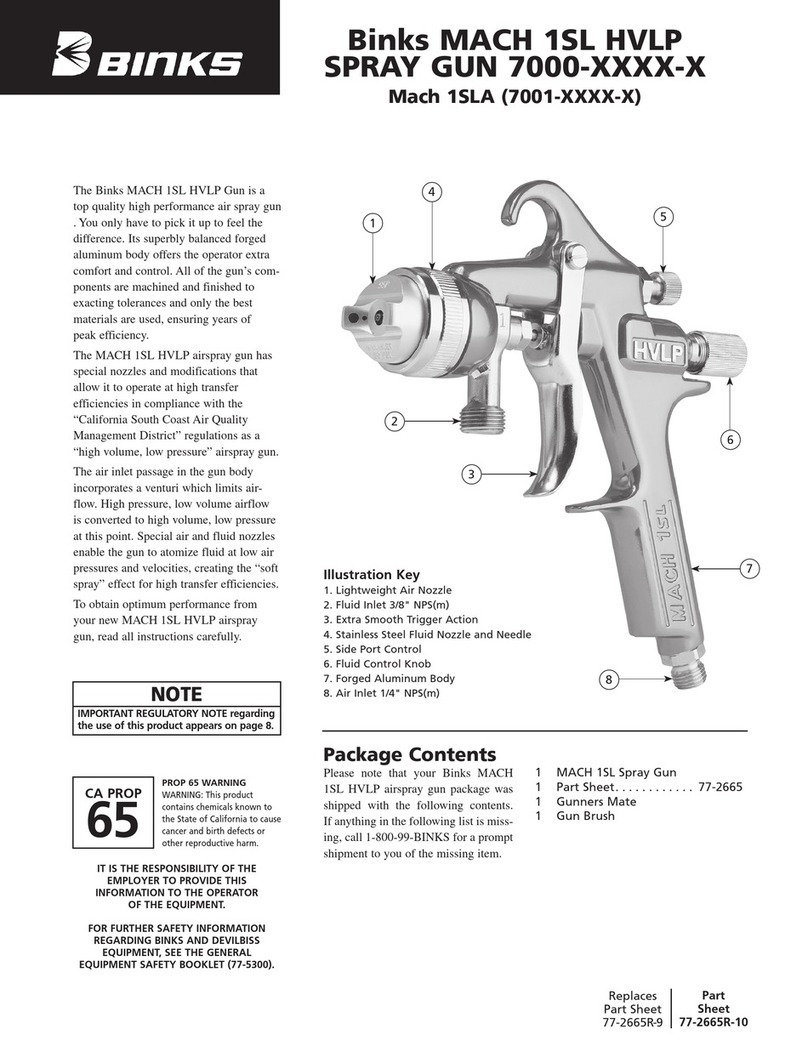

3

5/16” 1/4”

Only 30 PSI at gun inlet

25 feet of 1/4” I.D. hose causes

a drop of 26 PSI between the

air supply and the gun.

(NOT RECOMMENDED)

50 PSI at gun inlet

25 feet of 5/16” I.D. hose

causes a drop of 12 PSI

between the air supply

and the gun. For this reason

Binks recommends the use

of 5/16” hose.

(RECOMMENDED)

