Bindicator Roto-Bin-Dicator User manual

IOM

LAR180212 Rev. E

Roto-Bin-Dicator®

Single & Double Switch Models

Installation & Operation Manual

StockCheck.com

StockCheck.com

Roto-Bin-Dicator®

Single & Double Switch Models

Installation & Operation Manual

CONTENTS

I. HANDLING & STORAGE ...........................................................................................................................1

Inspection and Handling

Disposal and Recycling

Storage

II. GENERAL SAFETY....................................................................................................................................2

Authorized Personnel

Use

Misuse

III. PRODUCT DESCRIPTION.........................................................................................................................3

TechnicalSpecications

Approvals & Ratings

IV. MECHANICAL INSTALLATION..................................................................................................................4

Mounting Location

Mounting Surface Preparation

Mounting on Side of Bin

Mounting on Top of Bin

V. ELECTRICAL INSTALLATION.................................................................................................................... 5

Wiring for 24V/110V/220V AC Units

Wiring for 24VDC Units

VI. MAINTENANCE .........................................................................................................................................6

Preventative Maintenance

Replacement Parts

StockCheck.com

SAFETY SYMBOLS

WARNING:

IDENTIFIES CONDITIONS OR PROCEDURES, WHICH IF NOT

FOLLOWED, COULD RESULT IN SERIOUS INJURY. RISK OF

ELECTRICAL SHOCK.

CAUTION:

IDENTIFIES CONDITIONS OR PROCEDURES, WHICH IF NOT

FOLLOWED, COULD RESULT IN SERIOUS DAMAGE OR FAILURE

OF THE EQUIPMENT.

StockCheck.com

1

www.bindicator.com

LAR180212 Rev. E

I. HANDLING AND STORAGE

SAVE THESE INSTRUCTIONS

INSPECTION AND HANDLING

Do not dispose of the carton or packing materials.

Each package should be inspected upon receipt for damage that may have occurred due to mishandling during

shipping. If the unit is received damaged, notify the carrier or the factory for instructions. Failure to do so may

void your warranty. If you have any problems or questions, consult the manufacturer Customer Support at

800-778-9242.

DISPOSAL AND RECYCLING

This product can be recycled by specialized companies and must not be disposed of in a municipal collection

site. If you do not have the means to dispose of properly, please contact the manufacturer for return and

disposal instructions or options.

STORAGE

If the Roto-Bin-Dicator®is not scheduled for immediate installation following delivery, the following steps should

be observed:

1. Following inspection, repackage the unit into its original packaging.

2. Select a clean dry site, free of vibration, shock and impact hazards.

3. If storage will be extended longer than 30 days, the unit must be stored at temperatures between 32° and

158° F (0° and 70° C) in non-condensing atmosphere with humidity less than 85%.

CAUTION: DO NOT STORE A NON-POWERED UNIT OUTDOORS FOR A PROLONGED PERIOD.

Roto-Bin-Dicator®

Single & Double Switch Models

StockCheck.com

2

www.bindicator.com

LAR180212 Rev. E

II. GENERAL SAFETY

AUTHORIZED PERSONNEL

Allinstructionsdescribedinthedocumentmustbeperformedbyauthorizedandqualiedservicepersonnel

only. Before installing the unit, please read these instructions and familiarize yourself with the requirements and

functions of the device. The required personal protective equipment must always be worn when servicing this

device.

USE

The device is solely intended for use as described in this manual. Reliable operation is ensured only if the

instrumentisusedaccordingtothespecicationsdescribedinthisdocument.Forsafetyandwarrantyreasons,

useofaccessoryequipmentnotrecommendedbythemanufacturerormodicationofthisdeviceisexplicitly

forbidden.Allservicingofthisequipmentmustbeperformedbyqualiedservicepersonnelonly.Thisdevice

should be mounted in locations where it will not be subject to tampering by unauthorized personnel.

MISUSE

Improper use or installation of this device may cause the following:

• Personalinjuryorharm

• Applicationspecichazardssuchasvesseloverll

• Damagetothedeviceorsystem

If any questions or problems arise during installation of this equipment, please contact the manufacturer

Customer Support at 800-778-9242.

WARNING: ONLY CERTAIN MODELS CAN BE USED IN HAZARDOUS LOCATIONS; SEE NAMEPLATE.

THESE MODELS SHALL ONLY BE USED IN APPLICATIONS COVERED BY THE STATED RATINGS OR

NON-HAZARDOUS LOCATIONS.

