185924

#

Handle with O-Ring 185928

www.bettcher.com

Headquarters: 6801 State Route 60 • Birmingham, OH 44816

Tel: (440) 965-4422 • (800) 321-8763 • Fax: (440) 965-4900 • E-mail: service@bettcher.com

AirMax Lubrication

Proper lubrication improves both performance and parts

Whizard Oil

Specially formulated oil for air tools.

Essential for adding protective

lubrication to the AirMax motor,

®

AirShirz and all FRL (Filter,

Regulator, Lubricator)

Whizard Multipurpose

Lubricating Oil

#

16 Fluid oz 103603

Whizard Multipurpose

#

Lubricating Oil 103603

Performance lubricant that delivers

superior protection for high RPM

gear-head. Super-slick formula

provides premium protection from

friction, oxidation and high tempera-

tures. This is the best lubricant for

®

your AirMax gear head assembly.

4 oz. Tube

#184282

Premium, high-speed, long-lasting

synthetic lubricant tailored to exceed

the demanding conditions of USDA

inspected meat, poultry and food

processing facilities. Formulated for

all Whizard Trimmer grease cups for

better performance and protection.

13.5 oz. Cartridge

#102609

®

HIGH PERFORMANCE GREASE

MA X L U B E

HI G H P E R F O R M A N C E L U B R I C A N T Formulated for extended high

RPM performance and superior

#

gear head protection 184282

Performance and protection for

#

all trimmer models 102609

TS102 3.7.2018

Table of contents