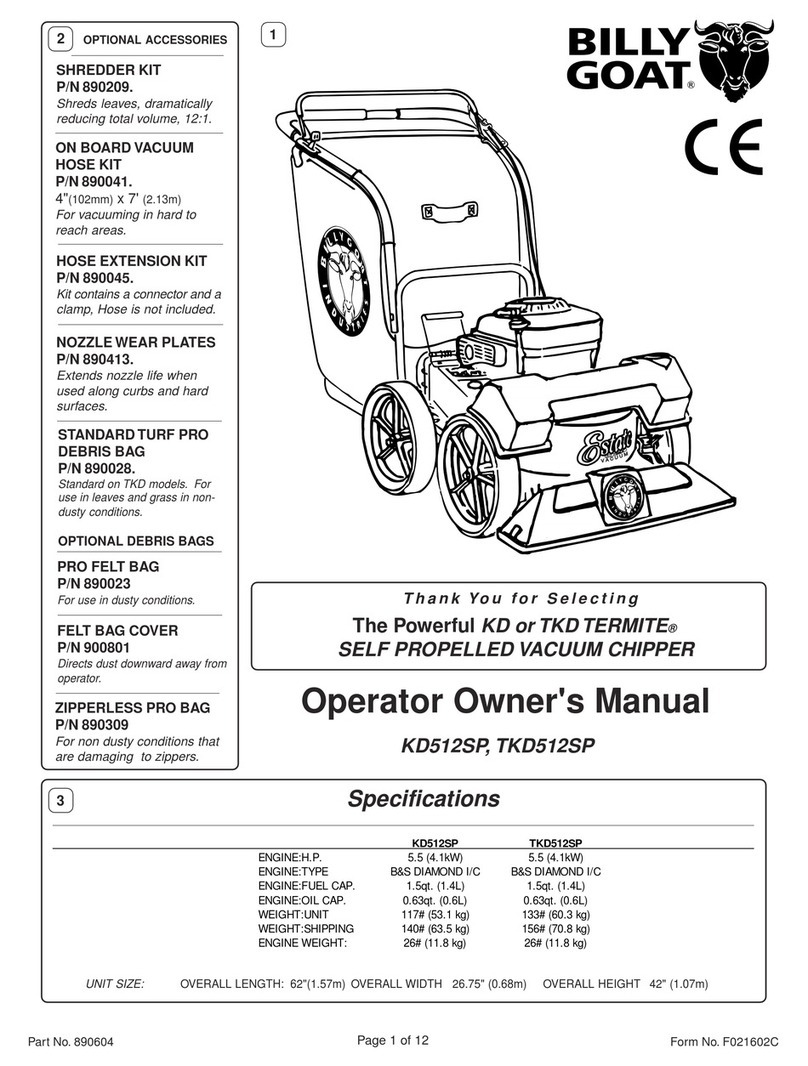

Part No. 890604 Form No. F021602C

Page 12 of 12

Engine Service and Warranty

Contact your nearest engine manufacturer's authorized

servicing dealer.

22.1 22

BILLY GOAT INDUSTRIES INC.

1803 S.W. Jefferson Street Lee's Summit, MO 64082 / USA

PHONE: 816-524-9666 FAX: 816-524-6983 www.billygoat.com

WARRANTY PROCEDURE

Please fill in the WARRANTY CARD and send the upper part to Billy Goat.

The WARRANTY terms are stated on the lower part which remains with the

user.Whenever a Billy Goat Machine is faulty due to a defect in material

and / or workmanship, the owner should make a warranty claim as follows:

The Machine should be taken to the dealer from whom it was

purchased or to an authorized Billy Goat dealer.

The owner should present the remaining half of theWarranty

Registration Card, or, if this is not available, the invoice or receipt.

TheWarranty Claim will be filled in by the authorized Billy Goat Dealer,

who will send it with the faulty part to Billy Goat headquarters.

The Quality / Service department at Billy Goat headquarters will study

the claim and parts and will notify their conclusions.

The decision by the Quality / Service department at Billy Goat

headquarters to approve or reject aWarranty claim is final and

binding.

Note:

To process aWarranty Claim, it is necessary to quote the Model

& Serial number that are printed on the Billy Goat Serial Plate.

Purchased

from

Purchase

Date

21

Serial Plate

Record your machine model, serial number and

date-of-purchase and where purchased

min-1

1803 S.Jefferson

P.O. Box 308

Lee's Summit,

MO 64063 / USA

Tel (816) 524-9666

Fax (816) 524-6983

Model Serial No.