With 60 psi applied at air supply

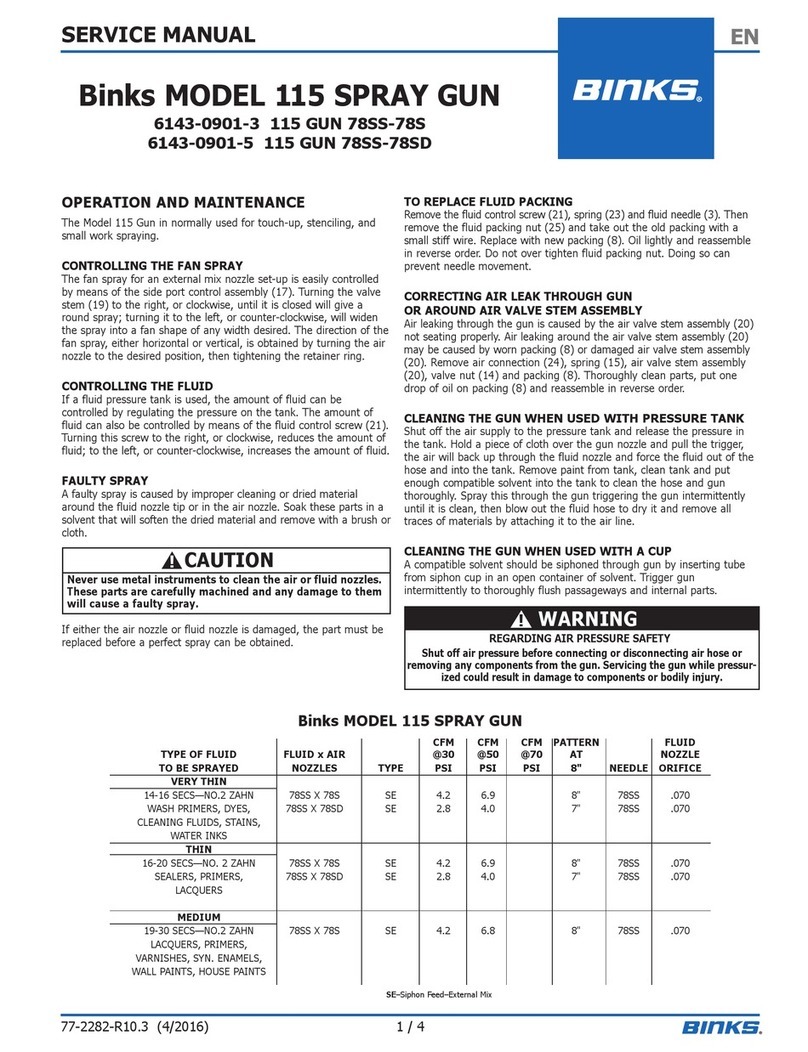

AIR PRESSURE

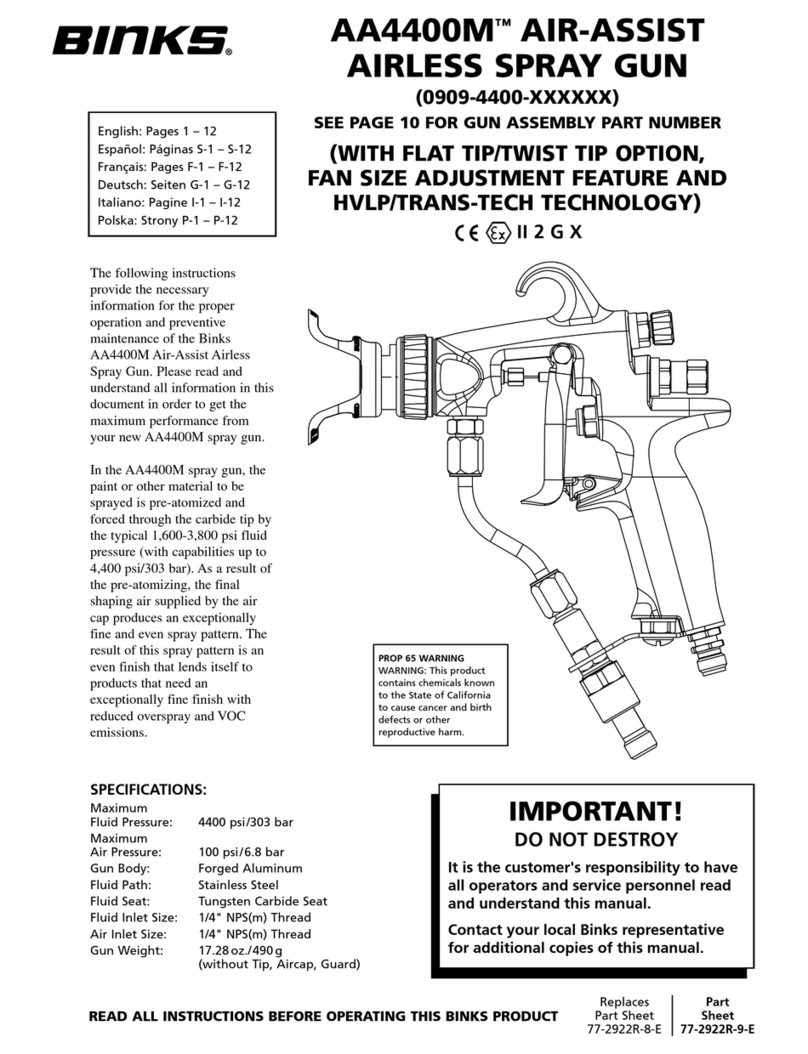

Atomizing pressure must be set prop-

erly to allow for the drop in air pres-

sure between the regulator and the

spray gun.

Separator filter is important.

Achieving a fine spray finish without the use of a good separator filter is virtually impossible.

A Binks regulator / separator filter serves a double purpose. It eliminates blistering and spot-

ting by keeping air free of oil and water, and it gives precise air pressure control at the gun.

Binks recommends using Model HFRL-508 Separator Filter / Regulator. See your local

distributor for other models.

Cross section view

showing comparison of inside

hose diameters (actual size).

