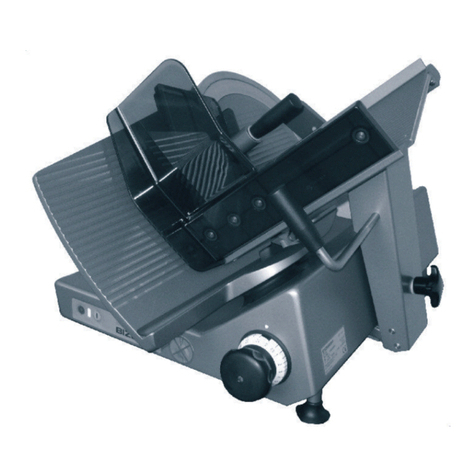

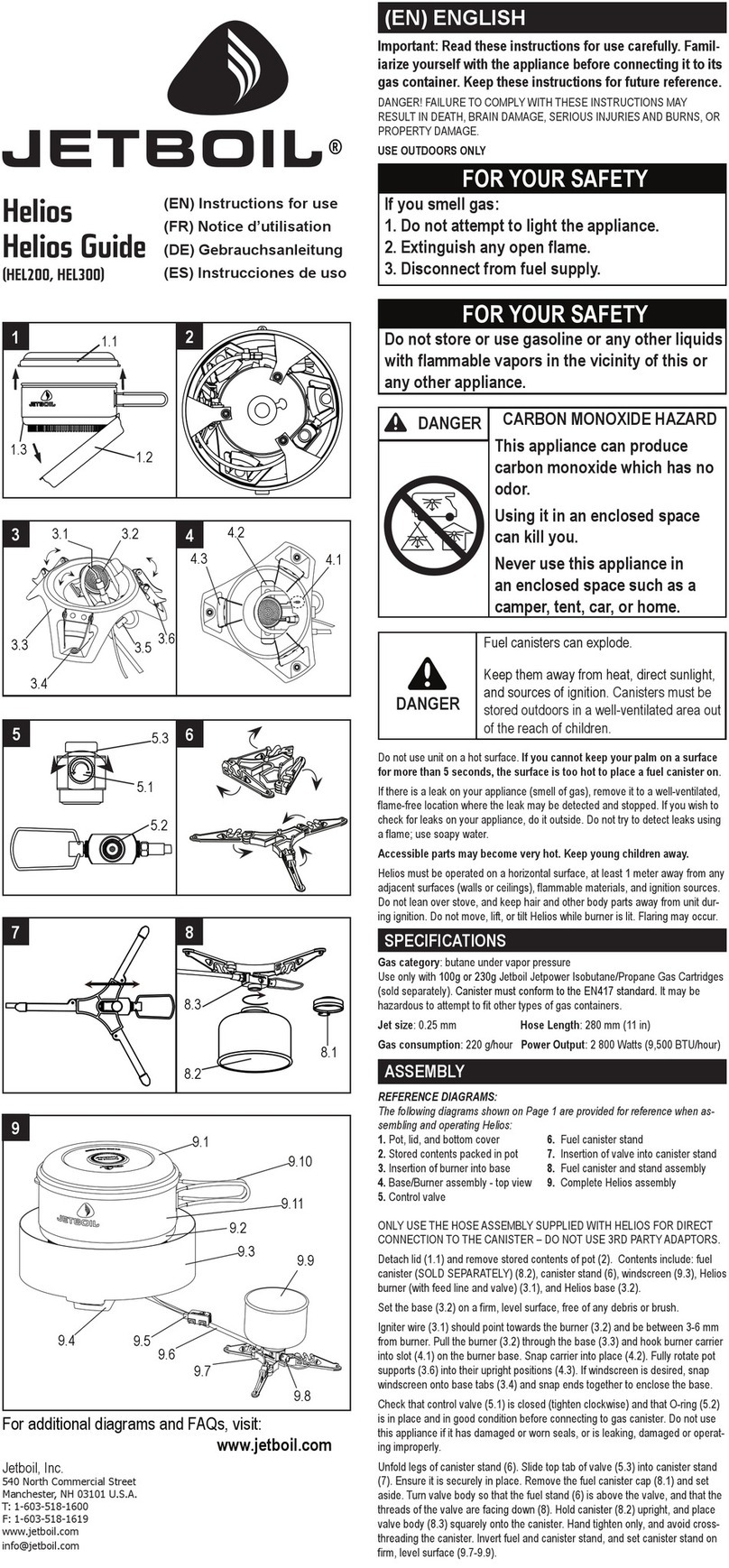

Bizerba VSI330 F User manual

Slicer

VSI330 F / VSI330 F W

VSI330 F T / VSI330 F TW

Instruction manual NSF

38065447002 en-US

Alle Rechte vorbehalten

All rights reserved

Tous droits réservés

Reservados todos los derechos

Tutti i diritti riservati

Bizerba SE & Co. KG,

72336 Balingen

Postfach 10 01 64

72301 Balingen, Germany

Telephone (+49 7433) 12-0, Fax (+49 7433) 12-2696

E-mail: [email protected]

