Bizerba BRS 38 User manual

OPERATING INSTRUCTIONS

BRS 38Type

6.009.98.5.10.02

BREAD SLICER

Alle Rechte vorbehalten

All rights reserved

Tous droits réservés

Reservados todos los derechos

Tutti i diritti riservati

2004

Bizerba mbH & Co. K

72336 Balingen

Postfach 10 01 64

72301 Balingen/ ermany

Tel. (07433) 12--0, Fax (07433) 122696

E--mail: marketing@bizerba.de

Internet: http://www.bizerba.com

DECLARATION OF TYPE CONFORMITY

Hauptverwaltung Balingen

Postfach 10 01 64, 72301 Balingen

Wilhelm--Kraut--Straße 65

72336 Balingen, Deutschland

We declare herewith that the type of the machine described below

A

n

y

m

o

d

i

f

i

c

a

t

i

o

n

m

a

d

e

t

o

t

h

e

m

a

c

h

i

n

e

Definition: Bread Slicer

A

n

y

m

o

d

i

f

i

c

a

t

i

o

n

m

a

d

e

t

o

t

h

e

m

a

c

h

i

n

e

described above without the prior

p

e

r

m

i

s

s

i

o

n

o

f

B

i

z

e

r

b

a

w

i

l

l

r

e

n

d

e

r

t

h

i

s

Type:

BRS 38

p

e

r

m

i

s

s

i

o

n

o

f

B

i

z

e

r

b

a

w

i

l

l

r

e

n

d

e

r

t

h

i

s

declaration invalid.

complies-- in the version supplied by us-- with the following

regulations applying thereto:

Notified body, verifying and certifying body Notified body

’Fachausschuss No. 0 391

Fleisch im B --PRÜFCERT’

E

C

m

a

c

h

i

n

e

r

y

d

i

r

e

c

t

i

v

e

9

8

/

3

7

/

E

C

T

y

p

e

e

x

a

m

i

n

a

t

i

o

n

E

C

m

a

c

h

i

n

e

r

y

d

i

r

e

c

t

i

v

e

9

8

/

3

7

/

E

C

EC EMC directive 89/336/EEC

T

y

p

e

e

x

a

m

i

n

a

t

i

o

n

certificate no. 03043 of 2003/10/07

Applied harmonized standards and technical

specifications:

Safety: EMC: DIN EN 50081--2

S

-

-

F

W

0

1

/

0

1

D

I

N

E

N

6

1

0

0

0

-

-

3

-

-

2

S

a

f

e

t

y

:

E

M

C

:

D

I

N

E

N

5

0

0

8

1

-

-

2

S

-

-

F

W

0

1

/

0

1

D

I

N

E

N

6

1

0

0

0

-

-

3

-

-

2

prEN 13870 DIN EN 61000--3--3

Signature of manufacturer: ppa.

Date: of 2003/10/31 Title of signatory: Managing Director

D

r

.

W

u

r

s

t

e

r

D

r

.

W

u

r

s

t

e

r

6.009.98.5.10.02

6.009.98.5.10.02

BRS 38

OPERATING INSTRUCTIONS

1

CONTENTS

6.009.98.5.10.02

PA E

1 GENERAL 4

1.1 Warranty 4.......................................

1.2 Warningnotice 5..................................

1.3 Overview/component description 6. . . . . . . . . . . . . . . . . .

1.4 Dimensional drawing/technical data 7. . . . . . . . . . . . . . . .

1.5 Machine description Bread Slicer 8. . . . . . . . . . . . . . . . . .

1.6 Products to be cut/application/environmental influences 9

2 INSTALLATION 10

2.1 Installation 10......................................

2.2 Electricalconnection 10.............................

2.3 Testrun 11........................................

PA E

3 OPERATING ELEMENTS 12

3.1 Keyboard 12.......................................

3.2 Slice thickness setting 13. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Productclamp 16..................................

3.4 Sliceholder 16.....................................

3.5 Bread holder for easy bagging 17. . . . . . . . . . . . . . . . . . . .

3.6 Collecting bin for crumbs 17. . . . . . . . . . . . . . . . . . . . . . . . .

4 OPERATION/SLICING 18

4.1 Cuttingofbread 18.................................

4.1.1 Halvingofbread 18.................................

4.1.2 Quarteringofbread 20..............................

4.2 Cutting of bread into individual slices 22. . . . . . . . . . . . . . .

4.2.1 Wholeloafofbread 22..............................

Bagging 24........................................

4.2.2 Singleslices 26....................................

2

6.009.98.5.10.02

CONTENTS

PA E

5 CLEANING 28

5.1 Preparingforcleaning 28............................

5.2 Cleaning 28.......................................

5.3 CleaningplanBRS38 32...........................

6 ACCESSORIES 34

6.1 Sanitizing/ Maintenance/ Servicing 34. . . . . . . . . . . . . . . . .

Bladereplacement 34...............................

6.2 Disturbances 35...................................

PA E

7 OPERATING CONDITIONS 36

7.1 EC directives / standards and recommendations 36. . . .

7.2 Powersupply 36...................................

7.3 Airconvection 37...................................

7.4 Limiting values for protection type,

temperature and air humidity 37. . . . . . . . . . . . . . . . . . . . . .

