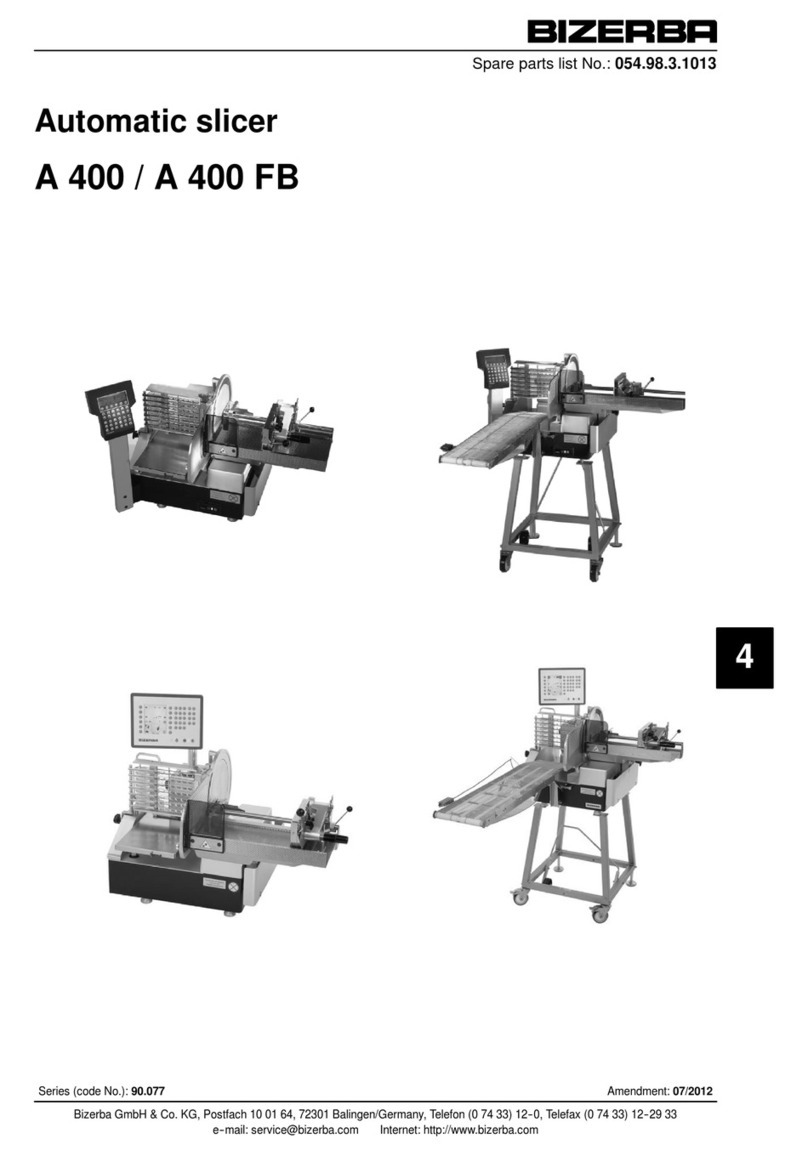

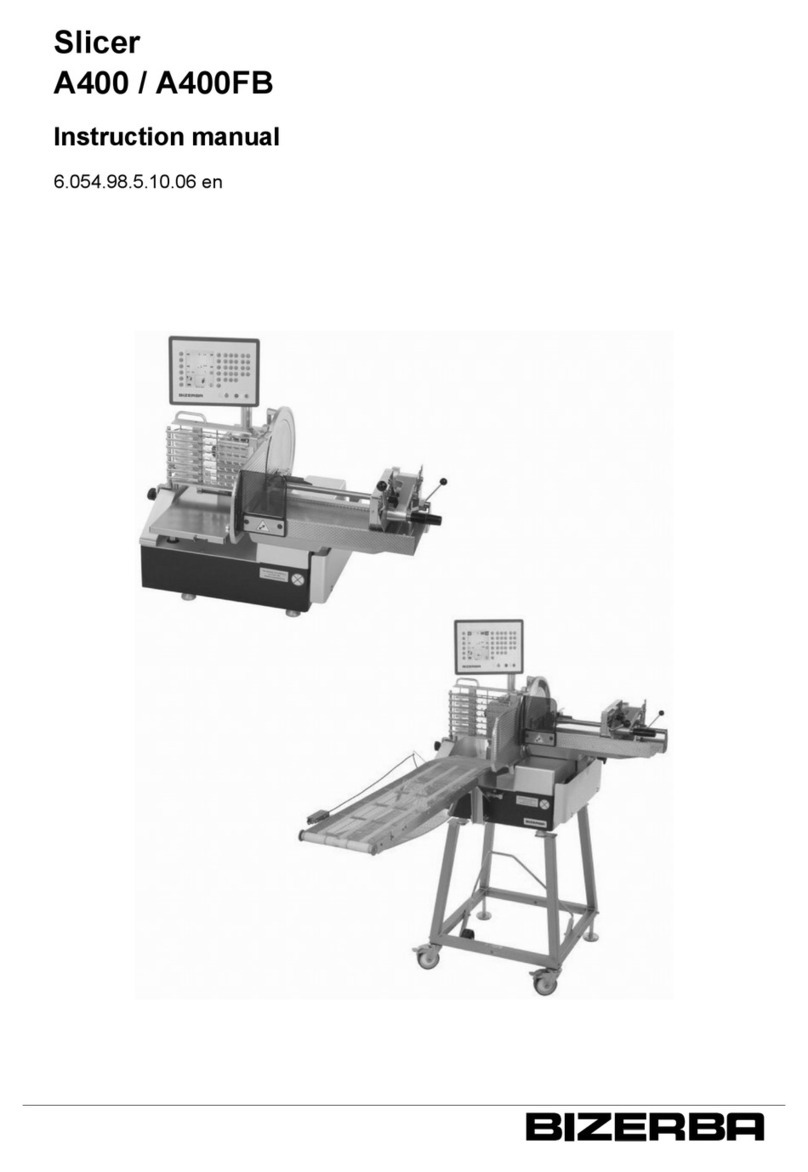

Bizerba A400 User manual

A400FB

A400

Slicers A400 / A400FB

Operating Manual

6.054.98.5.10.04

6.054.98.5.10.04Translation of original operating instructions

Alle Rechte vorbehalten

All rights reserved

Tous droits réservés

Reservados todos los derechos

Tutti i diritti riservati

E12 / 2007

Bizerba GmbH & Co. KG,

72336 Balingen

Postfach 10 01 64

72301 Balingen/Germany,

Tel. (+49 7433) 12--0, Fax (+49 7433) 12--2696

e--mail: [email protected]

Internet: http://www.bizerba.com

Operating Manual A400 / A400FB Contents

6.054.98.5.10.04 0--1

Contents Page

1 General 1 -- 1.................................................

1.1 Warranty information 1 -- 1......................................

1.2 Safety information 1 -- 2.........................................

1.3 Overview/Identification of components 1 -- 3.......................

1.4 Technical data 1 -- 5............................................

1.5 Device description, A400/A400FB slicer 1 -- 7......................

1.6 Sliced product, application area, ambient influences 1 -- 9...........

2 Device installation 2 -- 1......................................

2.1 Assembling the work table 2 -- 1..................................

2.2 Assembly on mobile bench 2 -- 1.................................

2.3 Electric connections 2 -- 2.......................................

2.4 Carry out a trial operation 2 -- 2..................................

2.5 Shaving option 2 -- 3............................................

3 Device and operating controls 3 -- 1...........................

3.1 Main switch 3 -- 1..............................................

3.2 Keyboard 3 -- 2................................................

