Bigassfans BAFWorks 3.0 User manual

INSTALLATION

GUIDE

For help, call 1 (877) BIG-FANS

or visit www.bigassfans.com

2425 Merchant St., Lexington, KY 40511

1 (877) BIG-FANS | WWW.BIGASSFANS.COM

BAFWORKS™

INSTALLATION

GUIDE

BAFWorks®3.0

For help, call 1-877-BIG-FANS

or visit www.bigassfans.com

Customer Service: 1-877-BIG-FANS

(International: +1 859 233 1271)

BAFWORKS®INSTALLATION GUIDE

i

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

BAFWORKS®INSTALLATION GUIDE

Installation Guide

BAFWorks®3.0

Installation Guide:

January 2017

Rev. I

This product was manufactured in a plant whose Management System is certied as being in conformity with ISO 9001.

BAFWorks is a trademark of Delta T Corporation, registered in the United States and/or other countries. iPad®, App StoreSM, and Safari®are registered trademarks of Apple Inc. This

document has not been authorized, sponsored, or otherwise approved by Apple Inc. NETGEAR and the NETGEAR logo are trademarks and/or registered trademarks of NETGEAR,

Inc. and/or its subsidiaries in the United States and/or other countries. Information is subject to change without notice. © 2011 NETGEAR, Inc. All rights reserved. All other trademarks

used herein are the properties of their respective owners. No part of this document may be reproduced or translated into a different language without the prior written consent of Big Ass

Solutions. The information contained in this document is subject to change without notice.

www.bigasssolutions.com/patents ▪ www.bigasssolutions.com/warranties

INSTALLATION

GUIDE

For help, call 1 (877) BIG-FANS

or visit www.bigassfans.com

2425 Merchant St., Lexington, KY 40511

1 (877) BIG-FANS | WWW.BIGASSFANS.COM

BAFWORKS™

Contact Information

Manufacturing

2425 Merchant Street

Lexington, KY 40511

1-877-BIG-FANS

www.bigasssolutions.com

Customer Service

2348 Innovation Drive

Lexington, KY 40511

1-877-BIG-FANS

www.bigasssolutions.com

Warranty Returns

800 Winchester Road

Lexington, KY 40505

1-877-BIG-FANS

www.bigasssolutions.com

Australia Ofce

Unit 22, 1029 Manly Road

Tingalpa QLD 4173, Australia

(07) 3292 0100

www.bigassfans.com/au

BAFWORKS®INSTALLATION GUIDE

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

ii

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

WARNING: The BAFWorks®Admin Lock feature is not a suitable replacement for proper lockout/tagout procedures as

prescribed in OSHA standard 29 CFR 1910.147. Before servicing equipment connected to the BAFWorks system, ensure

proper procedures have been taken to isolate equipment to be serviced. These procedures MUST be followed even if the

Admin Lock feature is enabled for a device in the BAFWorks application.

CAUTION: This guide is intended to provide instructions for installing BAFWorks and using it to control fans and other

devices. Consult the installation guide included with the fan or device for additional installation, operation, and safety

instructions.

WARNING: Installation work and electrical wiring must be done by qualied person(s) in accordance with all applicable codes

and standards.

CAUTION: Installation must be in accordance with the requirements specied in this installation manual and with any

additional requirements set forth by the National Electric Code (NEC), ANSI/NFPA 70-2011, and all local codes. Code

compliance is ultimately YOUR responsibility! Failure to comply with these codes could result in personal injury or property

damage.

WARNING: The fan controllers contain high voltage capacitors which take time to discharge after removal of mains supply.

Before servicing the fan controller, ensure isolation of mains supply from line inputs at the controller’s disconnect. Wait

three minutes for capacitors to discharge to safe voltage levels. Failure to do so may result in personal injury or death. Note:

Darkened display LEDs are not an indication of safe voltage levels.

WARNING: When cutting or drilling into a wall or ceiling, do not damage electrical wiring and other hidden utilities.

CAUTION: When service or replacement of a component in the fan requires the removal or disconnection of a safety device,

the safety device is to be reinstalled or remounted as previously installed.

WARNING: Power must be disconnected before installation and servicing, cleaning, and other user-maintenance. Failure to

disconnect power creates risk of re, electric shock, and serious bodily injury.

CAUTION: Exercise caution and common sense when powering BAFWorks, fans, and other devices. Do not connect

BAFWorks, fans, or other devices to a damaged power source. Do not attempt to resolve electrical malfunctions or failures on

your own.

CAUTION: The Big Ass Solutions product warranty will not cover equipment damage or failure that is caused by improper

installation.

ANY OF THE FOLLOWING ACTIONS BY THE CUSTOMER OR ANY AGENT OF THE CUSTOMER WILL CONSTITUTE A BREACH

OF AND WILL VOID ALL WARRANTIES:

• Failure to follow the required installation procedures specied in the Big Ass Solutions-supplied installation guide and

in all other documentation supplied with the fans and related equipment, including documentation provided by the

manufacturers of the individual fan and control components;

• Failure to follow all relevant codes and ordinances, including, but not limited to the National Electric Code and state and

local building codes;

• Failure to follow electrical engineering industry standards regarding the approved method of installing solid-state electrical

equipment having the characteristics of the fans, the fan controls, and their related components, even if such standards

are not specically referenced in any instructions or literature supplied by Big Ass Solutions or provided by manufacturers

of the fan and control components; and/or

• Failure to use all installation and mounting hardware supplied by Big Ass Solutions.

CAUTION: The following information is merely a guide for proper installation. Big Ass Solutions cannot assume

responsibility for the compliance or the non-compliance to any code, national, local, or otherwise for the proper installation of

the fan controllers, fans, or associated equipment. A hazard of personal injury and/or equipment damage exists if codes are

ignored during installation.

Leave this installation guide with the owner of the BAFWorks control system after installation.

