7

Use 41-4458 Teflon based grease to

lubricate all o-rings and moving parts

before reassembly into the gun body.

To further protect the environment,

avoid storing solvents or solvent-soaked

wipes, such as those used for surface

preparation and cleanup, in open or

absorbent containers.

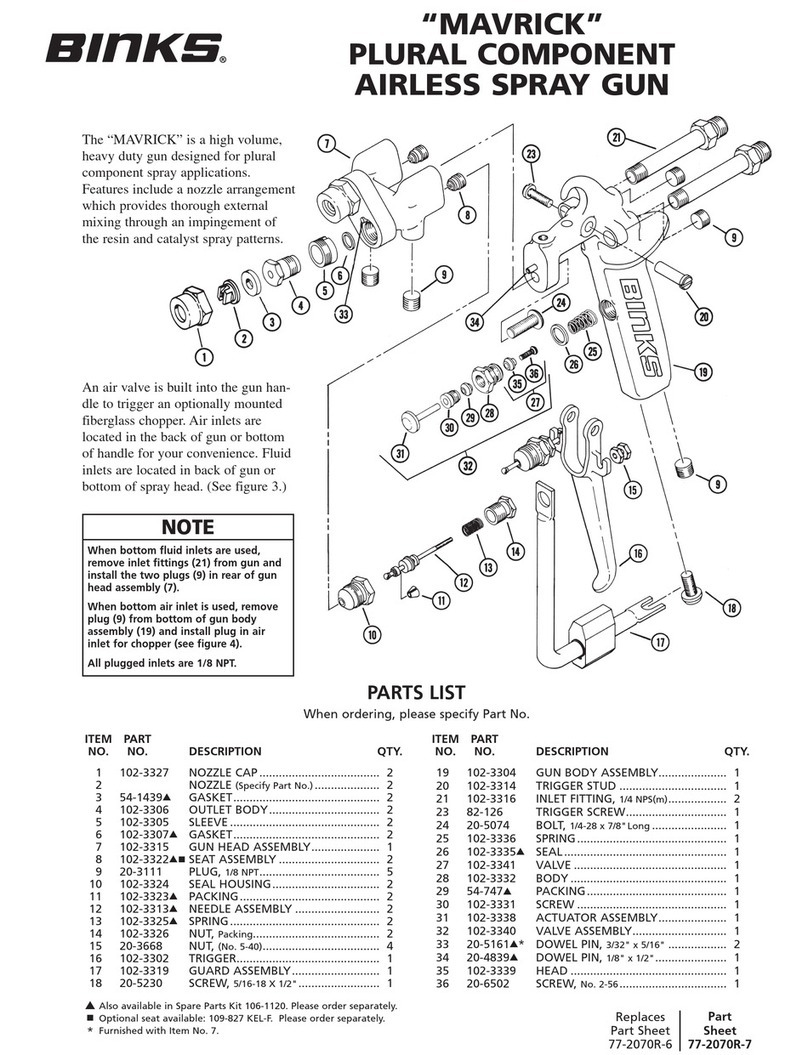

Numbers in parentheses refer to individual

items shown in the “exploded” drawing on

page 4.

cautIon

or scrape fluid or air nozzles. These

and altering their shape will cause

faulty spray.

!

cautIon

silicone since these lubricants can

cause finish defects.

!

WaRnIng

Be sure to follow all safety

precautions described on page 2

before working on the spray gun.

throughout the system and the

power or air supply for the fluid

pump has been disconnected. Always

test the repaired gun for leaks with

low pressure fluid before use.

!

