1. HOTENDS CLEANING

Recommended frequency: each time printing is finished.

Each time after printing completion, it is recommended to clean the hotends from molten/burnt material that

may be on the outside of the nozzle.

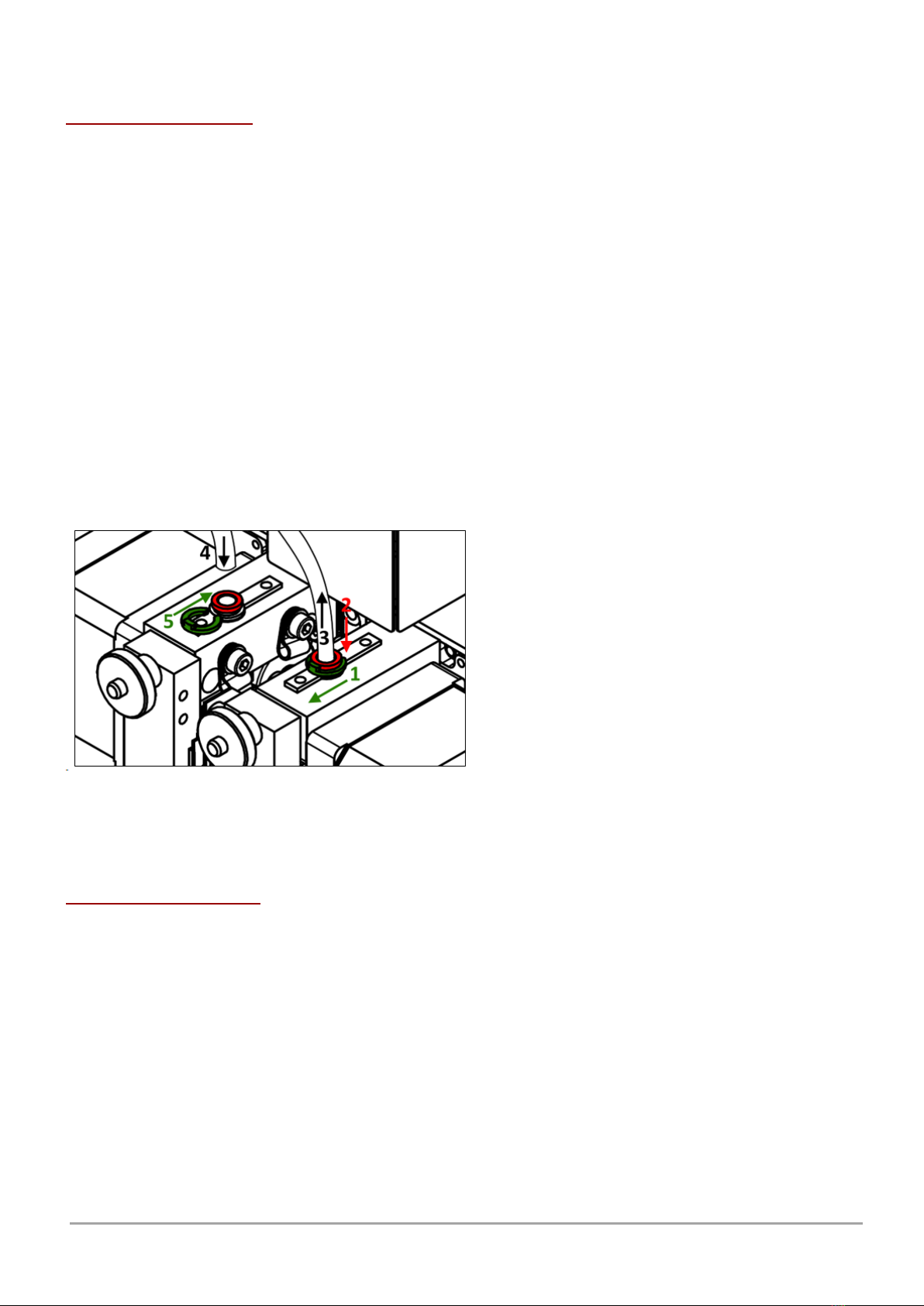

Procedure for hotend cleaning:

1. Set the heatbed to a position that allows good access to the hotends with the option: Manual Controls →

Down.

2. Warm up the T0 hotend with the option: Menu → Tune → Temperatures → Tool 0 and use the +/- keys to set

the desired temperature:

•for the PRO module up to 265°C,

•for the HF module up to 265°C,

•for the HT module up to 320°C,

•for HTmax module up to 400°C.

3. Warm up the T1 hotend with the option: Menu → Tune → Temperatures → Tool 1 and use the +/- keys to set

the desired temperature:

•for the PRO module up to 220°C,

•for the HF module up to 265°C,

•for the HT module up 265°C,

•for HTmax module up to 265°C.

