Bindicator Pulse Point LP-500ST User manual

Pulse Point™ LP-500ST

Installation & Operation Manual

IOM

O

Or

rd

de

er

r

f

fr

ro

om

m:

:

C

C

A

A

B

Br

ri

ig

gg

gs

s

C

Co

om

mp

pa

an

ny

y

622 Mary Street; Suite 101; Warminster, PA 18974

Phone: 267-673-8117 - Fax: 267-673-8118

www.cabriggs.com

CONTENTS

I. HANDLING AND STORAGE............................................................................................................................................................................1

Inspection and Handling

Disposal and Recycling

Storage

II. GENERAL SAFETY............................................................................................................................................................................................2

Authorized Personnel

Use

Misuse

III. PRODUCT DESCRIPTION..............................................................................................................................................................................3

Function

Applications

Features

Technical Specications

Figure 1: Temperature Table

Figure 2: Temperature Graph

IV. MECHANICAL INSTALLATION ....................................................................................................................................................................5

Guidelines

Mounting Considerations

Figure 3: High/Low Level Location

Figure 4: Mounting Position

V. ELECTRICAL INSTALLATION.........................................................................................................................................................................7

General Safety

Disconnect Requirements for Permanently Installed Equipment

Protective Earth Ground

Electrical Connections

Figure 5: Wiring

Figure 6: Fail-Safe Operation

VI. MAINTENANCE ...............................................................................................................................................................................................9

Preventative Maintenance

VII. TROUBLESHOOTING .................................................................................................................................................................................9

VIII. DIMENSIONAL DRAWINGS ..................................................................................................................................................................10

Pulse Point™ LP-500ST

Installation & Operation Manual

SAFETY SYMBOLS

WARNING:

IDENTIFIES CONDITIONS OR PROCEDURES, WHICH IF NOT

FOLLOWED, COULD RESULT IN SERIOUS INJURY.

CAUTION:

IDENTIFIES CONDITIONS OR PROCEDURES, WHICH IF NOT

FOLLOWED, COULD RESULT IN SERIOUS DAMAGE OR FAILURE OF

THE EQUIPMENT.

www.bindicator.com

I. HANDLING AND STORAGE

SAVE THESE INSTRUCTIONS

INSPECTION AND HANDLING

Do not dispose of the carton or packing materials.

Each package should be inspected upon receipt for damage that may have occurred due to mishandling

during shipping. If the unit is received damaged, notify the carrier or the factory for instructions. Failure to

do so may void your warranty. If you have any problems or questions, consult the manufacturer Customer

Support at 1-800-778-9242.

DISPOSAL AND RECYCLING

This product can be recycled by specialized companies and must not be disposed of in a municipal collection

site. If you do not have the means to dispose of properly, please contact the manufacturer for return and

disposal instructions or options.

STORAGE

If the product is not scheduled for immediate installation following delivery, the following steps should be

observed:

1. Following inspection, repackage the unit into its original packaging.

2. Select a clean dry site, free of vibration, shock and impact hazards.

3. If storage will be extended longer than 30 days, the unit must be stored at temperatures between -31

to 140° F (-35 to 60° C) in non-condensing atmosphere with humidity less than 98%.

CAUTION: DO NOT STORE A NONPOWERED UNIT OUTDOORS FOR A PROLONGED PERIOD.

Pulse Point™ LP-500ST

Installation & Operation Manual

1

www.bindicator.com

II. GENERAL SAFETY

AUTHORIZED PERSONNEL

All instructions described in the document must be performed by authorized and qualied service personnel

only. Before installing the unit, please read these instructions and familiarize yourself with the requirements and

functions of the device. The required personal protective equipment must always be worn when servicing this

device.

USE

The device is solely intended for use as described in this manual. Reliable operation is ensured only if the

instrument is used according to the specications described in this document. For safety and warranty reasons,

use of accessory equipment not recommended by the manufacturer or modication of this device is explicitly

forbidden. All servicing of this equipment must be performed by qualied service personnel only. This device

should be mounted in locations where it will not be subject to tampering by unauthorized personnel.

MISUSE

Improper use or installation of this device may cause the following:

• Personal injury or harm

• Application specic hazards such as vessel overll

• Damage to the device or system

If any questions or problems arise during installation of this equipment, please contact the manufacturer

Customer Support at 800-778-9242.

2

www.bindicator.com

III. PRODUCT DESCRIPTION

FUNCTION

The LP-500ST is a vibrating rod, level measuring switch suitable for low and high level indication of granules and

powders with a minimum density of 3.12 lbs/ft3(0.05 kg/dm3density), using vibratory technology.

