Part No. 890316 Form No. F082195D

THIS S MBOL MEANS WARNING OR CAUTION. DEATH, PERSONAL INJUR AND/OR PROPERT

DAMAGE MA OCCUR UNLESS INSTRUCTIONS ARE FOLLOWED CAREFULL .

BEFORE STARTING ENGINE, READ AND UNDERSTAND THE “ENTIRE OPERATOR'S MANUAL & EN-

GINE MANUAL.”

WARNING: DO NOT

1. DO NOT run engine in an enclosed area.

Exhaust gases contain carbon monoxide,

an odorless and deadly poison.

2. DO NOT place hands or feet near moving

or rotating parts.

3. DO NOT store, spill or use gasoline near

an open flame, or devices such as a stove,

furnace, or water heater which use a pilot

light or devices which can create a spark.

4. DO NOT refuel indoors where area is not

well ventilated. Outdoor refueling is

recommended.

5. DO NOT fill fuel tank while engine is

running. Allow engine to cool for 2 minutes

before refueling. Store fuel in approved

safety containers.

6. DO NOT remove fuel tank cap while

engine is running.

7. DO NOT operate engine when smell of

gasoline is present or other explosive

conditions exist.

8. DO NOT operate engine if gasoline is

spilled. Move machine away from the spill

and avoid creating any ignition until the

gasoline has evaporated.

9. DO NOT transport unit with fuel in tank.

10. DO NOT smoke when filling fuel tank.

11. DO NOT choke carburetor to stop

engine. Whenever possible, gradually

reduce engine speed before stopping.

12. DO NOT run engine at excessive

speeds. This may result in injury & /or

damage to unit.