BAFWORKS®INSTALLATION GUIDE

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

BAFWORKS®INSTALLATION GUIDE

Contents

Introduction Safety Instructions ii

Thank You 1

About Big Ass Solutions 1

About BAFWorks®1

BAFWorks System Diagram 2

Pre-Installation Parts and Hardware 3

Pre-Installation Requirements 5

Installation Overview 7

Electrical Installation:

Lights, Ventilation, &

Automation

Safety Guidelines 8

ADAM Module Basic Power and Data Wiring 8

Basic Relay Output Wiring 9

Wiring: 12 x 12 x 4 Lighting Panel, 6 Channel 13

Wiring: 12 x 12 x 4 Output Panel 14

Wiring: 12 x 12 x 4 Analog Input Panel, 8 Channel 15

Temperature Sensor Specications 16

Mounting Temperature Sensors 17

Basic Temperature Sensor Wiring 18

Mounting the BAFWorks®

Control System

Dimensions 19

Mounting the Control System 20

Electrical Installation: Fans Safety Guidelines 23

Installation Overview 23

Modbus Wiring Overview 24

Cable Types and Distances 24

Terminating or EOL Resistors 24

Terminations at the Modbus Gateway 25

Setup and Wiring: Delta E Series VFDs 26

Setup and Wiring: Delta M Series VFDs 28

Setup and Wiring: Lenze SMVector VFDs 30

RS-485 Network Biasing: Lenze SMVector VFDs 32

Setup and Wiring: Allen-Bradley®PowerFlex® VFDs 33

Connecting More Than 32 Fans (Daisy Chaining) 35

Fire Alarm Interface Methods 36

Fan Remote Operator

Station (Optional)

Dimensions 37

Installation 37

Operation 37

Remote Operator Station Wiring: Delta E Series VFDs 38

Remote Operator Station Wiring: Delta M Series VFDs 39

Remote Operator Station Wiring: Lenze SMVector VFDs 40

Remote Operator Station Wiring: Allen-Bradley PowerFlex VFDs 41

Conguring ADAM Modules Pre-Conguration Requirements 42

Downloading the Conguration Utility 42

Conguring the Modules 42

Recording Module Information 44

Setting Up the BAFWorks®

Application

Adding Output and Input Modules 45

Setting Up Fan Group Automation 47

Setting Up Ventilation Group Automation 48

Adding and Deleting Fans and Fan Groups 49

Adding and Deleting Lights and Light Groups 51

Adding and Deleting Louvers/Vents and Louver/Vent Groups 53

Conguring General Settings 55

BAFWORKS®INSTALLATION GUIDE

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

Setup Notes Setup Notes 57

Using BAFWorks Understanding the Home Screen 59

Working with All Devices 60

Conguring Individual Fan Settings 61

Starting and Stopping Fan Groups 62

Conguring Fan Group Settings 62

Scheduling Fan Group Events 63

Viewing Fan Diagnostic Information 64

Understanding Fire Alarm System Trip Behavior 64

Conguring Individual Light Settings 65

Turning Light Groups On and Off 66

Conguring Light Group Settings 66

Scheduling Light Group Events 67

Conguring Individual Louver and Vent Settings 68

Starting and Stopping Louver and Vent Groups 69

Conguring Louver and Vent Group Settings 69

Scheduling Louver and Vent Group Events 70

Troubleshooting Troubleshooting 71

Ports Used By ADAM Modules on Corporate Networks 71

Warranty Return

Instructions

Return Instructions 72

Warranty Claim Form Instructions 73

Warranty Claim Form 75

Responsibility Agreement 76

BAFWORKS®INSTALLATION GUIDE

1

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

BAFWORKS®INSTALLATION GUIDE

Introduction

INSTALLATION

GUIDE

For help, call 1 (877) BIG-FANS

or visit www.bigassfans.com

2425 Merchant St., Lexington, KY 40511

1 (877) BIG-FANS | WWW.BIGASSFANS.COM

BAFWORKS™

You’ve made a great choice! Big Ass Fans® are an efcient, cost-effective and seriously cool way to stay comfortable and save energy

all year long. More importantly, everything about your new fan—from the design of the motor to the angle of the airfoils—is based on

extensive research, testing, and innovative engineering. It will keep you and your space comfortable for years to come.

Any questions or comments? We’d love to talk. Just call 1-877-BIG-FANS (1-877-244-3267) or visit bigassfans.com/contact-us/.

About Big Ass Fans

Our provocative moniker originated with the massive overhead fans we perfected to bring comfort and energy savings to large industrial

buildings. Today, though, Big Ass Solutions is much more than industrial—and much more than Big Ass Fans or Big Ass Light. Big

Ass means quality, form, and function to solve problems in the built environment. It means having a herd of engineers on staff and the

world’s only R&D facility dedicated to testing air movement on a grand scale. It means speaking to our customers directly to understand

and solve their problems—if they need air movement, we do it bigger and better. If they need light, we make incredibly bright, long-

lasting LEDs. But mostly it means an insatiable drive to improve, engineer, design, test, re-engineer, re-design, and re-test until we get

it just right. That’s why there’s No Equal™.

About BAFWorks®

BAFWorks enables you to network and control all of the fans, lights, and ventilation systems in your facility from a secure, centralized

location. The system’s intuitive wall-mounted interface is simple to learn and makes controlling and automating your devices easier than

ever. This translates into year-round energy control and savings, as well as real-time operational information about your devices, right

at your ngertips.

Big Ass Solutions recommends reading this Installation Guide in its entirety before installing the control system so that a plan of action

can be made for system implementation.

BAFWORKS®INSTALLATION GUIDE

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

2Introduction (cont.)

BAFWorks®system diagram

The diagram below shows a typical BAFWorks®installation with fans, lights, exhaust fans and louvers, and temperature sensors.

1. The iPad and Wi-Fi router are located inside the provided wall mounting bracket. The Wi-Fi link must be dedicated to the iPad, as this is your only

means of fan control unless a remote operator station is installed. Big Ass Solutions does not recommend removing the iPad from the mounting

bracket. This will leave you without a means of fan control if the Wi-Fi signal is lost or if the iPad itself is lost. See page 23 for details.

2. ADAM modules can be daisy chained.

3. The BAF gateway is connected locally to the Wi-Fi router. If the gateway is remotely mounted, a customer-supplied 5VDC 100mA power supply must

be used. See page 21 for connection details for the wall-mounted components.

