BIQU Thunder User manual

Table of Content

One: Product Overview............................................................................. 1

Two: Tools and Supplies ........................................................................... 3

Three: Assembly........................................................................................ 4

3.1 Machine Assembly ....................................................................... 4

3.2 Machine Wiring............................................................................ 7

Four: User interface .................................................................................. 9

Five: Specification ................................................................................... 15

Six: Feature Overview ............................................................................. 16

Seven: Smart Phone Connection ............................................................ 18

Eight: Slicer.............................................................................................. 23

Nine: Connect and Print.......................................................................... 28

9.1 Repetier-Host Installation .......................................................... 28

9.2 Connect Printer with Repetier-Host........................................... 29

Ten: Trouble Shooting............................................................................. 34

Eleven: Important Information............................................................... 36

Shenzhen Bigtree Technology Co.,Ltd

1

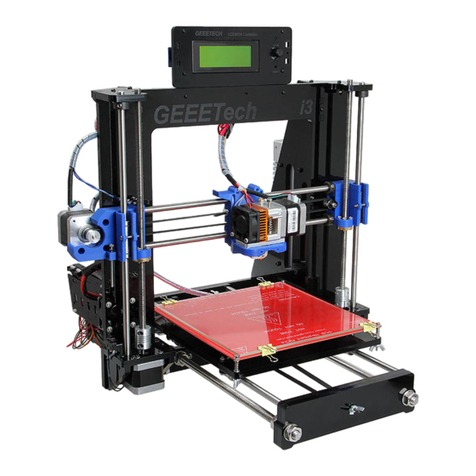

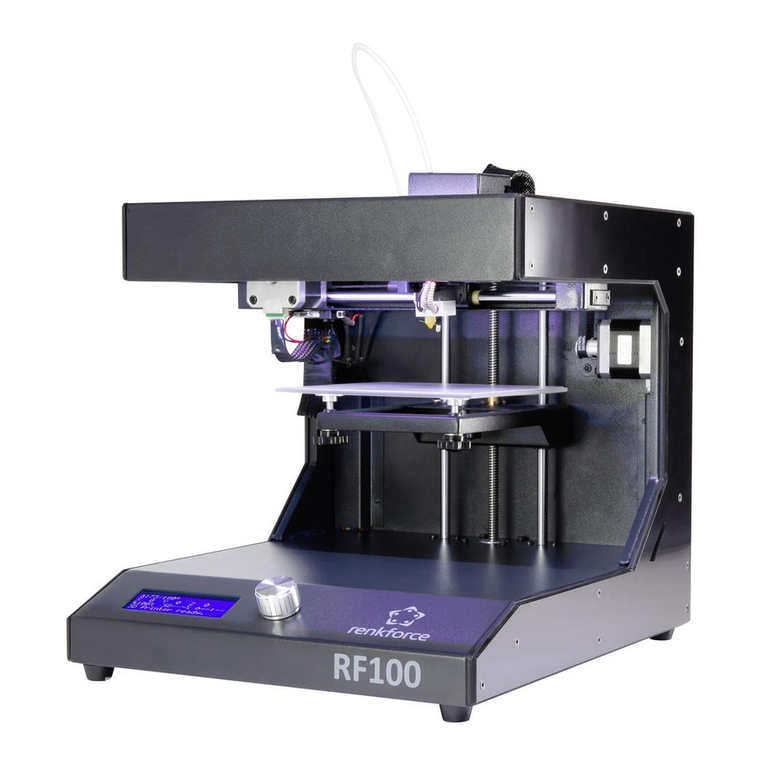

One: Product Overview

1. z-axis aluminum

extrusion

9. extruder module

2. cable chain

10. y-axis aluminum

extrusion

3. filament