3.3 Display icons 3 -- 5.............................................

3.4 Displays, stations 3 -- 7.........................................

3.5 Paper holder 3 -- 15.............................................

3.6 Sliced products support 3 -- 15....................................

4 Device operation/slicing 4 -- 1.................................

4.1 Insert long sliced product 4 -- 1...................................

4.1.1 Carriage 200/400 mm 4 -- 1.....................................

4.1.2 Carriage 600 mm 4 -- 2.........................................

4.2 Insert short sliced product 4 -- 2..................................

4.3 Slicing 4 -- 3...................................................

Operating Manual A400 / A400FB

Contents

6.054.98.5.10.04

0--2

Page

5 Cleaning 5 -- 1................................................

5.1 Cleaning preparation 5 -- 1......................................

5.2 Cleaning 5 -- 7.................................................

5.3 Slicer cleaning plan 5 -- 8........................................

5.4 Preparing the machine for operation 5 -- 10.........................

6 Sharpening the knife 6 -- 1....................................

6.1 Sharpening device 6 -- 1........................................

6.2 Preparing the sharpening process 6 -- 1...........................

6.3 Sharpening 6 -- 3...............................................

6.4 Honing process 6 -- 3...........................................

6.5 Remove sharpening device. 6 -- 4................................

6.6 Remove grinding dust 6 -- 4.....................................

7 Servicing/ Maintenance 7 -- 1..................................

8Faults 7--1..................................................

