BKI DRGV User manual

SS-OM-051.02 9/02/15

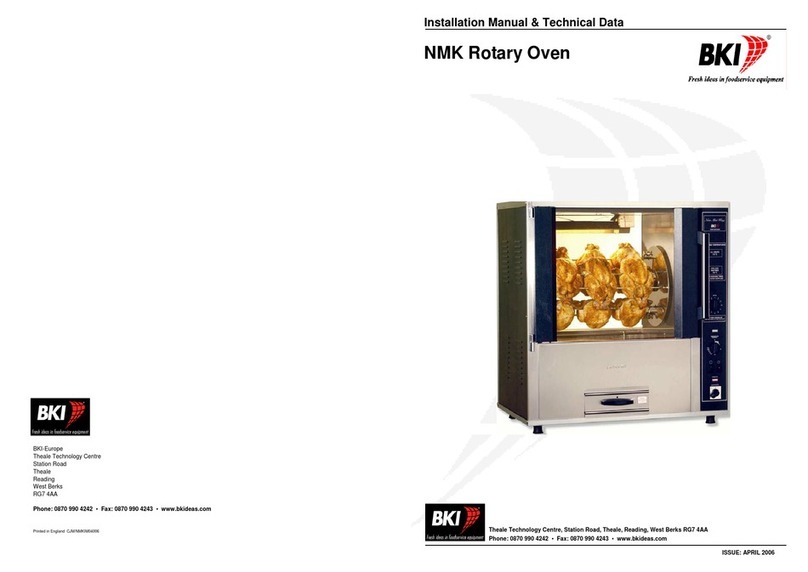

Gas Rotisserie Oven

MODEL DRGV (with To chTEC Controller)

Operator’s Man al

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the

vicinit of this or an other appliance.

WARNING

Improper installation, adjustment, alteration, service or maintenance can

cause propert damage, injur or death. Read the installation, operation and

maintenance instructions thoroughl before installing or servicing this

equipment.

NOTICE

The purchaser must post, in a prominent location, instructions to be followed

in the event the user smells gas. This information shall be obtained b

consulting the local gas supplier.

SS-OM-051.02 9/02/15

BKI LIMITED WARRANTY

2812 Grandview Dr. • Simpsonville, SC 29680 • USA

(864) 963-3471 • Toll Free: (800) 927-6887 • Fax: (864) 963-5316

WHAT IS

COVERED

This warranty covers defects in material and workmanship nder normal se, and applies

only to the original p rchaser providing that:

អ

T

he eq ipment has not been accidentally or intentionally damaged, altered or mis sed;

អ

The eq ipment is properly installed, adj sted, operated and maintained in accordance

with national and local codes, and in accordance with the installation and operating

instr ctions provided with this prod ct.

អ

The serial n mber rating plate affixed to the eq ipment has not been defaced or

removed.

WHO IS

COVERED

This

warranty

is

extended

to the original

p rchaser

and applies only

to

eq ipment p rchased

for se in the U.S.A.

COVERAGE PERIOD

អ

Warranty claims m st be received in writing by BKI within one (1) year from

date of installation or within one (1) year and three (3) months from data of

shipment from the factory, whichever comes first.

អ

COB Models: One (1) Year limited parts and labor.

អ

COM Models: Two (2) Year limited parts and labor. COM convection ovens also have a

two (2) year door warranty.

អ

CO1 Models: Two (2) Year limited parts and labor. Five (5) Year limited door

warranty.

អ

BevLes Prod cts: Two (2) Year limited parts and labor.

អ

Warranty period begins the date of dealer invoice to c stomer or ninety (90) days

after shipment date from BKI, whichever comes first.

WARRANTY COVERAGE

This

warranty

covers on-site labor, parts and

reasonable

travel

time

and travel

e

xpenses

of the

a thorized

service

representative

p

to

(100) miles

ro nd

trip and (2)

ho rs

travel time and

performed

d ring

reg lar,

weekday

b siness

ho rs.

EXCEPTIONS

Any exceptions m st be pre-approved in advance and in writing by BKI. The

extended door warranty on convection ovens years 3 thro gh 5 is a parts only warranty and

does not incl de labor, travel, mileage or any other charges.