11. x-axis aluminum

extrusion

4. circular connector

12. bearing

5. x-axis limit switch

13. spring

6. heated bed

14. support plate

7. fine adjust nut

15. screen

8. system unit

16. reset button

Shenzhen Bigtree Technology Co.,Ltd

2

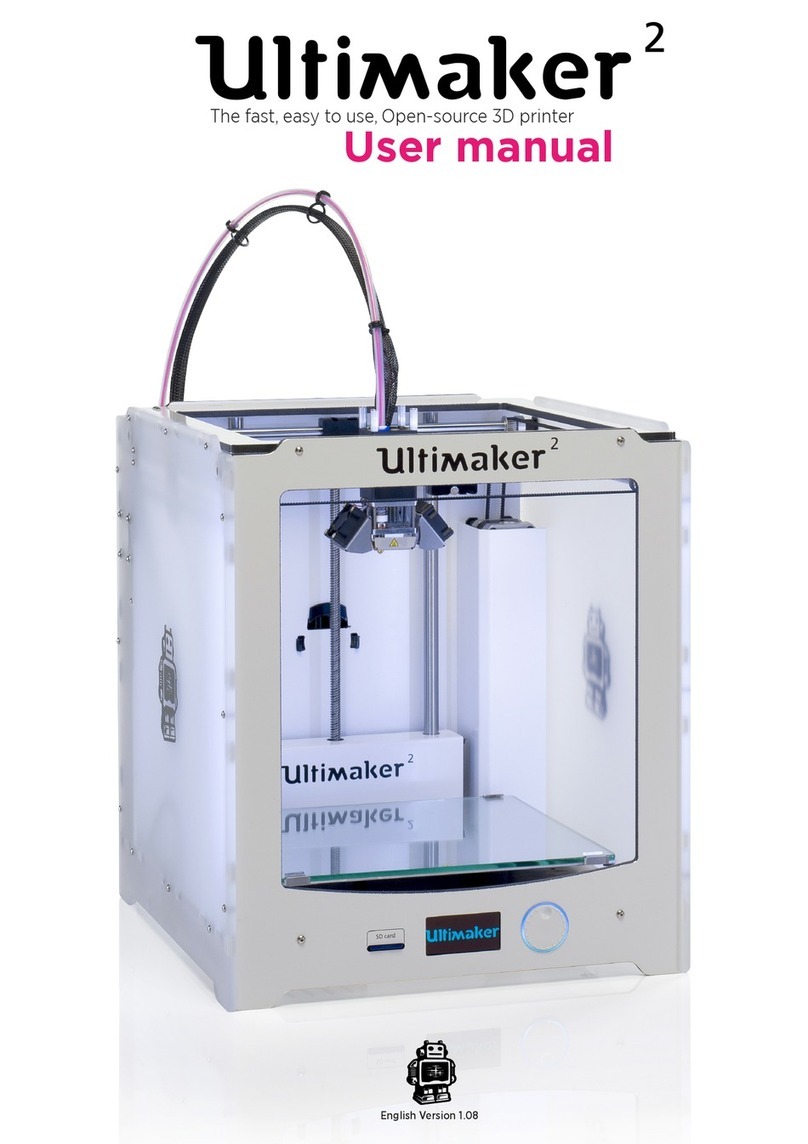

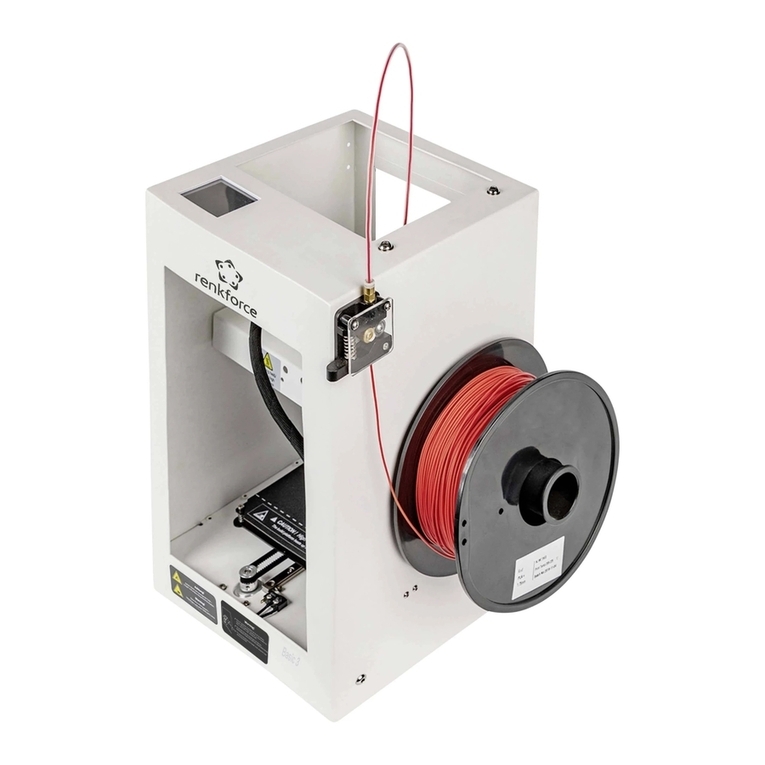

1. screw rod

8. extruder stepper

2. motor coupling

9. y-axis synchronous

wheel

3. z-axis stepper

motor

10. y-axis stepper motor

4. support plate

11. AC plug

5. teflon tube

12. on/off switch

6. one-touch fitting

13. x-axis stepper

7. extruder

14. filament holder

Shenzhen Bigtree Technology Co.,Ltd

3

Two: Tools and Supplies

Please make sure you receive all the tools and supplies, contact your

seller as soon as possible if anything is missing.

Shenzhen Bigtree Technology Co.,Ltd

4

Three: Assembly

3.1 Machine Assembly

Please make sure the machine is not damaged during shipping. If there is

any problem, contact the seller as soon as possible. If the machine is in

good condition, and no tools or supplies are missing, feel free to start

installing your printer.

Step one: place the aluminum extrusion (2) such that they are facing

toward the front of the printer (1), use the bolts from bag A1 (black

M5*25 bolt) (3) to fasten both aluminum extrusions.

Step two: check that the aluminum extrusion (1) is secured, make sure (2)

and (3) are orientated correctly according to the picture.

Step three: twist couplings of both z-axis steppers at the same time so

that the x-axis rail can slide in smoothly.

Step four: make sure the aluminum extrusion is facing the front (similar to

step one), use the hardware in bag A1 (black M5*25 bolts, M5 washers)

to secure the top aluminum extrusion.

Shenzhen Bigtree Technology Co.,Ltd

5