60 lbs. regulated pressure

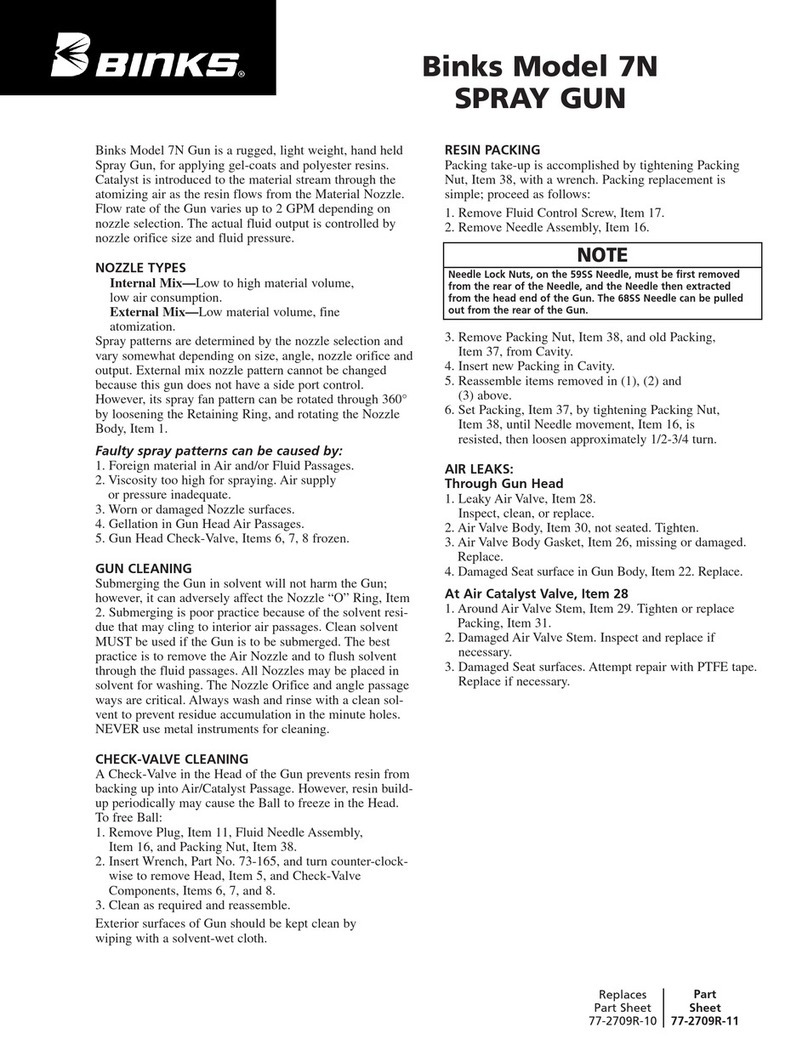

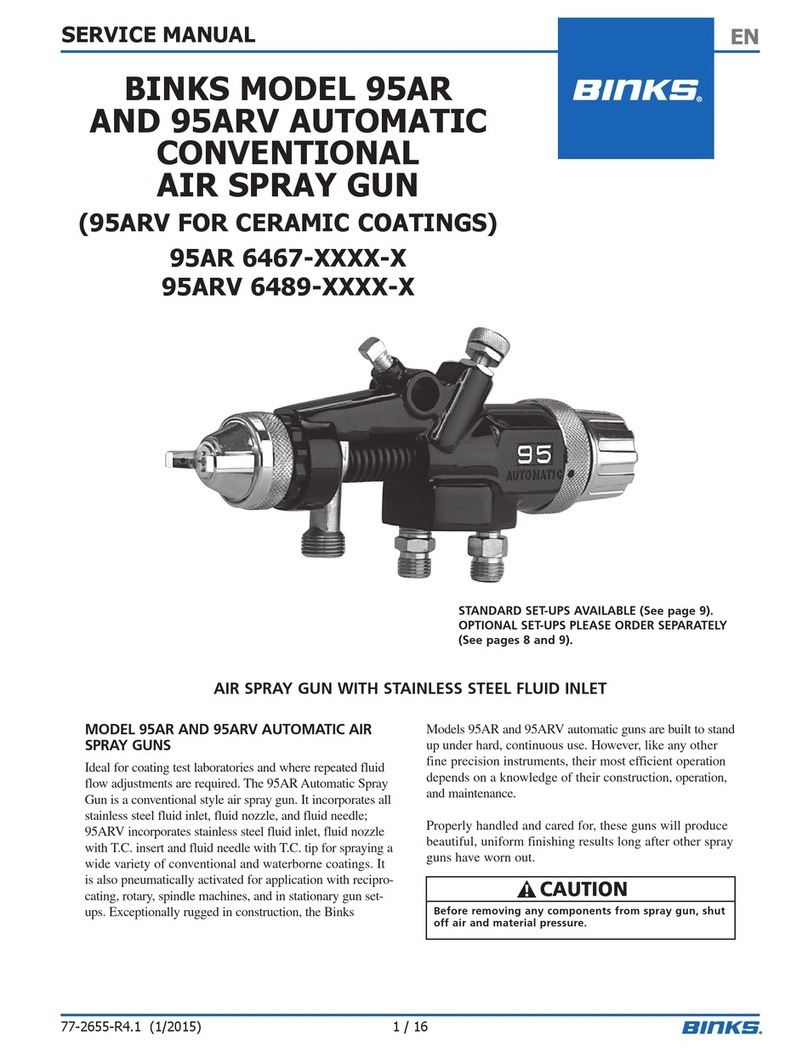

OPERATION AND MAINTENANCE FOR SV100 SPRAY GUN

Your new SV100 spray gun is excep-

tionally rugged in construction and is built

to stand up under hard, continuous use.

However, like any other fine precision

instrument, its most efficient operation

depends on a knowledge of its construction,

operation and maintenance. Properly

handled and cared for, it will produce

beautiful, uniform finishing results long

after other spray guns have worn out.