Internet: www.bizerba.com

Translation of original instructions 38065447002 en-US

© 04 / 2017

Bizerba Service

www.bizerba.com

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW Table of Contents

3 / 10138065447002 en-US

Table of Contents

1 About these instructions ........................................................................................... 5

1.1 Safe-keeping.................................................................................................. 5

1.2 Target group .................................................................................................. 5

1.3 Symbols used ................................................................................................ 5

1.4 Warnings........................................................................................................ 6

2 About this machine .................................................................................................... 7

2.1 Intended use .................................................................................................. 7

2.2 Machine description ....................................................................................... 8

2.2.1 Names of components VSI W...................................................................... 10

2.2.2 Names of components VSI T ....................................................................... 12

2.2.3 Names of components VSI TW.................................................................... 14

2.2.4 Accessories.................................................................................................. 15

2.3 Warranty ...................................................................................................... 16

2.4 Disposal of the machine / environmental protection .................................... 16

3 Safety instructions ................................................................................................... 17

3.1 General notes on safety............................................................................... 17

3.2 Safety instructions for transport and installation .......................................... 18

3.3 Safety instructions during operation, slicing................................................. 19

3.4 Safety instructions for sharpening, cleaning ................................................ 19

3.5 Protective and safety devices ...................................................................... 20

3.6 System design related residual hazards ...................................................... 21

4 Installation................................................................................................................. 23

4.1 Unpacking instructions................................................................................. 23

4.2 Transport and storage.................................................................................. 24

4.3 Installation and assembly............................................................................. 24

4.3.1 Installation requirements.............................................................................. 24

4.3.2 Position on stand ......................................................................................... 25

4.3.3 Electrical connection .................................................................................... 27

4.4 Start-up ........................................................................................................ 28

4.4.1 Switching the slicer on ................................................................................. 28

4.4.2 Switching the machine off ............................................................................ 28

4.5 Decommissioning......................................................................................... 29

5 Machine and operating elements............................................................................ 30

5.1 Display and operating unit ........................................................................... 30

5.2 Icons on the touchscreen............................................................................. 30

5.2.1 Parameter symbols ...................................................................................... 32

5.2.2 Anchor symbol ............................................................................................. 37

5.2.3 Depositing patterns ...................................................................................... 39

5.3 Paper holder ................................................................................................ 44

5.4 Product fixation device................................................................................. 45

Table of Contents

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW

4 / 101 38065447002 en-US

6 Operation................................................................................................................... 46

6.1 Log in operator............................................................................................. 46

6.2 Main page (individually configured operator page) ...................................... 46

6.3 Navigation between the pages..................................................................... 47

6.4 Parameter page ........................................................................................... 48

6.5 Tile manager ................................................................................................ 48

6.6 Search mask ................................................................................................ 49

6.7 Settings ........................................................................................................ 50

6.7.1 User management ....................................................................................... 51

6.7.2 Software settings ......................................................................................... 52

6.8 Inserting the product .................................................................................... 53

6.9 First cut function........................................................................................... 55

6.10 Slicing product ............................................................................................. 56

6.11 Slicing of target weight................................................................................. 59

6.12 Ending slicing............................................................................................... 60

7 Troubleshooting ....................................................................................................... 62

7.1 Procedure .................................................................................................... 62

7.2 Fault description........................................................................................... 62

8 Maintenance.............................................................................................................. 63

8.1 Preparation for cleaning............................................................................... 63

8.2 Removing components ................................................................................ 64

8.3 Cleaning....................................................................................................... 72

8.4 Cleaning plan for slicing machines .............................................................. 76

8.5 Preparing the machine for operation............................................................ 78

8.6 Service and maintenance ............................................................................ 85

8.6.1 Blade sharpening ......................................................................................... 86

8.6.2 Sharpening................................................................................................... 88

8.6.3 Honing.......................................................................................................... 88

8.6.4 Checking seals and sealings ....................................................................... 90

9 Technical data........................................................................................................... 92

9.1 Dimensions of VSI / VSI W with carriage 400 mm....................................... 92

9.2 Dimensions of VSI / VSI W with carriage 600 mm....................................... 93

9.3 Dimensions VSI T ........................................................................................ 94

9.4 Dimensions VSI TW..................................................................................... 95

9.5 Technical data.............................................................................................. 96

9.6 Power supply ............................................................................................... 96

9.7 Ambient conditions....................................................................................... 97

10 Attachment................................................................................................................ 98

10.1 Parameter defaults and input ranges........................................................... 98

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW About these instructions

38065447002 en-US 5 / 101

1 About these instructions

Read the instruction manual very carefully before connecting and switching on the machine

to ensure that you utilize the full quality and potential of this machine and avoid any potential

risks.

This instruction manual covers the use, installation, operating, cleaning and maintenance of

the machine.

Our products undergo continuous further development and are subject to different country-

specific regulations. Examples of pictures and graphics included in these instructions may

vary from the version you have received.

