Bizerba VS 12 User manual

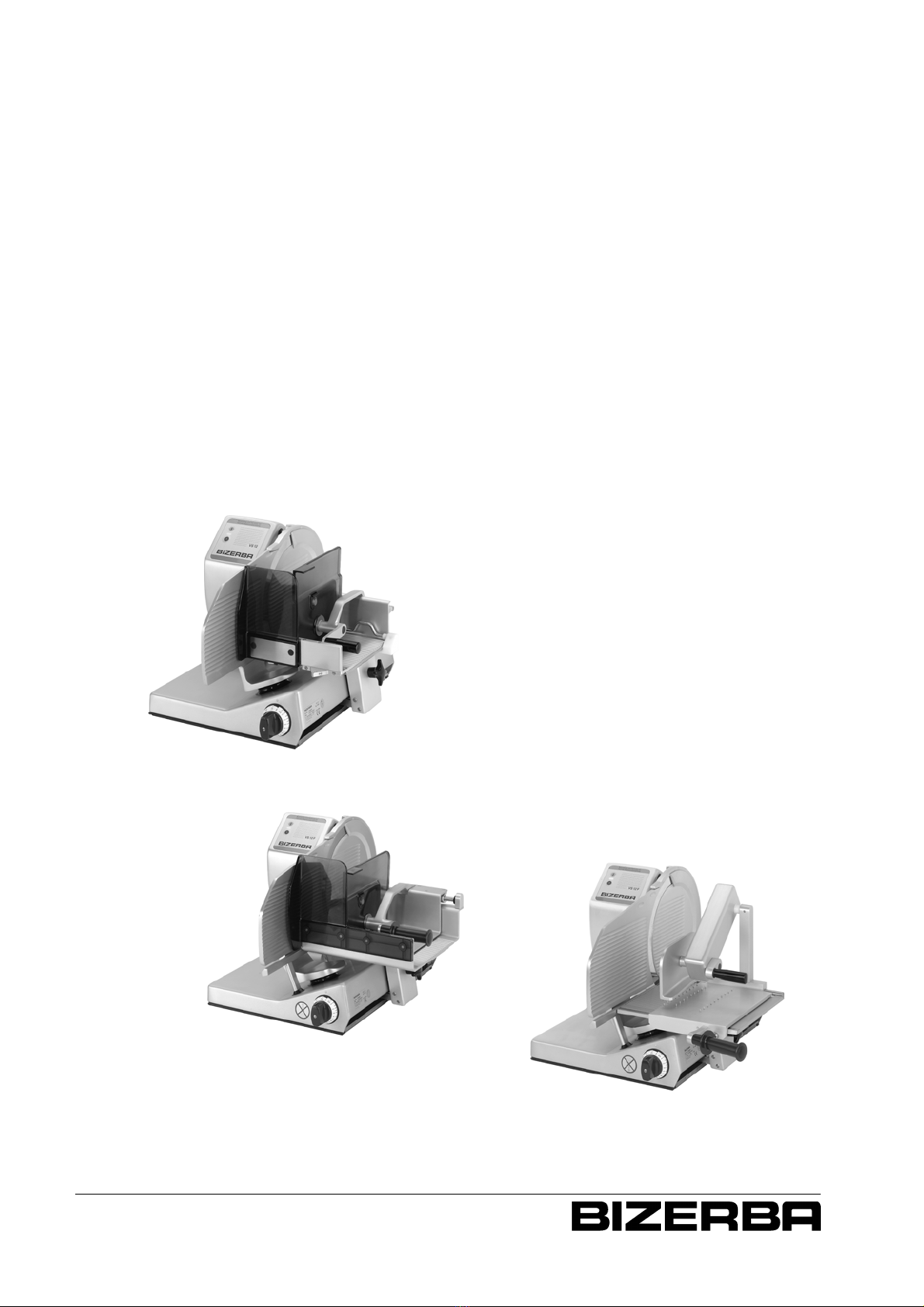

VS 12

VS 12 F--P

VS 12 F

Slicer

VS 12

Operating Instructions

6.080.98.5.10.03

6.080.98.5.10.03Translation of original operating instructions

Alle Rechte vorbehalten

All rights reserved

Tous droits réservés

Reservados todos los derechos

Tutti i diritti riservati

E05 / 2010

Bizerba GmbH & Co. KG,

72336 Balingen

Postfach 10 01 64

72301 Balingen/Germany,

Tel. (+49 7433) 12--0, Fax (+49 7433) 12--2696

e--mail: [email protected]

Internet: http://www.bizerba.com

Date: 27.05.2010

Manufacturer’s signature: ppa. ......................................................................

Signatory’s position: Martin Arndt

Chief Executive Officer Technology (CEO--T)

Bizerba GmbH & Co. KG

Hauptverwaltung Balingen

Postfach 10 01 64, 72301 Balingen

Wilhelm--Kraut--Straße 65

72336 Balingen, Germany

6.080.98.5.10.03

Declaration of conformity

We hereby declare that the design of the machine described below

Description: Slicer

Type: VS12, VS12--S, VS12--T, VS12--S/T,

VS12C, VS12C W, VS12C F,

VS12F, VS12F33, VS12F33--W,

VS12F37, VS12F--W, VS12F--W/T,

VS12F--P, VS12F--P/N, VS12F--P/W,

VS12F--P/N/W, VS12F37--P/N,

VS12F37--P/N/W,

VS12--W, VS12--W/T, VS12--W/S

the applicable requirements in the following EC guidelines:

EC machine guideline 2006/42/EC

EC EMC Guideline 2004/108/EC

Authorized person for combination of technical key documents:

Berthold Roller, Director Quality Management, Bizerba GmbH & Co. KG

The basis for the Declaration of Conformity is the contract documents

(Bizerba order documents). This declaration will lose its validity in the event of

modifications to the above--described device type which have not been agreed with

Bizerba or performed by Bizerba.