3

1 1 Warranty

GENERAL

6.009.98.5.10.02

Contact us or your local after--sales service, if

any information is not properly understood.

SEquipment should only be transported and

stored in its original packing.

SEquipment should not be started up before

the requirements of the Bizerba operating

conditions are met.

SEquipment causes vibrations during

operation, the supporting area should be

horizontal, level, stable and non--slippery.

Equipment should be arranged in such a

way as to facilitate operation, working

procedures and service.

SInitial installation, commissioning,

introduction, cleaning, maintenance and

servicing should only be carried out by the

relevant BIZERBA after--sales service or

by companies or personnel authorized by

BIZERBA.

SThe use of hardware and software which

may be necessary for a data dialog

between BIZERBA and non--BIZERBA

equipment is subject to written approval

from BIZERBA.

SEquipment should not be set into operation

before supervisory and operating

personnel have thoroughly read and

understood these operating instructions.

SOnly trained personnel should operate the

equipment. Training should be repeated.

SBIZERBA does not accept any liability for

damage arising as a result of installation by

anyone other than

BIZERBA--incorporated or designated

representatives, faulty electrical

connection by the user, improper

operation, inappropriate use, modification

of equipment in any way from its original

form, removal of guards, the use of spare

parts and accessories other than genuine

BIZERBA parts or accessories.

SThe user will be responsible for any

damage or injury arising as a result of

failure to observe the BIZERBA

instructions.

STherefore, it is strongly recommended to

use only genuine BIZERBA spare parts

and accessories.

SNormal wear and tear are not covered by

the guarantee.

To provide operational

assurance and to protect

personnel from possible

injuries, the requirements of

these instructions must be met

before the machine is set into

operation and during

operation

raphics appearing in these instructions may

differ slightly from the model supplied due to

country--specific regulations and further

product development. This does not affect the

contents of these operating instructions

4

1 2 Warning notice

6.009.98.5.10.02

GENERAL INSTALLATION OPERATION

ELEMENTS

BLADE

REPLACE-

MENT

CLEANING ACESSORIES OPERATION

CONDITIONS

OPERATION/

SLICING

The adjacent warning notice

serves for your own safety and

should be observed Failure to

comply with it could result in

serious bodily injury

SFor the space required, see the technical

data as per section 1.4.

SWhen operating the machine, pay special

attention to all movable parts, especially to

the blade.

SPrevent untrained personnel and

especially children from operating the

machine. Keep them away from the

operating area of the machine.

SDo not tamper with any protective devices

of the machine. Do not remove, change or

bypass them. It may result in serious bodily

injury.

SOperate concentrated.

SDo not use the machine for products other

than stated in the operating instructions.

SDo not cut frozen products.

SEquipment suitable for intermittent

operation.

SHave damaged power cables immediately

replaced by a qualified and certified

electrician or the relevant BIZERBA

after--sales service.

SKeep the working place clean and dry.

Provide a non--slippery supporting area.

SKeep the machine free of foreign objects.

SBefore cleaning the machine, always

disconnect the power cable from the

mains.

SImmediately switch off the machine if there

are any strange noises or if the machine

starts operating though the protective

cover is still open or if there are any

obstructions which could result in serious

bodily injury.

SContact the relevant BIZERBA after--sales

service if you cannot eliminate occuring

malfunctions yourself.