AI1-

AI1+

AI0-

AI0+

AGND

Ethernet

(Port2)

Ethernet

(Port1)

AI2+

AI2-

AI3+

AI3-

AGND

AI4+

AI4-

AI5+

AI5-

AI6+

AI6-

AI7+

AI7-

+VS

GND

RL2NO

RL2COM

RL2NC

RL3NO

RL3COM

RL3NC

RL4NO

RL4COM

RL4NC

RL5NO

RL5COM

RL5NC

N/C

+VS

GND

RL1NC

RL1COM

RL1NO

RL0COM

RL0NO /NC

Ethernet

(Port 2)

Ethernet

(Port 1)

RL2NO

RL2COM

RL2NC

RL3NO

RL3COM

RL3NC

RL4NO

RL4COM

RL4NC

RL5NO

RL5COM

RL5NC

N/C

+VS

GND

RL1NC

RL1COM

RL1NO

RL0COM

RL0NO/N C

Ethernet

(Port 2)

Ethernet

(Port 1)

iPad1

Wi-Fi Router1

CAT5

6 channel

max

6 channel

max Modbus 8 channel

max

Lighting

contactors

Load

center

Modbus

Indoor oor

temperature

Indoor ceiling

temperature

Outdoor

temperature

Up to 32 fans

Lighting branch circuits

Exhaust fans and louvers

ADAM 6160

Ouput modules2

BAF

Gateway3

ADAM 6117

Input module2

After BAFWorks is installed, the iPad® mobile digital device (and fan remote operator station[s], if installed) will be

your only means of fan control. You will not be able to use the wall-mounted controllers included with the fans. Before

installing BAFWorks, install the fan system and wall controllers according to the instructions in the fan Installation

Guide. This will give you a backup means of fan control in case a problem occurs with the BAFWorks system or if you

need to make parameter changes.

BAFWORKS®INSTALLATION GUIDE

3

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

BAFWORKS®INSTALLATION GUIDE

Pre-Installation

Parts and hardware

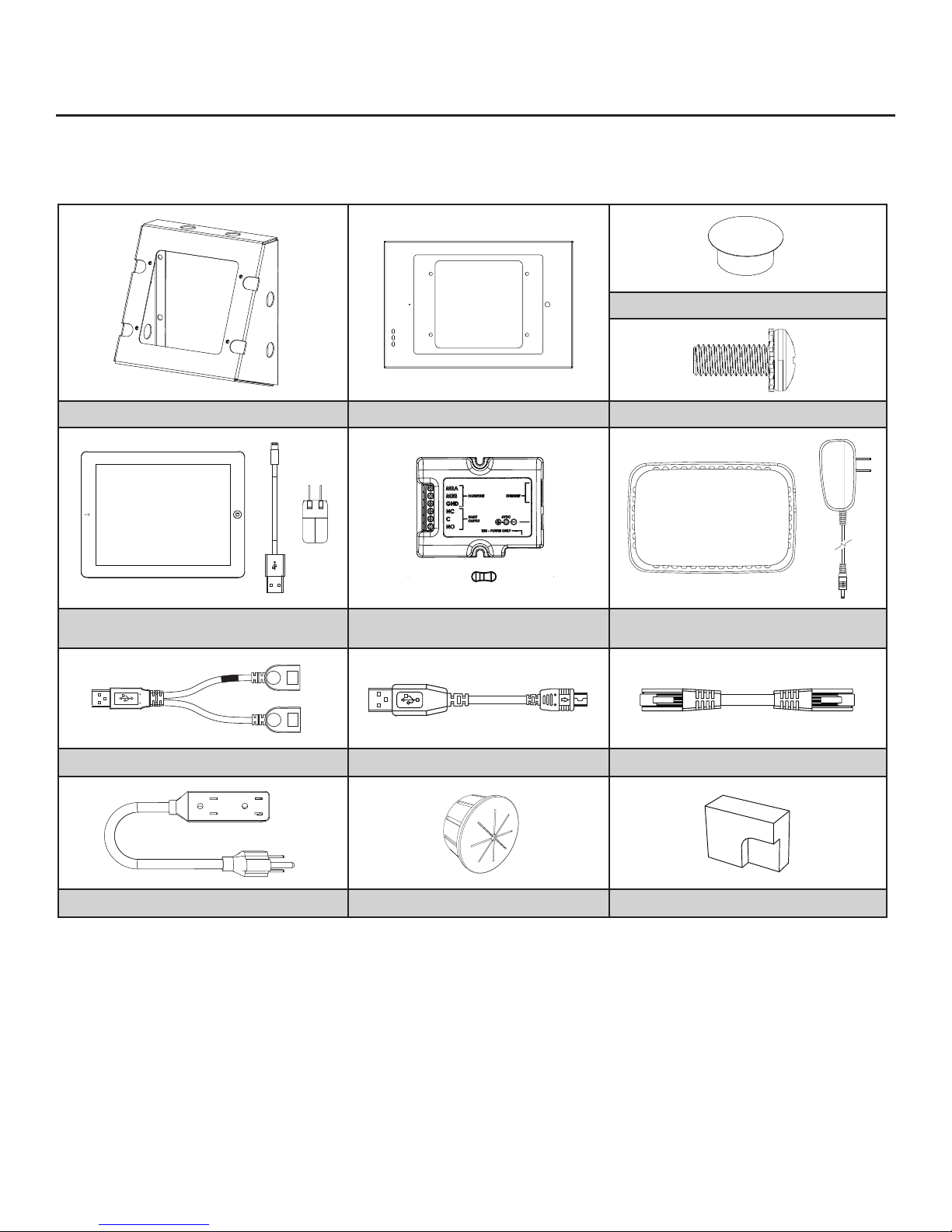

Note: The exact parts and hardware included will vary depending on the components (fans, lighting, ventilation, temperature sensors)

you are connecting to BAFWorks®. The drawings below and on the following page are not to scale.

Wall-mounted parts and hardware

(6) Mounting Bracket Knockout

Mounting Bracket iPad® Enclosure1(4) 10-32 x 1/2” Pan Head Screw2

iPad, 36” (914 mm) Data/Charging Cord,

& 2 A USB Charger BAF Gateway & (4) Resistor3Wi-Fi Router & AC Power Adapter4

USB Splitter512” (305 mm) USB Cord612” (305 mm) CAT5 Ethernet Patch Cable

9 ft (2.7 m) Power Cord Bushing Plug Foam Bumper

1. The iPad enclosure includes a key (not shown) for securing access to the iPad.

2. Included with the iPad enclosure

3. Includes two (2) 120 Ω 1/4 W resistors for end of line termination (Brown, Red, Brown, Gold) and two (2) 680 Ω 1/4 W resistors for proper line biasing

where required (Blue, Gray, Brown, Gold. Required for Lenze SMVector VFDs ONLY.)