4. Set the T0 hotend in the active position with the option: Manual Controls → Tool 0 Select.

5. Wear protective gloves.

6. Gently remove any molten/burnt material from the T0 nozzle with non-combustible material or tweezers.

7. Set the T1 hotend in the active position with the option: Manual Controls → Tool 1 Select.

8. Gently remove any molten/burnt material from the T1 nozzle with non-combustible material or tweezers.

9. After cleaning the hotends, turn off the heating with the option: Menu → Prepare → Cooldown.

2. HEATBED CLEANING

Recommended frequency: each time printing is finished.

A dirty or greasy printer heatbed can make printing difficult or completely impossible. It is recommended to clean

the heatbed each time after printing is finished or before it is started. Clean the printer heatbed by following the

instructions below.

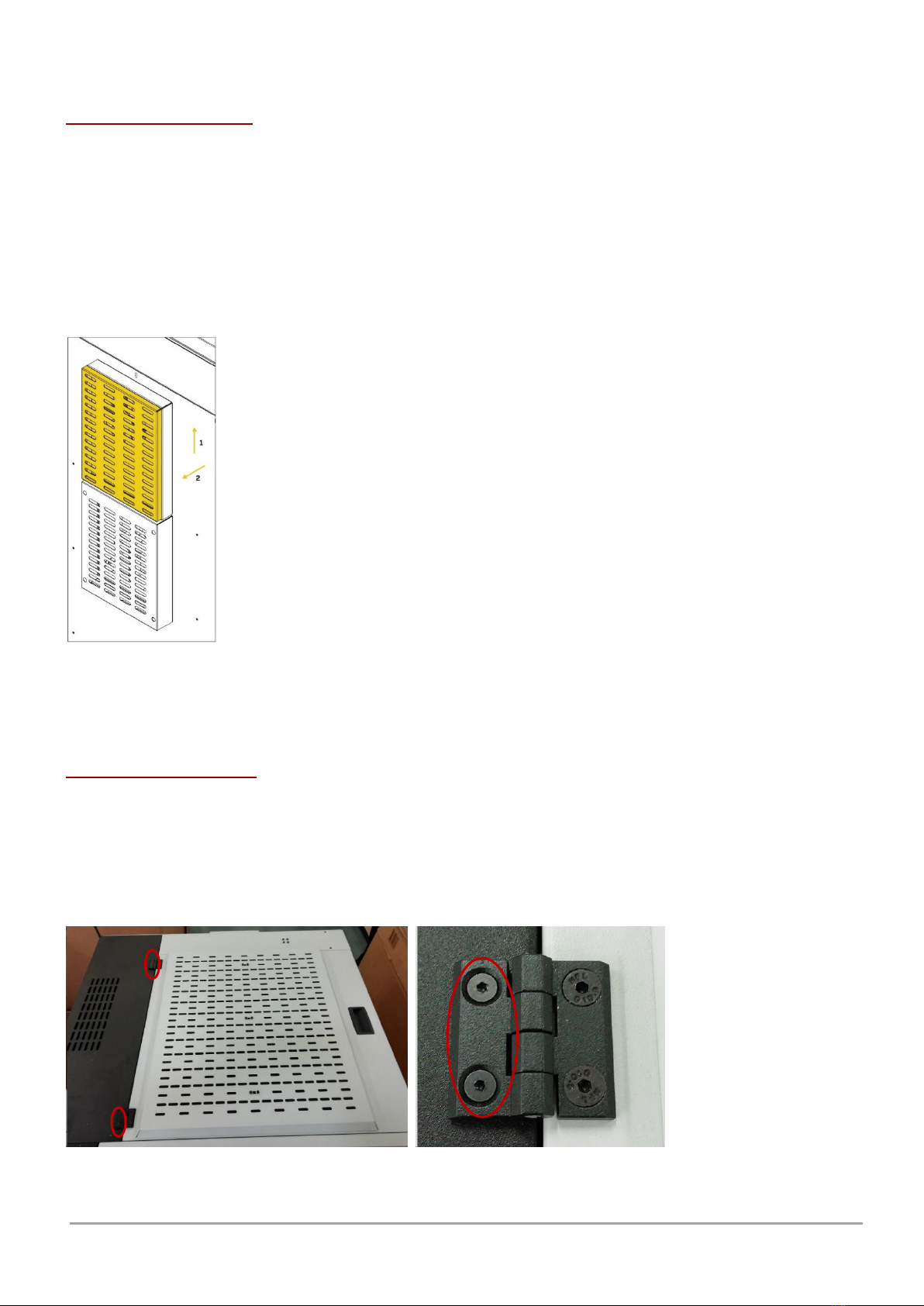

The procedure for cleaning the heatbed:

1. Set the heatbed to a position that makes it possible to clean it with the option: Manual Controls → Down.

2. Switch off all heating elements of the printer. Allow to cool completely and reach the ambient temperature.

3. Turn the printer off using the main power switch, then disconnect the printer from the power source.

4. Wear protective gloves.

5. Clean the heatbed surface of any plastic residue with a spatula.

6. Clean the heatbed with a damp cloth and then wipe dry with a paper towel.

7. Degrease the heatbed with a cloth soaked in ethyl alcohol or isopropyl alcohol and wait for the alcohol to

evaporate.