5

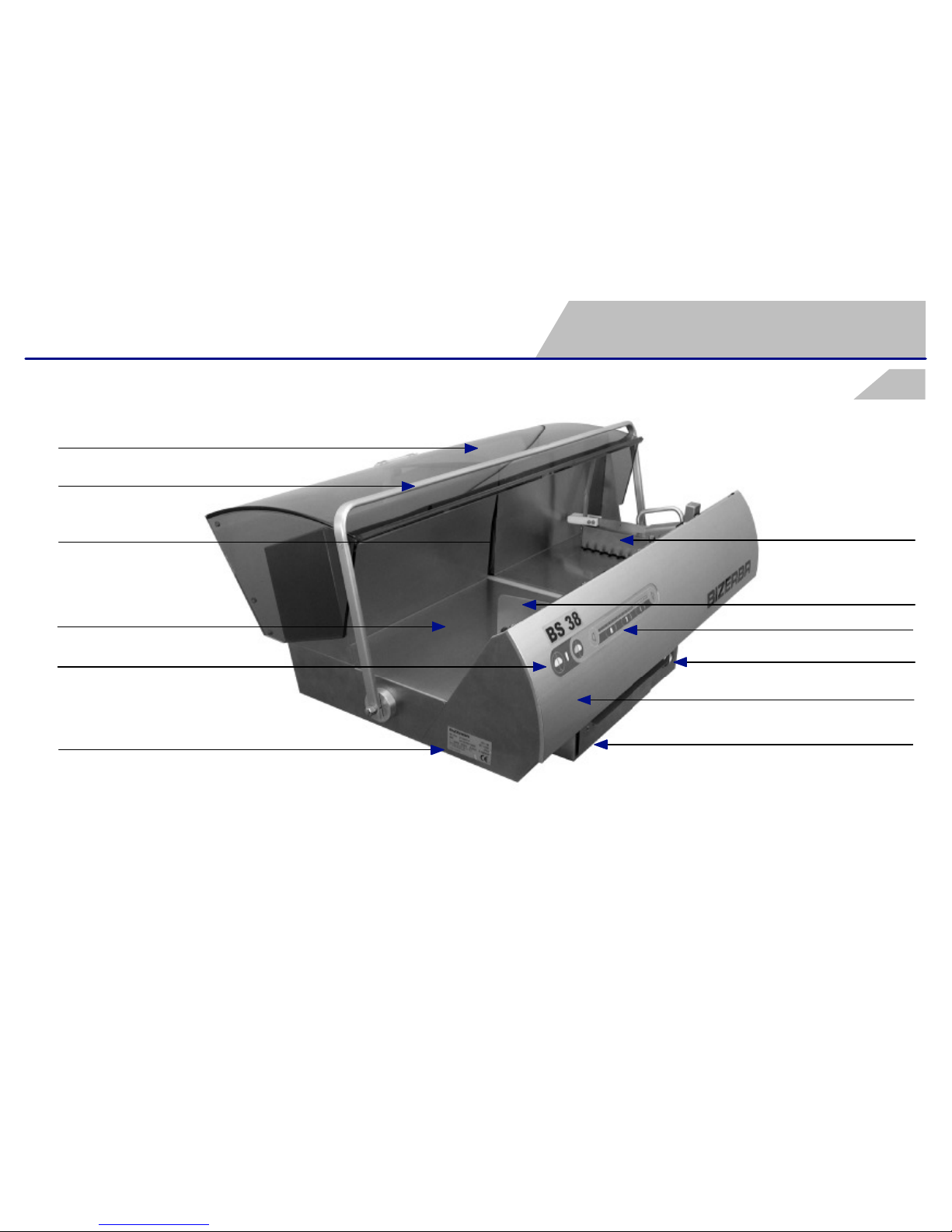

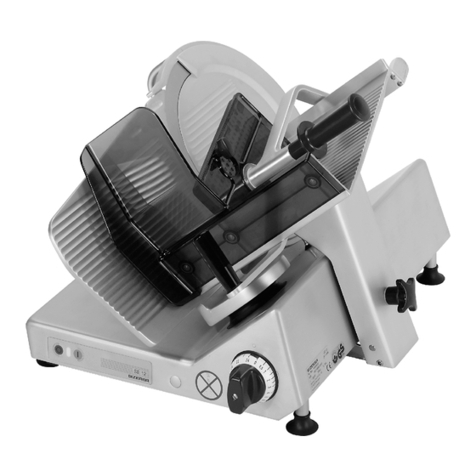

1 3 Overview/component description

GENERAL

6.009.98.5.10.02

Collecting bin for crumbs

Accessory kit (not illustrated)

containing cloth, handbrush

B

I

Z

E

R

B

A

o

i

l

e

r

Operating foil

Specification plate / CE symbol

GS plate

Slice thickness setting

Product clamp

Slice holder

Front cover

Protective cover

Blade in

blade guard

Main switch

Handle for

protective cover

Bread chute

6

1 4 Dimensional drawing/technical data

6.009.98.5.10.02

GENERAL INSTALLATION OPERATION

ELEMENTS

OPERATION/

SLICING CLEANING ACCESSORIES OPERATION

CONDITIONS

BLADE

REPLACE-

MENT

Weight = approximately 63 kg

Blade diameter = 250 mm

Number of blade revolutions = 700 U/min.

The most important technical data

Max. height of product --round = 300 mm

--oval = 300 x 380 mm

Max. height of product --round = 150 mm

--rectangular = 125 mm

Slice thickness control, = 5 to 30 mm

infinitely variable

Type of current, voltage, = see specification plate

Power consumption

LENGTH

Outside dimensions

max. space required

L B H

964 mm 658 mm 520 mm

Supporting area

L1 B1

440 mm 584.5 mm

WIDTH

7

1 5 Machine description Bread Slicer

GENERAL

6.009.98.5.10.02

The machine is designed with the following

guards and protective devices:

The Bizerba Bread Slicer is a universal device

for slicing bakery products like bread-- also

Eco--breads with a hard and thick bread crust.

You may halve or quarter the bread or cut it

into individual slices.

The circular blade with a special toothing is

electronically driven.

The product clamp on the right side as well

as the slice holder on the left side prevent the

product from slipping and moving.

The complete machine housing is made of

stainless steel, the front plate of anodized

aluminium.

The protective cover is made of transparent,

fracture--resistant and foodstuff--friendly

plastics.

All materials used in the food zone and

processing area are designed in conformity

with the applicable sanitation requirements.

All bearings in the visual area are lubricated

with lubricating agents permitted for use in

food zones.

The function keys are integrated in the

operating and display foil

The main switch uses a pilot lamp to control

the start of the machine.

A control contactor with a self--holding circuit

prevents the machine from being

automatically restarted after power failure.

SFront cover, fixed, non-- removable.

SRear wall, non--removable.

SDuring slicing protective cover is locked.

No slicing possible if cover is open.

SCollecting bin for crumbs locked during

slicing.

SProduct clamp disengaged when cover is

open.

SControl contactor in case of power failure.

