BIO UV MP030 EL Manual

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 1

REACTOR USING MEDIUM PRESSURE LIGHT

MP030 EL

MANUAL CLEANING

(Picture MP 030)

INSTALLATION AND MAINTENANCE

MANUAL

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 2

UVPS subsidiary of the BIO-UV

COMPLIANCE CERTIFICATE

CERTIFICATE OF CONFORMITY

BIO-UV and this subsidiary, hereby declares that the following products

BIO-UV MP Range

comply to the following standards:

NF EN 60439-1 (2000)

CEM: EN55015 (Ed.00) + A1 (Ed.01)

Number and year of EC stamp:

CG-03-006 dated 29/01/2003

LS-03-51003/NL dated 20/02/03

Benoît GILLMANN

Chairman and Managing Director of BIO-UV

Société BIO-UV SA

ZAC La Petite Camargue

34400 LUNEL France

Hotline: + 33 (0)890 71 03 70

(0,15€/min)

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 3

We thank you for choosing a BIO-UV reactor.

Our equipment has been designed to give you reliable and safe operation for many years to come.

The BIO-UV reactors have been designed for speed and ease of installation.

Their design also makes them easy to maintain..

Read these instructions carefully in order to optimise the operation of your reactor.

CONTENTS : pages

A. TECHNICAL CHARACTERISTICS...............................................................................................4

B. MAINTENANCE FILE ......................................................................................................................6

C. WARNINGS AND SAFETY ..............................................................................................................7

D. INSTALLATION OF THE REACTOR............................................................................................9

E. FLOW SENSOR................................................................................................................................13

F. MANUAL OF THE MONITOR BIO-UV MIII .............................................................................14

G. ALARM CONTACT (OPTION)......................................................................................................17

H. OPERATION OF THE 4-20MA OUTPUT (OPTION).................................................................17

I. INSPECTIONS AND PREVENTIVE MAINTENANCE .............................................................18

J. CHANGING THE WIPER SEALS.................................................................................................22

K. ELECTRICAL UNIT........................................................................................................................23

L. BLOWN UP VIEW............................................................................................................................24

ANNEX 1: Clearance dimensions – Blown up view – Designation

ANNEX 2: Electrical diagrams

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 4

A.TECHNICAL CHARACTERISTICS

MP030 EL RANGE 600 W 1 KW 3 KW

REACTOR

Material

Stainless steel 316L

Finish

Pickling and passivated

Maximum service pressure

3 bars

Weight (kg)

(1)

16

Ø and body length (mm)

204 x 276

Overall length (mm)

450

Volume (litres)

14,2

Connection type

Flange

Standard Connection

(2)

DN 80

ELECTRICAL UNIT

Type

Painted steel Painted steel

Dimensions (mm)

600 x 400 x 250 600 x 400 x 250

Weight (kg)

Power supply

Single-phase

240VAC

Power supply wiring

2G1.5mm² 2G2.5mm²

Earth cable

6 mm²

Differential protection

30 mA 30 mA

Thermo magnetic protection

10 A 2P 25 A 2P

Circuit breaker tripping curve

Curve C Curve C

Fuse

-

On / Off switch

Yes

Power on indicator light

Yes

UV lamp indicator light

Yes

Display

Monitor MIII

Protection index

IP 54

UV-C LAMP

Number of lamps

1 1 1

Electrical power

600 W 1 000 W 3 000 W

Unit UV-C power

90 W 150 W 375 W

Total UV-C power

90 W 150 W 375 W

Average lifetime

6 à 9 000 h 6 à 9 000 h 6 à 9 000 h

*operating continuously with one on/off per day.

Turning UV lamps on and off reduces their lifespan. A minimum time delay of 30 minutes must be

observed before turning a lamp back on again.

(1) Caution, with a cleaning system these values change.

(2) Except request specific to the order.

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 5

TESTS OF ACCEPTANCE

Client:

Order number:

Unit designation:

Serial number:

Date:

ELECTRICAL SECTION:

Test date:

Wiring carried out by:

Protection classification: IP 54

Observation:…………………………………………………………………………………………………

………………………………………………………………………………………………………………

………………………………………………………………………………………………………………

………………………………………………………………………………………………………………

…………

MECHANICAL SECTION :

DESIGNATION REFERENCE

Quartz

UVC Lamp

Quartz joint

Wiper joint

Motor / electric jack

Dimensions between flanges

Bri e

Re uction

Checker’s name: Signature:

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 6

B. MAINTENANCE FILE

CAUTION:

This sheet must be kept up to date.