1.1 Safe-keeping

The owner's manual are an integral part of the machine and must be stored close to the ma-

chine to be easily accessible to others.

If the machine is sold, the owner's manual must be included in its entirety.

1.2 Target group

The machine may only be operated by trained personnel. This means that the operator has

to be familiar with the contents of the instruction manual.

The minimum age of the operating personnel by German law is 14. Other age limits may ap-

ply according to the corresponding national regulations. Therefore the operating company

must check the legislation at the place of machine installation.

Installation, maintenance and repair works must be performed by Bizerba authorized special-

ists only.

1.3 Symbols used

Various symbols are used in these instructions.

Icon Description

Text with arrow prompts you to carry out an action.

1

Item number in figure.

<Key> Text within <> refers to a key.

"Display" Text within "" shows the display text.

Requirements are displayed with a gray background.

Instruction

These instructions are mandatory for you.

About these instructions

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW

6 / 101 38065447002 en-US

Information

Additional information for better understanding.

1.4 Warnings

Warnings are divided into danger levels by the signal word above the warning symbol.

Structure of warnings and meaning of signal words are described in these instructions as fol-

lows.

DANGER

Source of danger with high risk of imminent danger to persons!

The consequences are:

life threatening injuries,

serious health damage

– Measurements for prevention of danger are specified.

WARNING

Source of danger with medium risk of possible danger to persons!

The consequences can be:

serious injuries,

damage to health,

serious damage to property

– Measurements for prevention of danger are specified.

CAUTION

Source of danger with low risk of possible danger to persons!

The consequences can be:

injuries,

damage to property.

– Measurements for prevention of danger are specified.

NOTICE

Source of danger, improper use!

Damage to property can result.

– Measurements for prevention of danger are specified.

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW About this machine

38065447002 en-US 7 / 101

2 About this machine

2.1 Intended use

Bizerba slicers are technical equipment exclusively intended for commercial use.

They may only be operated by instructed personnel over the age of 14. [}5]

The fully automatic vertical slicers VSI slice the fed product and deposit the slices based on

the program setting.

Permitted product

Approved sliced products, taking sizes into consideration

– All kinds of cold cuts, deli meat

– Ham, bacon

– Smoked ham with / without rind

– Roast meats, roast beef

– Meat, roulades

– Sliceable cheese

– Fruit, vegetables

– Bread

Note: If cheese is the main product being sliced, we recommend using a special cheese

blade.

Slicing of other materials requires prior written approval by Bizerba product management.

Non-permitted product

The following may not be sliced due to risk of injury and damage:

– NON-FOOD articles

– Bone-in products

– Frozen products

Product sizes

With depositing system:

min. angular 50 x 50 mm = 2" x 2" or round 50 mm = 2" diameter

max. angular 240 x 180 mm = 9.5" x 7.1" or round 180 mm = 7.1" diameter

W/o depositing system:

max. angular 240 x 180 mm = 9.5" x 7.1" or round 225 mm = 8.8" diameter

Several sliced product pieces can be placed next to each other. Loading width max. 240 mm

= 9.5".

Applications

The slicing machines are intended for installation in the sales area. The use in the prepara-

tion area is permitted taking into account cleaning procedures and protection class.

Permissible ambient temperatures from -10°C to 40°C (+14 to +104 degF).

About this machine

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW

8 / 101 38065447002 en-US

Operating time

The slicers are designed for permanent operation.

2.2 Machine description

The fully automatic (F) vertical slicer (VS) for the industrial area (I) comes with a 330 mm

blade.

Type designations or versions

VSI330 F = machine with depositing table, 400mm or 600mm carriage

VSI330 F W = machine with depositing table, scale (W), 400mm or 600mm carriage

VSI330 F T = machine with conveyor belt (T), 400mm or 600mm carriage

VSI330 F TW = machine with conveyor belt (T), scale (W), 400mm or 600mm carriage

All versions are available with a mobile bench.

Drive

Blade drive and carriage drive are operated with supply voltage, the drive for the depositing

table, conveyor belts, depositing arm and chains are operated with low voltage.

The contractor control having a self-locking circuit prevents automatic restarting after a power

cut.

ON/OFF switch and function keys are located on the display and operating unit.

Depositing system

The slicers are equipped with an automatic slice depositing system. The depositing system

deposits slices with a max. slice thickness of 12 mm. A max. slice thickness of 22 mm can be

reached without depositing system and with unlocked slice thickness limit.

The depositing system consists of a chain frame with transport chains, feed roller with guide

cam and depositing arm.

The depositing system is controlled based on carriage speed and carriage stroke.

Product holder

The product holder with remnant holder is equipped with a movable gripper hook.

The remnant holder for the 400 mm carriage has its own clamping device which can be

swiveled up and stopped in place in order to insert the product. This is not possible for the

600 mm carriage.

Carriage

The machines are fitted with a 400 mm or 600 mm carriage.

With the cleaning program activated and a slice thickness setting below "0" the tilting lock of

the carriage is released. This allows the carriage to be tilted to the outside in any position.