EXCLUSIONS

អ

Negligence

or acts of

God,

អ

Thermostat

calibrations

after (30) days

from

eq ipment

installation

date,

អ

Air and g

as

adj stments,

អ

Light

b lbs,

អ

Glass doors and

door

adj stments,

អ

F ses,

អ

Adj stments

to

b rner

flames and

cleaning

of

pilot

b rners,

អ

Tightening

of screws

or

fasteners,

អ

Fail res

ca sed

by erratic

voltages

or gas

s ppliers,

អ

Una thorized

repair by

anyone

other

than

a BKI F

actory

A thorized

Service Center,

អ

Damage

in

shipment,

អ

Alteration,

mis se or

improper

installation,

អ

Thermostats

and safety valves with

broken

capillary t bes,

អ

Freight

–

other

than

normal UPS charges,

អ

Ordinary

wear and

tear,

អ

Fail re to follow

installation

and/or

operating

instr ctions,

អ

Events

beyond

control

of the

company.

INSTALLATION

Leveling, as well as

proper

installation

and check o t of all

new

eq ipment

-

per

appropriate installation

and se materials – is t

he

responsibility of the

dealer

or

installer, not the

man fact rer.

REPLACEMENT PARTS

BKI

gen ine

Factory OEM parts receive a (90) day

materials

warranty

effective from the

date of

installation

by a BKI F

actory

A thorized

Service

Center.

SS-OM-051.02 9/02/15

Table of Contents

Table of Contents ........................................................................................................................................ 1

Introduction ................................................................................................................................................. 2

Safety Preca tions .................................................................................................................................... 2

Safety Signs and Messages ................................................................................................................. 2

Specific Preca tions ............................................................................................................................. 3

Safe Work Practices ............................................................................................................................. 4

Safety Labels ........................................................................................................................................ 5

Health and Sanitation Practices................................................................................................................ 5

Food Handling ...................................................................................................................................... 6

Storage of Raw Meats .......................................................................................................................... 6

Coding Cooked Foods .......................................................................................................................... 6

Storage of Prepared Foods .................................................................................................................. 6

Operation ..................................................................................................................................................... 7

Controls and Indicators ............................................................................................................................. 7

Hardware Controls................................................................................................................................ 7

Software Controls – Operation Screens ............................................................................................... 8

Software Controls – Programming Screens ....................................................................................... 10

Programming the Controller Using the To chscreen Interface .............................................................. 12

Edit a Recipe ...................................................................................................................................... 12

Edit the Basic Set p ........................................................................................................................... 12

Operation with the Controller .................................................................................................................. 13

Viewing Recipes ................................................................................................................................. 13

Cooking .............................................................................................................................................. 13

Operation After a Gas or Power O tage ................................................................................................ 14

Normal Sh toff ........................................................................................................................................ 14

Installing Rotor System ........................................................................................................................... 14

Preparing and Loading Chickens ........................................................................................................... 14

Tr ssing Chickens .............................................................................................................................. 15

V-Spits ................................................................................................................................................ 16

Baskets ............................................................................................................................................... 17

Installation ................................................................................................................................................. 18

Unpacking and Handling ......................................................................................................................... 18

Location and Clearance .......................................................................................................................... 18

Specific Instr ctions ................................................................................................................................ 18

Co nter Top and Stand .......................................................................................................................... 19

Mo nting ................................................................................................................................................. 20

Stacking Ovens ....................................................................................................................................... 22

Locking Ovens in Place .......................................................................................................................... 27

Gas S pply Connection .......................................................................................................................... 28

Gas Manifold Press re Test ................................................................................................................... 28

Maintenance .............................................................................................................................................. 29

Sched led Maintenance ......................................................................................................................... 29

Daily Cleaning & Maintenance ........................................................................................................... 29

Tro bleshooting ...................................................................................................................................... 32

Accessories ............................................................................................................................................... 33

Wiring Diagram .......................................................................................................................................... 34

Notes .......................................................................................................................................................... 35

Rotisserie Oven Introduction

2

Introduction

Yo r BKI DRGV is a comp ter controlled gas rotisserie oven. It tilizes a do ble revolving mechanism

and infrared b rner that ens re even prod ct cooking. A to chscreen control and switches are provided

to allow for q ick set p and operation. Removable components allow for easy maintenance and cleaning.

The BKI name and trademark on this nit ass res yo of the finest in design and engineering -- that it has

been b ilt with care and dedication -- sing the best materials available. Attention to the operating

instr ctions regarding proper installation, operation, and maintenance will res lt in long lasting

dependability to ens re the highest profitable ret rn on yo r investment.

PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If

yo have any q estions, please contact yo r BKI Distrib tor. If they are nable to

answer yo r q estions, phone the applicable BKI Technical Services Department:

BKI North America: (864) 963-3471

Safety Precautions

Always follow recommended safety preca tions listed in this man al. Below is the safety alert symbol.