It provides a record of the reactor’s operating cycle.

Date Action By

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 7

C.WARNINGS AND SAFETY

BIO-UV reactors are ready to install, no works is required inside the reactor.

Read all the instructions in this manual before switching on the BIO-UV appliance.

INSTALLATION

RECOMMANDATIONS

The reactor must be installed:

-in a technical room, protected from light and rain,

-after the filter(s),

-in a dry zone, ambient humidity must be < 80%.

The installation zone temperature must be within 0°C and 40°C.

Keep any sources of hydrochloric acid vapours away from the installation.

The electrical unit should be positioned:

-so that it is protected from water,

-at eye level.

The air vent of fan must not be obstructed.

The cable length between the UV reactor and its electrical unit must not be modified.

Provide for sufficient space for reactor maintenance.

The reactor must be installed so that the UV lamp is in a horizontal position.

●The equipment must always be filled with water when operating and the

air must be bled out of it.

We recommend the presence of a by-pass.

●Before accessing the connection terminals, ensure that all supply circuits

are disconnected.

●The reactor installation as a whole must be protected with a suitably adapted

circuit breaker.

(See A. Technical characteristics)

●Check that cable complies with legislation and the required power level.

(See A. Technical characteristics)

●If, for installation reasons, the power supply cables connecting the cabinet to

the reactor have to be shortened, take care to fully crimp the new end fittings

at each end of the cables.

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 8

USE AND MAINTENANCE

●Allow the ultraviolet lamp to cool for at least 30 minutes before handling.

●Never look at the ultraviolet lamps when lit. This may cause severe injuries

or burns and may even lead to loss of eyesight.

●Do not touch the ultraviolet lamp with bare hands, as these would leave

impurities that shorten the life of the lamp. If you do touch it: clean with alcohol

or white vinegar.

●Never unscrew the quartz tube sealing nut when the reactor is on load as the

quartz tube could be blown out of the reactor with force and injure you.

●Do not use the reactor if the power supply wire is worn or damaged. In this

case it should be replaced.

●If the connecting cable between the reactor and the electrical cabinet is

damaged, it must be replaced by a special cable available as a spare part.

●Even when stopped, power is present in the electrical unit so make sure

that the main power supply upstream of the electrical cabinet is switched off

before carrying out any work on the equipment.

●To avoid electric short-circuits, do not place the electric wires or the reactor in

the pool water or in any other maintenance or cleaning fluid.

●Do not restart the system until the electric unit, the covers exterior elements of

the reactor are correctly back in place.

●Do not use the BIO-UV reactor for any other use than that for which it was

designed.