9 Special accessories 7 -- 2.....................................

10 Operating conditions 8 -- 1....................................

10.1 EC Directives/Norms and Recommendations 8 -- 1.................

10.2 Mains power supply 8 -- 1.......................................

10.3 Air convection 8 -- 2............................................

10.4 Limiting values for protection category, temperature and humidity 8 -- 2

Annex 9 -- 1..................................................

Set programs

Declaration of conformity A400

Declaration of conformity A400FB

Operating Manual A400 / A400FB General

1--1

6.054.98.5.10.04

1 General

1.1 Warranty information

_______________________________________________________________________

CAUTION This information is a prerequisite that must be fulfilled before

commissioning and during operation of our equipment in order

to guarantee reliable and fault--free operation.

_______________________________________________________________________

If you should have any questions in connection with the practical application of these

conditions, please contact us or the responsible Customer Service Agent.

-- Units should be stored and transported only in the original packaging until they are

installed.

-- Do not install or put into operation before the conditions are satisfied.

-- The installation surface must be horizontal, level, stable, anti--tilt and anti--slip.

Good accessibility and technical operating aspects must be taken into account.

-- The initial installation and commissioning as well as instruction in the operation, cleaning,

care and maintenance will be carried out by the responsible BIZERBA Customer Service

Agent or the BIZERBA specialist adviser.

-- The hardware and software required for a data dialogue between BIZERBA equipment

and equipment provided by others must be clarified with us in writing.

-- The supervisory and operating personnel must familiarize themselves thoroughly with the

instructions in this operator manual.

-- Only trained personnel may work with this machine. Extra training must be repeated if

necessary.

-- We cannot accept any liability in the event of unauthorized installation and unauthorized

electrical installation, incorrect operation, improper use, structural modifications, removal

of protective equipment, failure to use genuine BIZERBA spare parts and accessories or

the use of third party operating material.

-- In such cases, the user is acting at his own risk and must take responsibility himself for any

damage incurred.

-- For this reason, use only genuine BIZERBA spare parts and accessories.

-- We cannot accept any warranty or liability claims for natural wear and tear.

The diagrammatic representation of the machine may differ from that supplied due to

country--specific regulations and as a result of technical progress.

This does not affect the content of the operating instructions.

Operating Manual A400 / A400FB

General

1--2 6.054.98.5.10.04

1.2 Safety information

_______________________________________________________________________

CAUTION It is possible that severe injury could occur to fingers

and/or hands if this machine is not used and operated in

accordance with the instructions.

_______________________________________________________________________

Therefore, please be sure to observe the following safety information.

-- For the space requirements, the technical data must be taken into account.

(Chapter 1.4)

-- Attention must be paid to the moving parts when operating, in particular

knives and carriage.

-- Take care that unauthorized, untrained persons, and in particular children, are

unable to start the machine or to come within the working area of the machine.

-- There is an acute risk of injury for the operating personnel if protective safety

devices are removed, modified or circumvented.

-- Work with concentration and do not allow yourself to be distracted.

-- Slice permissible product only in accordance with this operating manual.

-- Do not slice frozen goods or foreign materials.

Do not try any experiments.

-- If the mains cable should become damaged, have a new cable fitted immediately

by a skilled electrician or by the responsible BIZERBA Customer Service Agent.

-- Keep the workplace clean and dry so that you have a non--slip area to stand on.

-- Do not place any foreign parts on the machine. Do not use as storage space.

-- Be sure to remove the mains plug when cleaning the machine.

-- Switch off the machine immediately if untypical noises are heard or if a risk of

injury is suspected.

-- Call the responsible Customer Service Agent if you are unable to rectify

the fault yourself.

Operating Manual A400 / A400FB General

1--3

6.054.98.5.10.04

1.3 Overview/Identification of components

A400

1

2

3

4

10

17

16

15

14

13

12

11

5

6

7

8

9

19

18

1 Blade guard ring 11 Rating plate

2 Blade 12 Receiving table

3 Blade cover 13 Rear wall

4 Sliced products support 14 Gauge plate

5 Sliced product holder cpl. with 15 Depositing arm

leftover slicer facility 16 Feed roller with guide cog

6 Feed carriage 17 Chain frame

7 Carriage 18 Main switch

8 Carriage guide 19 Operation and display plate

9 Protective cover

10 Drive housing

Accessory bag without fig.