8

1 6 Products to be cut /application / environmental influences

6.009.98.5.10.02

GENERAL INSTALLATION OPERATION

ELEMENTS

OPERATION/

SLICING CLEANING ACCESSORIES OPERATION

CONDITIONS

BLADE

REPLACE-

MENT

S

S

S

Sall types of bread

S

S

S

Se g Eco--breads

S

S

S

Se g coarse-- grained breads

S

S

S

Se g yeast cakes

In order to not damage the

machine and to prevent the risk of

bodily injury and also for sanitary

reasons do NOT cut:

Application

SThe slicer is designed for application in

salerooms.

Noise level

SBelow 75 dbA

Humidity

SProtection type IP 31. High air humidity or

moisture condensation occurring on the

machine may result in machine damage.

Temperature

SPermissible ambient temperatures:

+10°C to + 40°C

Safety

SThe machine has been designed in

conformity with the requirements of the

European standard prEN 13870.

Products permitted for cutting by taking

into account the permitted size:

S

S

S

SNON FOOD products

S

S

S

SFrozen products

S

S

S

SSausage, cheese

The machine is not suitable for

cutting of the following products:

S

S

S

SAny tipe of cakes covered with

powdered sugar

S

S

S

SProducts covered with frosting or

chocolate

9

2 1 Installation

To convey the slicer to the supporting area a

trolley and/or a lifting device is necessary.

(Weight of machine > 25 kg).

Pay attention to the supporting area and

required space (section 1.4)

Recommended height of working table:

approx. 800 mm

Requirements to be met by the supporting

area:

Shorizontal and level surface

Sstable and non--slippery

Srigid (for the machine weight,

see section 1.4)

INSTALLATION

6.009.98.5.10.02

2 2 Electrical connection

SCompare the voltage of outlet with that on

the specification plate.

SDo not connect the machine in case of

non--conformity. Contact BIZERBA

after--sales service!

SThe connector should meet the

country--specific standards (section 7.2)

10

Convey and store the

machine according to

the symbol indicated on

the packaging

2 3 Test run

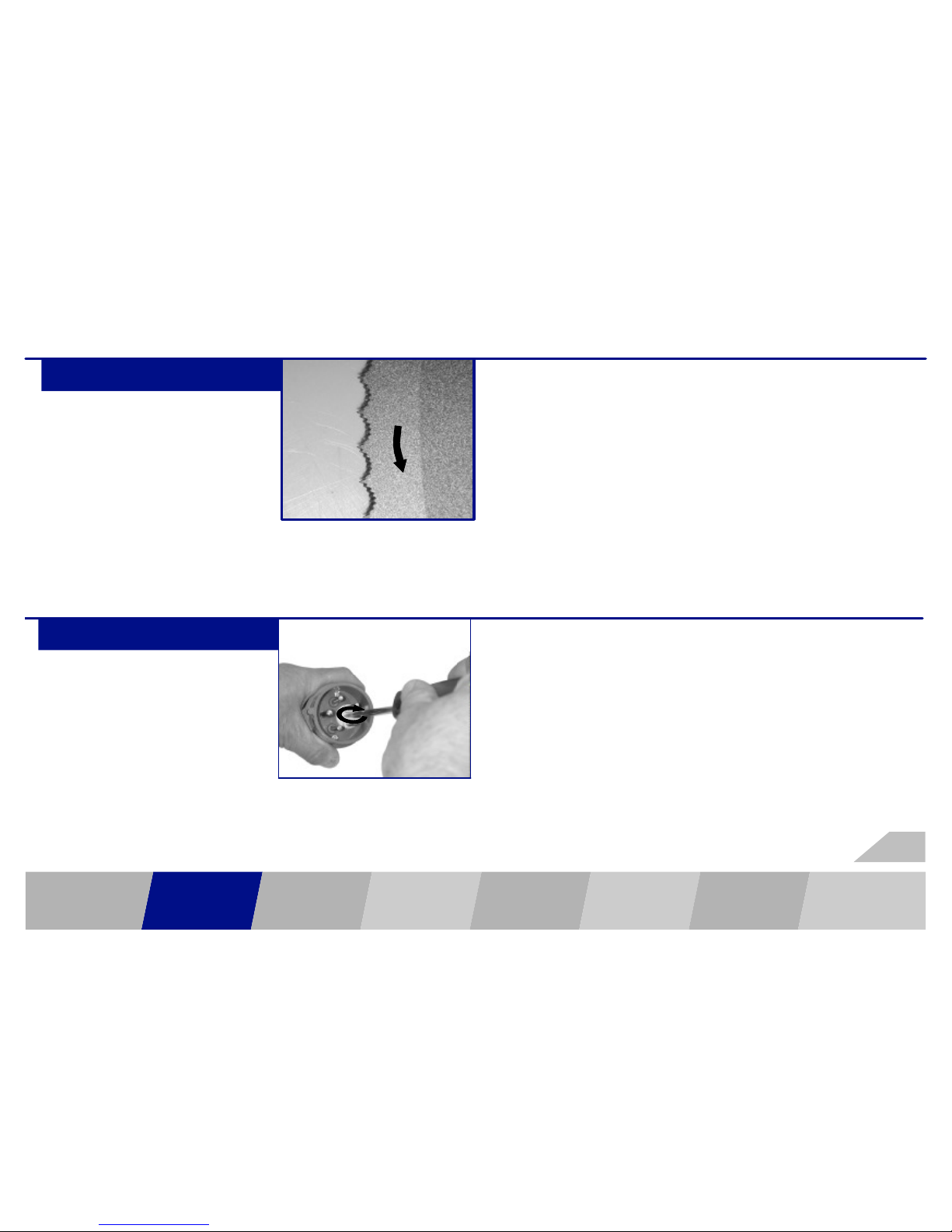

Test run or checking the direction of rotation (in the case of

three--phase current)

SProtective cover must be closed

SSwitch on machine by means of the main switch (keys

“One cut” and “Individual slices” flash).

