BIQU B1 User manual

Catalogue

1. Packing List.................................................................................................1

2. Equipment parameters.............................................................................. 2

3. Installation equipment...............................................................................3

4. Platform Calibration.................................................................................17

4-1 Platform Calibration...................................................................... 17

4-2 Fill in filament................................................................................ 21

5. Ready to print.......................................................................................... 22

5-1 Introduction to working mode......................................................22

5-2 Installing Driver software.............................................................. 23

5-3 Install Ultimaker Cura Software.................................................... 27

5-4 Software Settings...........................................................................30

5-5 Usage of Ultimaker Cura Software................................................36

6. Start Printing............................................................................................ 38

6-1 Offline printing.............................................................................. 38

6-2 Online Printing...............................................................................40

7. Other Functions....................................................................................... 42

7-1 Manual leveling............................................................................. 42

7-2 Automatic Leveling(Optional)..................................................45

7-3 Intelligent filament detection Sensor Module (Optional)............ 47

7-4 Model Preview...............................................................................49

7-5 Marlin Operating System...............................................................57

8. Troubleshooting.......................................................................................59

9. Cautions................................................................................................... 63

1

BIQU-B1 USER MANUAL

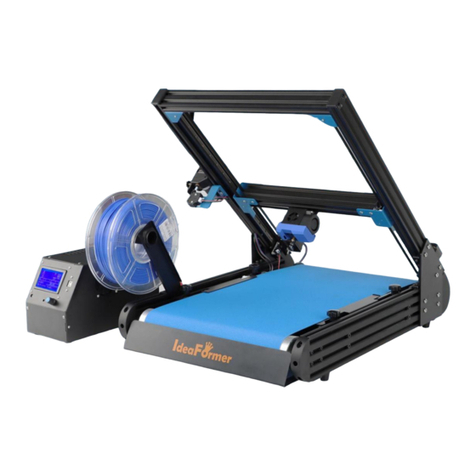

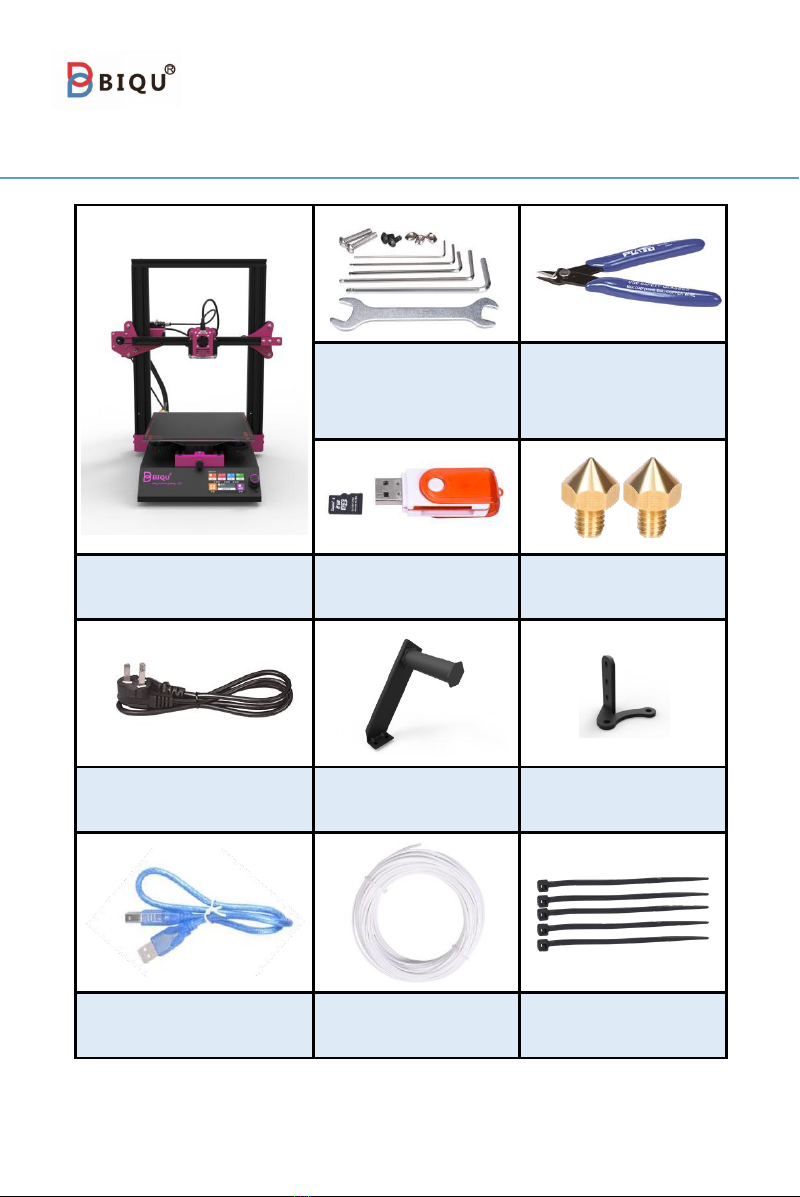

1. Packing List

Wrench and screw

bag

(1set)