4. 100–240 VAC 50/60 Hz, 5 VDC @ 1 A

5. Type A Male to Type A Female (with data), Type A Female (power only for BAF gateway). The “power only” side for the gateway is marked with a red

band.

6. Type A Male to Mini B Male

BAFWORKS®INSTALLATION GUIDE

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

4Pre-Installation (cont.)

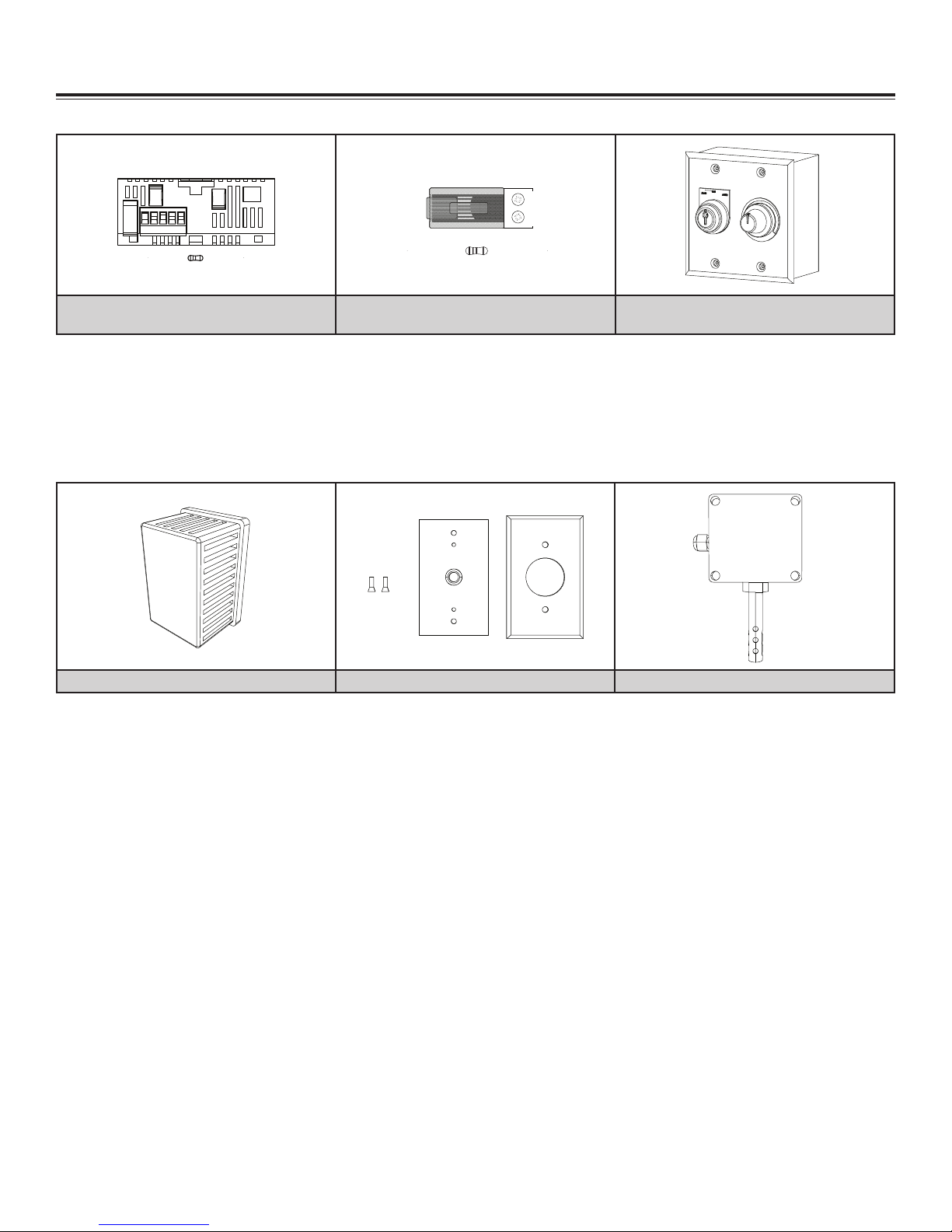

Temperature sensor parts and hardware

Indoor Temperature Sensor Indoor Sensor Mounting Hardware Outdoor Temperature Sensor

Fan parts and hardware

Modbus Communication Card

& 120 Ω 1/4 W Resistor1

RJ45 to Modbus Connector

& 120 Ω 1/4 W Resistor2Remote Operator Station3

1. One (1) Modbus communication card is required for each fan in the BAFWorks® system with a Lenze SMVector VFD.

2. One (1) RJ45 to Modbus connector is required for each fan in the BAFWorks system with a Delta E or M series VFD, or an Allen-Bradley®

PowerFlex® 4, 4M, or 40 VFD.

3. Included only if the remote operator station option is ordered. One remote operator station is required for each fan you plan to control locally. Four (4)

cover screws and two (2) keys for turning the mode selection knob are provided with each remote operator station. See page 37 for remote operator

station installation, operation, and wiring instructions.

5 4 3 2 1

Lighting, ventilation, and automation parts and hardware

The parts, hardware, and wiring required for connecting lights, ventilation, and temperature sensors to the BAFWorks system are

shipped in pre-assembled lighting, input, and output panels. The specic parts included on the panels (input modules, output modules,

etc.) depend on the types of devices you are connecting to the system. See pages 8–15 for panel diagrams and wiring details.

BAFWORKS®INSTALLATION GUIDE

5

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

BAFWORKS®INSTALLATION GUIDE

Pre-Installation (cont.)

Pre-installation requirements

1. Identify network to use for BAFWorks®

Choose one of the following:

a. Use the provided NETGEAR®N150 Wi-Fi router.