SOpen the protective cover shortly and close it again ( the

flashing stops).

SPress key “Individual slices”.

SThe blade must rotate in the direction of arrow.

STo stop the blade press key “Individual slices”

View from right side

6.009.98.5.10.02

GENERAL INSTALLATION OPERATION

ELEMENTS

BLADE

REPLACE-

MENT

CLEANING ACCESSORIES OPERATING

CONDITIONS

OPERATION/

SLICING

If the direction of rotation is incorrect, reverse

the polarity of the phase converter on the

three--phase plug of the machine.

SIf the right direction of rotation is set, remove

the sticker with the arrow indicating the di-

rection of rotation.

11

3 1 Keyboard

OPERATION ELEMENTS

6.009.98.5.10.02

Key “One cut”

Bread is cut once

(either halved or quartered)

Key “Individual slices”

Whole bread or part of it is cut into individual slices

Thickness of bread slices

reduced gradually --

Thin bread slices

with programmable slice thickness (8 mm ex work)

Medium--cut bread slices (thickness when switching machine on)

with programmable slice thickness (10 mm ex work)

Thick bread slices with progr. slice thickness (12 mm ex work)

Thickness of bread slices increased gradually +

Key function dscription for BRS 38

12

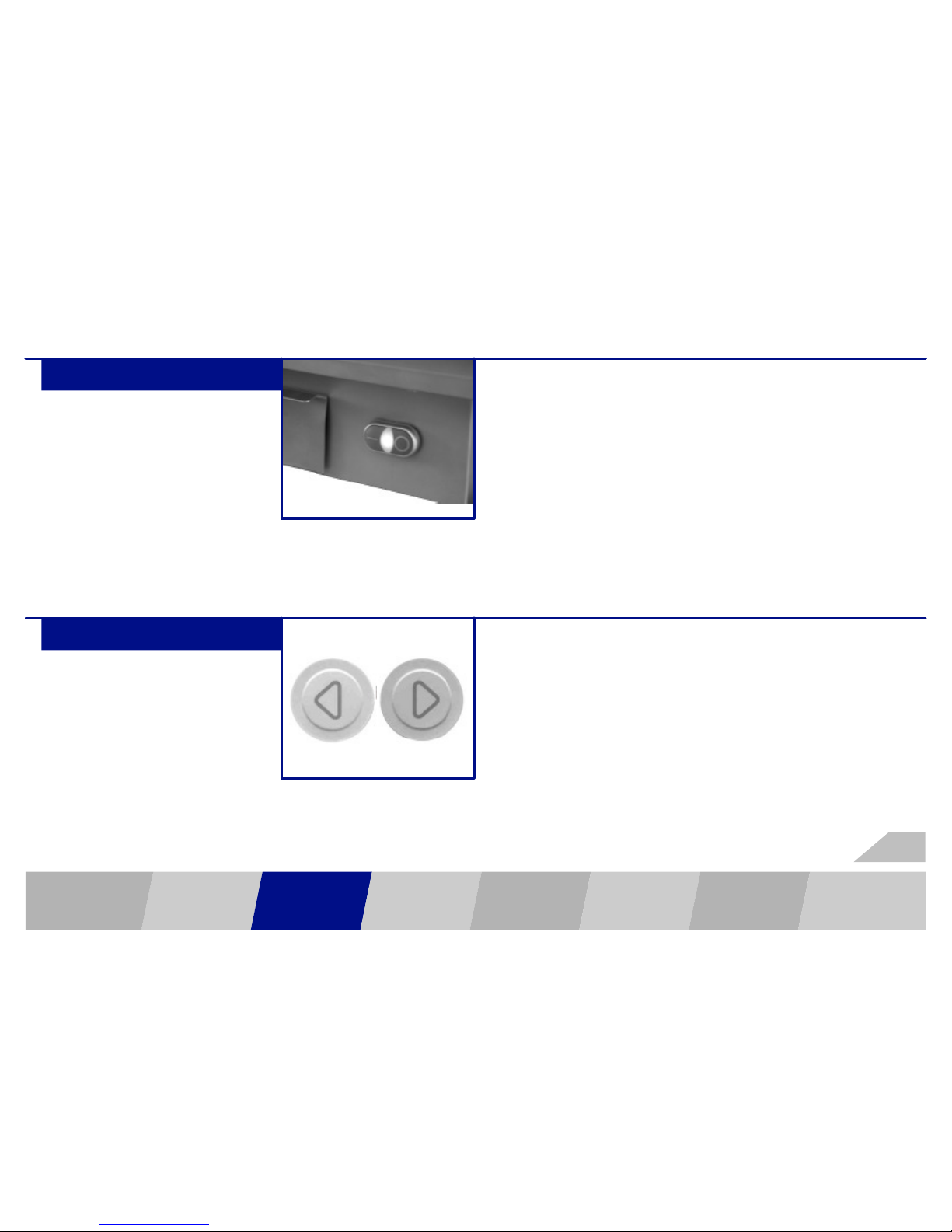

ON (green)

The machine is switched on before operation.

