Important!

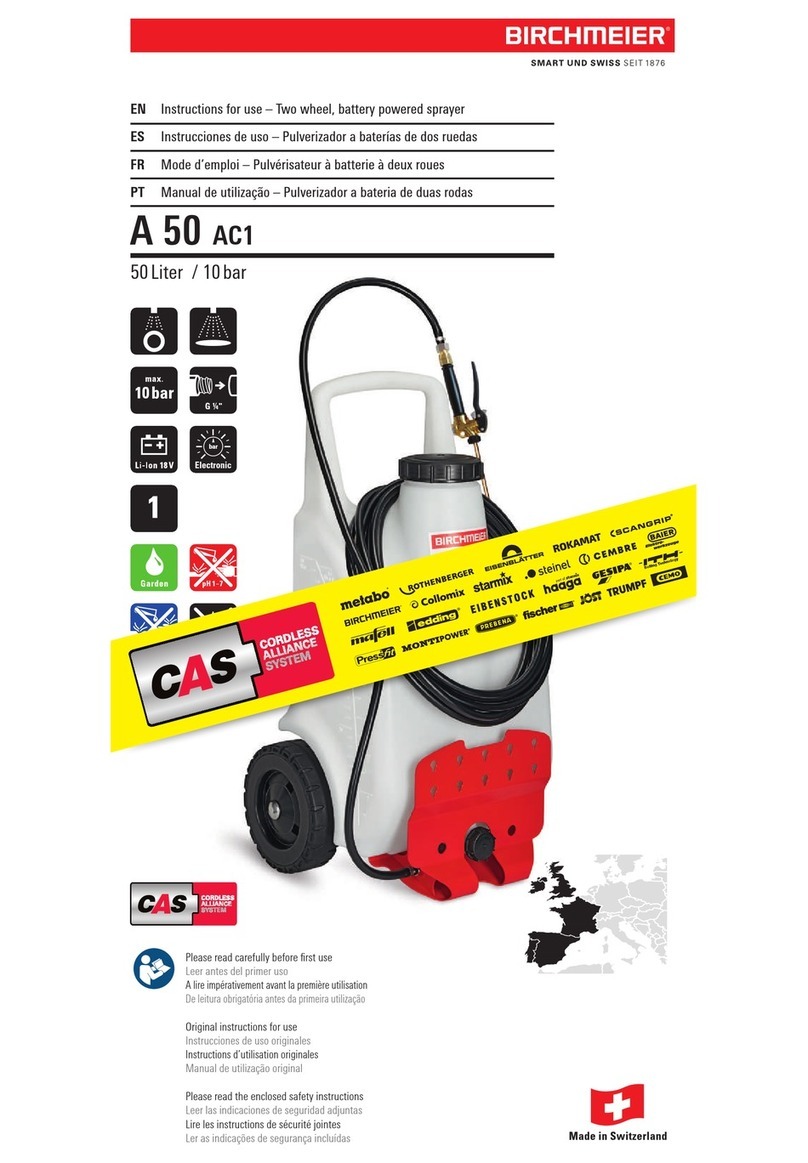

Before taking the sprayer into service for the first time, make sure to read the operating manual

thoroughly.

The user is liable for damages resulting from failure to observe these instructions.

Failure to observe the safety and warning alerts can result in injury to or death of persons!

Warning!

Do not use the sprayer while other persons are still in the working area.

Do not blow out a clogged nozzle or clogged valves with the mouth (danger of poisoning).

Clean the sprayer after each use, making sure not to cause pollution to water.

Do not fill chemicals into other containers (bottles, cans or the like). Store equipment and chemicals

such that they cannot be reached by children and household animals.

When the sprayer is passed on to third parties, definitely make sure that it is accompanied by the

operating manual.

The user is responsible versus third parties, and in particular domestic animals and children, that

when taking the sprayer into service any escaping media as a result of the opening of the safety

relief valve, as well as the spray jet during spraying operations, are not directed at said third parties.

When spraying the agent avoid contact with the spraying liquid. During this work make sure to wear

protective clothing, a protective mask and safety glasses and to protect the hands.

Do not spray against the wind, as well as during strong winds. Do not spray any more of the agent

than necessary for the surface to be treated.

Safety Instructions

Before each use check to ensure that the sprayer has been correctly assembled, and that it is in a

functional and undamaged condition. Special attention must be given to the tightness of the hose

connections, as well as to the correct functioning/freedom of movement of the safety relief valve (1).

The sprayer is equipped with a pressure relief valve (1) which discharges excessive pressure. The

pressure relief valve is adjusted to 4 bar / 58.02 psi. It is noted expressly that any and all

manipulation of the pressure relief valve is prohibited. In this case, any and all warranties of

BIRCHMEIER Sprühtechnik AG become null and void, and all liabilities are disclaimed by

BIRCHMEIER Sprühtechnik AG.

Make sure that the desired agent is suitable for this sprayer. The safety and handling instructions of

the chemical manufacturer are to be observed and adhered to. The use of any and all chemicals is

at your own responsibility and risk. If you should have any doubts in this respect, please consult our

after-sales service.

The sprayer must not be filled with caustic substances (e.g. disinfectants and impregnating liquids

which attack the skin or materials), corrosive substances (acids) or highly inflammable or

combustible substances.

The sprayer must not be filled with liquids at a temperature greater than 30°C / 86°F. Do not leave

the appliance standing in the sun under pressure. The effects of frost can damage the equipment.

Before unscrewing the pump (4) always first release the pressure via the pressure relief valve (1),

holding the sprayer away from the body at an angle.