StockCheck.com

3

www.bindicator.com

LAR180212 Rev. E

III. PRODUCT DESCRIPTION

Operation centers around the low torque, slow speed synchronous motor. The motor either turns the paddle in the

absence of the bulk material, or turns itself to actuate the micro switch when paddle rotation is stopped by the

bulk material. Constant power to the stalled motor keeps the switch actuated until the paddle is again free to turn.

TECHNICAL SPECIFICATIONS

FUNCTIONAL

Operating Power

24/120/240 VAC; 50/60 Hz, 24 VDC

Power Consumption 5 watts

Motor 1 rpm

Fail-Safe Circuitry Low level fail safe

Switch Rating General Purpose: SPDT 20A @ 125/250/480 VAC.

Pilot Duty: 345 VA, 115 VAC; 690 VA, 230 VAC

Operating Temp -40º F to 113º F (-40º C to 45º C)

PHYSICAL

Drive Shaft Assembly Precision machined shaft with two shielded ball bearings

Shaft Seal Teon®/Viton®Lipseal rated 1/2micron @ 30 psi (2.1 kg/cm2) @ 400º F (204º C)

Housing and Cover

Type 4X/IP66 polyester coated aluminum casting

Mounting Plate 8” outside diameter with 11/4” NPT pipe threaded coupling; standard polyester coated mild steel;

optional 304 stainless steel

Conduit Entry 3/4” NPT or M20 x 1.5

Rigid Shaft and

Paddle Metal parts of all designs are 304 stainless steel

Flex Shaft

Available in neoprene, 155º F (68º C) or silicone, 400º F (204º C) coatings

Shipping Weight Aluminum housing 10 lbs (4.5 kg)

Stainless Steel housing 16 lbs (7.3 kg)

Pollution Degree 2

Installation Category II

Altitude 6,562 ft (2000 m)

APPROVALS & RATINGS

UL (US and Canada):

Ordinary Location Type 4X; IP66

Hazardous Location, Type 4X

Explosion Proof

Dust Ignition Proof

ATEX/IEC/IECex: (Pending)

Dust and Gas Categories; IP66

CE

Electromagnetic Compatibility Directive

Low Voltage Directive

StockCheck.com

4

www.bindicator.com

LAR180212 Rev. E

IV. MECHANICAL INSTALLATION

GUIDELINES

The following precautions should be observed when installing and operating a Roto-Bin-Dicator PRO device:

• Theinstallationandwiringofthisproductmustcomplywithallnational,federal,state,municipaland

local codes that apply.

• Handlecarefullytopreventdamage.

• Donotallowmoisturetoentertheelectronicsenclosure.Conduitshouldslopedownwardfromthe

housing.Installdriploops(ordraintting)andsealconduitwithsiliconerubberproduct.

• Forhorizontallymountedunits,theconduitopeningsmustfacedownward.

The unit must be located at the position where level indication is desired. The unit may be mounted through the

top or side wall of the vessel. To ensure reliable operation, observe the following guidelines when choosing the

mounting location.

• DONOTmounttheRoto-Bin-DicatorPROinanareawherethepaddleorshaftcancontactthevessel.

• DONOTmounttheRoto-Bin-DicatorPROwherethepaddleorshaftaredirectlyintheowofmaterial.

Thematerialshouldbeabletoowontoandawayfromthepaddle.Ifnecessary,useabafetoprotect

thepaddleandshaftfromfallingmaterial(ie.avalanche,massowandin-comingowstream).The

bafeshouldbeplaced6to12inchesabovethepaddle,distancedependonpaddlesize.

WARNING: FOR PRODUCTS MARKED AS TYPE 4X, USE TYPE 4X HUB FITTING; FOR IP66 USE IP66

HUB FITTING.

WARNING: IN ORDER TO MAINTAIN SAFE OPERATION IN HAZARDOUS LOCATIONS, THE

INTEGRITY OF THE ALUMINUM CASTING AND THE EPDM SEALS MUST BE MAINTAINED. THE

USER/INSTALLER MUST AVOID INSTALLATIONS WHERE AGGRESSIVE SUBSTANCES MAY BE

PRESENT AND COULD AFFECT THE PERFORMANCE OF THESE MATERIALS. CARE MUST BE

EXCERCISED WHEN REMOVING AND REPLACING THE COVER, SO NO MARRING, SCRATCHING

OR DAMAGE OCCURS TO THE FLANGES.