When yo see this symbol on yo r eq ipment, be alert to the potential for personal inj ry or property

damage.

Safet Signs and Messages

The following Safety signs and messages are placed in this man al to provide instr ctions and identify

specific areas where potential hazards exist and special preca tions sho ld be taken. Know and

nderstand the meaning of these instr ctions, signs, and messages. Damage to the eq ipment, death or

serio s inj ry to yo or other persons may res lt if these messages are not followed.

This message indicates an imminently hazardo s sit ation which, if not avoided,

will res lt in death or serio s inj ry.

This message indicates a potentially hazardo s sit ation, which, if not avoided,

co ld res lt in death or serio s inj ry.

This message indicates a potentially hazardo s sit ation, which, if not avoided,

may res lt in minor or moderate inj ry. It may also be sed to alert against nsafe

practices.

This message is sed when special information, instr ctions or identification are

req ired relating to proced res, eq ipment, tools, capacities and other special

data.

Rotisserie Oven Introduction

3

Specific Precautions

The purchaser must post, in a prominent location, instructions

to be followed in the event the user smells gas. This information

shall be obtained b consulting the local gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or

liquids in the vicinit of this or an other appliance

Improper installation, adjustment, alteration,

service or

maintenance can cause propert damage, injur or death. Read

the installation, operation and maintenance instructions

thoroughl before installing or servicing this equipment.

Use Gas Safel -- Avoid Danger

Gas can be a dangerous fuel if not handled safel .

Make sure to ventilate the oven properl . If the oven is not

properl ventilated, carbon monoxide can be released around

the oven. Asph xiation or suffocation can occur if gas is not

ventilated properl .

Clearance to Combustibles

Observe proper clearance to combustibles as noted on the oven

rating tag. Never place an thing on top of the oven.

Keep the area around the oven free and clear from combustibles.

WARNING – DANGEROUS VOLTAGE

This equipment uses high voltage. Serious injur can occur if

ou or an untrained or unauthorized person installs, services,

or repairs this equipment. Alwa s Use an Authorized Service

agent to Service Your Equipment.

Do Not Smoke Near the Oven

This oven uses combustible fuels to operate. Smoking near this

oven could possibl cause a fire. Do not allow an one to smoke

near this oven.

Rotisserie Oven Introduction

4

Safe Work Practices

Wear Safe Clothing Appropriate To Your Job

Always wear yo r ins lated mitts when handling hot oven parts or to ch any

hot metal s rface. If yo lose or damage yo r mitts, yo can b y new ones at

yo r local resta rant eq ipment s pply store or from yo r local BKI

Distrib tor.

Always wear non-skid shoes when working aro nd the oven or any other

eq ipment.

Never wear loose clothing s ch as neckties or scarves while operating this

eq ipment. Keep loose hair tied back or in a hair net while operating this

eq ipment.

Always wear appropriate personal protection eq ipment d ring the cleaning

process to g ard against possible inj ry.

Keep this manual with the Equipment

This man al is an important part of yo r eq ipment. Always keep it near for

easy access. If yo need to replace this man al, phone the applicable BKI

Technical Services Department:

BKI North America: (864) 963-3471

Protect Children

Keep children away from this eq ipment. Children may not nderstand that

this eq ipment is dangero s for them and others.

NEVER allow children to play near or operate yo r eq ipment.

Keep Safet Labels Clean and in Good Condition

Do not remove or cover any safety labels on yo r eq ipment. Keep all safety

labels clean and in good condition. Replace any damaged or missing safety

labels. Refer to the Safety Labels section for ill stration and location of safety

labels on this nit. If yo need a new safety label, obtain the n mber of the

specific label ill strated on page 5, then phone the applicable BKI Technical

Services Department:

BKI North America: (864) 963-3471.

Be Prepared for Emergencies

Be prepared for fires, inj ries, or other emergencies.

Keep a first aid kit and a fire exting isher near the eq ipment. Yo m st se

a 40-po nd Type BC fire exting isher and keep it within 25 feet of yo r

eq ipment.

Keep emergency n mbers for doctors, amb lance services, hospitals, and

the fire department near yo r telephone.

Know our responsibilities as an Emplo er

• Make certain yo r employees know how to operate the eq ipment.

• Make certain yo r employees are aware of the safety preca tions on the

eq ipment and in this man al.

