5

Use Teflon (copper #540 395) based grease

to lubricate all o-rings and moving parts

before reassembly into the gun body.

To further protect the environment,

avoid storing solvents or solvent-soaked

wipes, such as those used for surface

preparation and cleanup, in open or

absorbent containers.

TROUBLESHOOTING

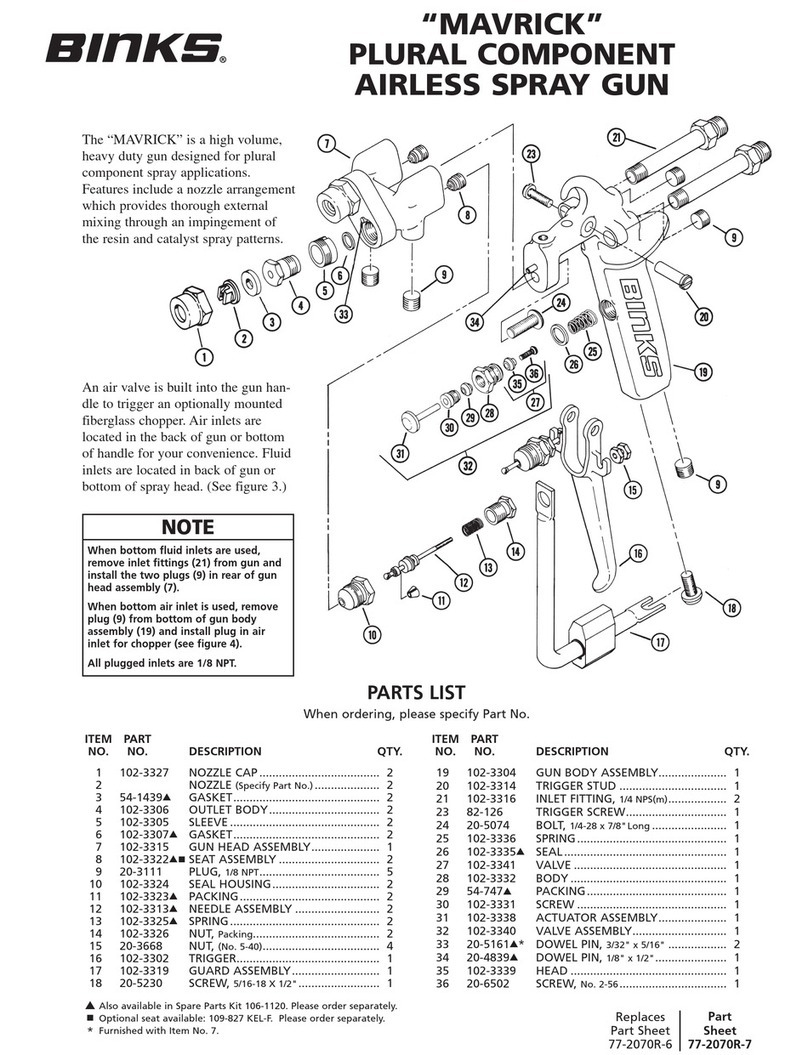

Numbers in parentheses refer to individual

items shown in the “exploded” drawing on

page 7.

SERVICING/REPLACING

AIR CAP, CARBIDE TIP AND

FLUID SEAT ASSEMBLY

Service symptoms:

• Build-up on air cap or

clogged carbide tip

• Fluid seat assembly not

sealing properly

1. Turn retaining ring (16) counter-

clockwise and remove.

2. Remove air cap (17) and carbide tip

assembly (18) from fluid seat

assembly (19). With the air cap facing

up, apply pressure to carbide tip (18)

and remove from air cap (17).

3. Turn fluid seat assembly (19)

counterclockwise and remove.

4. Service or replace and reassemble in

reverse order.

REPLACING FLUID

CARTRIDGE ASSEMBLY

Service symptoms:

• Fluid leaking from weeps port

1. Turn end cap (1) counterclockwise

and remove it and the piston return

spring from the piston body (23).

2. With two 5/16" wrenches (not

supplied with gun), loosen collet

locknut (9) from collet (10).