Unit(Weight) Engine Power

lbs. kg kW rpm

Engine stalls or labors when

chipping. Feeding branches into chipper too rapidly. Engine service may be

required. Feed branches at a slower rate. Service engine.

Poor chipping performance. Extremely hard wood. Dull or damaged chipper blade. Avoid extremely hard wood. Sharpen or replace chipper blade (see

page 8).

Will not vacuum or has poor

vacuumperformance. Clean debris bag. Shake bag clean or wash.Adjust nozzle height.

Check for hose kit cap. Unclog nozzle or exhaust (see page 5).

Allow air to feed with debris.

Solution

Problem Possible Cause

TROUBLESHOOTING

Before Requesting Service Review These Suggestions

Engine will not start. Check stop switches, throttle, and gasoline.Connect spark plug wire.

Clean or replace air cleaner.Or contact a qualified service person.

Self propelled drive will not

release. Clutch cable out of adjustment. Idler return spring disconnected or

broken.Belt is rubbing on chain guard Adjust clutch cable. Replace return spring. Remount chain guard

No self propelling. Clutch cable out of adjustment.Worn or broken belt.Worn or broken

clutchcable. Adjust clutch cable.Replace belt.Replace clutch cable.Replace any

worn or damaged or malfunctioning parts.

Throttle in off position. Out of gasoline. Bad or old gasoline. Spark

Plug wire disconnected. Dirty air cleaner.

Abnormal vibration. Loose or out of balance impeller or loose engine. Check impeller and replace if required.Check Engine.

Engine is locked, will not

pull over. Debris locked in chipper blade, hopper or inside impeller. Engine

problem. See page 5, Clearing a clogged chipper hopper. Contact an engine

servicing dealer for engine problems.

Dirty debris bag. Nozzle height set too high or too low. Hose kit cap

missing. Clogged nozzle or exhaust.Excessive quantity of debris.

20

19

( Continued from

page 11 )

PARTS LIST * Denotes

standard

hardware

item that

may be

purchased

locally.

Item

No. Description KD512SP

Part No. Qty. TKD512SP

Part No. Qty.

86 Wheel With Sprocket Ass'y Cast ( 21, 94, 95, 96) 890242 2 890242 2

87 Chain 52 Pitch 890239 2 890239 2

88 Belt 4L220 890586 1 890586 1

89 Washer Flat 5/16 (3/8 ID x 7/8 x 1 1/6) *8171003 4 *8171003 4

90 Bolt Carriage 5/16 - 18 x 3/4 *8024039 4 *8024039 4

91 Washer

pring Lock 5

16 *8177011 4 *8177011 4

92 Nut Regular 5/16 - 18 *8142002 4 *8142002 4

93 Jackshaft 900320 1 900320 1

94 Sprocket (per Assemby) (size # 65A26) 26 Teeth 890238 1 890238 1

95 Screw Self Tap 1/4-14 x 3/4 (Per Assembly) 800505 5 800505 5

96 Washer Lock ExternalTooth (Per Assembly) *8181007 5 *8181007 5

97 Jackshaft Ass'y (incl. 93, 101, 102, 107, 108, 109) 890197 1 890197 1

98 Shield Muffler TKDSP 890190 1 890190 1

99 LabelClutch 830503 1 830503 1

100

101 Bearin

Plate 900317 2 900317 2

102 Bearin

Ball

with

nap Rin

900321 2 900321 2

103

104 Rod Bail Clutch 900970 1 900970 1

105

106

107 Pulley 3"OD x 5/8 Bore 890583 1 890583 1

108

procket - 8 Tooth 900302 2 900302 2

109 Roll Pin 3/16 Dia. x 1 1/4 L

. *8195166 4 *8195166 4

110 Locknut 5/16 - 18 Flan

e 850164 5 850164 5

111

crew

ap 1

4-20 x 1-1

2 Hex 8041008 2

112 Bracket Clutch KDSP 890580 1 890580 1

113 Sprin

Tension 400217 1 400217 1

114 Bolt Idler 800888 1 800888 1

115 Bolt Shoulder 3/8" x 1/2" 830528 1 830528 1

116 Screw Cap 1/4 - 20 x 1" Lg. *8041006 1 *8041006 1

117 Arm Idler Wa KDSP 890582 1 890582 1

118 Guard Chain Ass'y TKDSP 890600 1 890602 1

119 Nut Lock 5/16-18 Thin *8161041 1 *8161041 1

120 Pulley Idler 1.13"OD x 3/8" Bore 890585 1 890585 1

121

122 Nut Lock 3/8-16 Thin *8161042 1 *8161042 1

a

e

ea

wner

s

anua

R

112 dB