Diagonal pliers

(1pcs)

BIQU-B1

(1pcs)

TF card and card

reader (1set)

Nozzle

(2pcs)

Power cable

(1pcs)

Rack

(1pcs)

BLtouch stand

(1pcs)

Data cable

(1pcs)

Filament for test

(45g)

Cable tie

(5pcs)

2

WWW.BIQU.EQUIPMENT

2. Equipment parameters

The basic parameters

Printer Name

BIQU-B1

Printing Size

235 x 235 x 270mm

Molding Tech

FDM

Nozzle Quantity

1 PCS

Layer Thickness

0.1mm - 0.3mm

Nozzle Diameter

Standard 0.4mm

Printing Accuracy

±0.05mm

Filament

PLA

Slicing Format

STL / OBJ/ AMF

Connecting Method

Via data cable / TF card / USB

Slicing Compatible

With Cura / Repetier-Host / Simplify 3D

Rated Voltage

100 - 120V / 200 - 240V 50 / 60 HZ

Output Voltage

24V

Rated Power

270W

Max Temp of Hot Bed

100℃

Max Temp of Nozzle

260℃

OS compatible

with Win 7 / Win 10

Maxium operating speed

180mm/s

Max Printing Speed

100mm/s

Normal Printing Speed

60mm/s

Language Transform

Supported

Resume Printing

With resume printing function

Filament Run Out Detection

With filament run out detection function

3

BIQU-B1 USER MANUAL

3. Installation equipment

Step 1

Connecting the terminal wire to the socket of the hot bed.

Step 2

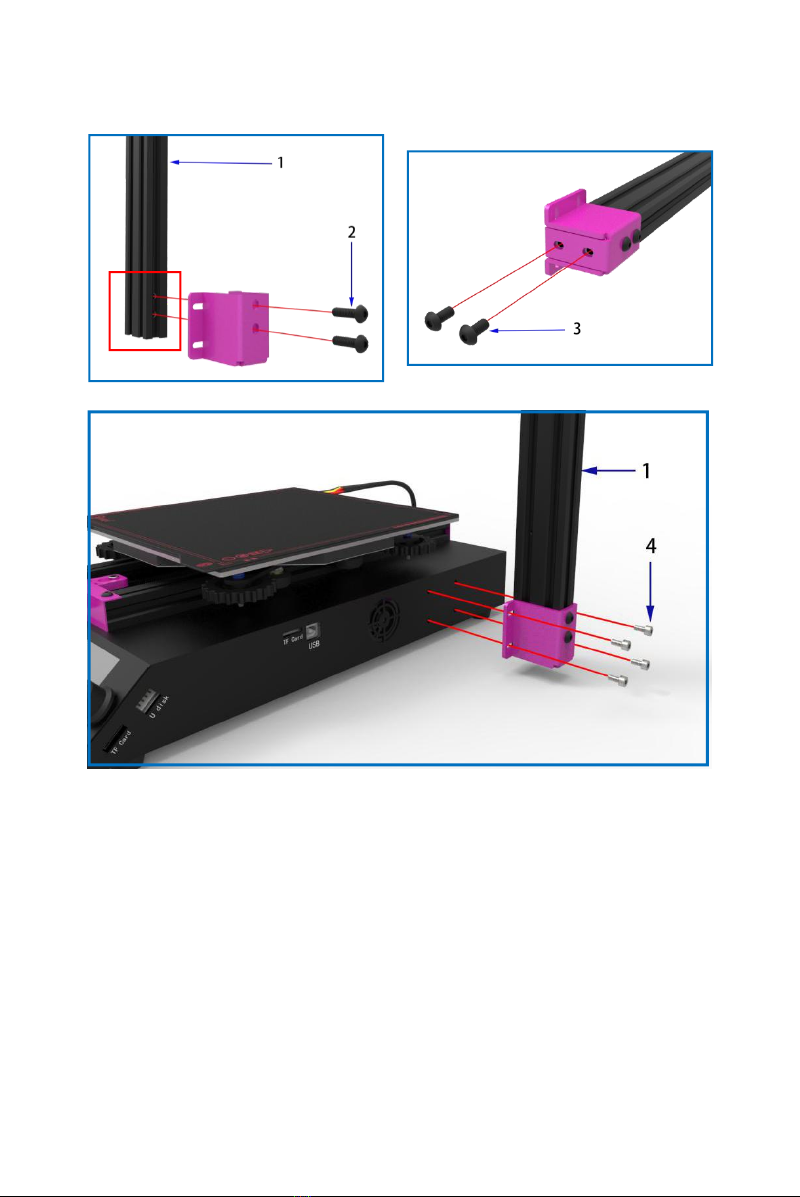

There are two M5 threaded holes on the end of the 2040 aluminum

profile,which is used for mounting the M5×16 hex socket head screws.