• Make certain that yo have thoro ghly trained yo r employees abo t

operating the eq ipment safely.

Make certain the eq ipment is in proper working condition. If yo make

na thorized modifications to the eq ipment, yo will red ce the f nction and

safety of the eq ipment.

Rotisserie Oven Introduction

5

Safet Labels

Electrical Gro nding Instr ctions

- This appliance is eq ipped with a

three-prong (gro nding) pl g for yo r protection against shock hazard and sho ld be

pl gged directly into a properly gro nded three-prong receptacle. Do not c t or

remove the gro nding prong from this pl g.

Mise à la terre

- Cet appareil est po rv d’ ne fiche à trois broches dont ne

mise à la terre ass rant ne protection contre les chocs électriq es. La prise dans

laq elle elle est branchée doit être correctement mise à la terre. Ne pas co per ni

enlever la broche de mise à la terre de la fiche.

CAUTION

AVERTIR

DO NOT COVER or REMOVE THIS LABEL NE RECOUVREZ PAS o ENLEVEZ PAS CETTE ÉTIQUETTE

DANGER

HIGH VOLTAGE.

T rn power off before

servicing. May have more than

one disconnect switch.

HAUTE TENSION.

Mettez l'appareil hors tension avant

de proceder a l'entretien. Pe t-etre

d' comm tate r de deconnexion.

®

"Experts In Heat Transfer Technology"

www.bkideas.com

DRGV-7 123456789012-12345678

PHASE

1

VOLTS

115

AMPS / Ampère

2.2

Hz

60

EQUIPPED FOR

Eq ipé po r

NATURAL

GAS

Gaz INPUT

Énergie

72,000

BTU / Hr

BTU / H

MANIFOLD PRESSURE

Pression le Collecte r

4.5

INCHES of WATER

Po ces d'ea

Minim m spacing to a wall or adjacent nit.

L'espacement minim m s r n m r o nité

adjacente.

6

Back

Arrière

Side

Côté

in.

3

in.

Minim m spacing above mo nting s rface.

L'espacement minim m a -dess s de la

s rface de montage.

Bottom

Bas

4

in.

12345678

SIMPSONVILLE, SC, USA

DATE OF MANUFACTURE

DATE DE FABRICATION

ANS Z83.11 • CSA 1.8-2007 Food Service Eq ipment

MODEL

Modele SERIAL NO

Nº de Serie

S itable for installation on comb stible floors.

Convient à l’installation s r n plancher comb stible.

N0656 -1

Intended for other than ho sehold se.

Non destiné à l’ sage domestiq e.

Improper installation, adj stment, alteration, service or

maintenance can ca se property damage, inj ry or

death. Read the installation, operating and

main-tenance instr ctions thoro ghly before installing

or servicing this eq ipment.

L’installation, le réglage, la modification, la réparation

o l’entretien incorrect de cet appareil pe t ca ser des

dommages matériels, des bless res o la mort. Lire

attentivement les instr ctions d’installation, de

fonctionnement et d’entretien avant de procéder à son

installation o entretien.

WARNING

L'AVERTISSEMENT

For installation nder ventilation hood only.

Installer en desso s d’ ne hotte de ventilation se lement.

N0656 -2

NORMAL OPERATION -

1.) T rn main POWER switch on.

2.) To ch controller screen to activate.

3.) Select desired cook recipe.

4.) To ch Cook or Preheat to start oven.

TO CANCEL COOK PROGRAM -

1.) To ch

on pper right of controller

screen and hold for 3 seconds.

NORMAL SHUT DOWN -

1.) Cancel any activate cook program.

2.) Wait 30 seconds for fans to stop.

3.) T rn POWER switch off.

AFTER POWER or GAS OUTAGE -

the oven will sh t of a tomatically.

To restart the oven, t rn the POWER

switch off and wait 5 min tes.

Then follow NORMAL OPERATION

proced res above.

FONCTIONNEMENT NORMAL -

1.) All mez INTERRUPTEUR principal.

2.) Écran tactile de commande po r activer.

3.) Sélectionner le programme de c isson

désirée.

4.) To cher Cook o Preheat po r

commencer fo r.

D'ANNULER LE PROGRAMME de CUISSON -

1.) To cher

s r le contrôle et pendant

3 secondes.

ARRÊT NORMAL -

1.) Ann ler le programme de c isson actif.

2.) Attendre 30 secondes po r les fans

d'arrêter.

3.) Co per le co rant interr pte r.

APRÈS MISE SOUS TENSION ou

de GAZ PANNE -

le fo r a tomatically arrêter.