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 9

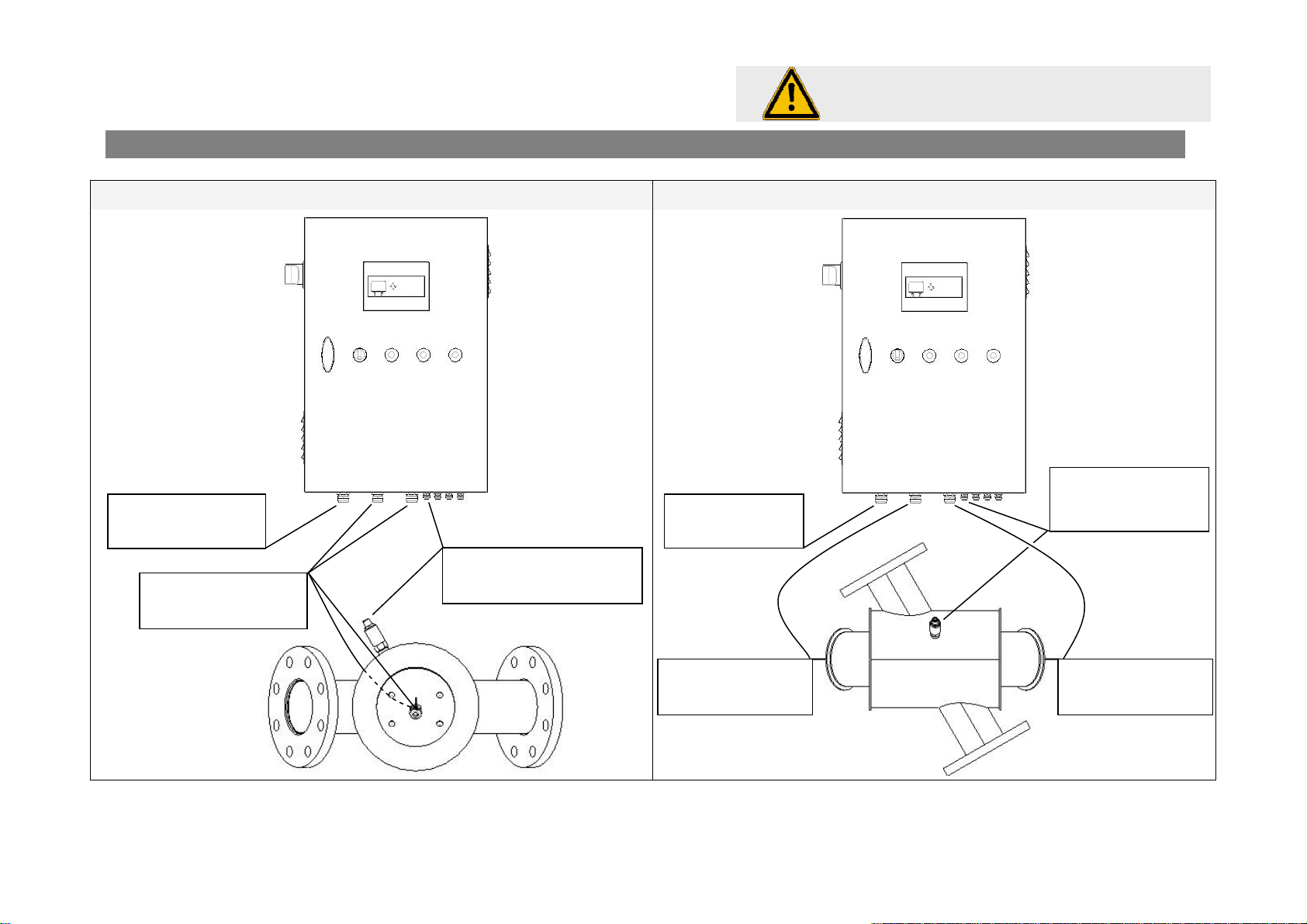

D.INSTALLATION OF THE REACTOR

Overall installation view

Reactor in a horizontal position Reactor in a vertical position

Marque, Modèles et Brevets déposés - Produits exclusifs

MP030_SN-GB.doc

Page 9

Copyright BIO-UV - 29/01/2009

LAMPS must be HORIZONTAL

Temperature

Sensor supply

General power

supply

UV lamps power

supplies

Temperature

Sensor supply

General power

supply

UV lamps power

supply

UV lamps power

supply

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 10

Strictly follow the instructions:

Positioning of reactor Clearance zone (mm) required

to work on the reactor

- The water channel is horizontal.

- The UV lamps are horizontal.

- The purges are at the base of the reactor.

Lamps are in vertical position:

PROHIBITED

Marque, Modèles et Brevets déposés - Produits exclusifs

MP030_SN-GB.doc

Page 10

Copyright BIO-UV - 29/01/2009

200

THE REACTOR MUST BE PROPERLY CONNECTED TO

EARTH AS PER THE DIAGRAM BELOW

The earth wires marked and are supplied with the UV reactor.

The earth wire marked must be connected when the reactor is installed on site (6 mm² minimum

COMPULSORY)

Any earthing fault of the reactor will lead to an exclusion of the guarantee in

the event of electrolytic corrosion.

6 mm² minimum

6 mm² minimum

6 mm² minimum

Main switchboard

V cabinet

1

2

3

3

1

2

COMPULSORY INSTALLATION INSTRUCTIONS

It is preferable to install the UV reactor in By-Pass, and this must absolutely not be linked to pump

operation.

Instruction No. 1: The UV lamp must be HORIZONTAL whatever the position of the reactor.