4

WWW.BIQU.EQUIPMENT

1.2040 aluminum profile—length 456mm (1pcs)

2. M5×16 hexagon round-head screws (2pcs)

3. M5×10 hexagon round-head screws (2pcs)

4. M4×8 hexagon cup-head screws (4pcs)

5

BIQU-B1 USER MANUAL

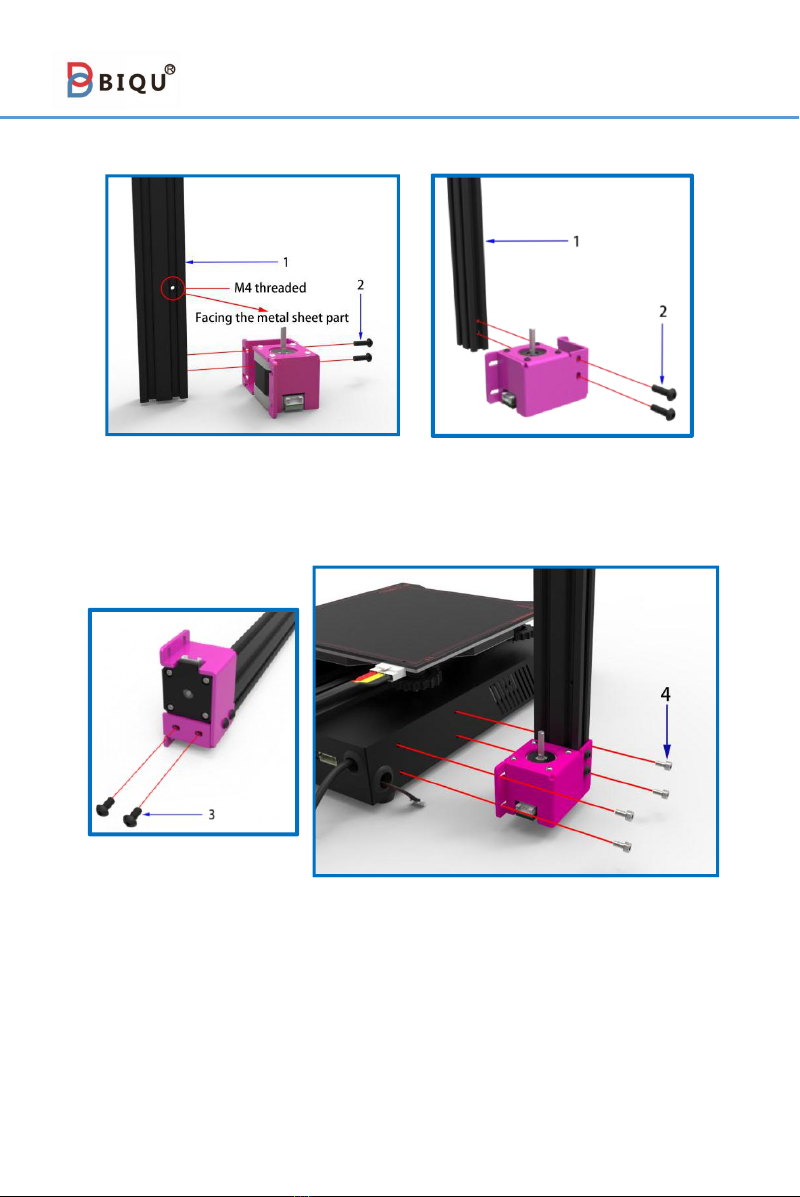

Step 3

There is a M4 threaded holes on another 2040 aluminum profile.

When installation, users make the threaded hole face the metal sheet

part.

1. 2040 aluminum profile--length 456mm (1pcs)

2. M5×16 hexagon round-head screws (2pcs)

3. M5×10 hexagon round-head screws (2pcs)

4. M4×8 hexagon cup-head screws (4pcs)

6

WWW.BIQU.EQUIPMENT

Step 4

1. T8 screw (1pcs)

2. Coupling device (1pcs)

There are machine screws inside the coupling device, which is used to

tighten the motor shaft and screw rod. The set screw is aligned with the plane

of the motor shaft when installing.