APPLICATIONS

Unlike radio frequency and capacitance technology sensors, the LP-500ST vibrating probe senses material using

a mechanical principle and is therefore not aected by the dielectric constant of the material. This makes it an

ideal sensor in plastics, dust, shavings, cement, lime, sand, grain, feed, sugar, etc.

FEATURES

• Universal power supply: AC or DC

• No calibration required

• Adjustable sensitivity

• Fine polished probe

TECHNICAL SPECIFICATIONS

FUNCTIONAL

Power Requirements 20 to 255 V AC/DC

Power Consumption ≤ 2.5 VA/2 W

Temperature See Figure 1

Outputs Main Relay: 8A SPDT @ 250 VAC, AC1

PERFORMANCE

Pressure Rating 362 psi (25 bar); cable extended 87 psi (6 bar)

Time Delay Field adjustable; 2 or 5 seconds

Fail Safe Field selectable, high/low level

Sensitivity 3.12 lbs/ft3(0.05 kg/dm3)

Maximum Particle Size 10mm

PHYSICAL

Enclosure Material, Rating Powder Coated Aluminum , IP67, NEMA 6

Conduit Entry

(2)

1/2”NPT;

(2) M20 x 1.5

Process Connections 11/2”NPT

Maximum Insertion Length (std unit) 8.15 in. (207 mm)

Shipping Weight (standard unit) 4.14 lb (1.88 kg)

3

www.bindicator.com

Figure 1: Temperature Table

Figure 2: Temperature Graph : Ambient Temperature Ta versus Medium Temperature Tm

TEMPERATURE DATA STANDARD AND PIPE EXTENDED VERSION CABLE EXTENDED VERSION

HIGH TEMP

Medium Temperature

Min -22º F (-30º C)

140º F

(60º C)

158º F

(70º C)

203º F

(95º C)

230

º F

(110º C)

320º F

(160º C)

140º F

(60º C)

158º F

(70º C

203º F

(95º C)

Ambient Temperature Range

Min -22º F (-30º C) 140º F

(60º C)

122º F

(50º C)

140º F

(60º C)

122

º F

(50º C)

95º F

(35º C)

140º F

(60º C)

122º F

(50º C)

140º F

(60º C)

Max. Surface Temperature

of Process Connection 185º F

(85º C)

185º F

(85º C)

203º F

(95º C)

203

º F

(95º C)

275º F

(135º C)

185º F

(85º C)

185º F

(85º C)

203º F

(95º C)

Max. Surface Temperature 185º F

(85º C)

185º F

(85º C)

203º F

(95º C)

230

º F

(110º C)

320º F

(160º C)

185º F

(85º C)

185º F

(85º C)

203º F

(95º C)

4

www.bindicator.com

IV. MECHANICAL INSTALLATION

GUIDELINES

The following precautions should be observed when installing and operating the product:

• The installation and wiring of this product must comply with all national, federal, state, municipal and

local codes that apply.

• This product is a precision device - handle the device with great care, especially the sensing probe.

• Any impact on the sensing probe may ruin its resonance system.

• A protective shield should be installed if the probe is exposed to falling material or excessive mechanical

load.

MOUNTING CONSIDERATIONS

Prior to installation, it is advised to check the switching function for proper adjustment on a sample quantity of

material. The unit may not work with mediums within the specied density range but having very large size of

granules or extremely little friction.

Screw in the device by its hexagon neck. After screwing tight the process connection, the housing can be

rotated (max. 300°), to adjust the cable gland to the required position. It might be necessary to install the device

at an oset level position relative to the switching level actually required taking into account angle of repose of

the material in the silo, see Figure 3.

Figure 3: High/Low Level Location

High Level Location Low Level Location

WARNING: REMOVE POWER FROM THE UNIT BEFORE INSTALLING, REMOVING, OR MAKING

ADJUSTMENTS

CAUTION: ATTEMPTING TO TIGHTEN THE LP500ST BY ROTATING THE HOUSING OR ROD

MAY DAMAGE THE UNIT AND VOID THE WARRANTY.

5

www.bindicator.com

Figure 4: Mounting Position

With powder level detection, device should be installed at an inclination exceeding the angle of repose (or, in

case of high level detection vertically), to prevent powder deposition on vibrating rod that might substantially

reduce the self-cleaning eect. Also avoid mounting the rod in a recess, see Figure 4.

In case of tanks that are likely to be exposed to intense vibrations, necessary provisions shall be made by the customer for

damping the vibrations acting on the device (e.g. vibration damping inserts made of rubber have to be applied).