Instruction No.2: The reactor must be correctly linked to the earth with a suitable wire of 6 mm²

minimum.

Instruction No.3: Fully observe instructions for the removal of lamps and quartz sleeves.

Instruction No.4: The UV sensor MUST be uppermost when the UV reactor is horizontal.

Instruction No.5: If the UV reactor is installed vertically, give preference to the input of water through

the bottom of the reactor and make sure that the purge valves are in the lower position.

Instruction No.6: Distance chemical products from the reactor to avoid any risk of corrosion.

UV REACTOR COMMISSIONING PROCEDURE

Action No.1: Fill the reactor with water and purge the air.

Check the absence of hydraulic leaks

Action No.2: Verify the correct operation of manual or automatic cleaning

Action No.3: Check the tightness of electrical terminal blocks and connectors

Action No.4: Calibrate the flowmeter

Action No.5: Turn on the lamps and check that they are working

Action No.6: Calibrate the UV sensor after a minimum of five minutes operation (UV lamp heating time)

Action No.7: Calibrate the 4-20 mA output (optional)

Action No.8: Test the correct operation of the flowmeter and the calibration carried out.

Action No.9: Fill in the maintenance sheet page 6

Reminder : If the UV lamps are turned off with the switch or the mains switch,

Wait 30 minutes befrore turning the UV lamps back on so as to not effect their

lifespan.

E. FLOW SENSOR

The flow sensor starts the unit when the flow is present and stops it when the flow rate

is insufficient in order to ensure sufficient time for lamp cooling.

The flow sensor is located on the reactor as on this picture:

At the start-up of reactor, it is NECESSARY to carry out a calibration on the basis of the

MINIMUM FLOW RATE in your installation..

Sensor setting to the minimum flow rate:

1. Provide power to the cabinet, lamp(s) off

2. Turn filtration on

3. Adjust filtration flow to the minimum (e.g.: By-Pass opening)

4. Press on the ►button of the flow sensor and hold it down.

5. The No.9 LED turns on and then flashes after approximately five seconds.

6. Release the button, calibration is finished ( lights 0 to 8 permanently on, No.9 flashes)

Setting the commutation threshold

To avoid to much stopping / starting of lamps due to fluctuations in flow, the

Commutation threshold (red LED) must not exceed No.5, if this is not the case:

1. Press briefly on ◄or ►, the red LED flashes

2. Press on ◄or ►as often as necessary to make LED 5 red

The system is now operational. Reset the flow rate to the maximum (close By-Pass).You can switch the

lamps on.

Stop filtration to check that the unit stops within a maximum time limit of approximately 60 seconds. (it

can only be turned back on can after a time delay of 30 minutes).

Correct setting: Incorrect settings:

F. MANUAL OF THE MONITOR BIO-UV MIII

(

)

Options according to the reactor

Marque, Modèles et Brevets déposés - Produits exclusifs

UV2000_NA-FR.doc

Page 14

Copyright BIO-UV - 29/01/2009

Activate/Deactivate

automatic cleaning

(

)

and

simultaneously

Main Display

Monitor

operating

indicator

R

On

F Flow

(

)

C Cleaning

(

)

Secondary display

L

EGEND

or

During 5s

o

r

During 5s

or

During 5s

Radiance V

management

(

)

Reset counter at

zero

Set power

regulation

(

)

Set cleaning

time cycle

(

)

During 5s

or

Set main alarm

threshold

S

et pre

-

alar

m

threshold

o

r

o

r

A1

A2

A3

B1

E1

G1

A

C

F

G

D

E

B

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 15

GENERAL INFORMATION:

This operating manual describes all possible options,

Some of them aren’t available on your device according to your reactor type.

Definition of the 3 letters on the first display

R means that the reactor is switched on and operating.

F means that the water is flowing and that the flow is adequate in relation to the

setting that you made on the flowmeter.

C means that the automatic cleaning function is activated.

Note: for the reactors which don't have a flowmeter, the letter “F” stays always on the display.

●The screen is backlit: Just pressing on a key switches the back lighting on for one minute.

●Activation/deactivation of automatic cleaning: Pressing simultaneously on buttons A and B activates or

deactivates the automatic cleaning.

●Caution: if the cleaning is deactivated when the hydraulic cylinder is operating, the cleaning carriage may stop

in the middle of the reactor and block some of the UV rays.

