Contents

Safety...........................................................................4

Operation...............................................................4

SoundPressure.......................................................6

Vibration................................................................6

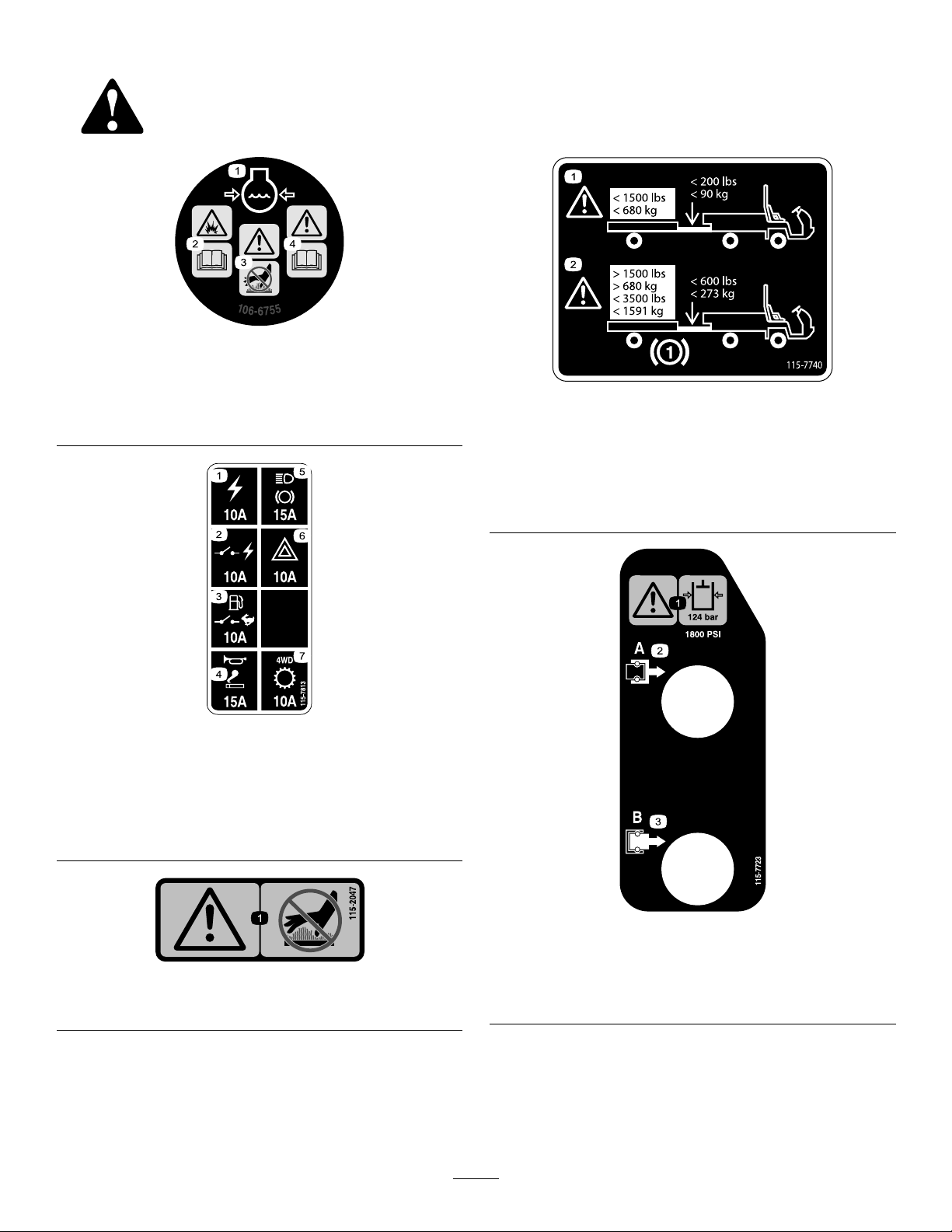

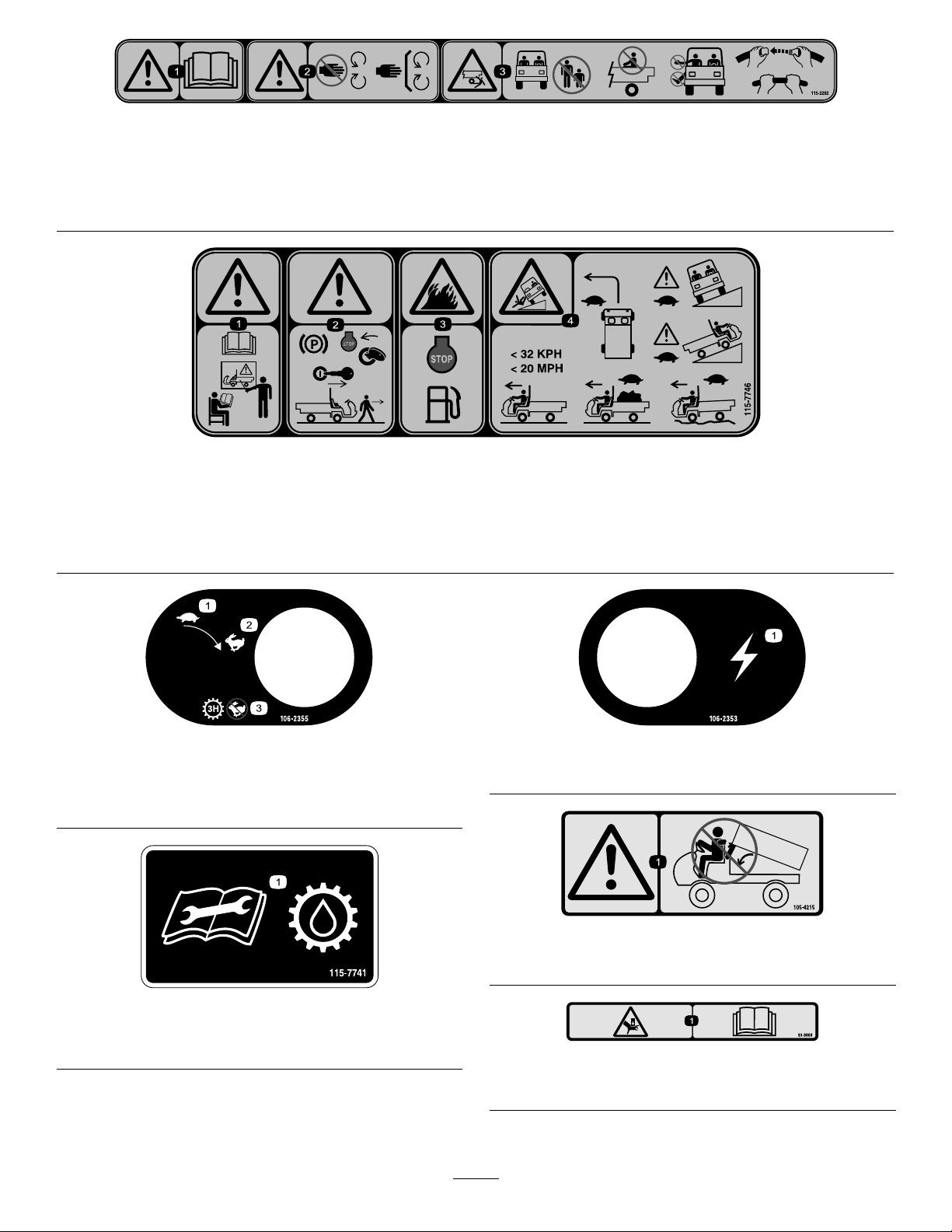