Step five: extruder stepper installation. Make sure you place the stepper

(1) with the correct orientation as highlighted with the red box. Four

threaded holes are facing the aluminum plate (2). Use then bag of

hardware labeled as A2 (black M3*10 bolt) (3). Tighten the stepper as

shown.

Step six: find the x-axis slider (1), use bag A3 hardware (black M4*8 bolt),

and tighten up extruder module (2).

Step seven: place the extruder wiring harness on the right, use the bolts

in bag A4 to secure the cable chain from left side (2) to right side (3), this

way is easier.

Shenzhen Bigtree Technology Co.,Ltd

6

Step eight: slightly loosen the nuts near plate (1) and filament holder (2),

fasten on the aluminum extrusion.

Step nine: slightly loosen the nuts near the T shape plate (1), fasten the

plate on the aluminum extrusion.

Note: refer to picture 10 about how to assemble parts on the aluminum

extrusion.

Shenzhen Bigtree Technology Co.,Ltd

7

3.2 Machine Wiring

Step one: screw the golden one-touch fitting (1) to the extruder and

connect the filament sensor cable (2) to the extruder.

Step two: connect the extruder cable E0 (1) to the extruder, connect x-

axis stepper cable and limit switch cable to (2) and (3).

Step three: connect the circular connector (1) on to the correct location

showed in the picture, align the connector before plugging in, then fasten

the connector.

Shenzhen Bigtree Technology Co.,Ltd

8

Step four: connect Z axis endstop cable (1) with endstop from inner side.

Step five: plug in the extruder cable (1).

Step six: wire the cable to the z-axis stepper motors (1) (2).

Shenzhen Bigtree Technology Co.,Ltd

9

Notes:

Double check your connection.

Use a scale/ruler to make sure (1) and (2) are at the same height.

Congratulations! The installation is finished. Start your 3D printing now!