The keys “One cut” and “Individual slices” flash

slowly (if protective cover is closed).

The flashing stops when the protective cover is

opened -- the BS 38 is ready for operation.

LAMP (white)

Indicates that machine is ready for operation.

OFF (red)

Machine is switched off.

Main switch

6.009.98.5.10.02

GENERAL INSTALLATION OPERATING

ELEMENTS

OPERATION/

SLICING CLEANING ACCESSORIES OPERATING

CONDITIONS

BLADE

REPLACE-

MENT

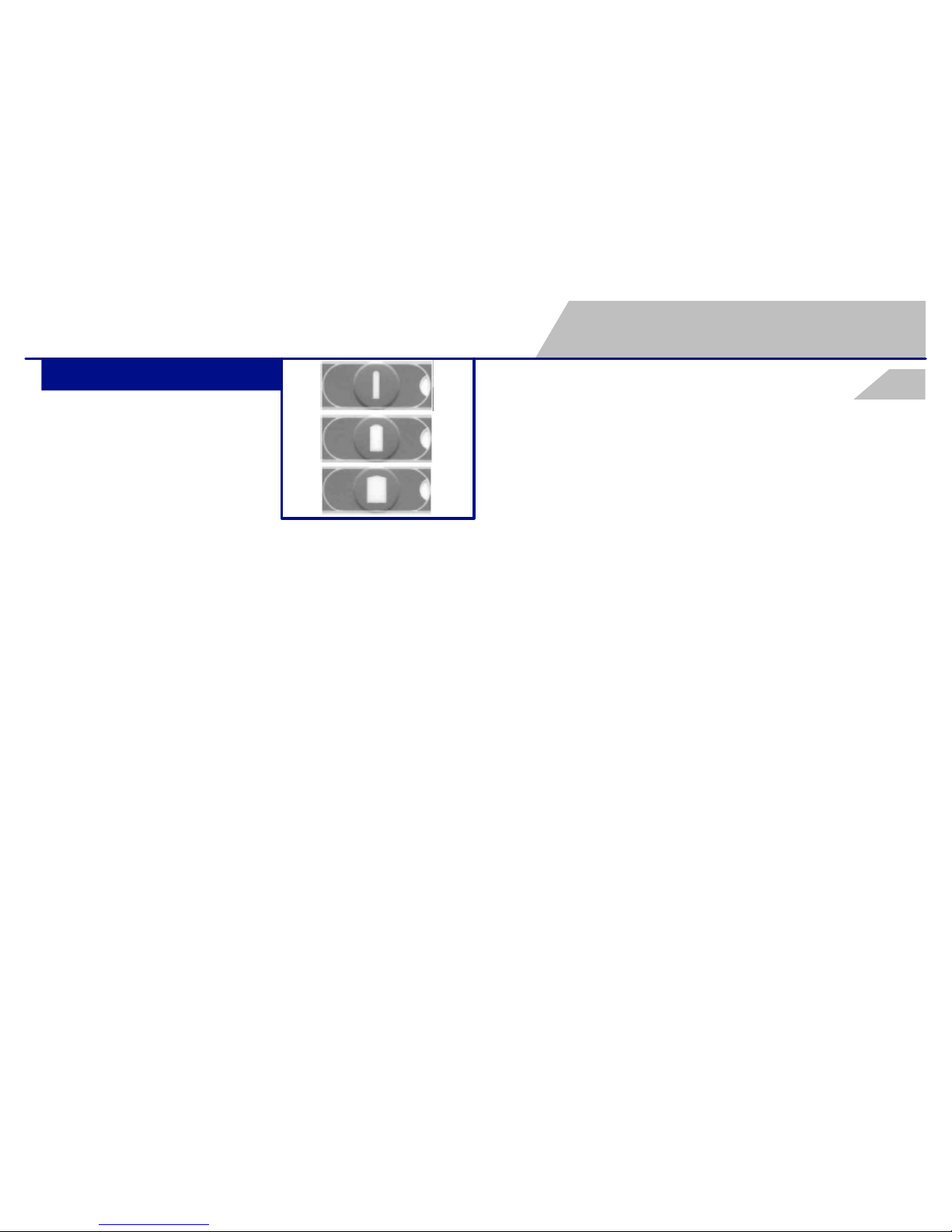

3 2 Slice thickness setting

SThe setting is made by means of two push-

buttons.

SThe gradually variable setting range:5 to 30

mm

5 to 16 mm -- 0.5 mm steps

16 to 20 mm -- 1 mm steps

20 to 30 mm -- 2.5 mm steps

SLight emitting diodes indicate the set slice

thickness.