ALERT MESSAGES:

The screen flashes when there is an alert message.

The alert messages are always shown on the secondary display and are independent of what is displayed on the

main display unit.

Display Meaning of the alert Solutions

This message appears when the

temperature of the cabinet exceeds 60°C.

The reactor is stopped automatically.

Check that the cabinet vents are not blocked.

Check that the fans are working properly.

This message appears when the

temperature of the reactor exceeds

44.5°C.

The lamps are stopped automatically.

Check that enough water is flowing through the

installation.

If there is a flowmeter, check that is correctly

calibrated.

This message appears when one or

several lamps are faulty.

The numbers show which of the lamps

are faulty.

Diagnose the cause of the breakdown.

This message appears when the

hydraulic cylinder on the automatic

cleaning is blocked. Diagnose the cause of the breakdown.

These 4 alert messages can be cleared by pressing on the key "OK".

It is preferable to carry out a maintenance operation before clearing the fault.

This message appears when the intensity

of the UVC radiation falls below the

pre-alarm threshold.

Check that the quartz sleeves are clean.

Check that the UV sensor is clean.

N.B.: when the lamps have been operating for a certain number of hours, this message appears naturally (normal wear of the lamps)

This message appears when intensity of

the UVC radiation falls below the main-

alarm threshold.

Check that the quartz sleeves are clean.

Check that the UV sensor is clean.

Chang the UV lamps.

This message appears when the lamps have been stopped (brought about by a safety

device). The lamps will not be relit until after a time delay of 30 minutes. This time delay is

to protect the lamps.

These 3 messages cannot be cleared unless the problem has been resolved.