3. Using a pair of pliers, grip collet (10)

and remove piston assembly (5).

4. Place the 3/8" deep socket (supplied

with gun) over cartridge assembly

(15) and turn counterclockwise.

5. Remove and reassemble in reverse

order using the new cartridge assembly.

6. After the piston assembly has been

positioned properly, tighten locknut (9)

to collet (10) “wrench tight”.

REPLACING O-RINGS ON

PISTON ASSEMBLY

Service symptoms:

• Atomizing air not cycling off

• Air not actuating fluid

1. Turn end cap (1) counterclockwise

and remove it and the piston return

spring from the piston body (23).

2. With two 5/16" wrenches (not

supplied with gun), loosen collet

locknut (9) from collet (10).

3. Using a pair of pliers, grip collet (10)

and remove piston assembly (5).

4. Replace o-rings (7, 8, 13 & 14) using

Standard Piston O-ring Repair Kit

54-5303 or High Performance Piston

O-ring Repair Kit 54-5307.

5. Apply MG75 Teflon based lubricant

provided in the o-ring repair kits to

o-rings and reassemble in reverse order.

6. After the piston assembly has been

positioned properly, tighten locknut (9)

to collet (10) “wrench tight”.

SERVICING/REPLACING FILTER

Service symptoms:

• Fluid tip clogging or restriction

in fluid flow

1. Using a 3/4" inch wrench, turn filter

retainer (27) counterclockwise and

remove.

2. Place a standard screwdriver inside the

cavity where the filter (30) is housed and

dislodge it by lifting up with the

screwdriver. Remove filter and clean or

replace as required. Most of the time you

can dislodge the filter using your finger.

3. Reassemble in reverse order.

REMOVING/REPLACING GUN

ASSEMBLY MODULE ONLY

FROM INLET MANIFOLD

ASSEMBLY

1. Using a 9/64" Allen wrench (supplied

with gun), turn retaining cap screw

(20) counter-clockwise typical

4 places and remove gun sub module.

2. Mount the new gun module, tightening

the retaining screws (20) “wrench tight”.

This will allow fluid and air passages

to seal with no contamination.

MAG AA AUTOMATIC MANIFOLD MOUNTED AIR ASSISTED AIRLESS SPRAY GUN

MAINTENANCE/TROUBLESHOOTING AND SERVICE INSTRUCTIONS

caution

Never use metal instruments to clean

or scrape fluid or air nozzles. These

parts have been carefully machined

and altering their shape will cause

faulty spray.

!

caution

Never use lubricants containing

silicone since these lubricants can

cause finish defects. Binks Gunners

Mate is recommended.

!

note

Disassemble spray gun and remove all

o-rings before immersing gun in or

subjecting it to a flood-wash of cleaning

solvent. Contact with solvents may induce

o-ring swelling beyond their

specification sizes and cause subsequent

malfunction of the gun.

note

Carbide fluid tip needs to be

oriented properly in the air cap. The

alignment pin in the air cap is to be

properly positioned to the slot in

the carbide tip.

note

Piston assembly (5) must be

bottomed out on the piston housing

(23) with collet (10) and locknut (9)

positioned such that the e-clip (12) is

resting against the piston assembly.

note

If the piston is not positioned

correctly, the fluid-to-air timing will

not work correctly. See pictorial

view on page 6.

WaRning

Be sure to follow all safety precautions

described on page 2 before working

on the spray gun. Never work on the

spray gun until fluid pressure has been

relieved throughout the system and

the power or air supply for the fluid

pump has been disconnected. Always

test the repaired gun for leaks with

low pressure fluid before use.

!

note

Piston assembly (5) must be

bottomed out on the piston housing

(23) with collet (10) and locknut (9)

positioned such that the e-clip (12) is

resting against the piston assembly.

note

If the piston is not positioned

correctly, the fluid-to-air timing will

not work correctly. See pictorial

view on page 6.

note

O-ring (28) does not require

replacement when servicing filter.

Replace o-ring (28) if a leak

develops around filter retainer (27).

note

O-rings (22 & 24) must be replaced

when replacing gun sub module.