Individual slice thickness

13

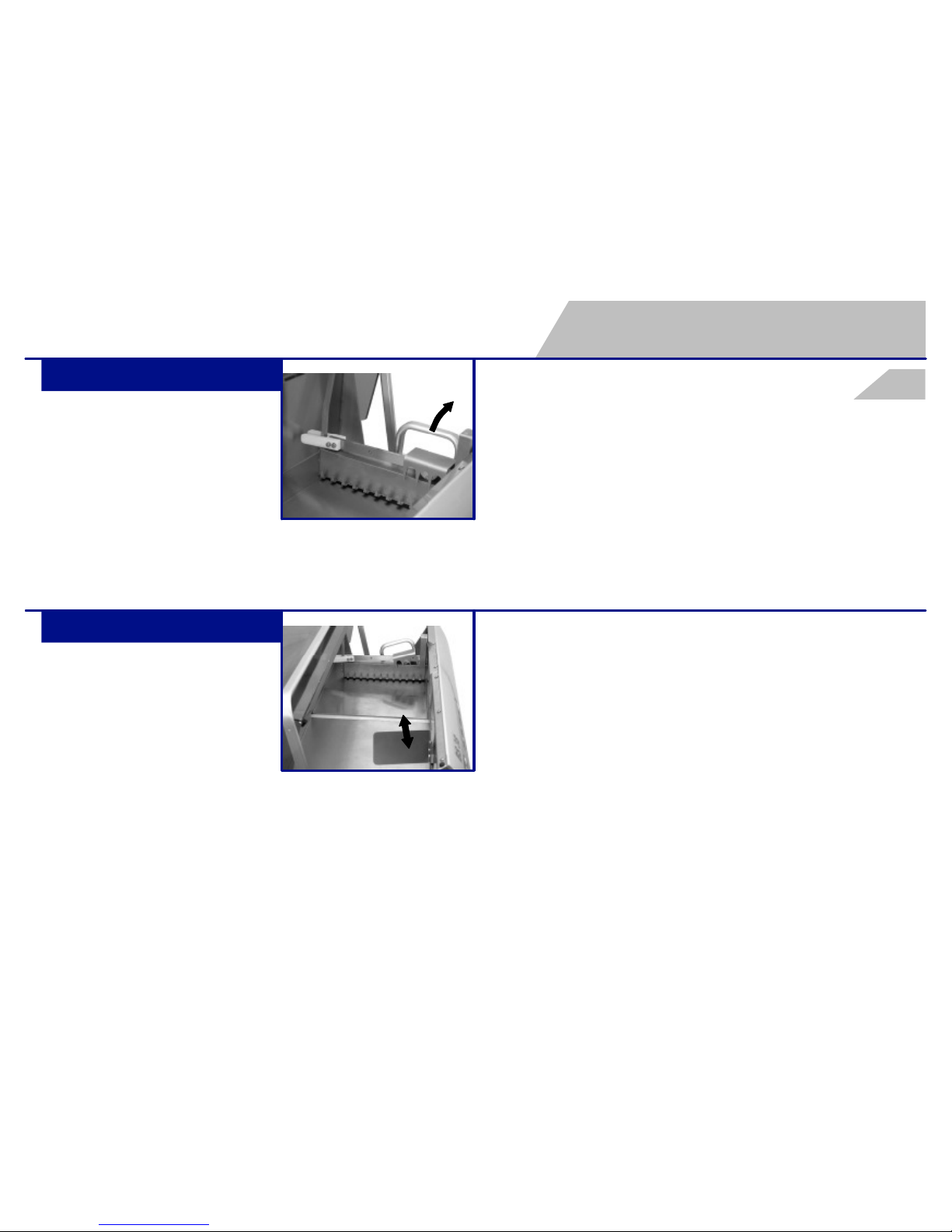

SFurthermore, it is possible to cut thin,

medium--cut or thick bread slices by means

of the pre--set key.

SThese are the pre--set values ex work:

thin -- 8 mm

medium--cut -- 10 mm

thick -- 12 mm.

SLight emitting diodes indicate the set slice

t

h

i

c

k

n

e

s

s

.

With pre--set key

OPERATION ELEMENTS

6.009.98.5.10.02

14

If required, the factory--set slice thicknesses

may be changed and stored as fixed values:

SPress the keys “Reduce slice thickness --”

and “Increase slice thickness +” simulta-

neously and hold them down for 1 second.

(all 3 memory keys flash)

SPress selected memory key.

The assigned value is displayed (value flas-

hes).

SSet required slice thickness within the pos-

sible range.

STo save value press selected memory key

again.

SThe key that was saved last before swit-

ching off the machine, is actived when swit-

c

h

i

n

g

o

n

a

g

a

i

n

t

h

e

m

a

c

h

i

n

e

.

Assigning of memory keys

and

or or

or-- +

6.009.98.5.10.02

GENERAL INSTALLATION OPERATING

ELEMENTS

OPERATION/

SLICING CLEANING ACCESSORIES OPERATING

CONDITIONS

BLADE

REPLACE-

MENT

15

If the keys “One cut” and “Indi-

vidual slices” flash, open pro-

tective cover.