If the provided Wi-Fi router is used, CAT5 cable must be routed between the router and all ADAM modules (star or daisy chain

topology). Keep in mind that the NETGEAR router includes only four (4) LAN ports; therefore, the maximum number of home runs is

limited to three (3).

b. Use the existing wired or wireless network.

Use this setup in locations where third-party Wi-Fi routers are not approved. Adhere to the following requirements:

• Use of the existing network requires close cooperation and planning with the facility’s network administrator.

• CAT5 cable must be routed between the ADAM modules and the nearest LAN port (star or daisy chain topology).

• CAT5 cable must be routed between the BAF gateway and the nearest LAN port.

• The Wi-Fi and LAN must be part of the same subnet or VPN.

• The iPad® IP address must be in the same range as the ADAM modules and the BAF gateway.

• Firewalls must not block the ports required by the system. Refer to the table below.

UDP/TCP ports used by ADAM modules (initial mode)

Function Protocol Port

UDP ASCII communication UDP 1025

Datastream UDP 5168

GCL IO message UDP 5168

P2P message UDP 1025

Search engine UDP 5048

TCP ASCII/Modbus communication TCP 502

Download TCP 5450

Download Adam6024 TCP 7000

When the ADAM modules are in normal mode, they follow the standard of Ethernet/IP. TCP port number 44818 is used for explicit

messaging and UDP port number 2222 is used for implicit messaging.

2. Identify hardware requirements

Identify the hardware required to interface with the facility’s equipment. Adhere to the following:

a. The lighting panel includes six (6) 4-pole, 20-amp lighting contactors and can control twenty-four (24) 20-amp lighting circuits in six

groups of four. The contactors are 120 VAC coil, but can be ordered with optional coil voltages if needed.

b. The 6 channel relay output panel includes one (1) ADAM 6160 module and can control six (6) loads independently (relay contacts

are limited to 5 A @ 250 VAC each). This panel should be used for interfacing with exhaust fan motor starters, louvers, and lighting

circuits, which are already controlled by lighting contactors.

c. The 12-channel relay output panel includes two (2) ADAM 6160 modules.

d. The 8 channel analog input panel includes one (1) ADAM 6117 module. It supports both voltage (±1, ±5, ±10) and current (±20 mA,

0–20 mA, 4–20 mA). Big Ass Solutions recommends and pre-congures the modules for 4–20mA operation.

i. One controlled fan zone requires two (2) channels (oor temperature sensor and ceiling temperature sensor).

ii. One controlled ventilation zone requires two (2) channels (oor temperature sensor and outdoor temperature sensor).

iii. The oor temperature sensor can be shared by fan automation and ventilation automation (i and ii).

iv. Additional controlled zones (if it is desired to control by temperature independently) will require additional channels and sensors.

e. All panels (a, b, c, and d) include a 30 W, 24 VDC power supply. AC input: 100–277 VAC, 50/60 Hz.

Read and complete all of the following steps prior to BAFWorks®installation!

BAFWORKS®INSTALLATION GUIDE

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

6Pre-Installation (cont.)

MAC ID sticker

relocated to outside

of module case

Case Screws

4. Congure signal input type (ADAM 6117 analog input modules only)

The ADAM 6117 module signal input type must be congured for 4–20 mA or 0–10 V. Big Ass Solutions recommends 4–20 mA.

With the case halves separated (see step 3 above), locate the input mode selection switches and set them to 4–20 mA. Refer to the

illustration below.

Back View Side View

Pre-installation requirements (cont.)

3. Obtain ADAM module MAC ID numbers

If multiple ADAM modules of the same module number will be used on the same network, Big Ass Solutions recommends obtaining and

recording each module’s MAC ID number. The MAC ID numbers will be helpful during ADAM module conguration.

To obtain an ADAM module’s MAC ID number:

1. Remove the two (2) small Phillips head screws from the back of the module and separate the case halves. Refer to the illustration

below.

2. Locate the module’s MAC ID sticker on the PC board.

3. Record the MAC ID number on page 58 of this manual and on page 28 of the BAFWorks®User Guide. You can also carefully peel

the sticker off of the PC board and relocate it to the outside of the module case for future reference. Refer to the illustration below.

Set ONLY the input mode selection switches to 4–20

mA. DO NOT toggle any of the other switches inside the

module. These switches are critical to module operation.

Toggling these switches may ruin the module.

BAFWORKS®INSTALLATION GUIDE

7

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

BAFWORKS®INSTALLATION GUIDE

Pre-Installation (cont.)

Installation overview

To install BAFWorks, complete the following steps. See the chapters, sections, and pages referenced below for detailed installation

instructions.

1. Install network-enabled hardware

Install, wire, and congure all ADAM modules, lighting/input/output panels, temperature sensors, and other network hardware as

described in “Electrical Installation: Lights, Ventilation, & Automation” on pages 8–18.

2. Install wall-mounted components

Mount the Wi-Fi router, BAF gateway, and iPad® to the wall and connect the wall-mounted components as described in “Mounting

the BAFWorks Control System” on pages 19–22.

3. Install Modbus wiring and congure fans

Install the fan Modbus wiring and complete all fan conguration and wiring as described in “Electrical Installation: Fans” on pages

23–36. If you are installing the remote operator station option, complete all installation and wiring steps in “Fan Remote Operator

Station (Optional)” on pages 37–41.

4. Congure ADAM modules

Download the conguration utility and congure the ADAM modules as described in “Conguring ADAM Modules” on pages 42–44.

5. Add ADAM modules and temperature sensors to BAFWorks

Add and congure the ADAM modules and temperature sensors as described in “Adding Output and Input Modules” on pages

45–46.

6. Congure fan automation settings

Congure the fan group automation settings as described in “Setting Up Fan Group Automation” on page 47.

7. Congure ventilation automation settings

Congure the ventilation group automation settings as described in “Setting Up Ventilation Group Automation” on page 48.

8. Add fans, lights, and ventilation

Add fans, lights, and louvers/vents to the BAFWorks system as described on pages 49–54 of the “Setting Up the BAFWorks

Application” chapter.

Complete all steps in “Pre-Installation Requirements” on page 5 before proceeding.