Scale

The slicers VSI W / VSI TW are fitted with a scale which is not metrologically approved. Por-

tions are sliced according to a pre-selected weight.

Materials

Machine housing, gauge plate and blade cover are made of anodized aluminum.

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW About this machine

38065447002 en-US 9 / 101

The carriage plate is made of stainless steel plate.

All components getting in direct contact with food and materials used in the working area

comply with the food hygiene regulations. For bearings in visual range, food-grade lubricants

are used.

Vibration

The total vibration of the items, which get into contact with hand and arm is below 2.5m/s2

and therefore below the required limited value.

About this machine

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW

10 / 101 38065447002 en-US

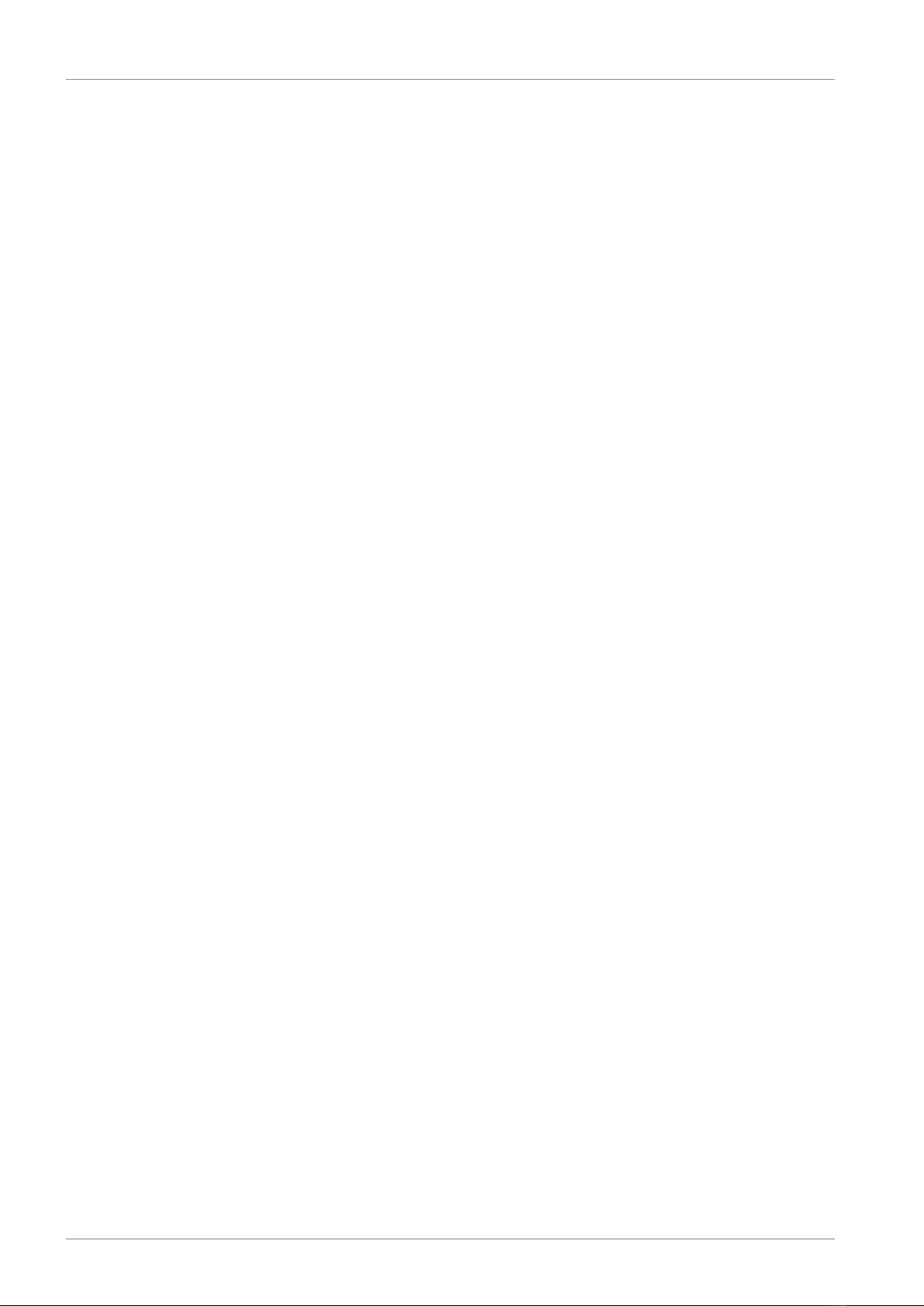

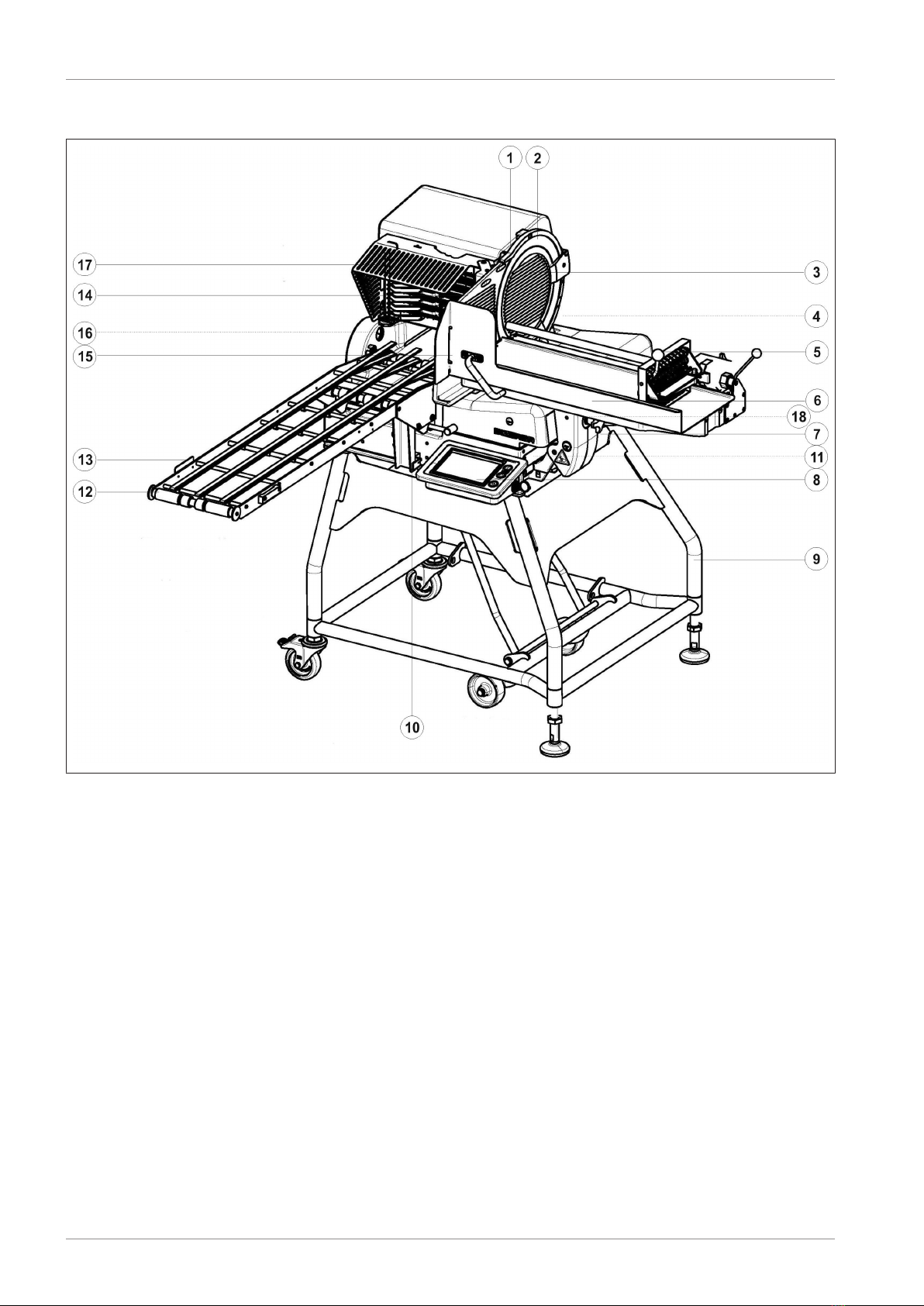

2.2.1 Names of components VSI W

Fig.1: Names of components VSI W

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW About this machine

38065447002 en-US 11 / 101

The machine is available in different versions. The figure shows an example:

1

Blade guard ring

2

Blade

3

Blade cover

4

Product holder complete with remnant holder

5

Product fixation device, horizontal

6

Feeding carriage

7

Carriage

8

Identification plate

9

Carriage guide

10

Machine housing

11

Scale

12

Depositing table

13

Gauge plate

14

Rear wall

15

Depositing arm

16

Feed roller with cam

17

Chain frame

18

Display and operating unit on top of machine housing (optionally at the bottom)