Step 5

1. M3×6 hexagon round-head screws (4pcs)

2. Hexagonal isolation column (1pcs)

7

BIQU-B1 USER MANUAL

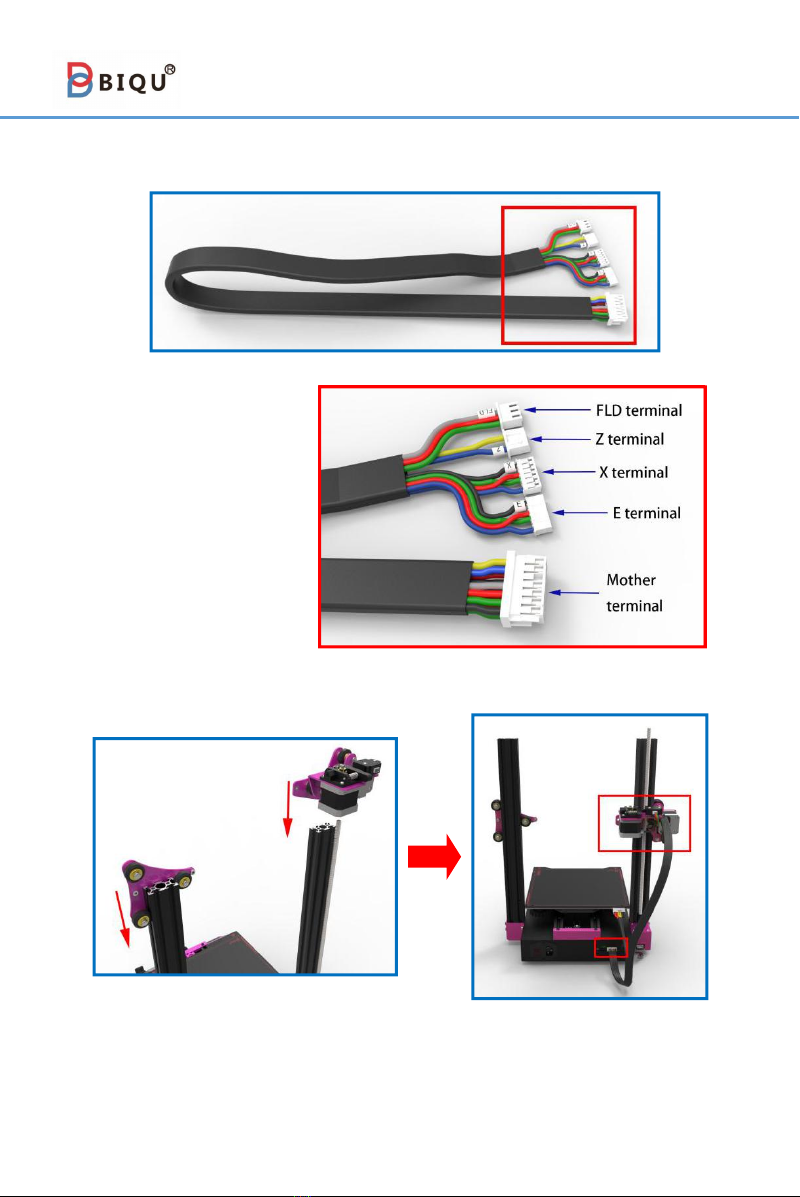

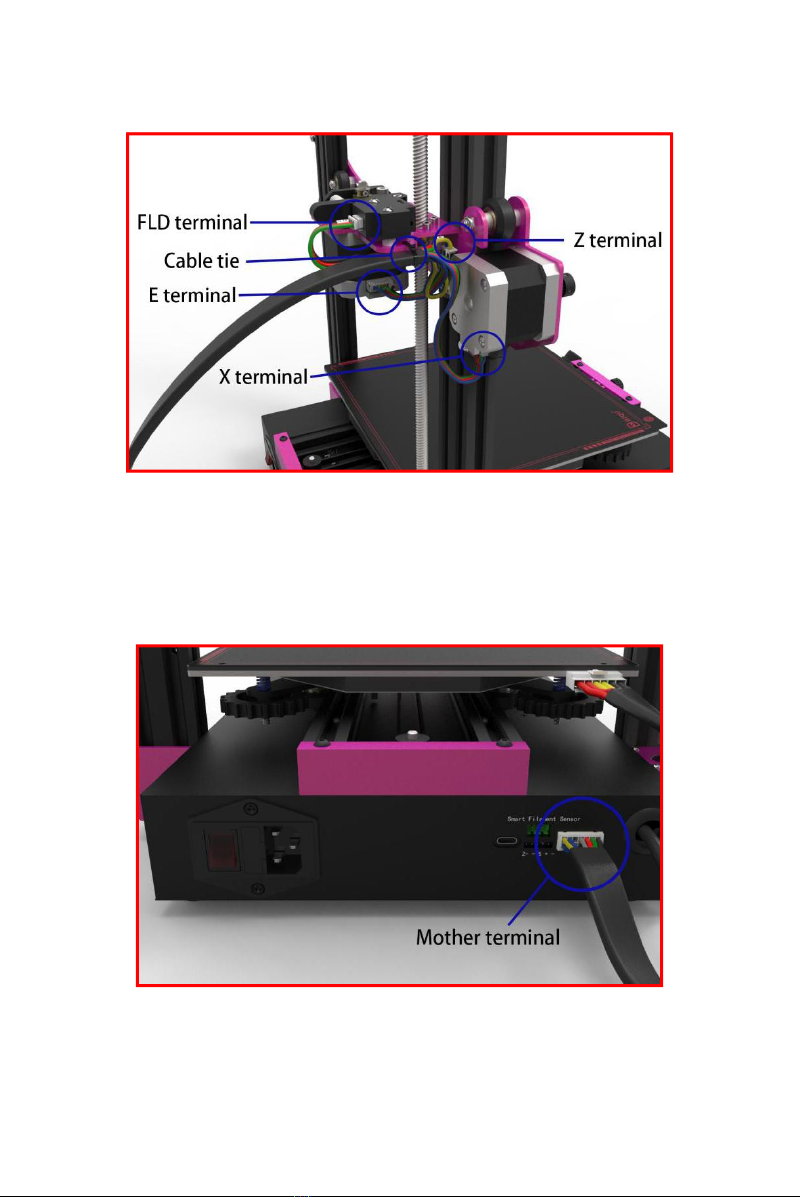

Step 6

4 in 1 terminal wire

8

WWW.BIQU.EQUIPMENT

As shown above, installing the 4 in 1 terminal wire to its

corresponding position. Then there are two key slots on the metal

sheet part. Users can use a cable tie to fix the terminal wire through

them.

9

BIQU-B1 USER MANUAL

1. Eccentric nut

Awareness: As the picture, please check whether the

interfaces are loose. If they are loose, please tight the eccentric nut

with wrench and make the groove of eccentric nut approach the

aluminum profile. Pulley on eccentric nut will preload aluminum

profile. The printer will be more stable by this way.

Step 7

Connecting the terminal wire on side to the motor’s port.