BAFWORKS®INSTALLATION GUIDE

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

8 Electrical Installation: Lights, Ventilation, &

Automation

WARNING: To reduce the risk of electric shock, wiring should be performed by a qualied electrician! Incorrect assembly can

cause electric shock or electrical component damage! Hazard of electrical shock!

WARNING: Installation must be in accordance with the requirements specied in this installation manual and with any

additional requirements set forth by the National Electric Code (NEC), ANSI/NFPA 70-2011, and all local codes. Code

compliance is ultimately YOUR responsibility! Failure to comply with these codes could result in personal injury or property

damage.

CAUTION: The Big Ass Solutions product warranty will not cover equipment damage or failure that is caused by improper

installation.

CAUTION: The following information is merely a guide for proper installation. Big Ass Solutions cannot assume

responsibility for the compliance or the non-compliance to any code, national, local, or otherwise for the proper installation of

this equipment. A hazard of personal injury and/or equipment damage exists if codes are ignored during installation.

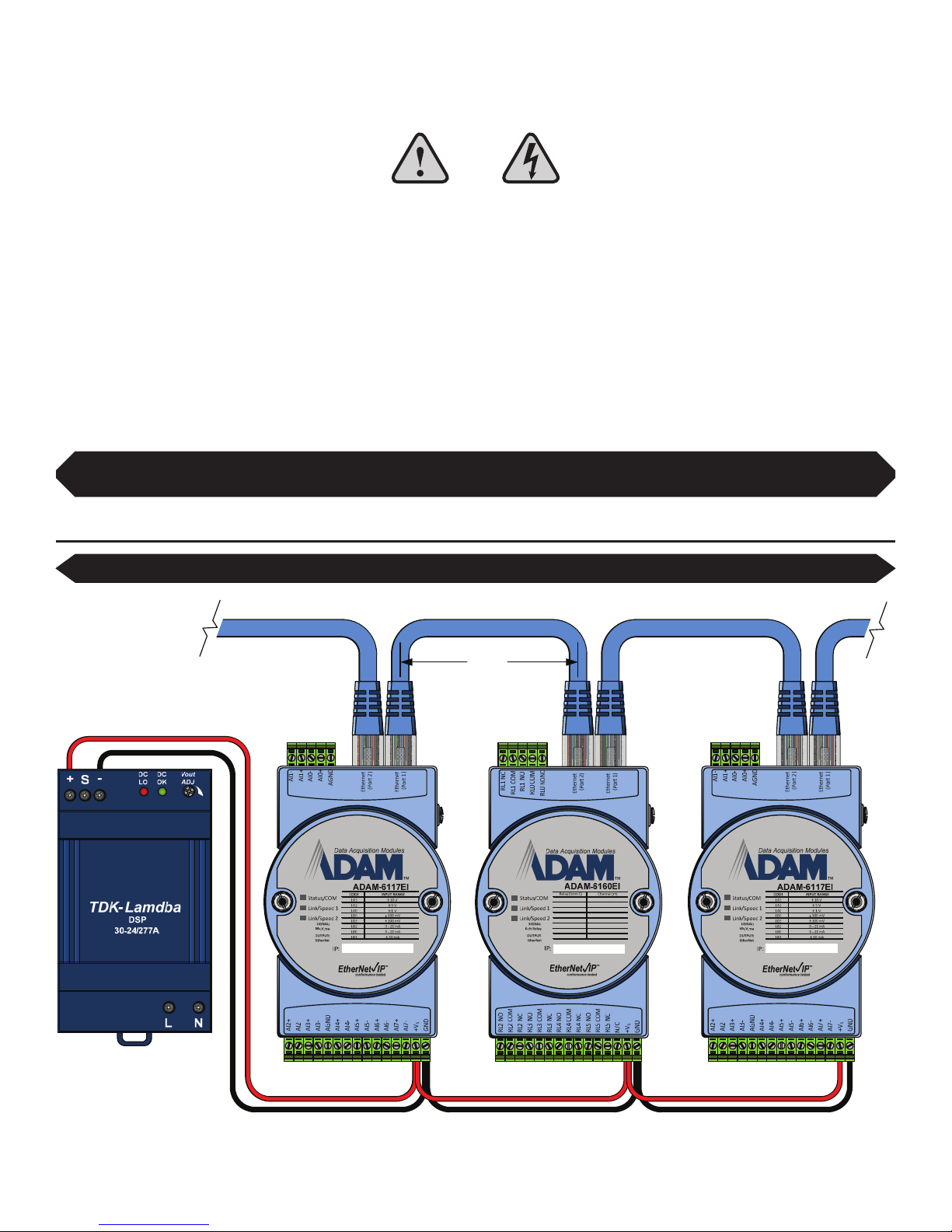

ADAM module basic power and data wiring

In from router

or switch

DC supply rating:

In: 100–277 VAC 50/60 Hz

Out: 24 VDC @ 30 W

ADAM module power consumption: 10–30 VDC, 3.5 W each

ADAM module environmental ratings: 14ºF–158ºF (-10ºC–70ºC), 20–95% RH non-condensing

RED

BLACK

100 m

330 ft

Complete all steps in “Pre-Installation Requirements” on page 5 and ensure that you have read "Installation Overview"

on page 7 before proceeding.

The maximum cable distance allowed between any two devices is 100 m (330 ft).