19

ON/OFF switch

About this machine

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW

12 / 101 38065447002 en-US

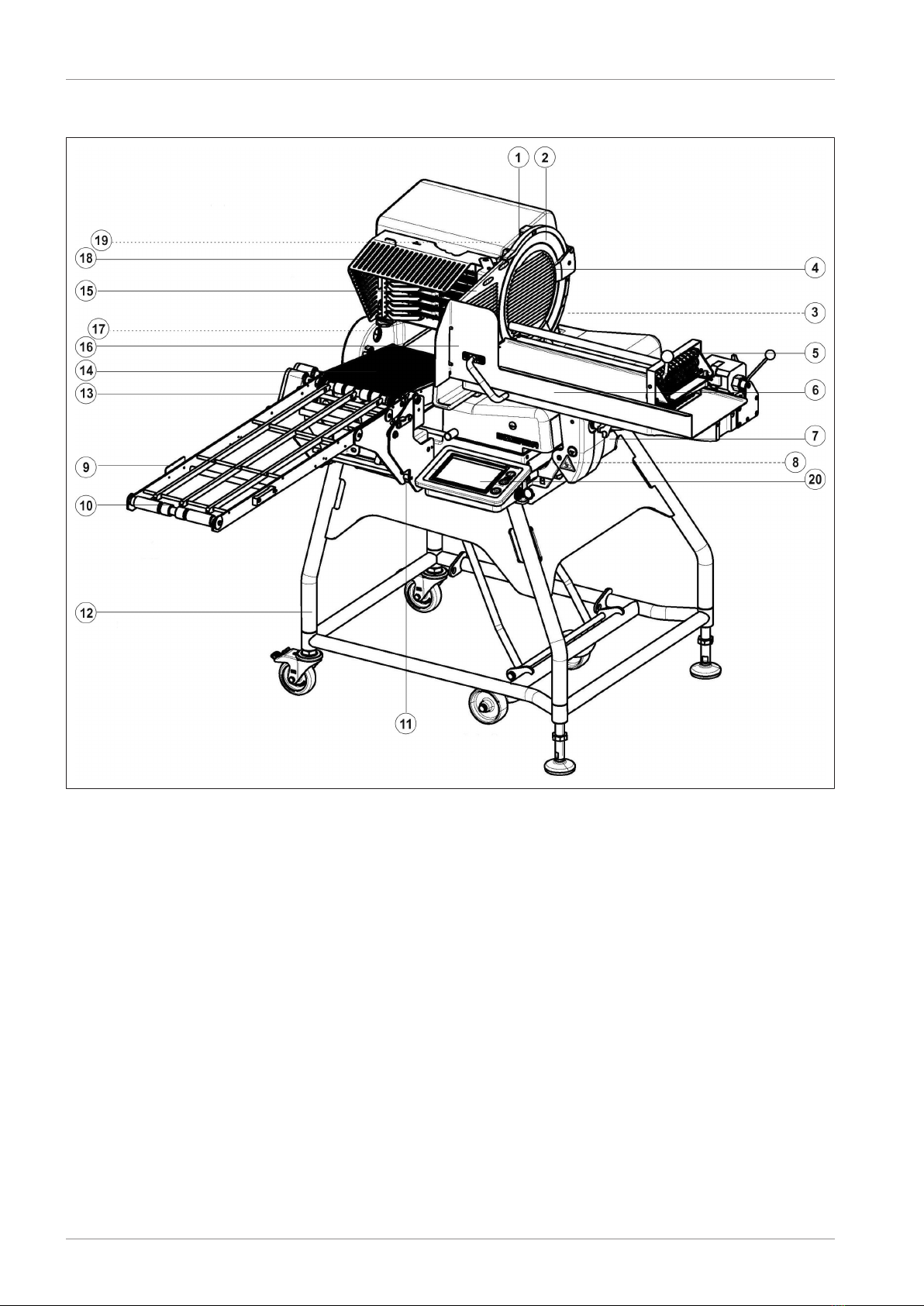

2.2.2 Names of components VSI T

Fig.2: Names of components VSI T

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW About this machine

38065447002 en-US 13 / 101

The machine is available in different versions. The figure shows an example:

1

Blade guard ring

2

Blade

3

Blade cover

4

Product fixation device, vertical

5

Product holder complete with remnant holder

6

Carriage

7

Carriage guide

8

Display and operating unit with ON/OFF switch at the bottom of the machine housing

(optionally on top)