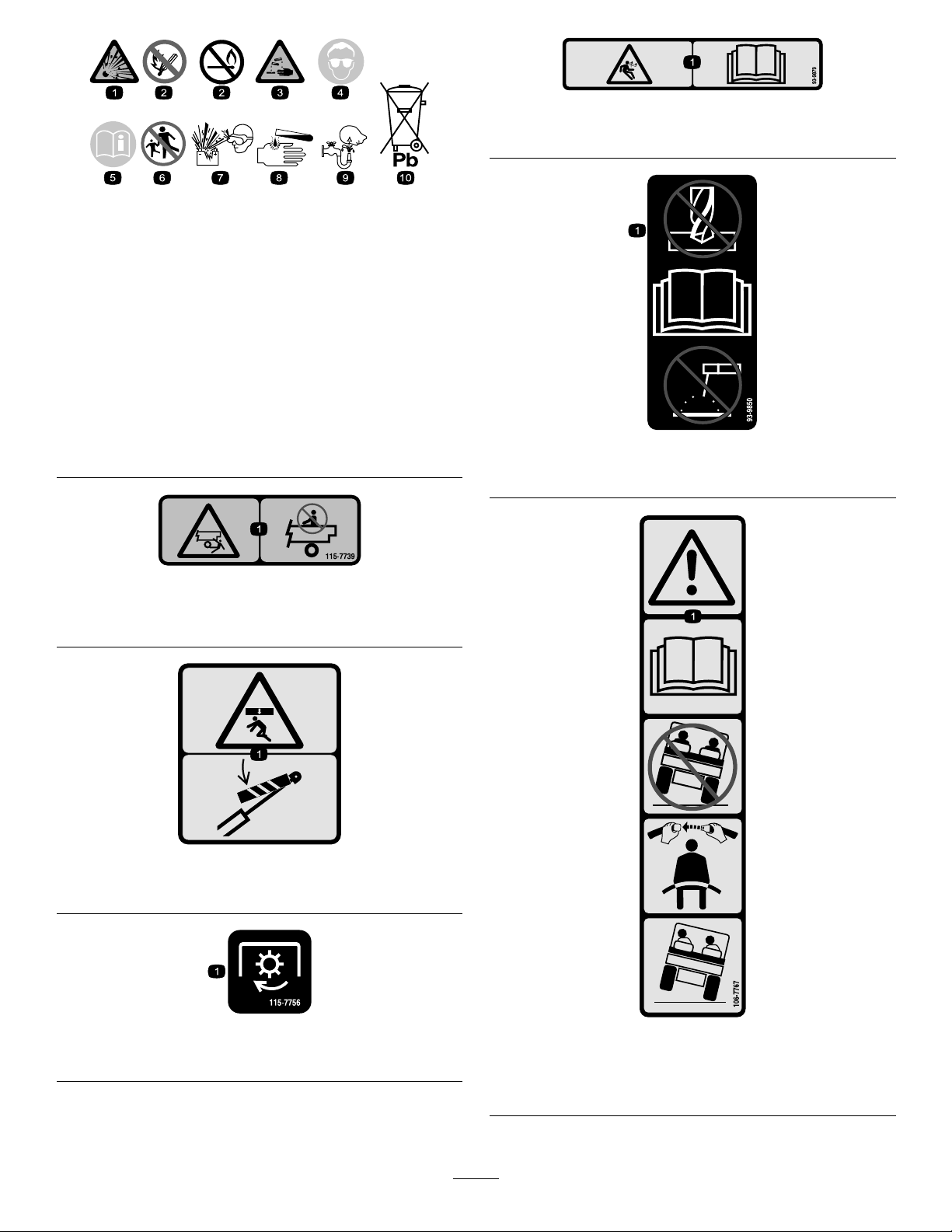

SafetyandInstructionalDecals.................................7

Setup...........................................................................12