6.080.98.5.10.03

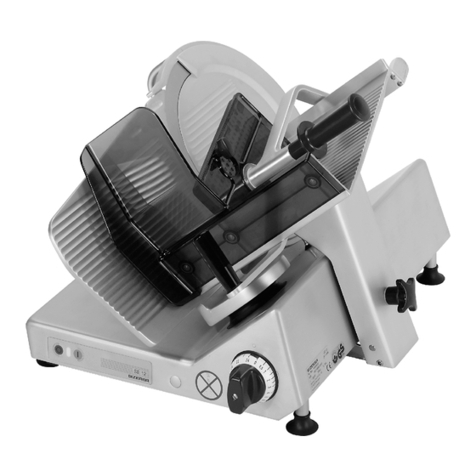

VS 12

VS 12 F/VS 12 F--P/VS 12 W/VS 12 C

OPERATING INSTRUCTIONS

1

1

2

3

4

List of Contents

6.080.98.5.10.03

PAGE

GENERAL 4...............................

1.1 Warranty 4.......................................

1.2 Warning notice 5..................................

1.3 Overview/component description 6..................

1.3.1 VS 12 6..........................................

1.3.2 VS 12 F 7........................................

1.3.3 VS 12 F--P 8......................................

1.3.4 VS 12 W 9.......................................

1.4 Dimensional drawing/technical data 10................

1.4.1 VS 12 10..........................................

1.4.2 VS 12 F 11........................................

1.4.3 VS 12 F--P 12......................................

1.4.4 VS 12 W 13.......................................

1.5 Machine description 14.............................

1.6 Products to be cut/application/environmental influences 15..

INSTALLATION 16..........................

2.1 Transport and storage 16...........................

2.2 Installation 16......................................

PAGE

2.3 Electrical connection 17.............................

OPERATING ELEMENTS 18..................

3.1 Keyboard 18.......................................

3.2 Slice thickness setting 19...........................

3.3 Product holder 19..................................

3.3.1 VS 12/VS 12 F/VS 12 W 19..........................

3.3.2 VS 12 F--P 20......................................

3.4 Product fixation device 20...........................

3.5 Bias cut slicing device 21............................

3.6 Feeding carriage 21................................

3.7 Scale 22..........................................

3.8 Weighing operation 23..............................

3.9 Error messages 26.................................

OPERATION/SLICING 28....................

4.1 Long products 28..................................

4.1.1 VS 12/VS 12 W 28.................................

2

5

6

7

8

6.080.98.5.10.03

List of Contents

PAGE

4.1.2 VS 12 F 30........................................

4.1.3 VS 12 F--P 32......................................

4.2 Short products (product ends) 34.....................

4.2.1 VS 12/VS 12 W 34.................................

4.2.2 VS 12 F 36........................................

4.2.3 VS 12 F--P 38......................................

4.3 VS 12/VS 12 W Option: bias cut slicing device 40......

4.3.1 Bias cut with long products 40.......................

4.3.2 Bias cut with short products 42.......................

CLEANING 44..............................

5.1 Preparing for cleaning 44............................

5.2 Cleaning 48.......................................

5.3 Cleaning plan VS 12 50.............................

5.4 Making the machine ready to operate 52..............

BLADE SHARPENING 56....................

6.1 Sharpener 56......................................

6.2 Preparing for sharpening 56.........................

6.3 Attaching of sharpener 57...........................

PAGE

6.4 Sharpening 58.....................................

6.5 Honing 58.........................................

6.6 Removing of sharpener 59..........................

6.7 Removing of sharpening dust 60.....................

ACCESSORIES 62..........................

7.1 Sanitizing/Maintenance/Servicing 62..................

7.2 Disturbances 63...................................

7.3 Optional equipment 63..............................

OPERATING CONDITIONS 64................

8.1 EC directives 64...................................

8.2 Power supply 64...................................

8.3 Air convection 65...................................

8.4 Limiting values for protection type, temperature and air

humidity 65........................................

3

1.1 Warranty GENERAL

6.080.98.5.10.03

Contact us or your local after--sales service, if

any information is not properly understood.

SEquipment should only be transported and

stored in its original packing.

SEquipment should not be started up before

the requirements of the Bizerba operating

conditions are met.

SThe supporting area must be horizontal,

level, stable and non--slippery. Equipment

must be arranged in such a way as to

facilitate operation, working procedures

and service.

SInstallation, commissioning, initial

introduction, cleaning, maintenance and

servicing should only be carried out by the

relevant BIZERBA after--sales service or

by companies or personnel authorized by

BIZERBA.

SThe use of hardware and software which

may be necessary for a data dialog

between BIZERBA and non--BIZERBA

equipment is subject to written approval

from BIZERBA.

SEquipment should not be set into operation

before supervisory and operating

personnel have thoroughly read and

understood these operating instructions.

SThis machine is a technical work resource

which is only suitable for application at

work.

SOnly trained personnel over 14 years

should operate the equipment. Training

should be repeated.

SBIZERBA does not accept liability for

damage arising as a result of installation by

anyone other than

BIZERBA--incorporated or designated

representatives, faulty electrical

connection by the user, improper

operation, inappropriate use, modification

of equipment in any way from its original

form, removal of guards, the use of spare

parts and accessories other than genuine

BIZERBA parts or accessories.

SThe user will be responsible for any

damage or injury arising as a result of

failure to observe the BIZERBA

instructions.

STherefore, it is strongly recommended to

use only genuine BIZERBA spare parts

and accessories.

SNormal wear and tear is not covered by the

guarantee.

To provide operational

assurance and to protect

personnel from possible

injuries, the requirements of

these instructions must be met

before the machine is set into

operation and during operation.

These instructions are subject to revision as

further product development, experience and

investigation may show is necessary or

desirable. Graphics appearing in these

instructions may differ slightly from the model

supplied due to country--specific regulations.