Applications

The equipment can be used to spray the recognized pesticides, weed-killers and liquid fertilizers, as

used in the home, in the garden, on the farm, or in vineyards.

Preparing the equipment for use

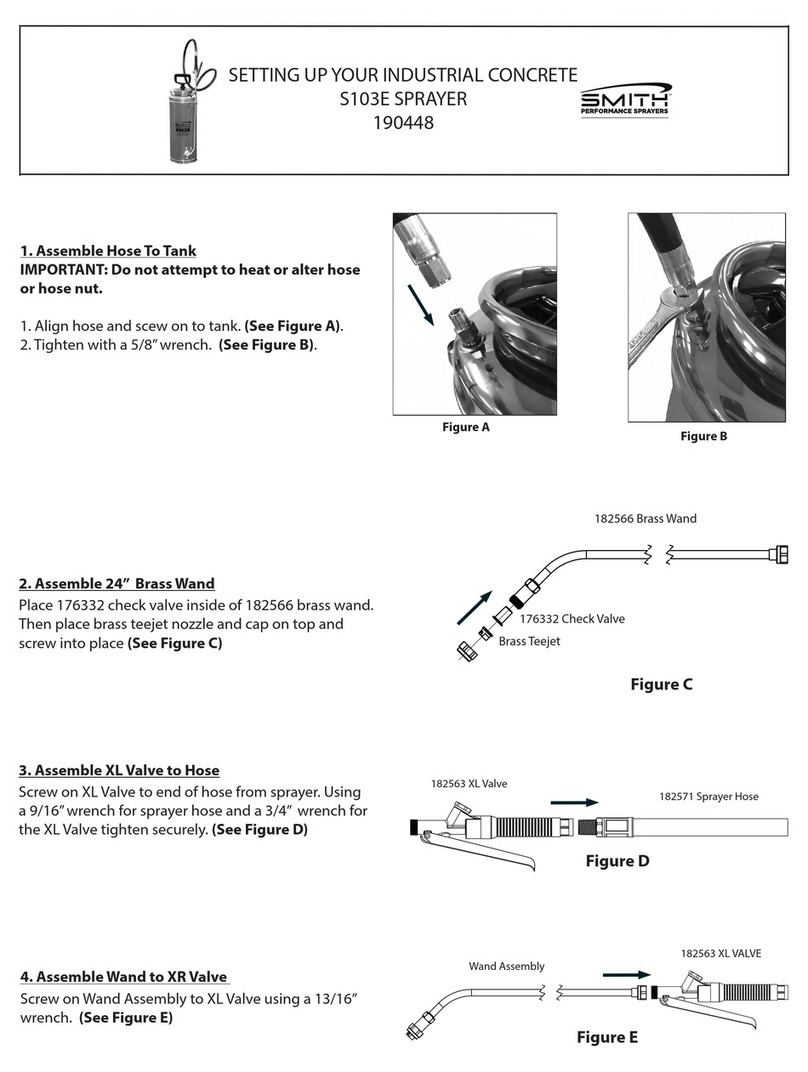

Fit the spray pipe according the spare parts diagram. Screw the stop valve (11) on to the hose (10)

and then insert the spray tube (13) with nozzle (15) in the stop valve and screw up tight. Finally, make

sure all joints are tight.

Operation

Filling the tank:

On each occasion first fully release the pressure in the tank by lifting the pressure relief valve (1).

Unscrew the pump (4) and fill the tank; the maximum permissible volume of liquid must not be

exceeded (see level-mark on the tank), so that sufficient space remains for the air-cushion. The

maximum permissible operating temperature is 30°C / 86°F.

Pressurizing the tank:

Screw in the pump (4) and tighten the connection firmly. Release the pump handle from the locked

position by pressing down on it slightly and turning it to the left. Pump up until the red mark appears on

the pressure relief valve (1). Operating pressure has then been reached. Fasten the pump handle in

the locked position again.

Compressed air: In order to pump up the appliance using an external pressure source a pressure-

reducing valve must be used, set to a maximum pressure of 4 bar / 58.02 psi. When a pressure of 4

bar / 58.02 psi has been reached the pressure source must be removed.

Spraying:

The liquid is sprayed by operating the spray-gun. The spray-pattern can be matched to the particular

requirement by turning the milled part of the adjustable regulating nozzle.

Releasing the pressure:

When spraying is completed or before unscrewing the pump in order to re-fill or empty the tank the

pressure must be fully released by lifting the pressure relief valve (1). When doing this, hold the

appliance at an angle, away from the body.

Care and maintenance

After use the appliance must be emptied; never store the spray-liquid in the sprayer.

Unscrew the pump and empty the tank.

The appliance must be washed out using a suitable agent and then rinsed with clean water; do not

use hot water (max. 30°C / 86°F).

Store the equipment away from the effects of frost. For storage the spray-tube may be hooked onto

the pump handle.

Particular attention must be given to parts which are subject to wear, such as the nozzle and

gaskets. The nozzle (15) must be cleaned periodically. These parts are easily replaceable.

Periodically apply a little oil to the piston-rod, the thread of the pump-tube and the O-ring (5) (see ->

oil). Screw in the pump only loosely when the appliance is not in use.

Do not clean the nozzle with hard objects, nor blow through it using the mouth. The most suitable

cleaning device is a nail-brush or tooth-brush.

To dry the sprayer, place it upside down, without the pump (4), and leave it standing open to the air.

Spare parts and repairs

If any part shows signs of damage or wear, replace it immediately. Use only BIRCHMEIER original

parts (see spare parts list).