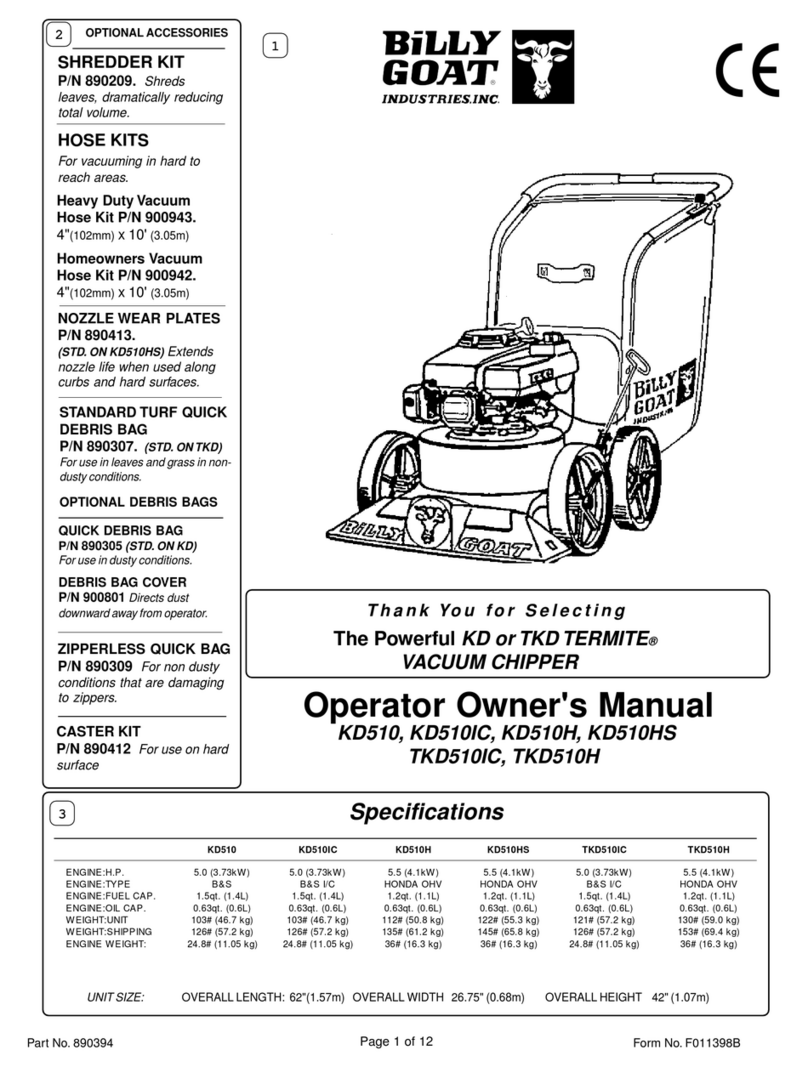

○○○○○○

SAFETY INSTRUCTIONS

GENERAL SAFETY

ASSEMBLY

PARTS BAG & CONTROLS

LABELS

OPERATION

MAINTENANCE

PARTS DRAWING & LIST

TROUBLESHOOTING

WARRANTY PROCEDURE

○○○

○○ ○○○○○

○○○○○○○○

○○○○○

○○

8 - 9

12

12

10 - 12

5 - 7

4

4

3

3

2

13. DO NOT tamper with governor springs,

governor links or other parts which may

change the governed engine speed.

14. DO NOT tamper with the engine speed

selected by the engine manufacturer.

15. DO NOT check for spark with spark

plug or spark plug wire removed. Use an

approved tester.

16. DO NOT crank engine with spark plug

removed. If engine is flooded, place

throttle in “FAST” position and crank until

engine starts.

17. DO NOT strike flywheel with a hard

object or metal tool as this may cause

flywheel to shatter in operation. Use

proper tools to service engine.

18. DO NOT operate engine without a

muffler. Inspect periodically and replace, if

necessary. If engine is equipped with

muffler deflector, inspect periodically and

replace, if necessary, with correct deflector.

19. DO NOT operate engine with an

accumulation of grass, leaves, dirt or other

combustible material in the muffler area.

20. DO NOT use this engine on any forest

covered, brush covered, or grass covered

unimproved land unless a spark arrester is

installed on the muffler. The arrester must

be maintained in effective working order by

the operator. In the State of California the

above is required by law (Section 4442 of

the California Public Resources Code).

Other states may have similar laws.

Federal laws apply on federal lands.

OPERATOR

21. DO NOT touch hot muffler, cylinder, or

fins because contact may cause burns.

22. DO NOT run engine without air cleaner

or air cleaner cover.

23. DO NOT operate during excessive

vibration!

24. DO NOT leave machine unattended

while in operation.

25. DO NOT park machine on a steep

grade or slope.

WARNING: DO

1. ALWAYS DO remove the wire from the

spark plug when servicing the engine or

equipment TO PREVENT ACCIDENTAL

STARTING.

2. DO keep cylinder fins and governor

parts free of grass and other debris

which can affect engine speed.

3. DO pull starter cord slowly until resis-

tance is felt. Then pull cord rapidly to avoid

kickback and prevent hand or arm injury.

4. DO examine muffler periodically to be

sure it is functioning effectively. A worn or

leaking muffler should be repaired or

replaced as necessary.

5. DO use fresh gasoline. Stale fuel can

gum carburetor and cause leakage.

6. DO check fuel lines and fittings fre-

quently for cracks or leaks. Replace if

necessary

7. Follow engine manufacturer operating

and maintenance instructions.

8. Inspect machine and work area before

starting unit.

SOUND TESTS VIBRATION LEVEL 2.2g

Vibration levels at the operators handles were

measured in the vertical, lateral, and longitudinal

directions using calibrated vibration test equipment.

Tests were performed on 05/19/95 under the conditions

listed:

WIND SPEED:

WIND DIRECTION:

UMIDITY:

TEMPERATURE:

BAROMETRIC PRESSURE:

GENERAL CONDI-

TION:

SOUND

Sound tests conducted were in accordance

with 79/113/EEC and were performed on 05/

19/95 under the conditions listed:

GENERAL CONDI-

TION:

L

A

p

109

30.06" g (763mm g)

67 %

South

5 MP (8.0 kmh)

62 F (16.7 C)

WIND SPEED:

WIND DIRECTION:

UMIDITY:

TEMPERATURE:

BAROMETRIC PRESSURE:

Page 2 of 12

97

L

A

Sunny

30.06" g (763mm g)