Content: Sharpening device, paper felt, cleaning cloth, hand brush, scrubber with brush, oil

Operating Manual A400 / A400FB

General

1--4 6.054.98.5.10.04

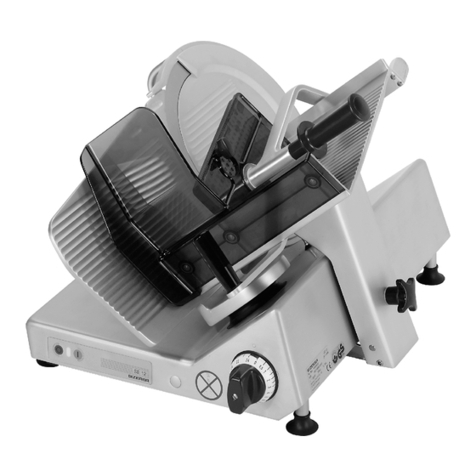

A400FB

1 2 3 4

10

17

16

15

14

13

12

11

5

6

7

8

9

19

18

21

20

1 Blade guard ring 11 Bench, mobile

2 Blade 12 Lock on belt support

3 Blade cover 13 Conveyor belt

4 Sliced products support 14 Light barrier

5 Sliced product holder cpl with 15 Gauge plate

leftover slicer facility 16 Rear wall

6 Carriage 17 Depositing arm

7 Carriage guide 18 Feed roller with guide cog

8 Protective cover 19 Chain frame

9 Drive housing 20 Main switch

10 Rating plate 21 Operation and display plate

Accessory bag without fig.

Content: Sharpening device, paper felt, cleaning cloth, hand brush, scrubber with brush, oil

Operating Manual A400 / A400FB General

1--5

6.054.98.5.10.04

1.4 Technical data

The most important technical data:

A402 A404 A406

Outside measurements = 850 x 800 mm = 1050 x 800 mm = 1255 x 800 mm

Work surface = 1010 x 850 mm = 1210 x 850 mm = 1280 x 850 mm

Installation area = 410 x 490 mm = 410 x 490 mm = 410 x 490 mm

Height = 670 mm / 835 mm

Receiving table = 254 x 346 mm

Table movement path = 160 mm

-- Paper size 1/8 sheet = 250 x 360 mm

Size of product to be sliced: -- round min/max = 50 / 180 mm

-- rectangular min/max = 50 x 50 / 175 x 240 mm

or = 30 x 240 mm

Slicing thickness, infinitely adjustable = 0.5 -- 12 mm

Number of carriage strokes = 30 -- 55 / min.

Diameter of blade = 330 mm

Blade speed = 266 rpm

Weight = approx.109 kg

Supply types, voltages and power consumption = see rating plate

Operating Manual A400 / A400FB

General

1--6 6.054.98.5.10.04

The most important technical data:

A402FB A404FB A406FB

Outside measurements = 850 x 1710 mm = 1050 x 1710 mm = 1255 x 1710 mm

Height = 1370 mm / 1535 mm

Conveyor belt, applicable length = 1000 mm

applicable width = 250 mm

Size of product to be sliced: -- round min/max = 50 / 180 mm

-- rectangular min/max = 50 x 50 / 175 x 240 mm

or = 30 x 240 mm

Slicing thickness, infinitely adjustable = 0.5 -- 12 mm

Number of carriage strokes = 30 -- 55 / min.

Diameter of blade = 330 mm

Blade speed = 266 rpm

Weight Machine = approx.116 kg

Weight Bench = approx. 16 kg

Supply types, voltages and power consumption = see rating plate

Operating Manual A400 / A400FB General

1--7

6.054.98.5.10.04

1.5 Device description, A400/A400FB slicer

Type designations or versions:

A402 = Receiving table design with 200 mm carriage

A404 = Receiving table design with 400 mm carriage

A406 = Receiving table design with 600 mm carriage

A402FB = Conveyor belt design with 200 mm carriage

A404FB = Conveyor belt design with 400 mm carriage

A406FB = Conveyor belt design with 600 mm carriage

All versions are available with a mobile bench.

The A400 / A400FB is a slicer that automatically feeds, slices and deposits according to the

respective program that is set.

This slicer is equipped with a power--driven carriage with automatic sliced product feed and

depositing system.

The machine and engine housing, gauge plate and blade guard are made of anodized cast

aluminum, the carriage guide is made of coated cast aluminum and the drive housing of

lacquered cast aluminum. The carriage plate is made of stainless steel plate.

The back panel is composed of transparent plastic.