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 16

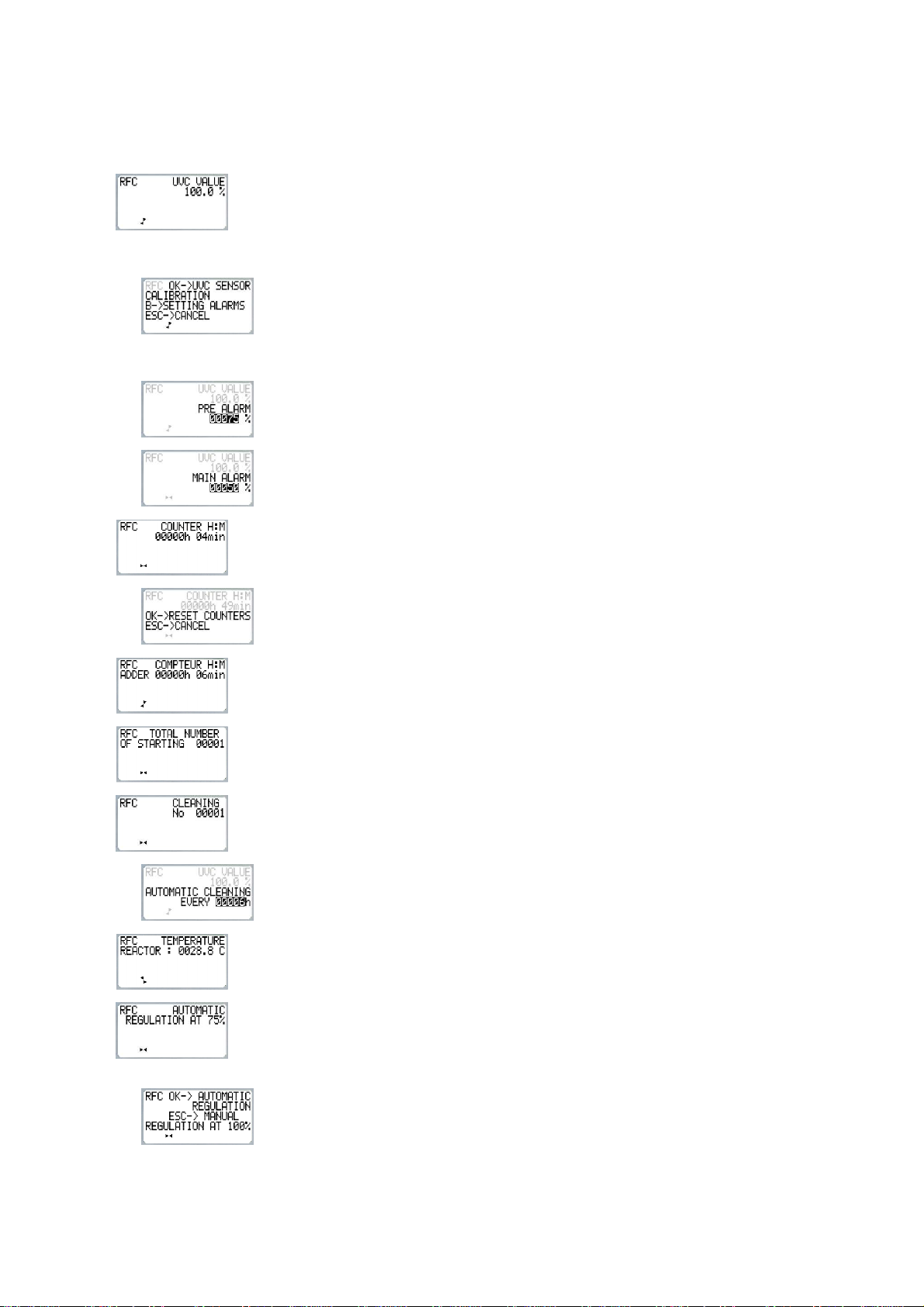

CONTENT OF MENUS AND SUB-MENUS:

Use the + or – keys to change from one menu to another.

Press on key A for 5 seconds to enter a menu.

When the word "OFF" is displayed, this means that the display option is not available on your device.

A

Display of UVC intensity measured by the sensor.

N.B.: each time the lamp is changed, you MUST calibrate the sensor even if the display

already shows 100%.

A1

Calibrating the sensor:

●It is important to carry out this operation when commissioning the reactor and also when

changing a lamp even if the display already shows 100%.

●It is important to wait 5 minutes before carrying out the calibration, to allow the lamps

to heat up.

●If your device is equipped with the power regulator, it is ESSENTIAL to switch over to

manual regulation (100%) before calibrating the sensor..

A2

Menu for adjusting the pre-alarm threshold. Set in the factory at 75%.

Allows you to set the UVC value at which the pre-alarm will trigger.

A3

Menu for adjusting the main alarm threshold. Set in the factory at 50%.

Allows you to set the UVC value at which the main alarm will trigger.

B

Display of lamp operating time. It is recommended to reset this counter at zero when you

change a lamp.

B1

Reset the hour counter and the number of lamp start-ups at zero.

C

Display the reactor's total operating time since commissioning. This counter cannot be reset at

zero..

D

Display of the number of lamp start-ups carried out. Resetting at zero is linked to that of the

hour counter.

E

Display of the total number of cleaning operations carried out since the reactor was

commissioned. This counter cannot be reset at zero.

E1

Adjustment of the frequency of the automatic cleaning cycle. Factory setting: one cleaning

cycle every 6 hours. Can be increased to a maximum of one cleaning cycle per hour.

F

Display of the reactor temperature.

G

Display of the type of power regulation used.

G1

Power regulation:

Allows you to set the type of power regulation of the UV lamps.

●On automatic regulation, the power switches automatically from 75% to 100% and back

depending on the reactor operating conditions.

●On automatic regulation, the lamps are always at 100% power.

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 17

G.ALARM CONTACT (OPTION)

The pre-alarm and main-alarm faults are indicated by snap contacts on the monitor which are transmitted

to terminal strips (see the wiring diagram in order to identify them).

The snap contacts are normally closed. They open when respective alarms are active.

H.OPERATION OF THE 4-20MA OUTPUT (OPTION)

The 4-20mA adjustment must be realised:

- at the first installation of the reactor,

- at each calibrating of the UV sensor.

The 4-20mA adjustment must be realised only after the UV sensor calibration.

(See Chapter MANUAL OF THE MONITOR BIO-UV MIII)

The 4-20 mA output is the image of the UV-C sensor output not the image of the UV-C

% display on the monitor screen.

CALIBRATION OF THE 4-20MA OUTPUT:

1

Before the second step, you must realise the UV-C sensor calibration.

2

Turn the small screw clockwise

until the red LED lighting.