This does not affect the contents of these

operating instructions.

4

1.2 Warning notice

6.080.98.5.10.03

GENERAL INSTALLATION OPERATING

ELEMENTS

OPERATION/

SLICING CLEANING BLADE

SHARPENING ACCESSORIES OPERATING

CONDITIONS

The following warning notice

serves for your own safety.

Failure to comply with it could

result in serious bodily injury.

SFor the space required, see the technical

data as per section 1.4.

SWhen operating the machine, pay special

attention to all movable parts, especially to

the blade and carriage.

SPrevent untrained personnel and

especially children from operating the

machine. Keep them away from the

operating area of the machine.

SPeople with pacemakers should consult a

doctor before operating the machine

(magnetic field).

SDo not tamper with any protective devices

of machine. Do not remove, change or

bypass them. It may result in serious bodily

injury.

SOperate concentrated.

SDo not use machine for products other

than stated in the operating instructions.

SDo not cut frozen products.

SHave damaged power cable immediately

replaced by a qualified and certified

electrician or the relevant BIZERBA

after--sales service.

SKeep working place clean and dry. Provide

non--slippery supporting area.

SKeep machine free of foreign objects.

SBefore cleaning the machine, always

disconnect power cable from the mains.

SImmediately switch machine off if there is

any rough operation or obstruction.

SContact the relevant BIZERBA after--sales

service if you cannot eliminate occurring

malfunctions yourself. 5

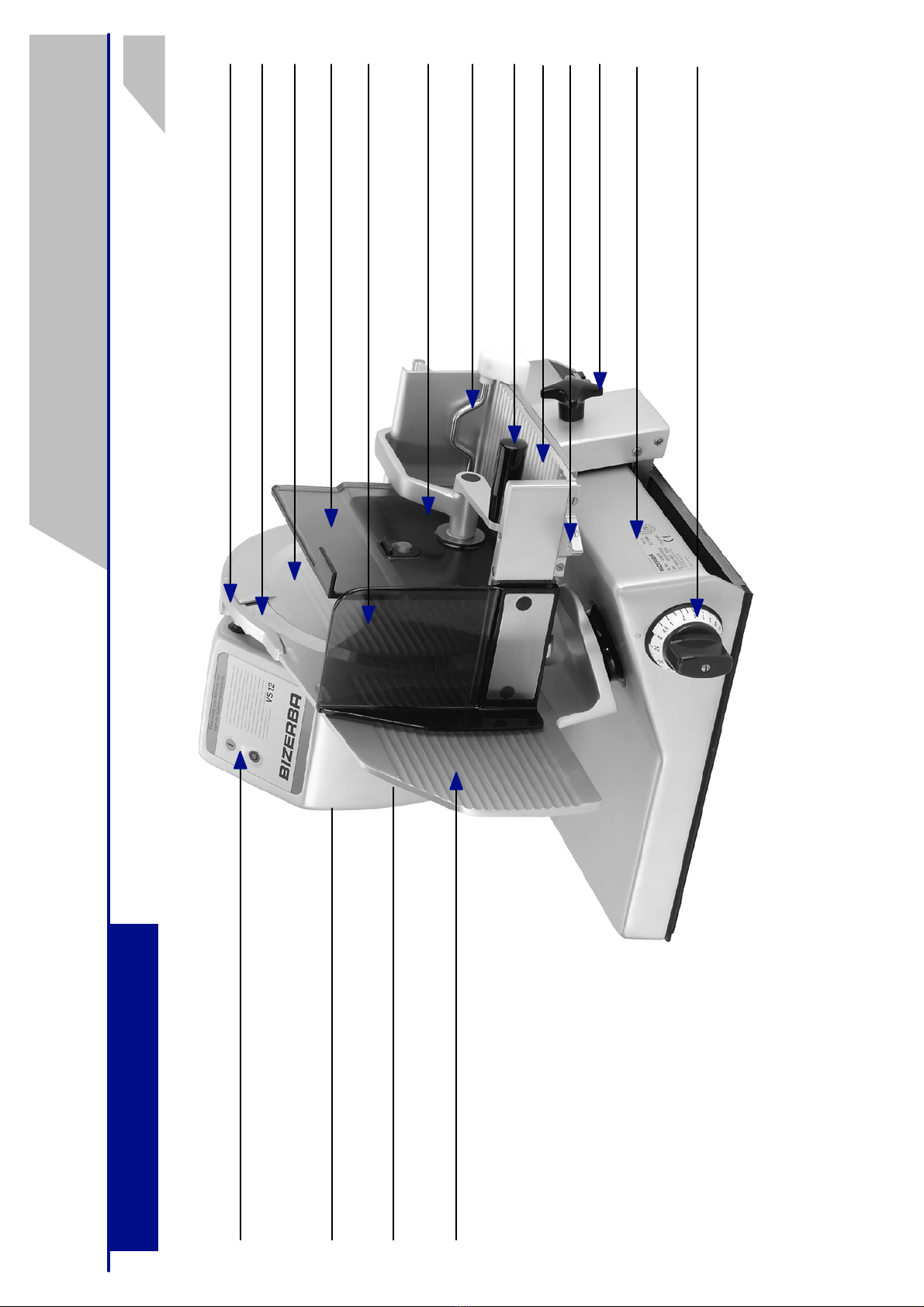

1.3 Overview/component description

1.3.1 VS 12

GENERAL

6.080.98.5.10.03

Blade cover

Accessory kit (not illustrated), containing:

sharpener, special cardboard, cloth, handbrush

with special flat brush, BIZERBA oiler

Deflector

Gauge plate

Keyboard ON/OFF

with pilot lamp

Remnant holder plate

Knob for carriage

Handle for product holder

Carriage

Specification plate: CE symbol

GS plate

Slice thickness control knob

Rear wall

Product fixation device

Blade guard ring

Blade

Guard plate

Three--square knob for blade cover

Bias cut plate

6

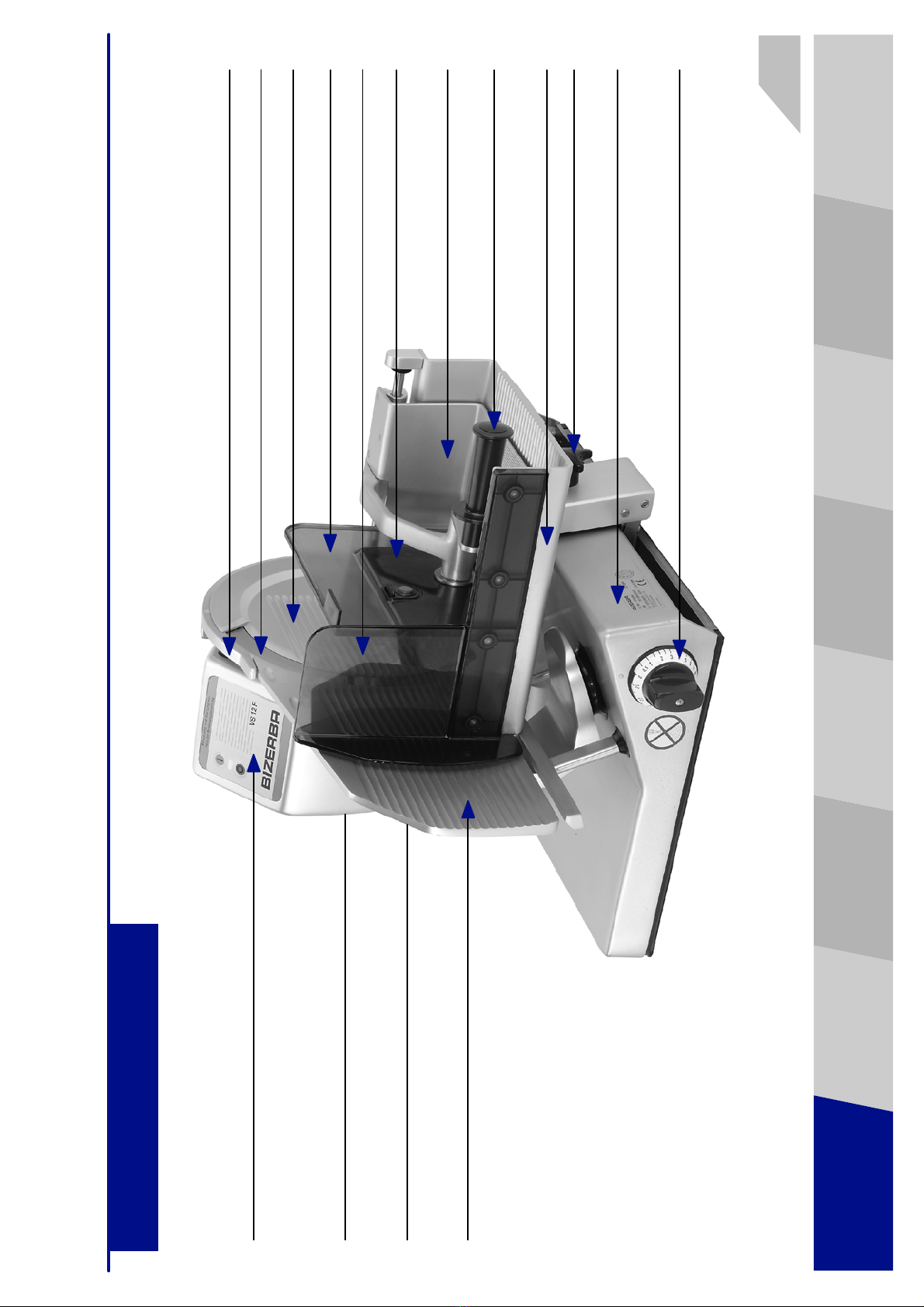

1.3.2 VS 12 F

6.080.98.5.10.03

GENERAL INSTALLATION OPERATING

ELEMENTS

OPERATION/

SLICING CLEANING BLADE

SHARPENING ACCESSORIES OPERATING

CONDITIONS

Guard plate

Accessory kit (not illustrated), containing:

sharpener, special cardboard, cloth, handbrush

with special flat brush, BIZERBA oiler

Three--square knob for blade cover

Deflector

Gauge plate

Keyboard ON/OFF

with pilot lamp

Rear wall

Knob for carriage

Handle for product holder

Carriage

Specification plate: CE symbol

GS plate

Slice thickness control knob

Feeding carriage

Remnant holder plate

Blade guard ring

Blade

Blade cover

7

1.3.3 VS 12 F--P

GENERAL

6.080.98.5.10.03

Accessory kit (not illustrated), containing:

sharpener, special cardboard, cloth, handbrush

with special flat brush, BIZERBA oiler

Three--square knob for blade cover

Deflector

Gauge plate

Keyboard ON/OFF

with pilot lamp Blade cover

Product holder

Knob for carriage

Handle for product holder

Carriage

Specification plate: CE symbol

GS plate

Slice thickness control knob

Feeding carriage

Handle for feeding carriage/carriage

Blade guard ring

Blade

8

1.3.4 VS 12 W

6.080.98.5.10.03

GENERAL INSTALLATION OPERATING

ELEMENTS

OPERATION/

SLICING CLEANING BLADE

SHARPENING ACCESSORIES OPERATING

CONDITIONS

Blade cover

Accessory kit (not illustrated), containing:

sharpener, special cardboard, cloth, handbrush

with special flat brush, BIZERBA oiler

Deflector

Gauge plate

Keyboard ON/OFF

with pilot lamp

Remnant holder plate

Knob for Carriage

Handle for product holder

Carriage

Specification plate: CE symbol

GS plate

Slice thickness control knob

Rear wall

Product fixation device

Blade guard ring

Blade

Guard plate

Three--square knob for blade cover

Load plate

9

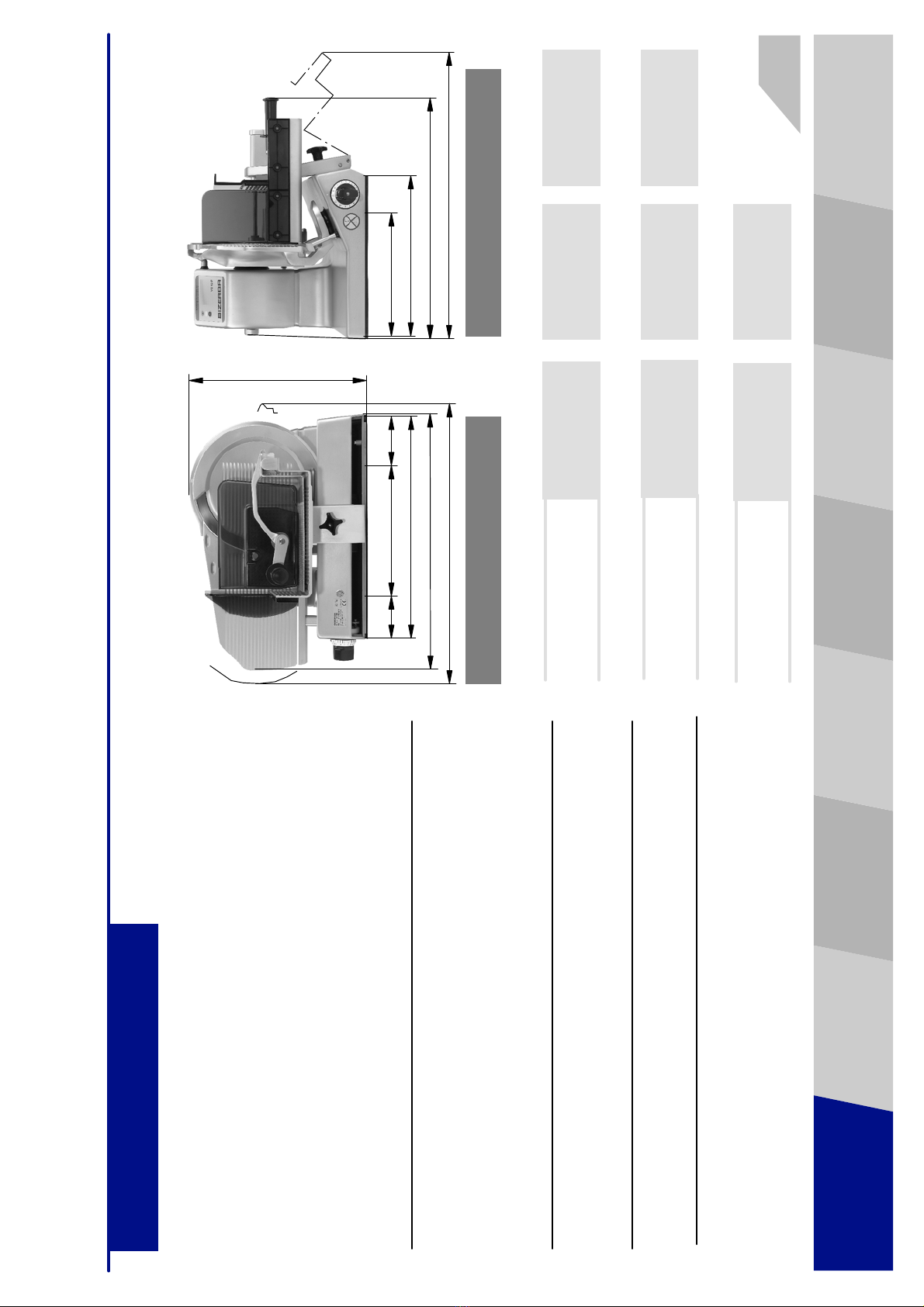

1.4 Dimensional drawing/technical data

1.4.1 VS 12

GENERAL

6.080.98.5.10.03

Dead weight = approx. 40,4 kg

Blade diameter = 330 mm

Number of blade revolutions = 266 r.p.m.

THE MOST IMPORTANT TECHNICAL DATA

Product size --round = 224 mm

--rectangular = 224 x 260 mm

Slice thickness control, = 0,5 to 24 mm

infinitely variable

Type of current, voltage, = see specification plate

power consumption

LENGTH

Outside dimensions

LBH

625 mm 570 mm 432 mm

Supporting area

L1 B1

(300) 520 mm (420) 430 mm

Processing area

L2 B2

740 mm672 mm

WIDTH

B1

B

B2

H

L1

L

L2

(L1) (B1)