6

www.bindicator.com

V. ELECTRICAL INSTALLATION

GENERAL SAFETY

When using electrical equipment, you should always follow basic safety precautions, including the following:

• The installation and wiring of this product must comply with all national, federal, state, municipal, and

local codes that apply.

• Do not modify any factory wiring. Connections should only be made to the terminals described in this

section.

PROTECTIVE EARTH GROUND

To eliminate shock hazards in the unlikely event of an internal insulation breakdown, the unit is provided with a

“protective earth” ( ) lead which must be connected to earth ground. In addition, the input power ground

lead must be connected to the “protective earth”( ) terminal provided. Wire sizes must be selected such that

it can safely carry the sum total of all circuits’maximum amperage.

ELECTRICAL CONNECTIONS

Note: The LP-500ST model can be operated from 20-255 V AC/DC and provides reverse polarity protection in

the event of a wiring error.

1. Remove the top cover of the housing to access the connection terminals and adjusting switches.

2. Do not remove the wire form terminal pin 1, see Figure 5, because it is an internal connection. For

grounding the unit, use the PE grounding screw terminal PE.

3. After proper installation and the electrical connection, established the device is ready for operation. The

switched-on state is indicated by the lighting of the LED.

The DENSITY (switch A) switch is to be set in accordance with the density of the material:

• LOW position, recommended for loose and light materials with density below 3.12 lbs/ft3(0.05 kg/dm3)

represents small energy and amplitude of vibration as well as great sensitivity of detection.

• HIGH position, recommended for (thick and heavy) materials with density over 6.24 lbs/ft3(0.1 kg/dm3)

represents vibration with great energy and amplitude and small sensitivity of detection

The instrument may not switch correctly in mediums with density less than 3.12 lbs/ft3(0.05 kg/dm3) or with

very small internal friction.

To obtain FAIL SAFE alarm (switch C), use the de-energized or open state of the output as an alarm, thus a

power breakdown will also be considered as alarm, see Figure 6.

The delay (switch B) is to be selected to comply with requirements of the process control technology the

units are used for.

WARNING: VERY HIGH VOLTAGE IS PRESENT ON THE ROD. REMOVE POWER

FROM THE UNIT BEFORE INSTALLING, REMOVING, OR MAKING ADJUSTMENTS

CAUTION: ATTEMPTING TO TIGHTEN THE ST1000 BY ROTATING THE HOUSING OR ROD

MAY DAMAGE THE UNIT AND VOID THE WARRANTY

7

www.bindicator.com

Power Probe Fail Safe Mode LED Relay Solid State

Output

On

Not Vibrating

(Covered)

Low Green Energized On

High Red De-Energized O

Vibrating (Free) Low Red Energized O

High Green Energized On

Fails

Low or High Not Lit De-Energized O

54

6

54

6

54

6

54

6

54

6

6

45

2, 7 k

6

45

2, 7 k

6

45

2, 7 k

6

45

2, 7 k

6

45

2, 7 k

N

L1

PE

Device

to be

controlled

+5 V

IN

GND

50VAC

350mA

2,7k

N1L1

Status LED A B C

N

L1

PE

50VAC

350mA

2,7k

N1L1

Status LED

Overload LED

A B C

N

L1

PE

≤ 5 W

50VAC

350mA

2,7k

N1L1

Status LED

Overload LED

A B C

Status LED

N L1

PE PE

NO CNC

N1L1

250VAC

8A/AC1

A B C

Wiring of optional coupled sink input to solid state

output version supplied from an AC line

Wiring of a load to a solid state output version supplied

from an AC line

Wiring of relay output version

Wiring of a logical voltage input to a solid state ouput

version supplied from an AC line

Figure 6. Fail-Safe Operation

Figure 5.

8

www.bindicator.com

VI. MAINTENANCE

PREVENTATIVE MAINTENANCE

The LP-500ST model does not require maintenance on a regular basis. In some instances, however, the vibrating

section may need a cleaning from deposited material. This must be carried out gently, without harming the

vibrating section of the vibrating rod.

VII. TROUBLESHOOTING

Contact your local factory representative if additional assistance is needed. Please provide the following

information:

• Model number

• Date of Purchase

• Application information (type of material, mounting conguration, etc.)

• Description of problem

If your local representative is unable to determine the cause of diculty, you will be referred to a factory engineer.

Equipment shipped back to the factory without proper authorization will be refused and returned at the shipper’s

expense.