10

WWW.BIQU.EQUIPMENT

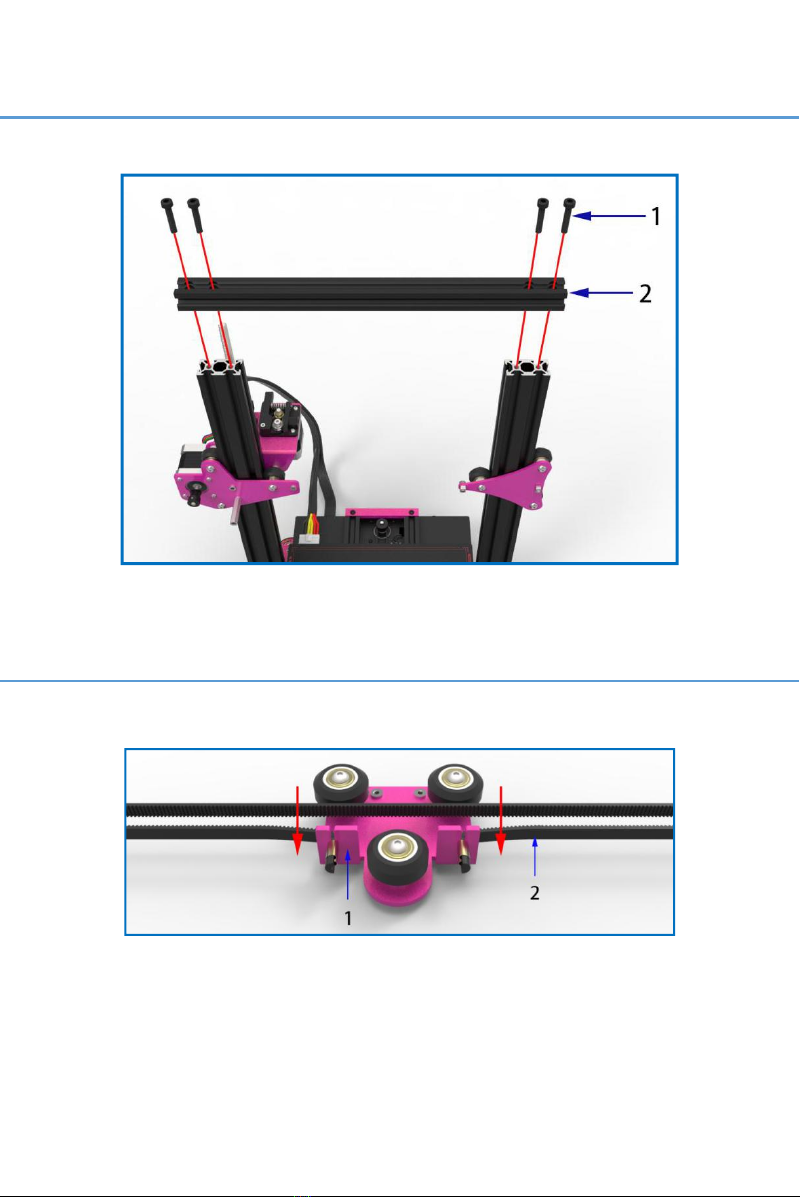

Step 8

、

1. M5×25 hexagon cup-head screws(4pcs)

2. 2020 aluminum profile—length 323mm(1pcs)

Step 9

1. X slider sheet(1pcs)

2. Belt(1pcs)

11

BIQU-B1 USER MANUAL

Step 10

1. M4×8 hexagon cup-head screws(2pcs)

2. M4 boat-shape nut(2pcs)

3. 2020 aluminum profile—length 338mm(1pcs)

4. M5×18 hexagon cup-head screws(2pcs)