100/120 mm

L1a/L1b

L1a L1b

10

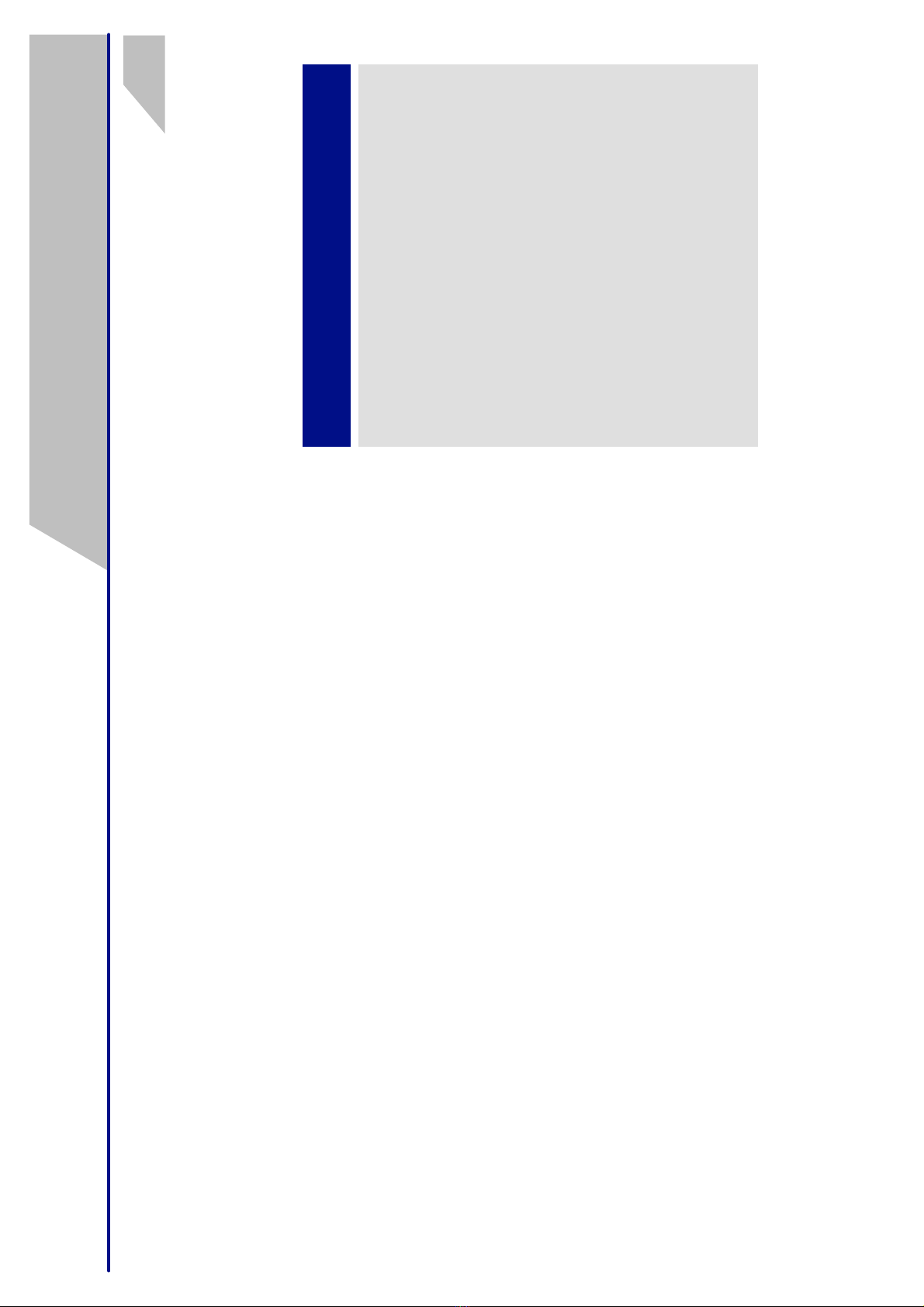

1.4.2 VS 12 F

6.080.98.5.10.03

GENERAL INSTALLATION OPERATING

ELEMENTS

OPERATION/

SLICING CLEANING BLADE

SHARPENING ACCESSORIES OPERATING

CONDITIONS

Dead weight = approx. 47,5 kg

= approx. 105 lbs

Blade diameter = 350 mm

= 13.78”

Number of blade revolutions = 266 r.p.m.

THE MOST IMPORTANT TECHNICAL DATA

Product size --round = 270 mm

= 10.63”

--rectangular = 260 x 315 mm

= 10.24” x 12.40”

Slice thickness control, = 0,5 to 24 mm

infinitely variable = 0.02 to 0.94”

Type of current, voltage, = see specification plate

power consumption

LENGTH

Outside dimensions

LBH

706 mm

27.80”

674 mm

26.53”

480 mm

18.90”

Supporting area

L1 B1

(385) 605 mm

(15.16) 23.82”

(425) 430 mm

(16.73) 16.93”

Processing area

L2 B2

770 mm

30.31”

860 mm

33.86”

WIDTH

B1

B

B2

H

L1

L

L2

(B1)(L1)L1a L1b

100/120 mm

3.94/4.72”

L1a/L1b

11

1.4.3 VS 12 F--P

GENERAL

6.080.98.5.10.03

Dead weight = approx. 50,3 kg

= approx. 111 lbs

Blade diameter = 350 mm

= 13.78”

Number of blade revolutions = 266 r.p.m.

THE MOST IMPORTANT TECHNICAL DATA

Product size --round = 270 mm

= 10.63”

--rectangular = 260 x 325 mm

= 10.24” x 12.80”

Slice thickness control, = 0,5 to 24 mm

infinitely variable = 0.02 to 0.94”

Type of current, voltage, = see specification plate

power consumption

LENGTH

Outside dimensions

LBH

706 mm

27.80”

695 mm

27.36”

480 mm

18.90”

Supporting area

L1 B1

(385) 605 mm

(15.16) 23.82”

(425) 430 mm

(16.73) 16.93”

Processing area

L2 B2

730 mm

28.74”

890 mm

35.04”

WIDTH

B1

B

B2

H

L1

L

L2

(B1)

(L1)

100/120 mm

3.94/4.72”

L1a/L1b

L1a L1b

12

1.4.4 VS 12 W

6.080.98.5.10.03

GENERAL INSTALLATION OPERATING

ELEMENTS

OPERATION/

SLICING CLEANING BLADE

SHARPENING ACCESSORIES OPERATING

CONDITIONS

Dead weight = approx. 42,9 kg

Blade diameter = 330 mm

Number of blade revolutions = 266 r.p.m.