9

www.bindicator.com

VIII. DIMENSIONAL DRAWINGS

Values in inches (mm)

Standard

2 x M20 x 1.5

S = 46

3.5 (90)

8.1 (207)

4.6 (116)

5.2 (133)

2 x NPT 1/2”

11/2” BSP /

11/2” NPT

2 x M20 x 1.5

S = 46

3.5 (90)

1.0 - 9.8 ft (0.3 - 3 m)

4.6 (116)

5.2 (133)

2 x NPT 1/2”

11/2” BSP /

11/2” NPT

Pipe Extension

2 x M20 x 1.5

S = 46

3.5 (90)

3.2 - 65 ft (1 - 20 m)

4.6 (116)

5.2 (133)

2 x NPT 1/2”

11/2” BSP /

11/2” NPT

Cable Extension

10

150 Venture Boulevard

Spartanburg, SC 29306

Tel: (800) 778-9242

Fax: (864) 574-8063

sales@bindicator.com

www.bindicator.com

2015 All rights reserved.

All data subject to change without notice.

STS180212 Rev C

Table of contents

Other Bindicator Measuring Instrument manuals

Bindicator

Bindicator Pulse Point II Series User manual

Bindicator

Bindicator MP Series User manual

Bindicator

Bindicator PRD1000 User manual

Bindicator

Bindicator SonoTracker Ultrasonic Liquid Level User manual

Bindicator

Bindicator VRF-2000R Series User manual

Bindicator

Bindicator Roto-Bin-Dicator User manual

Popular Measuring Instrument manuals by other brands

Bresser

Bresser 40-25860 instruction manual

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS WATERPROOF PHSCAN 2 PH TESTER manual

Akron Brass

Akron Brass AkroFlow 9301 Installation, operating and maintenance instructions

wattwatchers

wattwatchers A6M+One installation guide

Dakota Digital

Dakota Digital Odyssey II Series quick start guide

LI-COR

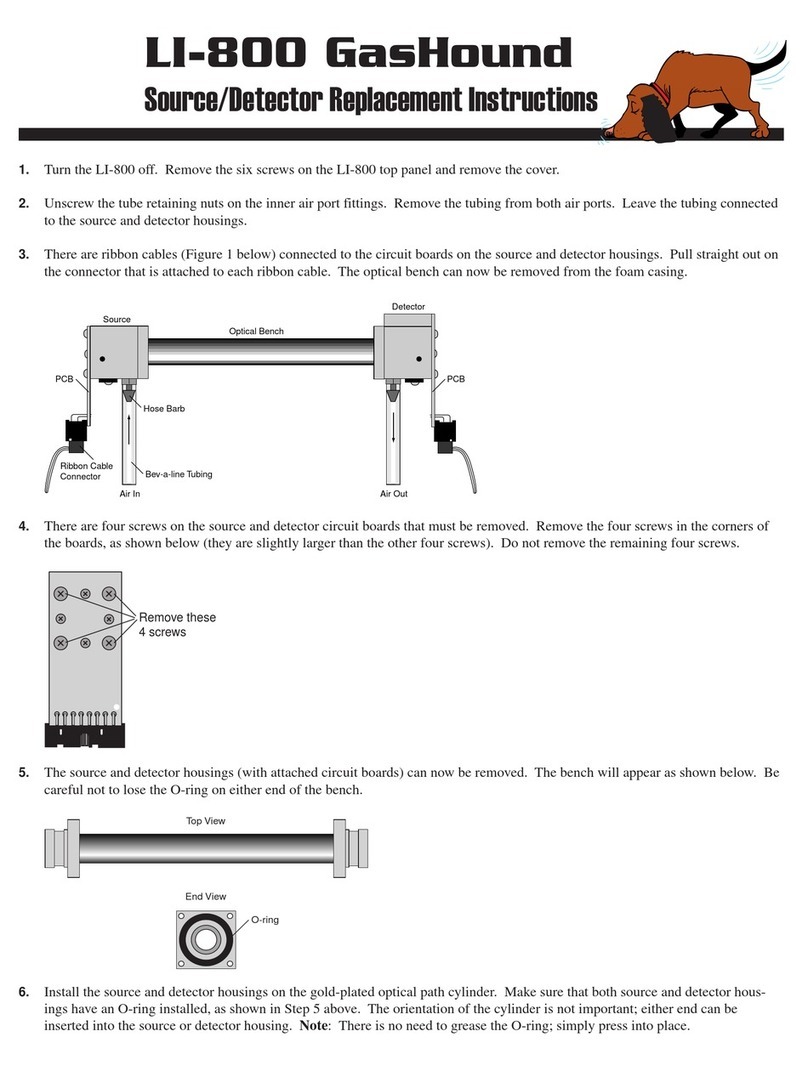

LI-COR LI-800 Replacement instructions