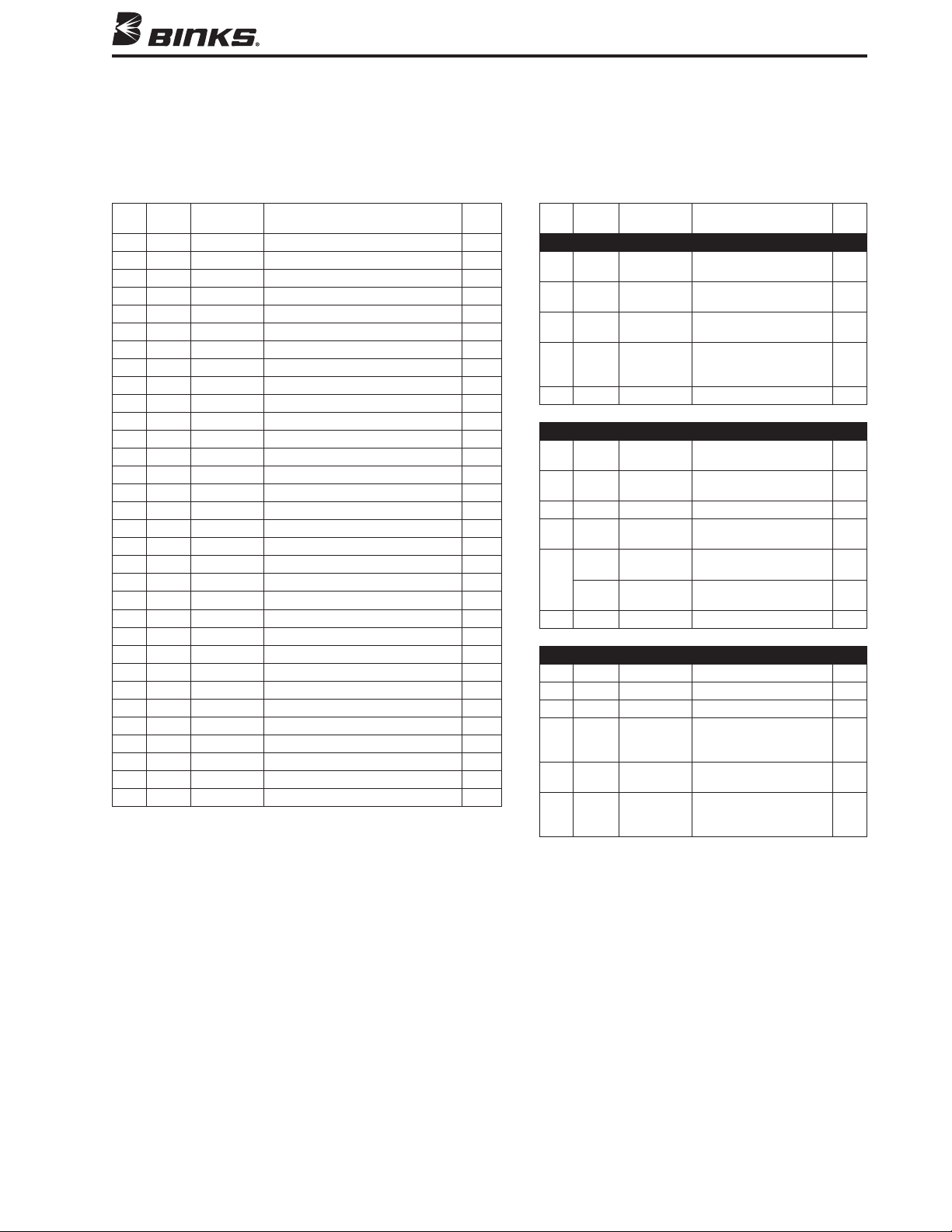

FLAT TIP AIR CAP, CARBIDE TIP

Service symptoms (Flat Tip):

•Coating build-up on air cap or

clogged carbide tip

•Fluidseatassemblynot

sealing properly

1. Depressurize the spray gun.

2. Turn retaining ring (19) counter-

clockwise and remove.

3. Remove air cap (19) and carbide tip

assembly (20) from fluid seat

assembly (21). With the air cap facing

up, apply pressure to carbide tip (20)

and remove from air cap (19).

4. Turn fluid seat assembly (21)

counterclockwise and remove.

5. Service or replace and reassemble in

reverse order.

note

Carbide fluid tip needs to be

oriented properly in the air cap.

The alignment pin in the air cap is

to be properly positioned to the slot

in the carbide tip.

TWIST TIP AIR CAP, CARBIDE

ASSEMBLY

Service symptoms (Twist Tip):

•Coating build-up on air cap

•CloggedTwistTip

Coating build-up:

1. Depressurize the spray gun.

2. Remove air cap (38) from the spray

gun and wash in solvent.

3. Reinstall the air cap (38).

Clogged Twist Tip:

1. Point the spray gun toward booth filter

and away from your body.

2. Rotate Twist Tip 180 degrees to

un-clog the tip.

Service symptoms:

•Fluidleakingfromweepsport

1. Turn rear cap (1) counterclockwise

and remove the piston return spring

from the piston housing (26) and

needle return spring (4).

2. With two 5/16" wrenches (not

supplied with gun), loosen collet

locknut (10) from collet (11).

3. Using a pair of pliers, grip collet (11)

and remove piston assembly (16).

4. Place the 3/8" deep socket (supplied

with gun) over cartridge assembly

(18) and turn counterclockwise.

5. Replace fluid needle (17) or fluid

cartridge assembly (18) and reassemble

in reverse order using the new

components as required.

note

bottomed out on the piston assembly

resting against the piston assembly.

note

If the piston is not positioned

correctly, the fluid-to-air timing will

not work correctly. See pictorial

6. After the piston assembly has been

positioned properly, tighten locknut

(10) to collet (11) “wrench tight”.

REPLACING O-RINGS ON

PISTON ASSEMBLY

Service symptoms:

•Atomizingairnotcyclingoff

•Airnotactuatingfluid

1. Turn end cap (1) counterclockwise

and remove the piston return spring

from the piston housing (26) and

needle return spring (4).

2. With two 5/16" wrenches (not

supplied with gun), loosen collet

locknut (10) from collet (11).

3. Using a pair of pliers, grip collet (11)

and remove piston assembly (16).

4. Replace o-rings (8, 9, 14 & 15) using

Standard Piston O-ring Repair Kit

54-5303 or High Performance Piston

O-ring Repair Kit 54-5307.

5. Apply 41-4458 Teflon-based

lubricant provided in the o-ring repair

kits to o-rings and reassemble in

reverse order.

note

bottomed out on the piston housing

resting against the piston assembly.

note

If the piston is not positioned

correctly, the fluid-to-air timing will

not work correctly. See pictorial

6. After the piston assembly has been

positioned properly, tighten locknut

(10) to collet (11) “wrench tight”.

Service symptoms:

•Fluidtipcloggingorrestriction

influidflow

1. Using a 3/4" inch wrench, turn filter

retainer (35) counterclockwise and

remove.

2. Place a standard screwdriver inside the

cavity where the filter (33) is housed and

dislodge it by lifting up with the

screwdriver. Remove filter and clean or

replace as required. Most of the time you

can dislodge the filter using your finger.

3. Reassemble in reverse order.

note

note

all o-rings before immersing gun in

or subjecting it to a flood-wash of

may induce o-ring swelling beyond

their specification sizes and cause

(continued on page 8)