The boat-shape nut may rotate during installation. Users could

use the screws to fix it on the aluminum profile.

Step 11

Installing the belt onto the 2020 aluminum profile.

12

WWW.BIQU.EQUIPMENT

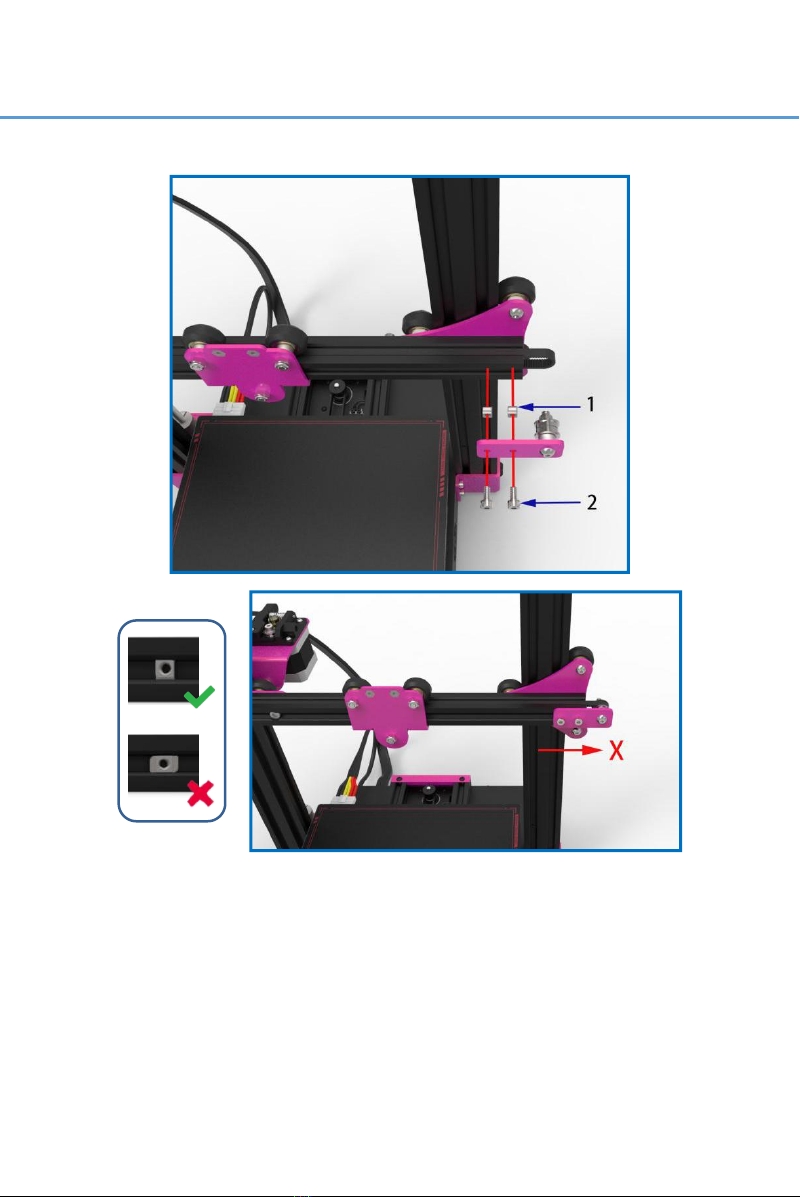

Step 12

1. M4 boat-shape nut(2pcs)

2. M4×8 hexagon cup-head screws(2pcs)

Notice: The boat-shape nut may rotate during installation. Users

could use the screws to fix it on the aluminum profile.