9

Stand, mobile

10

Lock at belt support

11

Identification plate

12

Conveyor

13

Light sensor

14

Gauge plate

15

Rear wall

16

Depositing arm

17

Chain frame with feed roller

18

Star knob screw on carriage foot

About this machine

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW

14 / 101 38065447002 en-US

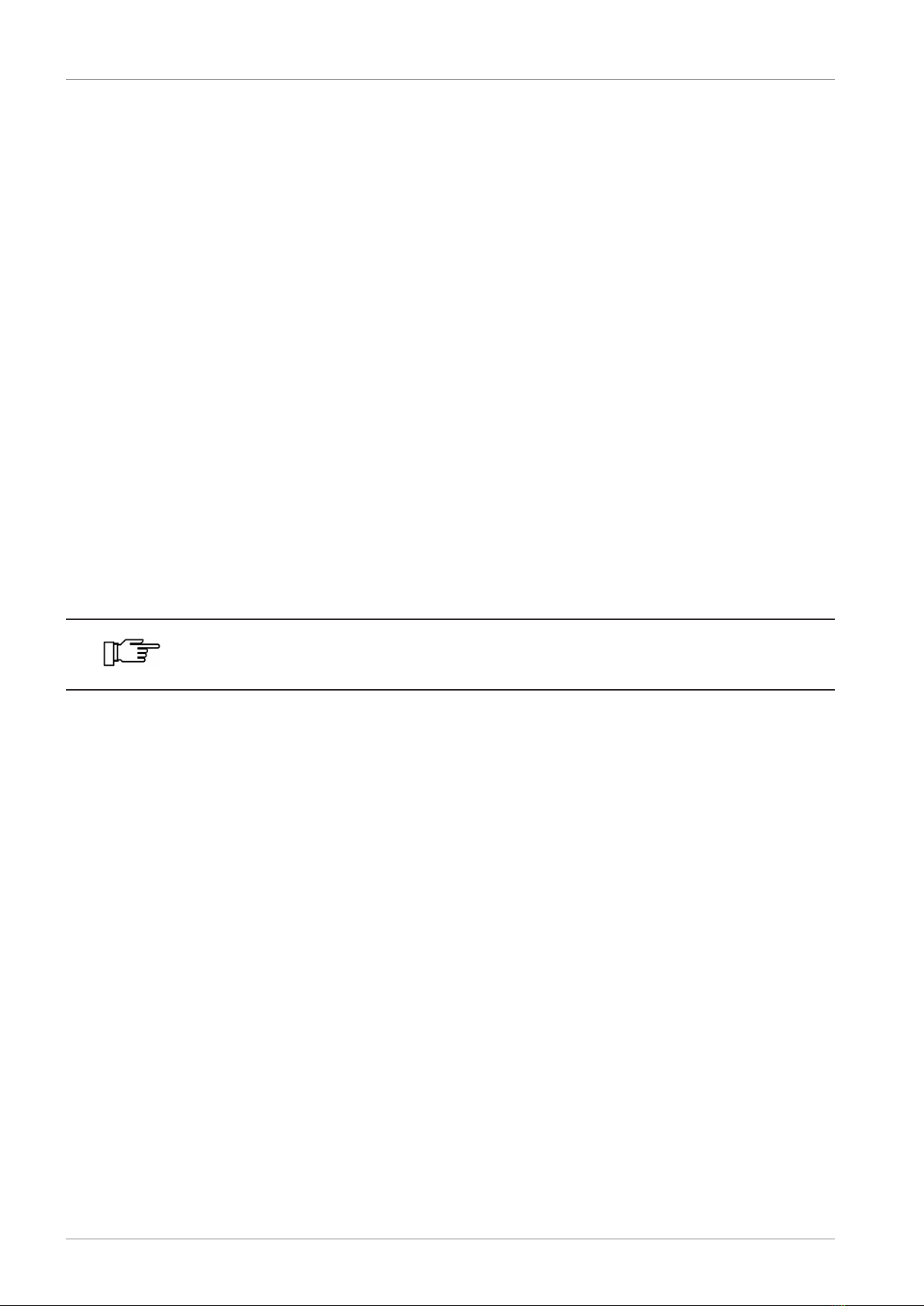

2.2.3 Names of components VSI TW

Fig.3: Names of components VSI TW

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW About this machine

38065447002 en-US 15 / 101

The machine is available in different versions. The figure shows an example:

1

Blade guard ring

2

Blade

3

Product fixation device, vertical

4

Blade cover

5

Product holder complete with remnant holder

6

Carriage

7

Carriage guide

8

Identification plate

9

Light sensor

10

Conveyor

11

Lock at belt support

12

Stand, mobile

13

External drives for conveyor belts

14

Weighing conveyor with scale

15

Gauge plate

16

Rear wall

17

Depositing arm

18

Chain frame with feed roller

19

Deflector

20

Display and operating unit with ON/OFF switch at the bottom of the machine housing

(optionally on top)

2.2.4 Accessories

Only use the original Bizerba spare parts and accessories in order to en-

sure safe and trouble-free operations.

standard

– Instruction manual

– Accessories kit including sharpener, paper felt, cleaning cloth, scrubber and brush and

service oil

optional

– Stand

– Blade available in various models

– Depositing arm for shaving

– Checkered plate for depositing table

– 4 handles for the machine

About this machine

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW

16 / 101 38065447002 en-US

– Cover caps for the threaded holes of the handles

2.3 Warranty

We are not responsible for damages caused by:

– Non-compliance with the instruction manual

– or unauthorized and incorrect electrical installation by the customer

– incorrect operation, utilization contrary to terms and conditions

– structural modifications, removal of protective devices

– use of replacement parts and accessory components or third-party resources that are not

Bizerba originals

– natural wear and tear

In such cases, the user is acting at his own risk and is responsible for any damage occurred.

2.4 Disposal of the machine / environmental protection

To ensure that the machine is recycled environmentally friendly, return the machine to the

manufacturer or the dealer after intended use has expired.

Naturally, Bizerba and its dealers will take back free of charge old machines no longer in op-

eration.

Please contact your specialist in this case.

The application of these disposal regulations are based upon legal regula-

tions of the respective country.

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW Safety instructions

38065447002 en-US 17 / 101

3 Safety instructions

The safety instructions must be observed throughout the installation, operation, cleaning and

maintenance procedures.