CAUTION: WHEN MOUNTING UNITS, NEVER ADJUST THE ORIENTATION BY TURNING THE HOUSING.

USE 2-1/4 IN. WRENCH FOR PROCESS FITTING UNITS, OTHERWISE A STRAP WRENCH SHOULD BE

USED TO TIGHTEN INTO PLACE.

WARNING: FOR UNITS INSTALLED IN HAZAROUS LOCATIONS, TO REDUCE THE RISK OF IGNITION OF

HAZARDOUS ATMOSPHERES, CONDUIT RUNS MUST HAVE A SEALING FITTING CONNECTING WITHIN

18 IN. OF THE ENCLOSURE.

WARNING: REMOVE POWER FROM THE UNIT BEFORE INSTALLING, REMOVING, OR MAKING

ADJUSTMENTS.

StockCheck.com

5

www.bindicator.com

LAR180212 Rev. E

Mounting Plate

H-20 gasket

8.0” O.D.

6.0” I.D.

11/4” NDT

installation for use with mounting plates

1. On a 7 in. bolt circle, drill and tap or drill 6 equally spaced holes in the bin wall for 1/4 in. bolts or cap

screws. If not tapped, bolt heads should be tack welded to the bin inner wall.

2. Cut a 5 in. diameter hole to pass the paddle through. Contact factory for non-standard wall thickness

greater than 1/4 in.

MOUTING - SIDE OF BIN

1. Conduit opening must face down.

2. Assemble gasket between the mounting plate and the bin wall.

3. Flat washer, customer supplied, is recommended between mounting plate and fastening hardware.

Mounting Plate & Gasket Diagram

MOUNTING - TOP OF BIN

1. Assemble gasket between the mounting plate and the bin.

2. Flat washer, customer supplied, is recommended between mounting plate and fastening hardware.

NOTE:Allextendedunitsshouldhaveshaftguardand/orexcoupling.

NOTE: Extended units with shaft lengths greater than 12 inches require a shaft guard.

NOTE: It is recommended that the shaft guard be braced to bin will at 6 foot intervals.

installation for use without mounting plates

Preferred mount is through half couplings; a full coupling will allow material to collect around the shaft, which

may cause additional drag on the rotating shaft.

StockCheck.com

6

www.bindicator.com

LAR180212 Rev. E

V. ELECTRICAL INSTALLATION

CAUTION: IF THE UNIT WAS SUPPLIED WITH A GASKET, AVOID FOLDING, CUTTING OR TEARING

THE GASKET. DAMAGING THE GASKET CAN ALLOW MOISTURE TO ENTER THE ENCLOSURE AND

DAMAGER THE UNIT

GENERAL SAFETY

When using electrical equipment, you should always follow basic safety precautions, including the following:

• Unitsinstalledinhazardouslocationsmustobserveallgovernmentregulationsregardingequipmentin

hazardous locations.

• Theinstallationandwiringofthisproductmustcomplywithallnational,federal,state,municipal,and

local codes that apply.

• Properlygroundtheenclosuretoanadequateearthground.

• Donotmodifyanyfactorywiring.Connectionsshouldonlybemadetotheterminalsdescribedinthis

section.

• Allconnectionsmustuseconductorswithaninsulationratingof300Vminimum,ratedfor221ºF

(105º C),aminimumammabilityratingofVW-1,andbeofappropriategaugeforthevoltageandcurrent

required(seespecications).

• Donotallowmoisturetoentertheelectronicsenclosure.Conduitshouldslopedownwardfromthe

housing. Install drip loops and seal conduit with silicone rubber product.

DISCONNECT REQUIREMENTS FOR PERMANENTLY INSTALLED EQUIPMENT

A dedicated disconnecting device (circuit breaker) must be provided for the proper installation of the unit. If

independent circuits are used for power input and outputs, individual disconnects are required. Disconnects

must meet the following requirements:

• Locatedincloseproximitytothedevice

• Easilyaccessibletotheoperator

WARNING: FOR PRODUCTS MARKED AS TYPE 4X, USE TYPE 4X HUB FITTING; FOR IP66 USE IP66

HUB FITTING.