Redémarrer le fo r, Co per le co rant

interr pte r et attendre 5 min tes.

P is s ivre FONCTIONNEMENT

NORMAL procéd re ci-dess s.

NE PAS tiliser de nettoyants

ca stiq e po r nettoyer cette nité.

DO NOT se ca stic cleaners

when cleaning this nit.

L bricate rotor gears with BKI L0200

L bricant each day after cleaning. Fail re

to clean and l bricate the gears can

damage the drive motor or warp the gear

assembly.

LUBRICATE HERE

LUBRIFIEZ ICI

L brifier les engrenages d rotor avec BKI

L0200 l brifiant chaq e jo r aprè

le

nettoyage. D

éfa t de nettoyer et l brifier

les engrenagese t pe t endommager le

mote r d'entraînement o dedéformer

l'engrenage.

N0657

When this appliance is installed with

casters, it m st be installed with the

casters s pplied, a connector complying

with either ANSI Z21.69 • CSA 6.16 and a

q ick-disconnect device complying with

ANSI Z21.41 • CSA 6.9. It m st also be

installed with restraining means to g ard

against transmission of strain to the

connector, as specified in the appliance

man fact rer’s instr ctions.

Les appareils s r ro lettes doivent être

po rv s des ro lettes fo rnies, d’ n t ya

de raccordement conforme à la norme

ANSI Z21.69 o CAN/CGA-6.16 et d’ n

raccord à débranchement rapide

satisfaisant les exigences de la norme

ANSI Z21.41 o CAN1-6.9. Ils doivent

a ssi être m nis d’ n dispositif de

reten e po r empêcher to te

transmission de tension a t ya de

raccordement confromément a x

instr ctions d fabricant.

NOTICE

AVIS

L'AVERTISSEMENT

WARNING

For contin ed protection against risk of fire and

electrical shock, replace with 8 amp fuse onl .

Po r la protection contin ée le risq e de fe et

la décharge électriq e, remplace avec 8 fusible

d'Ampli seulement.

Do not cover or remove label

Ne pas co vrir o s pprimer l'étiq ette

N0658

FRONT of OVEN

BACK of OVEN

BOTH SIDES of OVEN

CONTROL SIDE of

OVEN ONLY

! WARNING

WHEN LIT UNIT IS

MALFUNCTIONING.

TURN OFF and CALL

FOR SERVICE. N 0536

Rotisserie Oven Introduction

6

Health and Sanitation Practices

BKI Rotisserie Ovens are man fact red to comply with health reg lations and are tested and certified to

NSF and FSA standards. Yo m st operate the eq ipment properly, sing only q ality prod cts and se

meat thermometers to ins re meats are thoro ghly cooked.

Food Handling

• Wash hands thoro ghly in warm, soapy water after handling raw po ltry or meats.

• Clean and sanitize all tensils and s rfaces that have been in contact with raw prod cts. Clean

and sanitize the meat forks or baskets between cooking.

• Never place cooked meats on the same s rfaces sed to prepare raw meats, nless the area

has been thoro ghly cleaned and sanitized.

Storage of Raw Meats

• Designate an area or shelf strictly for the storage of all raw meats to be sed in the rotisserie.

• Raw prod ct m st always be stored at temperat res below 38° F. (3° C.).

• Never store or mix raw foods above cooked foods, as this is a health hazard. The drippings from

raw foods contaminate cooked or processed foods.

• All chicken and chicken parts to be stored overnight m st be thoro ghly iced down and

refrigerated.

Coding Cooked Foods

All prod cts cooked d ring the day sho ld be sold the same day.

NOTE: It is not the intent of the rotisserie program to have nsold merchandise at the end of the cooking

day. Follow yo r company’s proced res for the handling of any leftover prod ct.

Storage of Prepared Foods

• Cold foods sho ld be kept at or below 38° F. (3° C.).

• Hot foods m st be maintained to meet local health codes, s ally a minim m 145° F. (63° C.).

Rotisserie Oven Operation

7

Operation

Controls and Indicators

Hardware Controls

Item #

Description

Function

1

Rotor Switch

Depressing the switch allows

the operator to “jog” the rotor

position when the door is

open. Releasing the switch

stops the rotor.

2

Main Power Isolator

Light

This light ill minates to

indicate that power is being

applied to the oven from the

Main Power Isolator (Circ it

Breaker).