THE MOST IMPORTANT TECHNICAL DATA

Product size --round = 224 mm

--rectangular = 224 x 260 mm

Slice thickness control, = 0,5 to 24 mm

infinitely variable

Type of current, voltage, = see specification plate

power consumption

LENGTH

Outside dimensions

LBH

625 mm 585 mm 432 mm

Supporting area

L1 B1

(300) 520 mm (420) 430 mm

Processing area

L2 B2

755 mm672 mm

WIDTH

B1

B

B2

H

L1

L

L2

(L1) (B1)

100/120 mm

L1a/L1b

L1a L1b

13

1.5 Machine description GENERAL

6.080.98.5.10.03

The machine is designed with the following

guards and protective devices:

The complete machine housing, the gauge

plate, the blade cover, the carriage, the

feeding carriage and the remnant holder plate

of the VS 12 F--P are made of anodized

aluminium.

VS 12 C/VS 12 C W/VS 12 C F

Surface refinement with Ceraclean.

The rear wall,theguard plate and the

remnant holder plate of the

VS 12/VS 12 F/VS 12 W are of transparent,

fracture--resistant and foodstuff--friendly

plastics. All materials used in the food zone

and processing area are designed in

conformity with the applicable sanitation

requirements. All bearings in the visual area

are lubricated with lubricating agents

permitted for use in food zones.

All function keys are integrated into the

operating and display foil. The green ON

and red OFF pushbuttons use a pilot lamp to

control the start of the machine. The red

pushbutton responds already at a slight

touch. A control contactor with a self--holding

circuit prevents the machine from being

automatically restarted after power failure. A

slice thickness setting below ’0’ unlocks the

tilting safety device allowing the carriage to be

tilted in any position.

Sblade guard ring, stationary,

non--removable

Senclosed blade cover, stationary,

removable

Sgauge plate, covering the stroke area

Sprotective circuit to provide protection in

case of power failure

Ssharpener with protective cover of the

exposed blade area

VS 12/VS 12 F/VS 12 W

Srear wall, non--removable

Sunstable equilibrium of product holder in its

upper position

Sforce--guided product holder in a cutting

area of < 60 mm

This gravity feed slicer has the blade

power--driven. An a. c. or three--phase motor

drives the machine via a ribbed belt in almost

noiseless operation.

The product is fed toward the blade by

manually moving the carriage forth and back.

To enhance the frictional property of the

product, all parts coming into contact with the

product are provided with grooves.

VS 12/VS 12 W

The carriage is provided with an additional

product fixation device which prevents the

product from slipping and moving

downwards.

VS 12/VS 12 F/VS 12 W

To position the product to be cut, the product

holder may be swivelled up to its unstable

equilibrium.

VS 12 F/VS 12 F--P

The carriage equipped with an additional

feeding carriage is especially suitable for

cutting of large--surface products.

VS 12 F--P

The product holder is designed with a

clamping device.

VS 12 W

The slicing machine using an integrated scale

permits the sliced product to be

simultaneously weighed.

14

1.6 Products to be cut/application/environmental influences

6.080.98.5.10.03

GENERAL INSTALLATION OPERATING

ELEMENTS

OPERATION/

SLICING CLEANING BLADE

SHARPENING ACCESSORIES OPERATING

CONDITIONS

Sall types of sausage

Sham/bacon

Ssmoked meat with/without rind

Sroast/roast beef

Smeat/meat rolls

Scheese

Sbread

Pay attention to permitted size of

product

Do not cut:

Note

SIf mainly cutting cheese, the use of a

special cheese knife is recommended.

See optional equipment.

Application

SThe slicer is designed for application in

salerooms. It is also permitted for use

under wet environmental conditions by

taking into account the cleaning plan and

protection type IP33.

Operating time

SDesigned for continuous operation.

Working place--related emission

noise level value

SLpA =53dB(A).

SThe value takes into consideration an

instable measuring of 3 dB.

Vibration

SThe total vibration of the items, Which get

into contact with hand and arm is below

2.5m/s2 and therefore below the required

limited value.

Humidity

SProtection type IP 33. High air humidity or

moisture condensation occurring on the

machine may result in machine damage.

Temperature

SPermissible ambient temperatures:

-- 1 0 °Cto+40°C

Products permitted for cutting:

SNON FOOD products

Sbone--in products

Sfrozen food

otherwise you will damage the machine

and risk bodily injury.

15

2.1 Transport and storage

When transporting the machine shoes with steel caps should be worn and

lifting devices should be used.

At least two persons are necessary to move the machine.

Weight of machine is higher than 25 kg.

INSTALLATION

6.080.98.5.10.03

2.2 Installation

Only lift the machine out of the packaging by the

lifting straps. The drawing ”Packing/unpacking

the machine” is included.

Pay attention to the required space (see section

1.4).

Recommended height of working table:

approximately 800 mm

Requirements to be met by the supporting

area:

Shorizontal and level surface

Sstable and non--slippery

Srigid (for the machine weight,

see section 1.4)

16

Convey and store the

machine according to

the symbols indicated on

the packaging.

The lifting straps must only

be used for machine hand-

ling until it is unpacked.

They must not be used as

load--carrying equipment.

Be careful when un-

packing!

Carriage might

move due to its un-

laden weight.