1InstallingtheSteeringWheel(TCmodels

only).................................................................12

2InstallingtheRolloverProtectionSystem

(ROPS).............................................................12

3CheckingtheFluidLevels.....................................13

ProductOverview.........................................................14

Controls...............................................................14

Specications........................................................17

Attachments/Accessories........................................17

Operation....................................................................18

OperatingtheCargoBox.........................................18

CheckingtheEngine-oilLevel..................................19

AddingFuel...........................................................20

CheckingtheCoolantLevel.....................................21

CheckingtheTransaxle/Hydraulic-uid

Level.................................................................21

CheckingtheHighFlowHydraulic-uidLevel(TC

modelsonly)......................................................22

CheckingtheFront-differential-oilLevel(4-wheel

drivemodelsonly)...............................................22

CheckingtheTorqueoftheWheelNuts.....................23

CheckingtheTirePressure......................................23

CheckingtheBrake-uidLevel.................................23

StartingtheEngine.................................................24

DrivingtheVehicle.................................................24

StoppingtheMachine.............................................25

StoppingtheEngine...............................................25

BreakinginaNewMachine......................................25

CheckingtheSafety-interlockSystem........................25

EnsuringPassengerSafety.......................................26

EnsuringProperSpeed...........................................26

EnsuringProperTurning.........................................26

EnsuringProperBraking.........................................26

PreventingTipOvers..............................................27

OperatingonHills..................................................27

LoadingandDumping............................................27

UsingtheDifferentialLock......................................28

Using4-wheelDrive(4-wheeldrivemodels

only).................................................................28

TransportingtheMachine........................................28

TowingtheMachine...............................................29

TowingaTrailerwiththeMachine.............................29

UsingtheHydraulicControl....................................29

Maintenance.................................................................32

RecommendedMaintenanceSchedule(s)......................32

OperatinginAdverseConditions..............................33

PremaintenanceProcedures........................................34

UsingtheBedSupport............................................34

RemovingtheFullBed............................................35

InstallingtheFullBed.............................................35

RaisingtheMachine................................................36

RemovingtheHood...............................................37

InstallingtheHood.................................................37

Lubrication...............................................................38

GreasingtheBearingsandBushings..........................38

EngineMaintenance..................................................40

ServicingtheAirCleaner.........................................40

ChangingtheEngineOilandFilter...........................40

FuelSystemMaintenance...........................................41

CheckingtheFuelLinesandConnections..................41

ServicingtheFuelFilter/WaterSeparator...................41

ElectricalSystemMaintenance....................................42

ServicingtheFuses.................................................42

JumpStartingtheMachine.......................................43

ServicingtheBattery...............................................44

DriveSystemMaintenance.........................................44

ChangingtheFront-differentialOil(4-wheeldrive

modelsonly)......................................................44

InspectingtheConstant-velocityBoot(4-wheel

drivemodelsonly)...............................................44

AdjustingtheShiftCables........................................45

AdjustingtheHigh-to-LowCable.............................45

AdjustingDifferential-lockCable..............................45

InspectingtheTires................................................45

CheckingtheFrontWheelAlignment........................46

CoolingSystemMaintenance......................................47

RemovingDebrisfromtheCoolingSystem................47

ChangingtheEngineCoolant...................................47

BrakeMaintenance....................................................48

AdjustingtheParkingBrake.....................................48

AdjustingtheBrakePedal........................................49

BeltMaintenance......................................................50

AdjustingtheAlternatorBelt...................................50

ControlsSystemMaintenance.....................................50

AdjustingtheAcceleratorPedal................................50

AdjustingtheClutchPedal.......................................51

ConvertingtheSpeedometer....................................51

HydraulicSystemMaintenance....................................52

ChangingtheHydraulicuidandCleaningthe

Strainer..............................................................52

ReplacingtheHydraulicFilter..................................52

ChangingtheHigh-owHydraulicuidandFilter

(TCmodelsonly)................................................53

RaisingtheCargoBoxinanEmergency.....................53

Cleaning...................................................................55

WashingtheMachine..............................................55

Storage........................................................................55

3