All materials used in the food zone and in the working area comply with the food hygiene

conditions.

The carriage guide is protected across the whole stroke area by a protective cover.

The sliced good holder and leftover slicer facility is equipped with a movable gripper hook.

The leftover sliver facility for 200 mm and 400 mm carriage has its own clamping facility, which

can be swiveled up and stopped in place for the sliced product to be placed inside. (This is

not possible for 600 mm carriage)

The delivery facility constitutes a chain frame with transport chain, feed roller with guide cog

and the depositing arm and the receiving table incl. paper holder.

Separate drive systems for blades, carriage, sliced product feed, slicing thickness setting,

delivery device and receiving table.

The blade drive is operated with supply voltage; the other drives are operated with low voltage.

All bearings including the gears and open sliding surfaces are covered with a lubricant

permitted in the foodstuff sector.

The main switch is on the operating and display panel.

It is itemized as a foil switch where the keys are green = on/red = off and a signal lamp to

indicate switched on status. The red key reacts to touch and has an emergency--off function.

The <Start/Stop slicing> key is on the keyboard of the operating and display panel.

The contact control with latch circuit prevents automatic restarting after a power cut.

All machine functions and delivery programs are entered at the operating and display panel

via the foil keyboard.

Input can be made at different stations (workstations, measuring stations, PLU station...).

These stations are accessed by operator guidance keys and function keys.

Operating Manual A400 / A400FB

General

1--8 6.054.98.5.10.04

The following are termed as protective and safety facilities:

-- Blade guard ring, fixed, not removable

-- Blade cover, fixed, removable

-- Gauge plate, to cover stroke

-- Rear wall, not removable

-- Protective cover for carriage guide, to cover stroke

-- Autom. switch off when drive system is overloaded

-- Autom. switch off the blade and carriage drive when in the insert position

-- Cleaning program, locked machine setting

-- Sharpening program, locked machine setting

Operating Manual A400 / A400FB General

1--9

6.054.98.5.10.04

1.6 Sliced product, application area, ambient influences

The following are approved sliced products that comply with the permissible

dimensions:

-- Sausage of all kinds

-- Ham/Bacon

-- Smoked meats with/without rind

-- Roast meats/Roast beef

-- Meat/Roulades

-- Hard cheese

-- Bread

The following may not be sliced due to risk of injury and damage:

-- NON--FOOD products

-- Sliced products with bones

-- Frozen sliced products

Note: If cheese is sliced usually, we recommend using a special blade.

See special accessories.

Application area: The slicing machine is intended for installation in the sales area.

Installation is permitted in the preparation room.

Serviceable life: Designed for permanent use (2 shift operations at 16/day)

Noise level: A400: 69 dB(A)

A400FB: 71 dB(A)

Moisture: Class of protection IP 33. High air humidity and the formation

of condensation water can result in damage to the machine.

Temperature: Permissible ambient temperatures from --10_Cto+40_C.

Accident protection:

The regulations of the European standard EN 1974 were

taken into account in the complete design.

Operating Manual A400 / A400FB Device installation

2--1

6.054.98.5.10.04

2 Device installation

The machine has to be transported and stored in accordance with the symbols on the

packaging.

Follow the instructions on how to unpack 6.054.49.106.00.

2.1 Assembling the work table

Assembly, start--up and instruction is carried out for the first time by the responsible BIZERBA

customer services office or the BIZERBA trade consultant.

Please take not of operating criteria.

Pay attention to the mounting surface and the space requirements (Chapter 1.4)

Requirements for mounting surface:

-- horizontal and flat

-- anti--tilt and anti--slip

-- stable and rigid (weight approx. 109 kg / 116 kg)

_______________________________________________________________________

Important note!

For the stability of the machine when using a desk--top

mounting, it is of absolute necessity that the installation surface

is secured according to the attached drawing.

Drawings and individual parts are found in the machine accessory

bag.

_______________________________________________________________________

2.2 Assembly on mobile bench

Assembly, start--up and instruction is carried out for the first time by the responsible

BIZERBA customer services office or the BIZERBA trade consultant.

Please take not of operating criteria.

Installation surface and required space (chapter 1.4)

Requirements for mounting surface:

-- horizontal and flat

-- anti--slip and secure

_______________________________________________________________________

Important note!

To ensure the stability of the machine with a mobile bench, it is

of absolute necessity that it is secured on the installation

surface in accordance with the attached drawing.

Drawings and individual parts are found in the bench--packaging

accessories bag.