WARNING: FOR UNITS INSTALLED IN HAZAROUS LOCATIONS, TO REDUCE THE RISK OF IGNITION OF

HAZARDOUS ATMOSPHERES, CONDUIT RUNS MUST HAVE A SEALING FITTING CONNECTING WITHIN

18 IN. OF THE ENCLOSURE.

WARNING: REMOVE POWER FROM THE UNIT BEFORE INSTALLING, REMOVING, OR MAKING

ADJUSTMENTS.

CAUTION: TO REDUCE THE RISK OF IGNITION IN HAZARDOUS ATMOSPHERES, DISCONNECT THE

EQUIPMENT FROM SUPPLY CURCIUT BEFORE OPENING. KEEP ASSEMBLY TIGHTLY CLOSE WHEN IN

OPERATION.

StockCheck.com

7

www.bindicator.com

LAR180212 Rev. E

• Appropriatelymarkedasthedisconnectforthedeviceandassociatedcircuit

• Sizedappropriatelytotherequirementsoftheprotectedcircuit(Seespecications)

PROTECTIVE EARTH GROUND

To eliminate shock hazards in the unlikely event of an internal insulation breakdown, the unit is provided with

a “protective earth” ( ) lead which must be connected to earth ground. In addition, the input power ground

lead must be connected to the “protective earth” ( ) terminal provided. Wire sizes must be selected such that

it can safely carry the sum total of all circuits’ maximum amperage.

WIRING

1. Connect the power source for the motor to the terminal block. Continuous power is essential. The motor

maybestalledindenitelywithoutdamage.

2. Make wiring connections to the control micro switch using a separate circuit from that of the motor.

3. Apply power to the motor circuit, checking the freeness of operation and actuation of the micro switch.

4. Fasten the housing cover securely to prevent damage from dust or moisture.

WIRING FOR SINGLE SWITCH WIRING FOR DOUBLE SWITCH

24/120/240 VAC UNITS

warning: Do not power motor through a microswitch.

WIRING FOR 24 VDC UNITS

StockCheck.com

8

www.bindicator.com

LAR180212 Rev. E

VI. MAINTENANCE

PREVENTATIVE MAINTENANCE

No scheduled preventative maintenance is required for the Roto-Bin-Dicator®units when properly applied and

installed correctly. There is no cleaning required for the unit before or during installation.

If the cover is removed after the unit has been in service, it is recommended to replace the gasket to prevent the

ingress of water or dust. At a minimum, the gasket (or o-ring, used in hazardous locations) should be inspected

for folds, cracks and tears.

RECOMMENDED SPARE PARTS

MOUNTING PLATES

Includes H-20 Mounting Gasket

PART NUMBER MODEL DESCRIPTION

LAR110130 H-19 Mild Steel (Side of Bin)

LAR110140 H-19SS 304 Stainless Steel (Side of Bin)

LAR110180 H-192 Mild Steel (Top of Bin)

LAR110190 H-192SS 304 Stainless Steel (Top of Bin)

SHAFT COUPLINGS

PART NUMBER MODEL DESCRIPTION

LAR110270 H-36 Neoprene 3 in. Flexible Shaft; 170º F (77º C) Max Temp

LAR120640 H-38 Stainless Steel, 3 in.

LAR110275 H-36S

Molded Silicone 3 in. Flexible Shaft; 400º F (204º C) Max Temp

PADDLES

All are stainless steel except model H-373.

PART NUMBER MODEL DESCRIPTION

LAR110310 H-370 4-Vane; 11/2”x 5” Diameter with Pins

LAR110360 H-371 4-Vane; 2” x 7” Diameter with Pins

LAR110430 H-373 Multiex;SolidNeoprene11/2” x 24” with Pins

LAR110450 H-374 Multiex;StainlessSteel11/2” x 17” with Pins

LAR111037 H-379 1-Vane; Insertable with Pins

LAR111040 H-372A 1-Vane; 1” x 27/8” with 45º Cut

LAR111200 H-380 2-Vane Collapsible, Stainless Steel

note. Consult the manufacturing facility on applications where the housing ambient temperature is above 200º F (93º C).

WARNING: IN ORDER TO MAINTAIN SAFE OPERATION IN HAZARDOUS LOCATIONS, THE

INTEGRITY OF THE ALUMINUM CASTING AND THE EPDM SEALS MUST BE MAINTAINED. THE

USER/INSTALLER MUST AVOID INSTALLATIONS WHERE AGGRESSIVE SUBSTANCES MAY BE

PRESENT AND COULD AFFECT THE PERFORMANCE OF THESE MATERIALS. CARE MUST BE

EXCERCISED WHEN REMOVING AND REPLACING THE COVER, SO NO MARRING, SCRATCHING

OR DAMAGE OCCURS TO THE FLANGES.