67 %

South

5 MP (8.0 kmh)

62 F (16.7 C)

Sunny

IN THE INTEREST OF SAFET

5

6

7 8

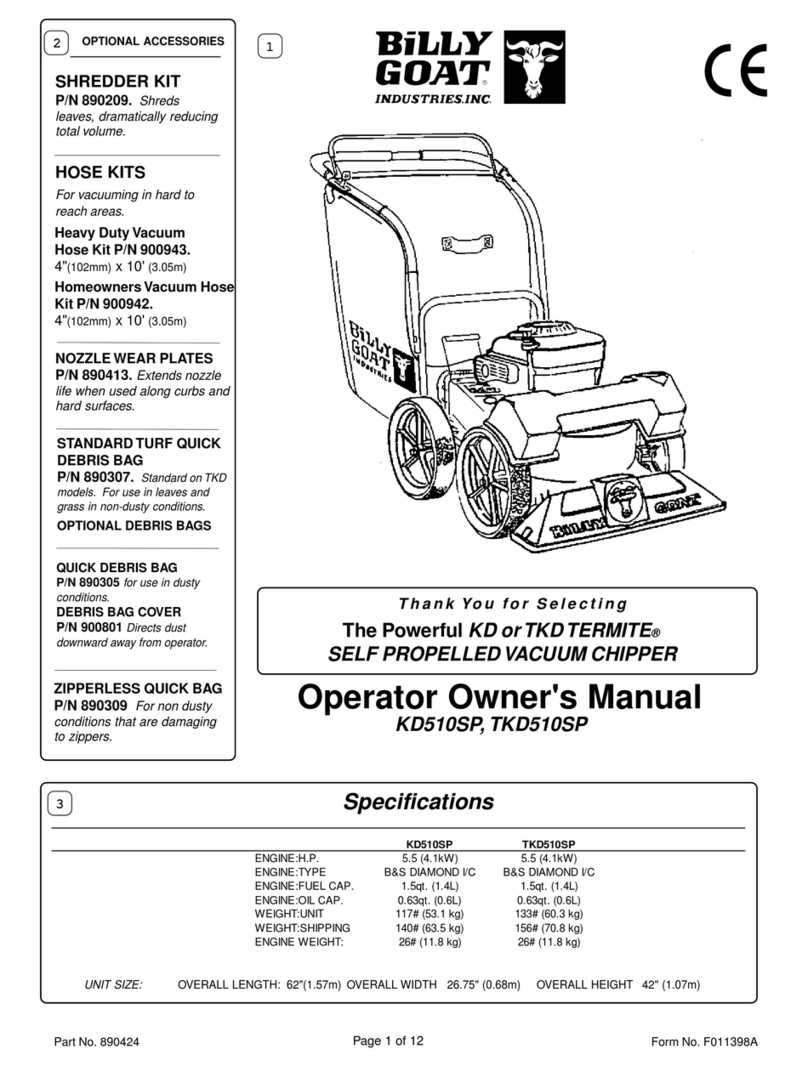

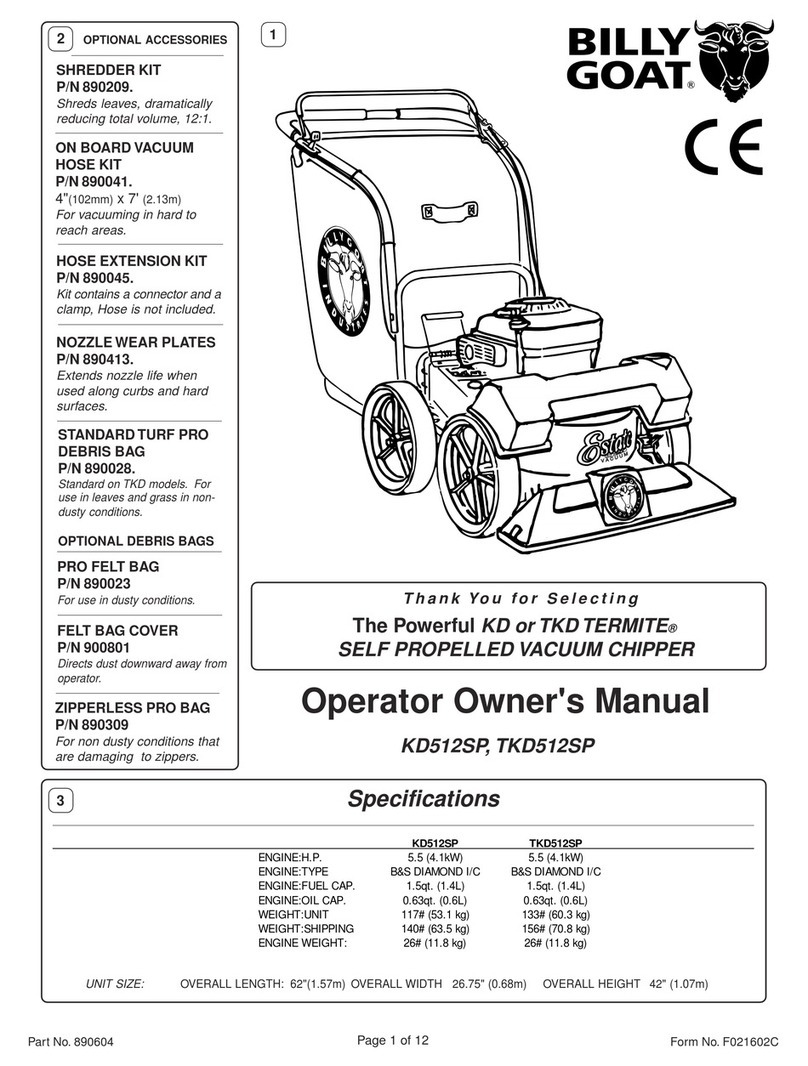

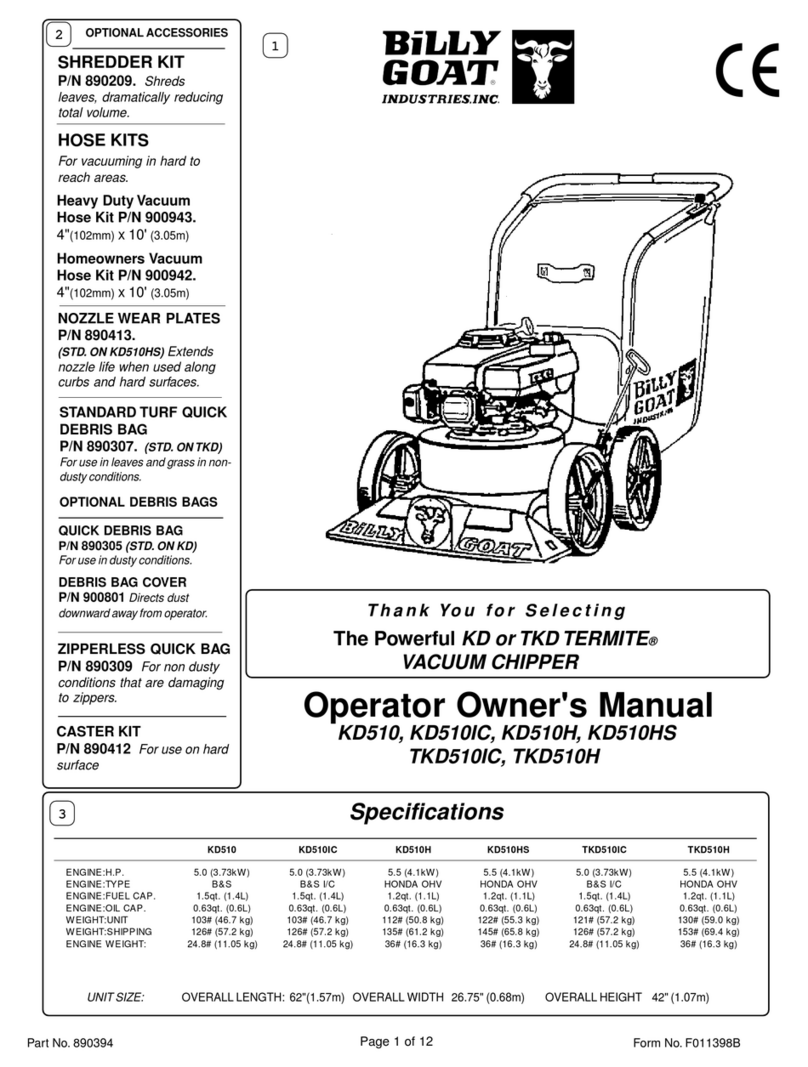

TABLE OF CONTENTS

○○○○○○○○○

VIBRATION

WARNING: The Engine Exhaust from this product contains chemicals known

to the State of California to cause cancer, birth defects or other reproductive harm.