3.1 General notes on safety

DANGER

Damaged power supply cables or faulty protective devices!

danger to life due to electric current Acute risk of injury of operating

personnel.

– Damaged supply lines must be replaced immediately with new cables

and installed by a professional electrical company or by Bizerba Ser-

vice.

– The mains cable must be routed in a way that it is no cause of risk.

– Protective devices must be checked every day with regards to function

before start-up.

– Protective devices may not be removed, modified or bypassed.

DANGER

Open the electrical installation area!

danger to life due to electric current

– The electrical installation area may only be opened by Bizerba Ser-

vice.

– Pull power plug before moving the machine.

WARNING

Unauthorized persons!

Serious injuries to fingers and hands and damage to health.

– Only trained personnel over 14 years may operate, clean and maintain

the machine. [}5] Subsequent training sessions should be repeated

whenever necessary.

– Unauthorized persons, particularly children, may not stay in the work

area of the machine.

Safety instructions

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW

18 / 101 38065447002 en-US

3.2 Safety instructions for transport and installation

WARNING

Damaged handles, threaded holes!

Risk of injury if handles are not correctly fastened.

– Check handles and threaded holes for damage prior to use.

– Do not use damaged handles or threaded holes.

– Use handles only for lifting the machine.

CAUTION

Carriage might move due to its unladen weight.

Risk of hand injuries due to crushing!

– Be careful when unpacking.

DANGER

Tipping hazard when improperly installed!

This may result in serious injuries and damage to property.

– Installation requirements must be met.

– Operate machine on stand only if its weight rests on the feet and the

casters are locked.

– The machine must only be moved on a level surface with a very low

degree of roughness and unevenness of not more than 2 cm.

– Installation, moving and operation are not permitted on surface that

are not level.

WARNING

Incorrect supply voltage!

Destruction of electric components, fire hazard.

– Do not connect the machine to the power supply if the power supply

data does not correspond to the machine's connection values.

Mains data must be identical.

– Inform Bizerba Customer Service.

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW Safety instructions

38065447002 en-US 19 / 101

3.3 Safety instructions during operation, slicing

WARNING

Rotating blade!

Cut injuries

– Do not allow yourself to become distracted. Concentrate on the task in

hand and avoid time pressure.

– During operation, do not reach into the path of the carriage.

–Never push product ends towards blade by hand.

WARNING

Moving components!

Risk of entanglement, shearing, crushing and being hit.

– Do not wear loose clothing or wear hair down.

– Do not reach into paths of carriage, product holder, gauge plate, de-

positing system, conveyor and depositing table.

– Only clean machine when switched off and power plug is pulled.

CAUTION

There are spikes on the product holder!

Driver hooks on feed carriage, grip hooks!

Risk of injury.

– Use handle when working with product holder.

– Claws are lowered into a rest position.

3.4 Safety instructions for sharpening, cleaning

WARNING

Unprotected blade!

Coming in contact with the sharp blade can lead to serious injuries.

– Always wear cut-proof gloves during the cleaning and sharpening pro-

cedures and shoes with toe caps when the blades are replaced.

– Do not clean the blades when operating the machine.

Safety instructions

Instruction manual NSF VSI / VSI W / VSI T / VSI

TW

20 / 101 38065447002 en-US

WARNING

Chain spikes, driver spikes of feeding carriage, gripper hooks, de-

flector edge!

Stab and cut wounds.

Twisted guide cam or chain spikes can cause malfunctions.

– Always wear cut-proof gloves when cleaning.

– Avoid touching the chain spikes.

– Claws are lowered into a rest position.

WARNING

Missing components!

The operator can only be protected from injuries and the machine

protected against damage if all the components of the machine are

assembled properly.

– Check if the machine is complete before it is re-started.

– Check if components are positioned correctly and firmly.

– Only use original Bizerba spare parts and accessories.

3.5 Protective and safety devices

– Blade guard ring, stationary, cannot be removed

– Blade cover stationary, removable

– Gauge plate, covering carriage stroke area

– Rear wall, cannot be removed

– Stand casters

– Protective cover of chain frame and working area of depositing arm

– Automatic switch-off when drive system is overloaded

– Automatic switch-off of blade and carriage drive when in product loading position

– Cleaning program, locked machine setting

– Sharpening program, locked machine setting

Remaining risks that cannot be excluded by technical measures:

– Risk of tripping/slipping if the work area is not kept tidy.

– Risk of injury if the required personal protective clothing is not worn.

This manual suits for next models

3

Table of contents

Other Bizerba Kitchen Appliance manuals

Bizerba

Bizerba VS 12 F--P User manual

Bizerba

Bizerba A400 User manual

Bizerba

Bizerba A400 User manual

Bizerba

Bizerba VS 12W User manual

Bizerba

Bizerba SE 12/18L User manual

Bizerba

Bizerba VS 12 User manual

Bizerba

Bizerba VS 12 D-V User manual

Bizerba

Bizerba VS12D User manual

Bizerba

Bizerba FW N22 User manual

Bizerba

Bizerba A400 User manual