BAFWORKS®INSTALLATION GUIDE

9

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

BAFWORKS®INSTALLATION GUIDE

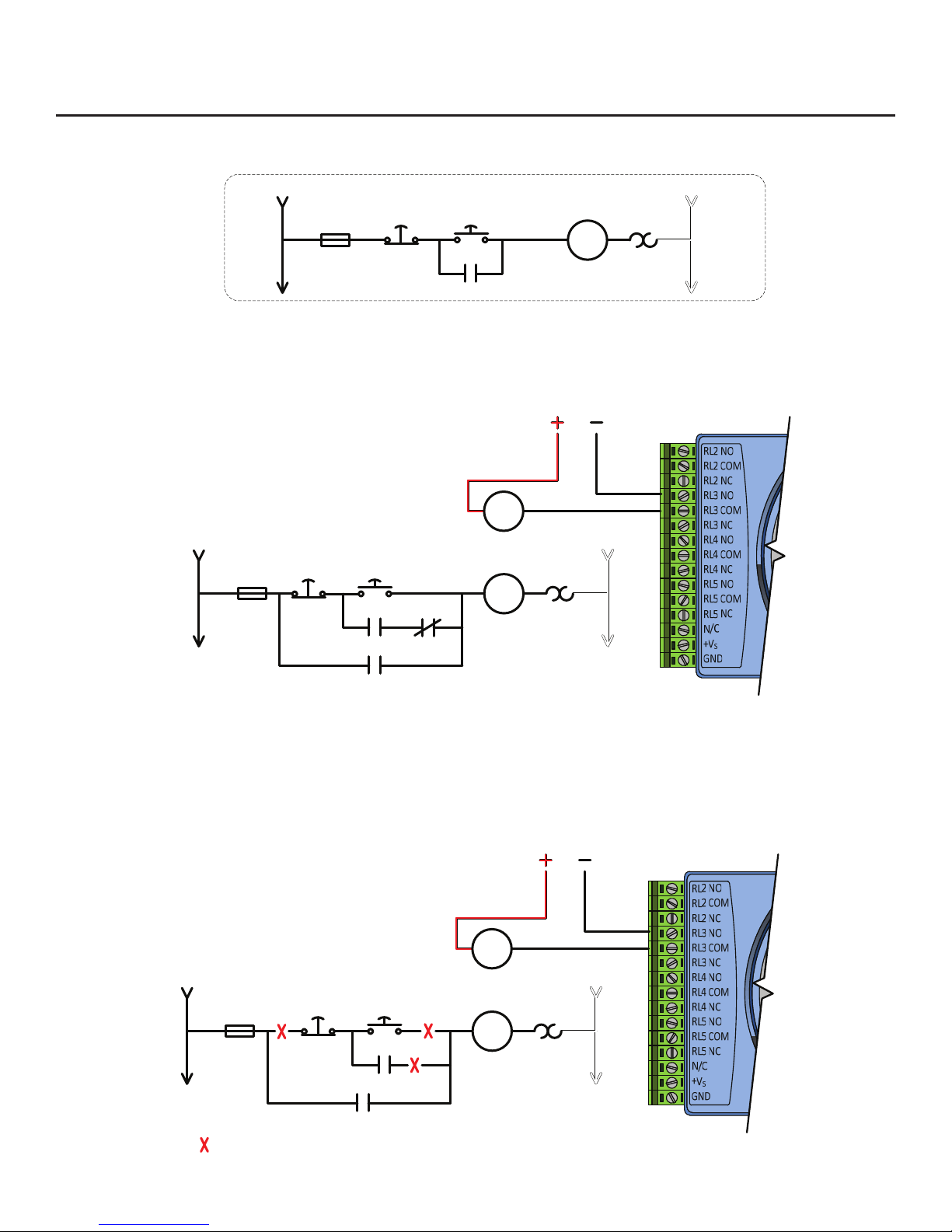

Basic relay output wiring

The ADAM 6160 relay output module includes six (6) form C relays. These relays are rated for up to 5 A @ 250 VAC and can be used to

directly drive smaller loads, such as lighting contactors or motor starters. For loads that exceed the 5 A rating, the relay outputs can be

used to drive pilot or isolation relays to achieve higher current capacity. Some typical wiring examples are shown below.

Controlling a load directly

Electrical Installation: Lights, Ventilation, & Automation (cont.)

Using a low voltage pilot/isolation relay

ADAM 6160 Relay Output Module

ADAM 6160 Relay Output Module

250 VAC

Line Max

AC Line

Fuse

R

DC Supply

AC Neutral

Load

N.O.

N.C.