CAUTION: IF THE UNIT WAS SUPPLIED WITH A GASKET, AVOID FOLDING, CUTTING OR TEARING

THE GASKET. DAMAGING THE GASKET CAN ALLOW MOISTURE TO ENTER THE ENCLOSURE AND

DAMAGER THE UNIT

StockCheck.com

9

www.bindicator.com

LAR180212 Rev. E

SHAFT EXTENSIONS

PART NUMBER DESCRIPTION

LUB040500 316 Stainless Steel, 1/8 in. pipe

SHAFT GUARDS

PART NUMBER DESCRIPTION

LUB040510 316 Stainless Steel, 1-1/4” NPT

HEAVY DUTY ROTO-BIN-DICATOR PARTS

PART # MODEL DESCRIPTION

LAR110070 A-H-9A-K-HD Heavy Duty Roto-Bin-Dicator®Motor Replacement Kit: 120 VAC,

4 W, 1 rpm, 50/60Hz; Includes bracket and washer (see Note 1)

LAR110100 A-H-9D-K-HD Heavy Duty Roto-Bin-Dicator®Motor Replacement Kit: 240 VAC,

4 W, 1 rpm, 50/60 Hz; Includes bracket and washer (see Note 2)

LAR110940 A-RX-1 Lower Frame Assembly (General Purpose): Aluminum,

Gasket, Clutch/Drive Shaft, Bearings, Seal, and Stub Shaft

LAR110945 Lower Frame Assembly (General Purpose): Stainless Steel,

Gasket, Clutch/Drive Shaft, Bearings, Seal, and Stub Shaft

LAR111002 RX 1/RX 2 Housing Assembly (Explosionproof): Aluminum, Clutch/Drive

Shaft, Bearings, Shaft Seal, and Stub Shaft; Cover Included

LAR111024 Standard Motor Replacement Kit: 24 VAC, 4W, 1 rpm, 50/60 Hz

LAR111025 H-10C Micro Switch, SP/DT with Barrier

LAR111026 H-10E Double Micro Switch, SP/DT with Barrier, Nut, and Screw

LAR120050 H-3 Switch Bracket

LAR120070 Housing Cover (General Purpose): Stainless Steel

LAR120470 H-23 Barrier, Terminal Block

LAR121960 RX-2 Housing Cover (General Purpose): Aluminum

LAR130300 H-11 Terminal Block

LAR111193 24 VDC to 24 VAC Inverter Board

LAR150170 Refurbished Stainless Steel RSSP1G

NOTE 1. Replaces the Standard 120 VAC Motor Replacement Kit (Part Number LAR110030, Model A-H-9A-K).

NOTE 2. Replaces the Standard 240 VAC Motor Replacement Kit (Part Number LAR110060, Model A-H-9D-K).

COMMON ROTO-BIN-DICATOR®PARTS

PART NUMBER MODEL DESCRIPTION

LAR120480 H-24

Motor Support Bracket; Not used with Fail-Safe or Fail-Safe-Plus Roto-Bin-Dicator®Models

LAR121930 H-35 Stub Shaft with Pins

LAR122142 316 Stainless Steel Tag

LAR131230 Lip Seal, RBD

LAR131394 Aluminum Tag

LAR131413 Lip Seal, 90psi

LUA031190 5954 Pin for Paddle (1/8” x ¾”)