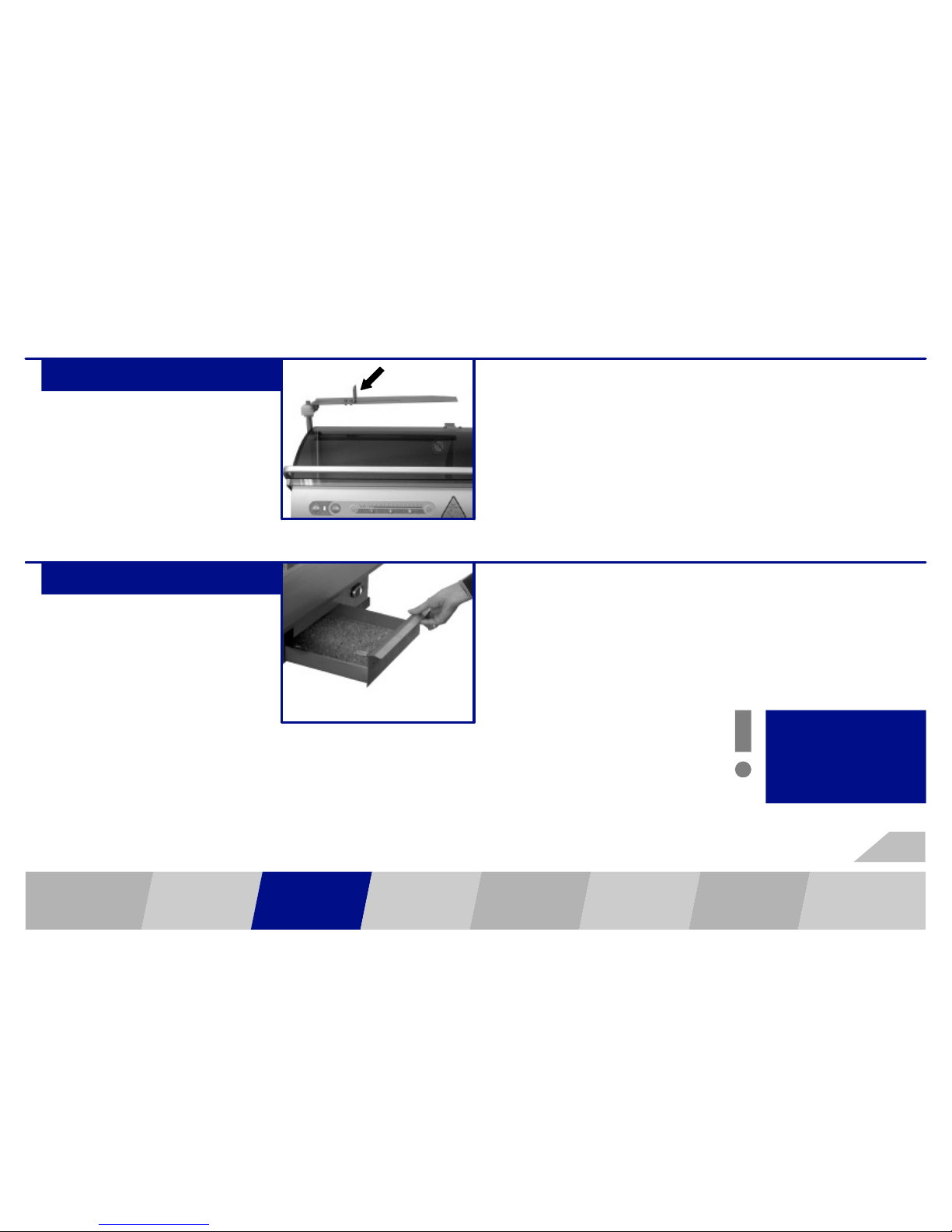

3 3 Product clamp

The product clamp is only used when slices are

cut.

It clamps the product to be cut.

After closing the protective cover and pressing

the key” Individual slices” it moves to the left,

according to the set slice thickness.

OPERATION ELEMENTS

6.009.98.5.10.02

3 4 Slice holder

The slice holder as well is only used when sli-

ces are cut.

It is placed on the left side of the product to be

cut and prevents the slices from moving or fal-

ling out during the cutting process.

The slice holder is on its shaft and is movable

over half of the machine width.

16

3 5 Bread holder for easy bagging

SSimplifies the bagging of sliced bread

SThe sliced bread is manually positioned on

the movable stop unit of the bread holder.

Pull the bag over the bread and the bread

holder.

Remove bagged bread from bread holder.

6.009.98.5.10.02

GENERAL INSTALLATION OPERATING

ELEMENTS

OPERATION/

SLICING CLEANING ACCESSORIES OPERATING

CONDITIONS

BLADE

REPLACE-

MENT

3 6 Collecting bin for crumbs

STo collect bread crumbs.

SEmpty after finished work at latest. Then, in-

sert again completely.

SOnly when the protective cover is open, it is

possible to remove and re--insert the collec-

ting bin.

17

No cutting possible

if collecting bin for

crumbs is missing

or not completely

inserted

Table of contents

Other Bizerba Kitchen Appliance manuals

Bizerba

Bizerba VS12D User manual

Bizerba

Bizerba A400 User manual

Bizerba

Bizerba VS 12W User manual

Bizerba

Bizerba SE 12/18L User manual

Bizerba

Bizerba VS 12 F--P User manual

Bizerba

Bizerba FW N22 User manual

Bizerba

Bizerba GSP H User manual

Bizerba

Bizerba GSP H User manual

Bizerba

Bizerba VS 12 D-V User manual

Bizerba

Bizerba VSI330 F User manual