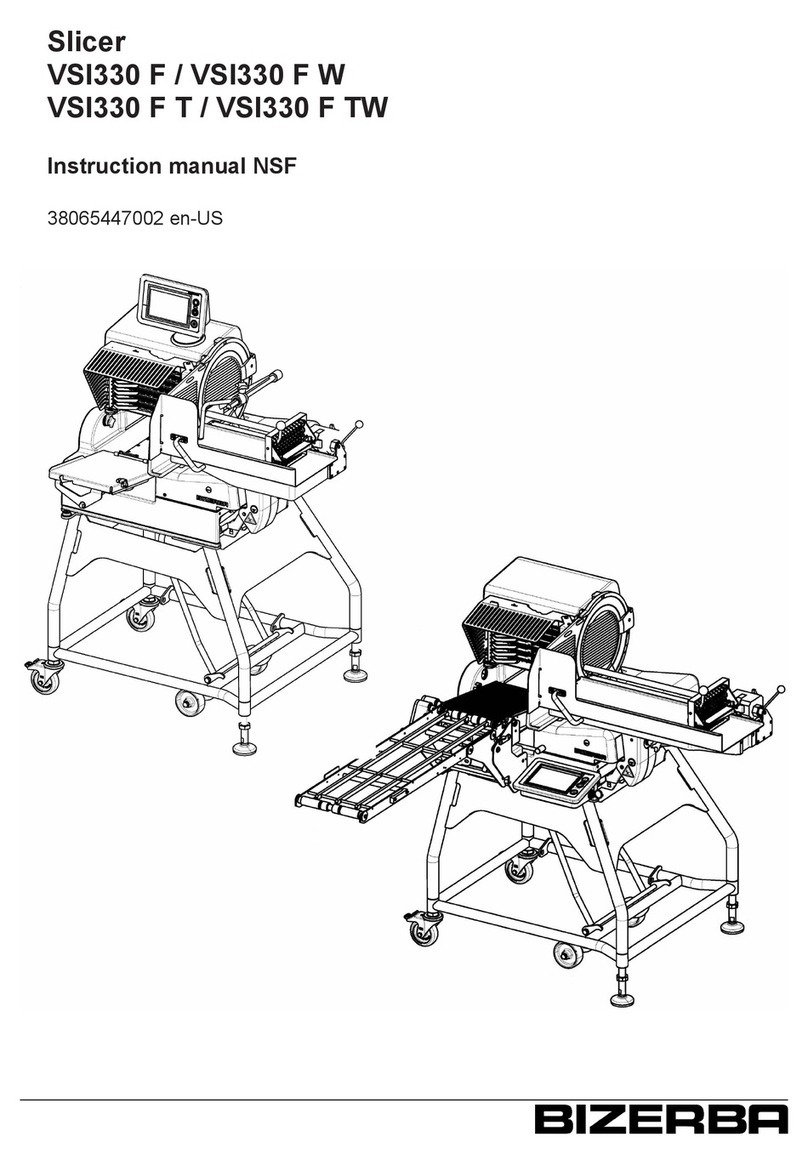

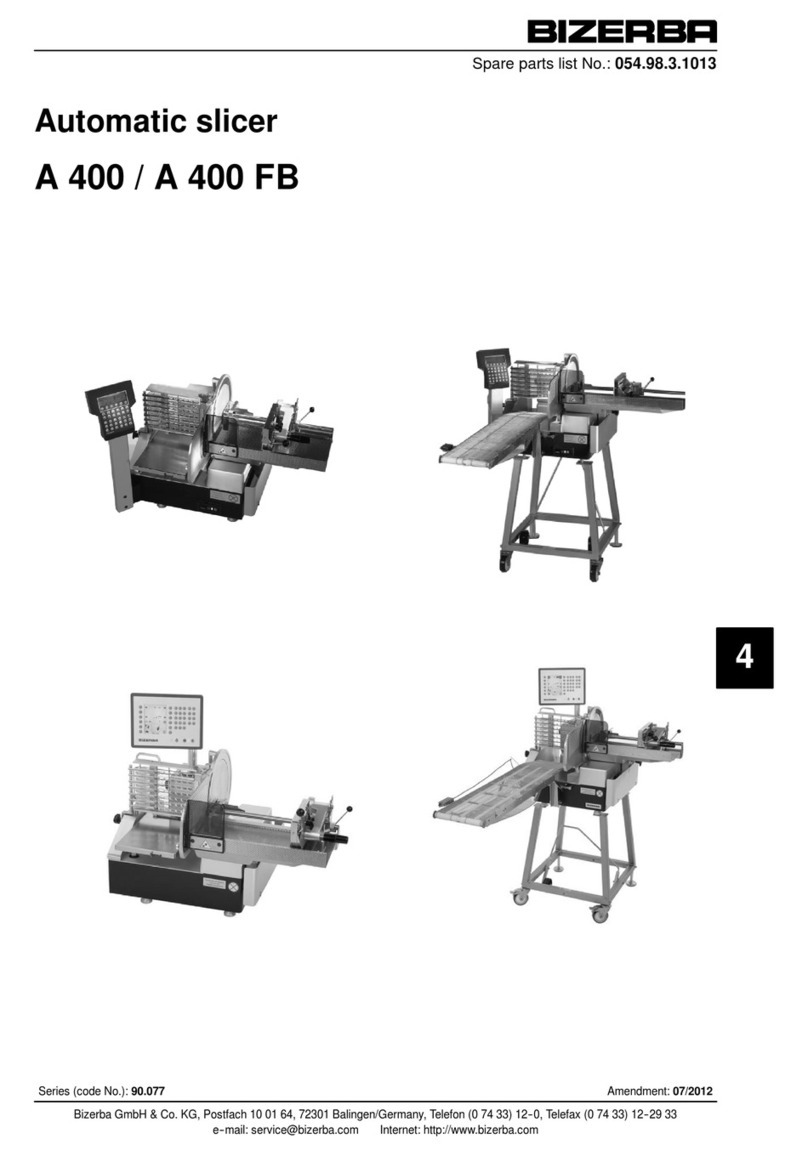

This manual suits for next models

3

Table of contents

Other Bizerba Kitchen Appliance manuals

Bizerba

Bizerba VSI330 F User manual

Bizerba

Bizerba FW N22 User manual

Bizerba

Bizerba GSP H User manual

Bizerba

Bizerba VS12D User manual

Bizerba

Bizerba SE 12/18L User manual

Bizerba

Bizerba A400 User manual

Bizerba

Bizerba VS 12 F--P User manual

Bizerba

Bizerba A400 User manual

Bizerba

Bizerba VS 12W User manual

Bizerba

Bizerba A400 User manual