LUBK43300 Fiber Gaskets, Pack of 5

LUBK43303 Food Grade Gaskets, Pack of 5

LUBK43304 Fiber Gasket, Metric, Pack of 5

LUBK43307 Food Grade Gasket, Metric, Pack of 5

LUBK43314 G-Thread Fitting Gasket, Pack of 5

StockCheck.com

10

www.bindicator.com

LAR180212 Rev. E

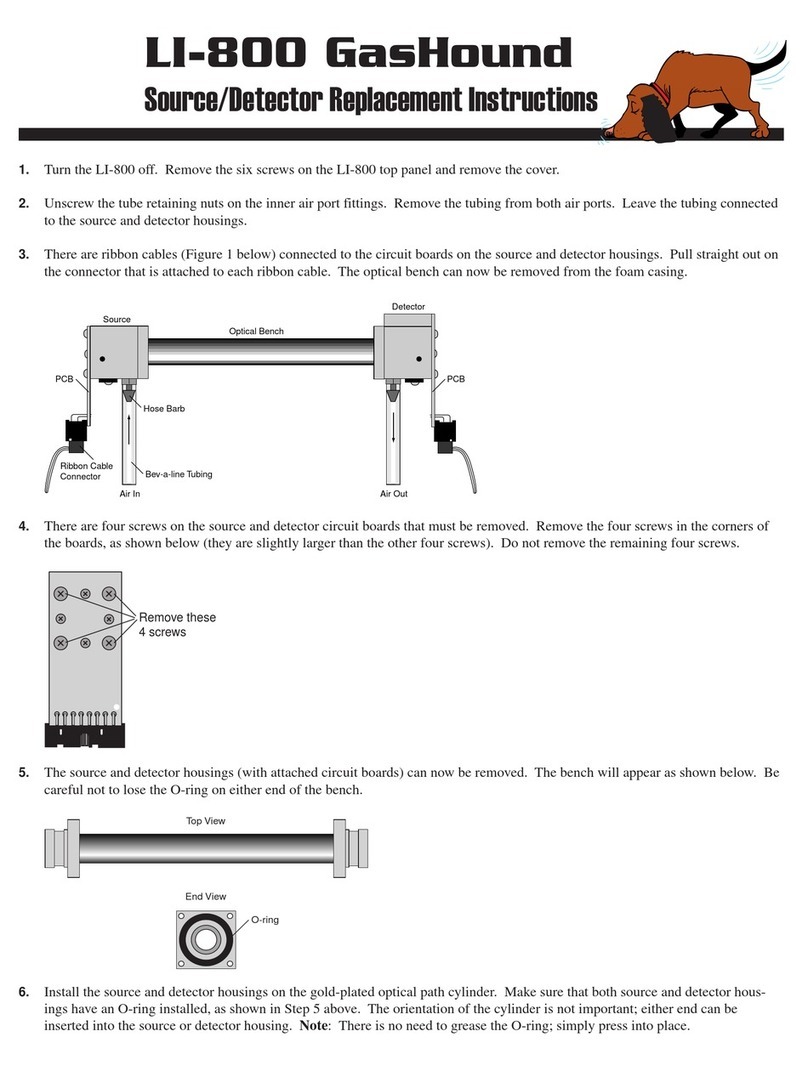

LOWER HOUSING ASSEMBLY

**NOT FOR EXPLOSION PROOF UNITS**: Bindicator® does not recommend the customer replacing the H-21 Clutch Assembly. Instead,

replace the lower housing assembly, which includes all of the parts listed below.

DETAIL NUMBER PART NUMBER DESCRIPTION QTY REQUIRED

1 LAR130330 H-12 Bearing 2

2 LAR131250 Spring Washer 2

3 LAR131230 H-32Teon®Lip Seal 1

4 LUA031190 5954 Roll Pin 1

5 LUC033190 Retaining O-Ring 1

6 LAR111012 H-21 Clutch Assembly 1

6

5

4

1

2

3

StockCheck.com

11

www.bindicator.com

LAR180212 Rev. E

Notes:

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

StockCheck.com

150 Venture Boulevard

Spartanburg, SC 29306

Tel: (800) 778-9242

Fax: (864) 574-8063

sales@bindicator.com

www.bindicator.com

2014 All rights reserved.

All data subject to change without notice.

LAR180212 Rev. E

StockCheck.com

Table of contents

Other Bindicator Measuring Instrument manuals

Bindicator

Bindicator Pulse Point II Series User manual

Bindicator

Bindicator MP Series User manual

Bindicator

Bindicator SonoTracker Ultrasonic Liquid Level User manual

Bindicator

Bindicator VRF-2000R Series User manual

Bindicator

Bindicator Pulse Point LP-500ST User manual

Bindicator

Bindicator PRD1000 User manual

Popular Measuring Instrument manuals by other brands

Bresser

Bresser 40-25860 instruction manual

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS WATERPROOF PHSCAN 2 PH TESTER manual

Akron Brass

Akron Brass AkroFlow 9301 Installation, operating and maintenance instructions

wattwatchers

wattwatchers A6M+One installation guide

Dakota Digital

Dakota Digital Odyssey II Series quick start guide

LI-COR

LI-COR LI-800 Replacement instructions