Four: User interface

Recommend to touch screen by nail/stylus

4.1 Auto Leveling

Plug in the power cord (1), remove the film pressure sensor, one end

connects to the nozzle and the other connect to the side of the unit as

shown in the picture (2); click “more” on the main interface, press “auto

leveling” and confirm, and you will see “leveling is completed” after the

print bed is leveled. Note: make sure your print environment is less than

45 degree Celsius so that the film pressure sensor can work properly,

you don’t need to redo auto leveling for future print.

Shenzhen Bigtree Technology Co.,Ltd

10

Shenzhen Bigtree Technology Co.,Ltd

11

Note: If you are not satisfied with the result from auto calibration, you

can enter into “Baby step” interface (1) , and then adjust the nozzle

height by pressing “+” or “-” to adjust the nozzle height during print. If the

nozzle is too close to the print bed, press “+”, otherwise, press “-”. Long

press “+” or “-“ to speed up the process, and this technic is also

applicable to increase or decrease nozzle temperature.

Shenzhen Bigtree Technology Co.,Ltd

12

4.2 Auto Feeding

Unbox the filament, cut the end of the filament to a 45 degrees angle and

make it straight (1). Press “More” on the main interface (2), then press

“change filament” (3). Press “A” to heat up the nozzle (4). After finished

heating, feed the filament to the extruder(5), and then press “A” again (4).

Note: a. Please make sure there is no filament inside Teflon tube before

you use auto feeding function. If there is, please heat up nozzle and use

tool to squeeze filament out beforehand.

b. It is normal to hear "click" sound from extruder when filament is

extruding from nozzle, just wait for "Bi" sound, it means auto feeding

finished.

Shenzhen Bigtree Technology Co.,Ltd

13

4.3 Printing

4.3.1 Insert the SD card, press “print”, select the model you would like to

print.

Shenzhen Bigtree Technology Co.,Ltd

14

4.3.2 After the print is completed, wait for the nozzle, heated bed and

print to cool down before taking the soft magnet bed out and remove

your print.

Shenzhen Bigtree Technology Co.,Ltd

15

Five: Specification

Printer description

PLA 3D printer, entry level 3D printer, easy

assembly, designed by BIQU

Slicer

Cura, Slic3r, Simplify 3D

Extrusion type

Bowden extrusion

Print material

PLA/ABS/TPE/TPU/Wood/Metal PLA/Metal

ABS/Carbon Fiber/Glow-in-the-Dark Material

Max print volume

300*300*400mm

Filament diameter

1.75mm

Max print speed

100mm/s

Number of extruder

1

Stepper accuracy

X 0.012mm

Y 0.012mm

Z 0.004mm

Net weight

12.26kg

Total weight

16.2kg

Leveling

Manual & Auto leveling

Package size

735mm*520mm*295mm

Structure material

Metal

Layer height

0.1mm-0.4mm

Printing surface

Soft magnet bed

Resume printing

Non-trace resume after power off capable

LCD Screen

English/Chinese/Japanese

Shenzhen Bigtree Technology Co.,Ltd

16

Six: Feature Overview

Soft magnet bed

Easy removed magnet heated bed

Power off after prints

Auto power off after prints are done, low

power consumption, safe, longer life

Auto leveling

Auto leveling for better precision

Cloud app

Connect printer with your phone, remote

control printer, online .stl file data base

Auto install and change

filament

Easy to change filament

Filament jam detection

Smart detection on filament jam

Non-trace Resume print

3D printer can remember the print status if

there is accident power off, and it can

resume printing when power is on again

Note: If you used Auto OFF function for your last print, please

remember to turn off power switch and then turn it on to run the

printer again.

Shenzhen Bigtree Technology Co.,Ltd

17

Navigate to Feature Interface

Method one: click “Settings”icon, then click “Function”icon

Method two: If the printer is printing, you can long press “more” on the

printing interface to enter feature interface.

Shenzhen Bigtree Technology Co.,Ltd

18

Seven: Smart Phone Connection

7.1 For Android, please download and install “MyMiniFactory” through

Google Play; For IOS, please download and install “MyMiniFactory”

through App Store.

7.2 Click on the mobile phone to enter the software, fill in the user

information and check the agreement to register the account, return to

the login interface to fill in the account and password to log in, click the

small icon in the user interface, select "Connect 3D printer", add the

printer.

Table of contents

Other BIQU 3D Printer manuals