When installation, in order to tighten the pulley and the belt,

users could push the parts slowly in the X direction.

13

BIQU-B1 USER MANUAL

Step 13

1. M3×8 hexagon cup-head screws(2pcs)

Step 14

1. Feed tube(1pcs)

2. Quick connector(2pcs)

14

WWW.BIQU.EQUIPMENT

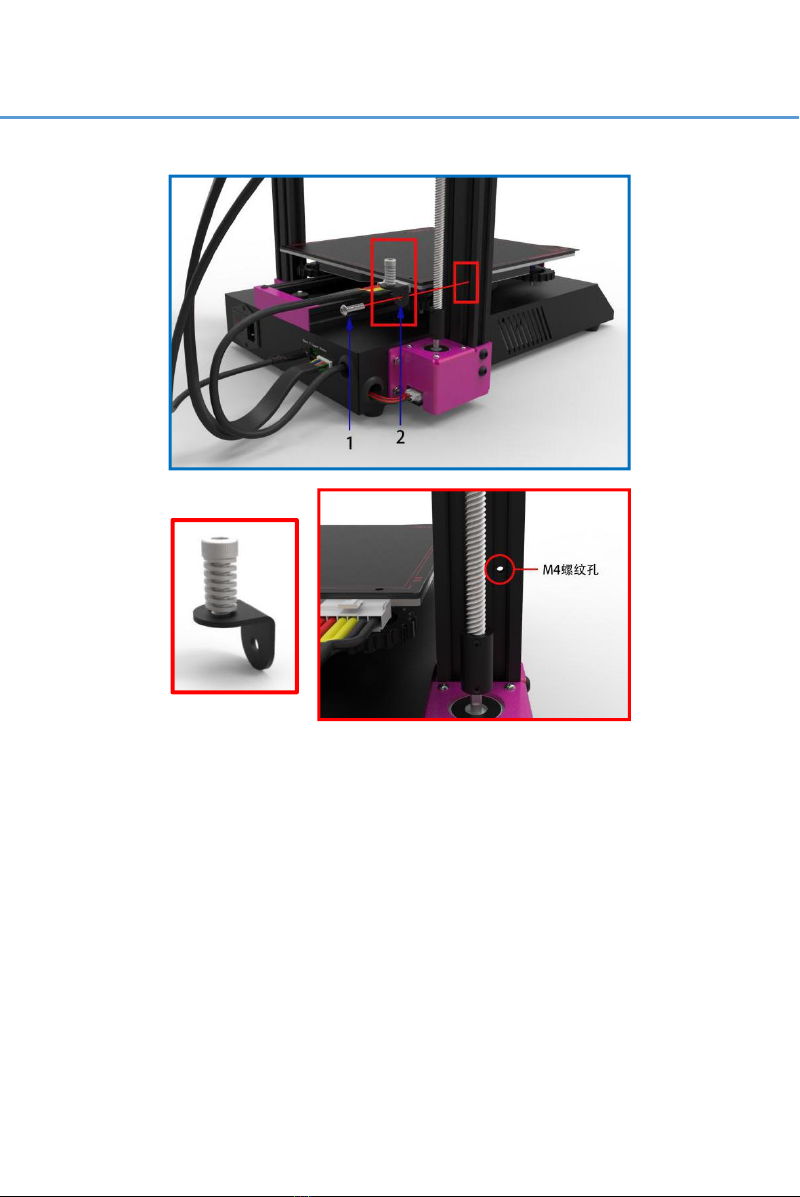

Step 15

Step 16

1. M4×8 hexagon round-head screws(2pcs)

2. M4 boat-shape nut(2pcs)

The boat-shape nut may rotate during installation. Users could

use the screws to fix it on the aluminum profile.

15

BIQU-B1 USER MANUAL

Step 17

1. Type-C data cable(1pcs)2. Cable tie(1pcs)

As shown above, there are two key slots on the metal sheet part.

Users can use a cable tie to fix the Type-C cable through them. But

before fixing the data cable, users would better leave a certain length

at the Type-C cable's end which closes to the nozzle. It facilitates the

movement of the nozzle.

Awareness:

1.do not unplug the Type-C data cable when the machine is on.

2.The Type-C cable is customized, it can not be replaced by others.

16

WWW.BIQU.EQUIPMENT

Step 18

1. M4×16 hexagon round-head screws(1pcs)

2. Z axis limit module

Fixing the Z-axis limit module on the aluminum profile by using the

M4 threaded holes and the above screws.

Awareness: Please check all the screws and make sure that they are

properly installed.

Installation Finished!