3

The 4-20mA output is calibrated at 100% of UV sensor.

Screw

Red

LED

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 18

I. INSPECTIONS AND PREVENTIVE MAINTENANCE

In the event of work on the UV reactor, ensure that personnel are qualified and authorised.

RECOMMENDATIONS FOR VERIFYING OPERATION AND USE

The following points must be regularly checked in order to make sure that the UV reactor is operating

perfectly:

•Lamp operation check: Green light on

•UV intensity check: The display on the Millénium III monitor must show a value greater than

50%

In the event of a UV intensity fault (<50%); do not carry out the sensor calibration procedure

which must only be carried out with: new lamps(s), clean quartz, clean UV sensor

•Check the operation of the flowmeter: In the event of an interruption in flow (backwashing of

filters for example), the UV lamps must automatically turn off within 60 seconds, and restart 30

minutes after return to service. (See message on Millenium III display)

•Check the correct operation of electrical cabinet ventilators in order to avoid all risk of

overheating.

Check that the grills or filters are not obstructed.

•Activate the MANUAL cleaning device of the UV reactor on a daily basis

(Not applicable in the event of an automatic device: In this case make sure that the latter is

working)

•Checked the number of stop/starts of lamps on the Millénium III monitor display, which must be

coherent with the number and frequency of technical stoppages (filter backwashing, etc).

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 19

RECOMMENDED INSPECTIONS AND PREVENTIVE MAINTENANCE

0 Changing UV lamps At the end of their life span:

-either display on the Millénium III monitor: UV

intensity <50%

-or combined chlorine rate in the basin

OPERATIONS ON EACH UV LAMP

CHANGEOVER AT LEAST ONCE

PER YEAR

Checking the general state of the UV

reactor

1 Replacement of quad ring seals Compulsory Compulsory

2 Checking the presence of quartz sheath

Teflon shims Compulsory

3 Cleaning or replacing the quartz sheath Compulsory

4 Replacing the cleaning wipers Recommended

5 Cleaning the UV sensor Compulsory Compulsory

6 Check the operation of the flowmeter Compulsory

7 Check the operation of ventilators:

- Cleaning grills

- Filter replacement (if applicable)