_______________________________________________________________________

Operating Manual A400 / A400FB

Device installation

2--2 6.054.98.5.10.04

2.3 Electric connections

compare existing mains voltage with the

information on the rating plate

if this does not correspond, under no

circumstances connect the slicer to the

socket but inform BIZERBA Customer

Service!

-- The socket must comply with the national country

regulations (e.g. VDE)

-- when installing in the preparation area (wet area),

the mains connection must be designed accordingly.

The slicer itself is not protected against spray water!

2.4 Carry out a trial operation

for example, check the direction of the rotation of the

rotary current

Switch on the machine (main switch chapter

3.1)

The signal lamp lights up

Start the machine <Start/stop slicing>

Blade has to turn in the direction of the arrow

_______________________________________________________________________

CAUTION Carriage starts to move

_______________________________________________________________________

Stop the machine <Start/stop slicing>

If the rotary direction is incorrect, pole reversal of phase turner at the rotary current

socket of the machine.

Operating Manual A400 / A400FB Device installation

2--3

6.054.98.5.10.04

2.5 Shaving option

In order to mount the shaving attachment to the chain frame

first of all the depositing arm has to be disassembled.

(see p. 5--2)

The shaving attachment is secured to the

chain frame by means of a triangular screw at

the distance indicated in the picture.

Activate the shaving function in the operator

menu. (see p. 3--8)

Operating Manual A400 / A400FB Device and operating controls

6.054.98.5.10.04 3--1

3 Device and operating controls

3.1 Main switch

By pressing the green switch on the operating and display panel, the machine is switched

on.

The signal lamp lights up, the display is activated, the carriage, receiving table and depositing

arm move into their basic setting.

By pressing the red key, the machine is switched off (e.g. when work is finished).

Only use during operations in the event of an EMERGENCY--OFF.

The running of the machine is stopped at whatever position it is at.

Operating and display panel

”Display”

Main switch

off/on

Operating Manual A400 / A400FB

Device and operating controls

3--2 6.054.98.5.10.04

3.2 Keyboard

Key Function

<Start/Stop slicing>

ON: The machine starts to move, the set program is worked through,

the LED is lit.

OFF: The machine remains in its basic setting, the set program is

interrupted.

<Cleaning> key

The slicing thickness is automatically set to < --1 mm.

The cleaning station appears in the display.

The carriage can only be tilted out in this setting.

<Sharpening> key

The slicing thickness is automatically set to > +15 mm.

The sharpening station appears in the display.

The sharpener can only be mounted in this setting.

<Sliced product left> or at top

The sliced product is deposited to the left or top of the table.

On correct entry of the sliced product dimensions.

<Sliced product central >

The sliced product is deposited to a central position on the table.

On correct entry of the sliced product dimensions.

<Sliced product right> or bottom

The sliced product is deposited to the right or bottom of the table.

Operating Manual A400 / A400FB Device and operating controls

6.054.98.5.10.04 3--3

Depositing program <Stack> (PLU1)

The sliced product is deposited in a stack.

Desk--top machine max. 90 mm, conveyor belt machine max. 60 mm.

Depositing program <Shingle> (PLU3)

The sliced product is deposited in a shingle.

<Clear conveyor belt> (only activated for conveyor belt machines)

Function keys <F1> bis <F12>

The activation keys for neighboring display fields.

The keys are assigned differently on the various stations.

10--key keyboard

Number keys <0> to <9>

Input is always related to the marked input range.

<C>--key (Clear)

Correction key for all numeric input

<Enter> key

Confirmation key after each numeric input.

<Comma>--key

Only for input of slicing thicknesses that include a comma.

Operating Manual A400 / A400FB

Device and operating controls

3--4 6.054.98.5.10.04

Program --Keys

<Open>--key

Request PLU from memory.

The PLU station appears in the display.

<Save>--key

Save new PLU to memory or overwrite or delete existing PLU.

The PLU station appears in the display.

Other manuals for A400

2

This manual suits for next models

1

Table of contents

Other Bizerba Kitchen Appliance manuals

Bizerba

Bizerba VS 12W User manual

Bizerba

Bizerba VS12D User manual

Bizerba

Bizerba FW N22 User manual

Bizerba

Bizerba GSP H User manual

Bizerba

Bizerba SE 12/18L User manual

Bizerba

Bizerba VS 12 F--P User manual

Bizerba

Bizerba GSP H User manual

Bizerba

Bizerba VS 12 D-V User manual

Bizerba

Bizerba A400 User manual

Bizerba

Bizerba BRS 38 User manual