Fuse

5A Load Max

AC Neutral/L2

BAFWORKS®INSTALLATION GUIDE

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

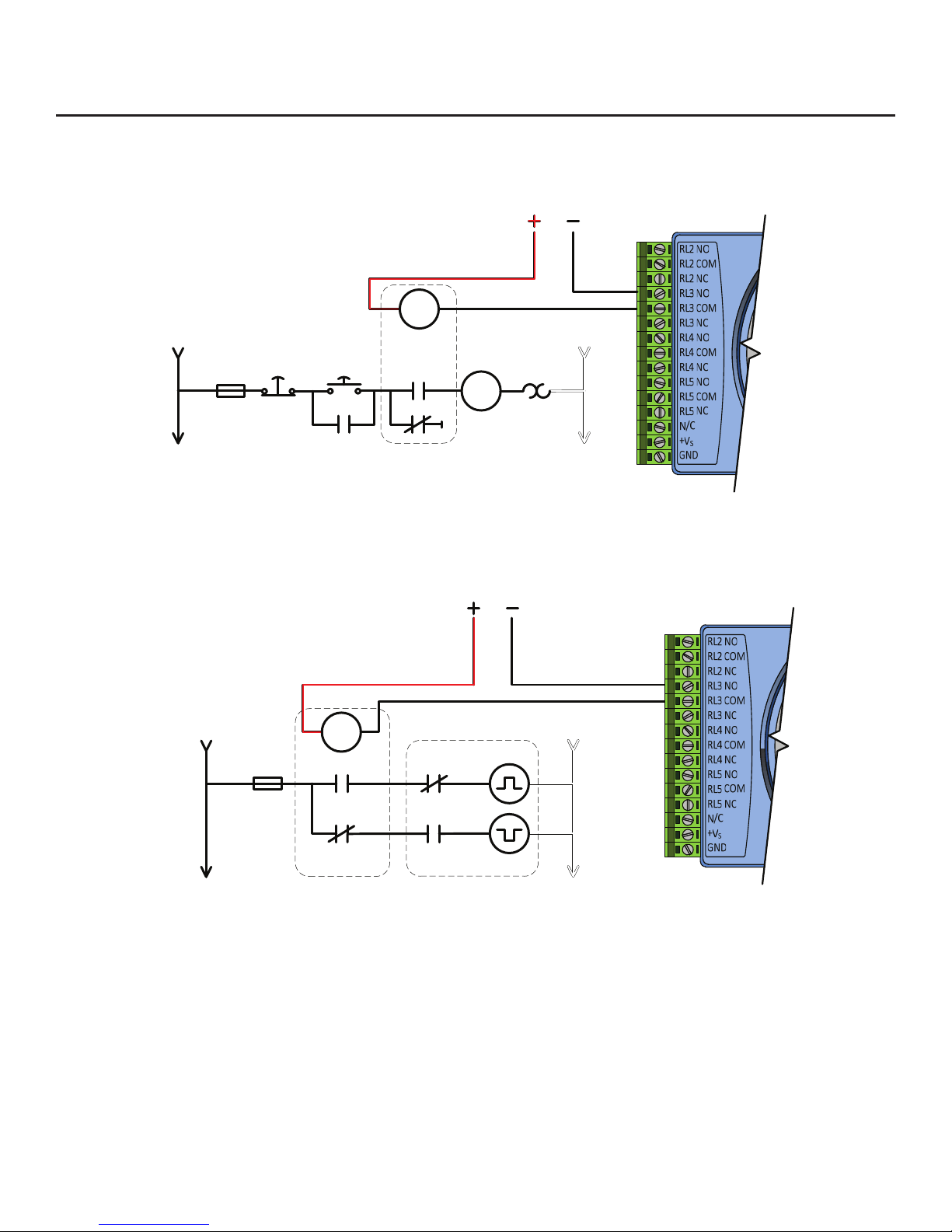

10 Electrical Installation: Lights, Ventilation, & Automation (cont.)

Basic relay output wiring (cont.)

Typical 3-wire combination motor starter control wiring (single station)

Interfacing with 3-wire start/stop circuits

With a low voltage SPDT relay, the existing push

button controls can still be used*.

*The addition of an SPDT pilot relay as shown above allows the use of both iPad® start/stop and the existing start/stop push buttons.

However, relay contact ight time is critical. If the pilot relay's N.C. contact re-closes too quickly upon an iPad stop command relative

to the motor starter's auxiliary contact opening, the motor starter may fail to de-energize if the iPad was used to energize the starter. If

this occurs, the existing start/stop push buttons must be disconnected from the circuit, and the motor starter must be controlled from the

iPad only as shown below.

ADAM 6160 Relay Output Module

ADAM 6160 Relay Output Module

AC Line

AC Line

AC Line

Fuse

Fuse

Fuse

Stop

Stop

Stop

Start

Start

Start

MS

O.L.

AC Neutral

AC Neutral

AC Neutral

DC Supply

DC Supply

R N.O.

R N.O.

R N.C.

MS aux

MS aux

R

R

MS

MS

MS aux

= cut or disconnect

BAFWORKS®INSTALLATION GUIDE

11

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

BAFWORKS®INSTALLATION GUIDE

Electrical Installation: Lights, Ventilation, & Automation (cont.)

Basic relay output wiring (cont.)

Using the ADAM module and/or pilot relay as a circuit enabler

Shown with low voltage SPDT relay

ADAM 6160 Relay Output Module

Interfacing with mechanically held lighting contactors

With a low voltage SPDT pilot relay

ADAM 6160 Relay Output Module

There are many different topologies for mechanically held contactors. This diagram serves as a generic representation of the

contactor's coil lead functions. The pilot relay's N.O. and N.C. contact are used to alternate the contactor's on and off coil leads. This

diagram can also be used as a basic guide for modifying an electrically held contactor to operate as a mechanically held contactor.

Auxiliary contact ight time is critical in these applications. Normally Closed Late Break and/or Normally Open Early Make auxiliary

contacts may be necessary for proper operation.

Contact the lighting contactor manufacturer if additional details are needed.

AC Line

AC Line

Fuse

Fuse

Stop

N.O.

Start

N.C.

AC Neutral

AC Neutral

DC Supply

DC Supply

R N.O.

N.C.L.B.*

R N.C.

N.O.E.M.*

Lighting Contactor

Pulse ON

Pulse OFF

MS aux

Pilot Relay

R

R

MS

BAFWORKS®INSTALLATION GUIDE

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

12 Electrical Installation: Lights, Ventilation, & Automation (cont.)

Basic relay output wiring (cont.)

Using the ADAM module with 3-way or multi-way lighting circuits

Shown with 3-way light switch, 4-way light switch, and low voltage SPDT pilot relay

ADAM 6160 Relay Output Module

Note: ADAM 6160 relay module contacts are rated for 5 A max @ 250 VAC. The relay module contacts can be used to pilot smaller

loads, but use of a pilot relay with a suitable contact rating for the connected load and branch circuit is recommended. When connected

in this fashion, the On/Off status displayed on the iPad®may not represent the actual load state.

AC Line

4-Way 3-Way

Load

AC Neutral

DC Supply

R N.O.

R N.C.

R

BAFWORKS®INSTALLATION GUIDE

13

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

BAFWORKS®INSTALLATION GUIDE

Electrical Installation: Lights, Ventilation, & Automation (cont.)

Wiring: 12 x 12 x 4 lighting panel, 6-channel

The standard lighting control panel shown below includes six (6) 4-pole, 20 A contactors with 120 VAC coils. This allows switching of up

to twenty-four (24) 20 A lighting circuits in six (6) groups of four (4) circuits each.

Note: Alternate contactors and coil voltages can be supplied upon request (12–277 V AC/DC).

1

2

2

2

GND

1

1

`

H/F1

N/F2

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BROWN

BROWN

BLUE

BLUE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

GREEN WITH YELLOW

RED

RED

Note: Only one contactor coil circuit is

shown for clarity (#2). All six contactor

coil circuits (#0–5) will be prewired to the

ADAM module.

BAFWORKS®INSTALLATION GUIDE

WWW.BIGASSSOLUTIONS.COM ©2013 DELTA T CORP. ALL RIGHTS RESERVED

14 Electrical Installation: Lights, Ventilation, & Automation (cont.)

Wiring: 12 x 12 x 4 output panel

1

2

2

2

GND

1

1

H/F1

N/F2

DC+

DC-

DC-

DC-

DC+

DC+

RED

RED

RED

RED

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLUE

BLUE

BLUE

BLUE

BROWN

BROWN

BROWN

BROWN

WHITE

WHITE

WHITE

WHITE

WHITE

GREEN WITH YELLOW

GREEN WITH YELLOW

OUT to 24 VDC load/pilot

relay; wired N.O.

OUT to AC line powered load/pilot

relay; wired N.O.

Table of contents