Recommended

Compulsory

8 UV sensor calibration Only new lamps, quartz sheath clean or new, UV

sensor cleaned

9 Pneumatic silencer replacement Only in the event of corrosion

10 Check the earthing of the reactor

11 Check the operation of the thermostat in the

electrical cabinet Recommended

12 Check the operation of the circuit breaker Recommended

13 Check tightening:

- Of terminal blocks in the cabinet

- Of connectors

- Of UV lamp connections

Recommended

MP 030 EL NM GB Copyright BIO-UV - 29/01/2009

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 20

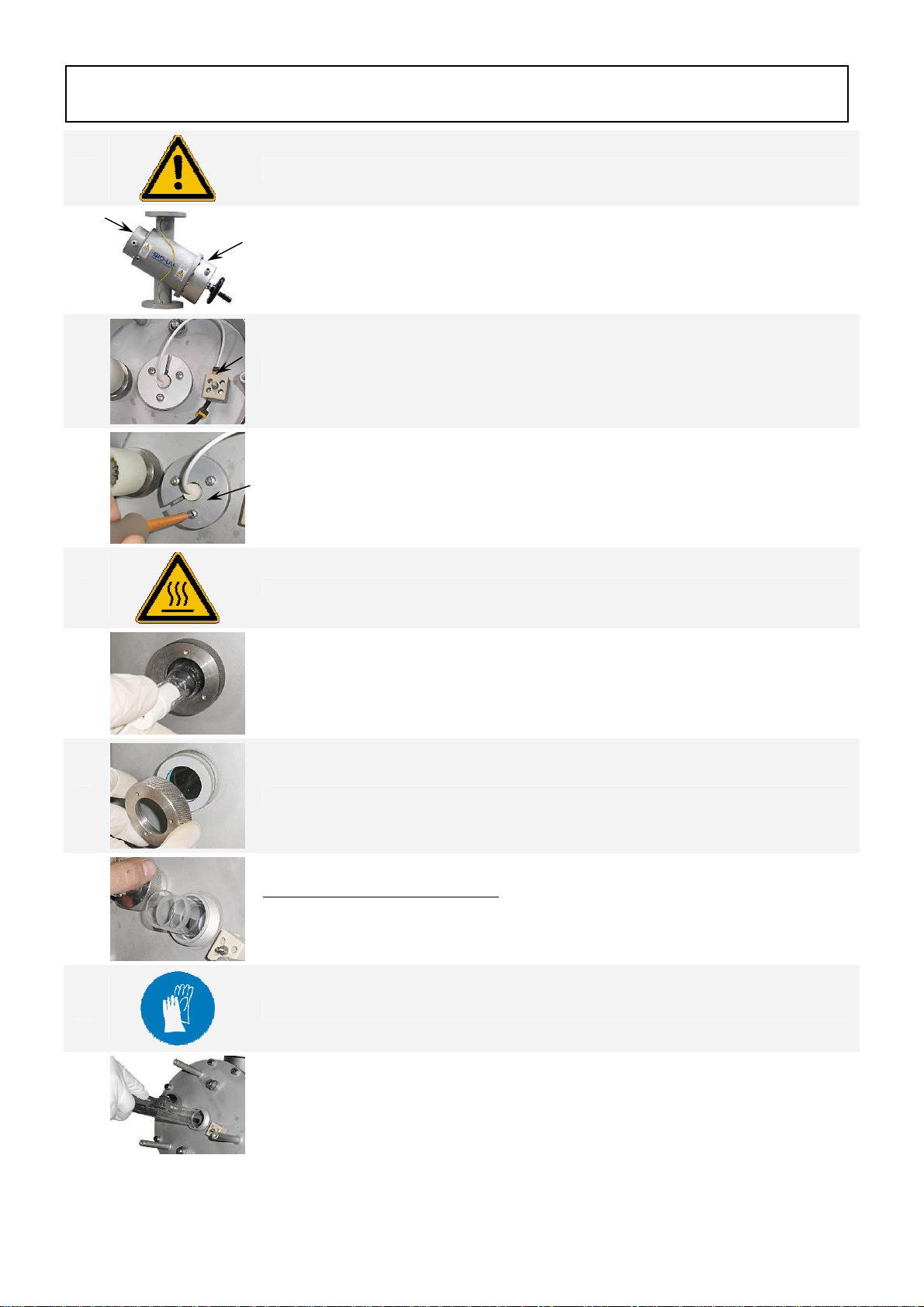

1

SWITCH OFF the reactor, CUT the POWER source and EMPTY IT

2

Unscrew and remove the 2 covers.

3

Remove the wires from the lamp on both sides by unscrewing the terminals (only

the cables white supplying the lamp).

4

Unscrew the aluminium lamp base, 3 screws, on both sides.

5

Make sure that the UV lamp is cooled before handle it.

6

Take out the lamp together with its Teflon supports (if there are any) and place it

on a clean and soft surface.

Carry out this operation CAREFULLY taking care not to place your fingers

outside the cap.

7

Unscrew the MP nuts on both sides and remove the aluminium washer.

8

Gently remove the quartz sleeve:

●Push one end of the quartz sleeve in order to pull the other end.

●Remove the quartz sleeve and its seals.

9

Clean the quartz sleeve with acid or white vinegar or replace it if necessary.

10

While remaining in the axis, gently reposition the quartz sleeve in the direction

indicated by the label on the reactor.

CHANGING UV LAMPAND QUARTZ SLEEVE

Table of contents

Languages:

Other BIO UV Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Oxford Instruments

Oxford Instruments PlasmalabSystem100 Installation data

Agilent Technologies

Agilent Technologies 6890 Series Service manual

seward

seward Stomacher 80 Biomaster user manual

ScanSpeed

ScanSpeed Mini instruction manual

Hamamatsu Photonics

Hamamatsu Photonics C12666MA manual

IKA

IKA MS 3 digital operating instructions

Thermo Scientific

Thermo Scientific IMH 60 operating instructions

RADWAG

RADWAG UYA 4Y PLUS Startup guide

Peak Scientific

Peak Scientific Genius SQ 24 user manual

Covaris

Covaris microTUBE-500 manual

Bayer HealthCare

Bayer HealthCare Clinitek Status Operator's manual

Thermo Electron

Thermo Electron HERAsafe KS Service instructions