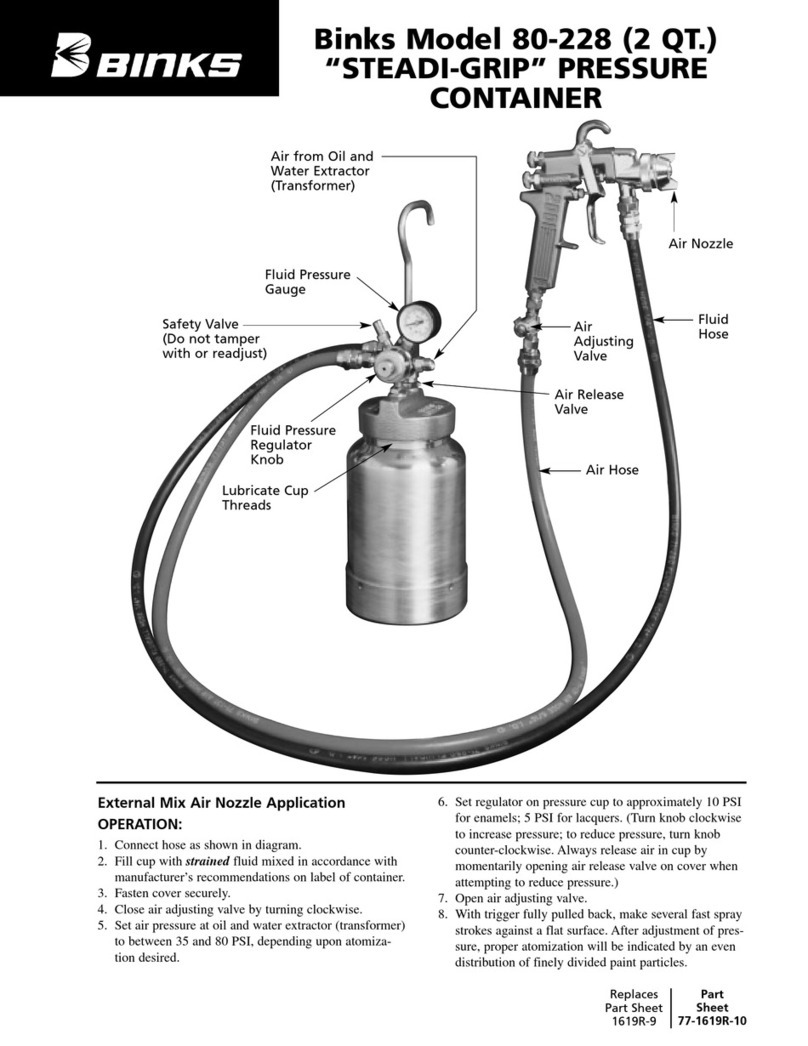

SET-UP FOR SPRAYING

Connecting Gun To Air Hose

Air should be supplied by a suitable

length of 5/16" diameter air hose fitted

with a 1/4" NPS(f) connection at gun

end. For hose lengths over 50', use 3/8"

diameter hose.

SPRAY GUN CLEANING

INSTRUCTIONS

In certain states it is now against the law

to spray solvents containing Volatile

Organic Compounds (VOC)’s into the

atmosphere when cleaning a spray gun.

In order to comply with these air quality

laws Binks recommends one of the fol-

lowing two methods to clean your spray

finishing equipment:

1. Spray solvent through the gun into a

closed system. An enclosed unit or

spray gun cleaning station condenses

solvent vapors back into liquid form

which prevents escape of VOC’s into

the atmosphere.

2. Place spray gun in a washer type

cleaner. This system must totally

enclose the spray gun, cups, nozzles

and other parts during washing, rins-

ing and draining cycles. This type of

unit must be able to flush solvent

through the gun without releasing

any VOC vapors into the atmosphere.

Additionally, open containers for storage

or disposal of solvent or solvent-con-

taining cloth or paper used for surface

preparation and clean-up may not be

used. All containers shall be nonab-

sorbent.

Pointers On Cleaning

When used with 1 quart cup, relieve

pressure in the cup. Then unscrew,

empty and carefully rinse cup out with

thinners. Place clean thinners in the cup

and spray this through the gun until it is

clean. Blow air through gun to dry it.

CAUTION

All parts on a spray gun should be

screwed in hand tight at first; this

will avoid the possibility of cross

threading the parts. If the parts

cannot be turned by hand easily,

make sure you have the correct

parts, unscrew, realign, and try

again. NEVER use undue force in

mating parts.

!