17

BIQU-B1 USER MANUAL

4. Platform Calibration

4-1 Platform Calibration

After the installation of BIQU B1, users need to perform a platform

calibration on BIQU B1. The steps are as follows:

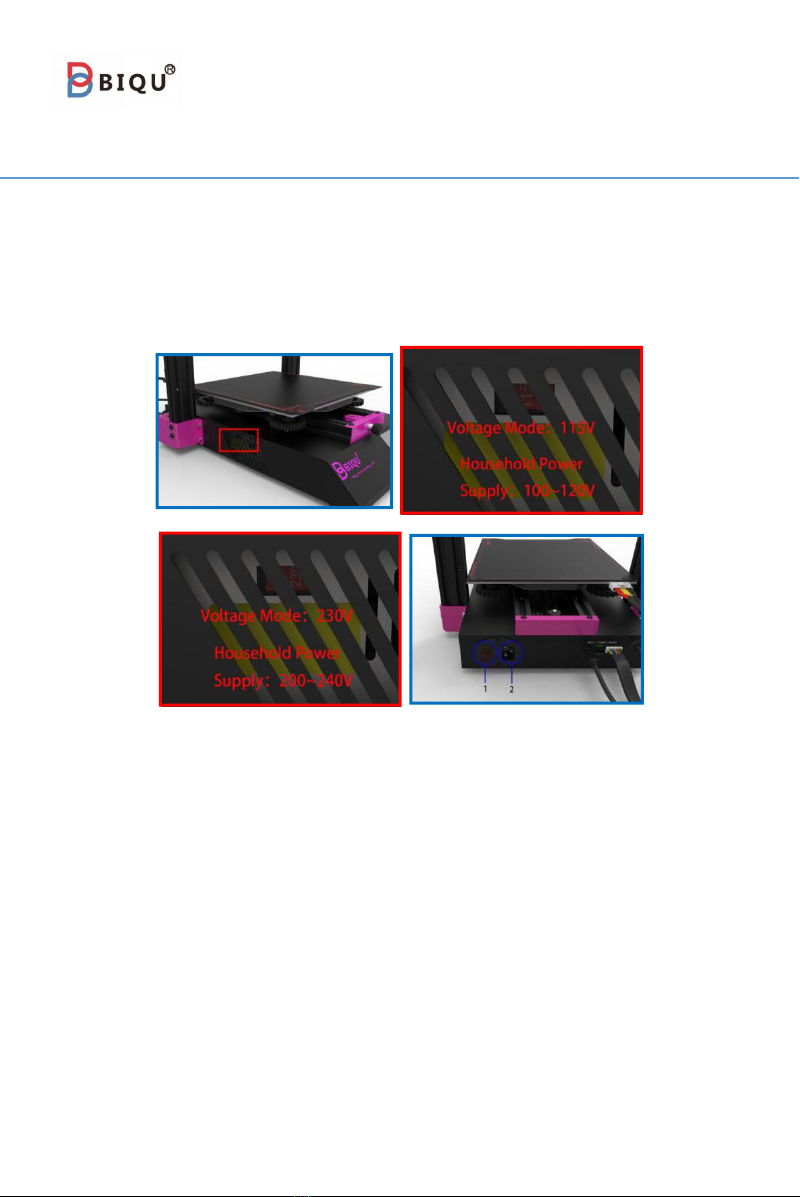

Step 1

1. Power switch

2. Power cord socket

Awareness: Before turning on, please check whether the

voltage mode matches your household power supply. If not, you

can select the mode by using screwdriver.

Confirming that the wiring is steady and correct. Inserting one

end of the power cord into the power cord socket and the other

end into the household power supply, and then turn on the power

switch of the machine.

Awareness: do not unplug the Type-C data cable when the

machine is on.

18

WWW.BIQU.EQUIPMENT

Step 2

Clicking on the touch screen homepage① “Menu ”→②

“Movement”→③“Home”→④“Z”。

The nozzle moves back to the zero point of the Z axis, which is

above the platform. Twist the 4 hand-tight nuts counterclockwise

under the hot bed so that there is a distance of 3 ~ 6mm between

the hot bed and the nozzle.

1. Hand-screw nut(4pcs)

①

②

④

③

Table of contents

Other BIQU 3D Printer manuals

Popular 3D Printer manuals by other brands

Monoprice

Monoprice 33820 user manual

Kulzer

Kulzer cara Print 4.0 Instructions for use

FLASHFORGE 3D PRINTER

FLASHFORGE 3D PRINTER CREATOR PRO 2 user guide

MiiCraft

MiiCraft MiiCraft+ user manual

NJIT Makerspace

NJIT Makerspace Trotec Speedy 400 Flexx quick start guide

SprintRay

SprintRay MoonRay quick start guide