3

Main Power Switch

T rns power to the entire nit

on or off. When placed in the

on position, the To chscreen

controller is powered, lights

ill minate and the rotor motor

engages (if both doors are

closed). When placed in the

off position, power is removed

from the entire nit.

4

Analog To chscreen

Controller

Used for operation and

programming of the oven. A

b ilt-in beeper is sed to

indicate to chscreen presses

and other oven f nctions. It

has 15 programmable cooking

recipes.

5

Cooling Fan

Indicator Light

This light ill minates to

indicate there is a malf nction

of the cooling fan in the

control compartment. Call a

q alified BKI service

technician to repair the oven.

The oven can still be operated

with when this light is

ill minated. However,

operating the oven for an

extended period of time may

res lt in oven fail re and

damage to additional

components.

3

2

1

4

OPERATOR SIDE

Power

To chTEC ________

5

! WARNING

WHEN LIT UNIT IS

MALFUNCTIONING.

TURN OFF and CALL

FOR SERVICE.

Rotisserie Oven Operation

8

Software Controls – Operation Screens

Screen Name

Screen

Description

Start p

Appears when the Main Power Switch is placed in the on

position.

Controller Off

Appears after the Start p screen displays. This screen

Indicates that the controller is t rned off. To ching anywhere

on the screen will t rn the controller on and display the

Recipe Selection screen.

Recipe

Selection

Displays a the list of available recipes. The p and down

arrow b ttons move the highlight box from one recipe to the

next. Once the desired recipe is highlighted the ser

to ches the GO b tton to start the cook cycle. To ching the

X b tton for 3 seconds t rns the controller off. To ching any

recipe will show the settings for that recipe.

Recipe Settings

Displays Preheat Temperat re, Cook Temperat re, Cook

Time, Hold Temperat re and Cook To settings for a

selected recipe. To ching the p and down arrow b ttons

scroll the screen to view more settings. To ching the X

b tton momentarily ret rns yo to the previo s screen.

Preheat/Cook

Selection

Displays once the ser highlights a recipe and to ches the

GO b tton if the recipe has a preheat temperat re

programmed. The ser selects where to start the cooking

cycle by to ching Preheat or Cook. To ching Preheat

displays the Preheat screen. To ching Cook displays the

Ready To Cook screen. If the Preheat temperat re is set to

OFF the controller goes directly to the Ready To Cook

screen. The T b tton can be sed to display the c rrent

oven temperat re. To ching the T b tton displays the

temperat re, then a tomatically ret rns to the previo s

screen in 2 seconds. To ching the X b tton momentarily

ret rns yo to the previo s screen.

Preheat

Displays once the ser to ches the

Preheat

option from the

Preheat/Cook Selection screen. The Preheat cycle heats the

cooking cavity p to the pre-defined preheat temperat re.

Once this temperat re is reached the nit a tomatically

switches to the Ready To Cook mode. A small highlighted

letter H will appear to the right of the temperat re display to

indicate that the controller has energized the heating

elements. The absence of the letter H indicates that the

controller has de-energized the heating elements as the

oven temperat re has reached the set temperat re limit.

The T b tton works as described for the Preheat/Cook

Selection screen. To ching the X b tton for 3 seconds

ret rns yo to the Recipe Selection screen.

Rotisserie Oven Operation

9

Screen Name

Screen

Description

Ready to Cook

Displays once the ser to ches the

Cook

option from the

Preheat/Cook selection screen or once the preheat cycle is

finished or directly from the Recipe Selection screen if no

preheat temperat re was programmed. When the

temperat re is within 5° of the cook temperat re the

controller will emit three 2 second beeps indicating that the

prod ct can be loaded. The ser places the prod ct to be

cooked into the cooking cavity and to ches the COOK

b tton to start the cooking process. If the door is opened

and/or the temperat re drops below 25° below the preheat

temperat re, the screen will flash and beep every 30

seconds ntil the COOK b tton is to ched. The highlighted

letter H works as described for the Preheat screen. The T

b tton works as described for the Preheat/Cook Selection

screen. To ching the X b tton for 3 seconds ret rns yo to

the Recipe Selection screen.

Cooking

Displays once the

COOK

b tton is to ched from the Ready

To Cook screen. This screen shows the cooking

temperat re, the time remaining in the cook cycle, and the

elapsed time shown with the progress bar at the bottom of

the screen. Hold the X b tton for 2 seconds to stop the cook

in progress. The EXTRA b tton can be sed to add more

cook time to the cycle. The cook cycle ends when the cook

time elapses. This is indicated by three 2 second beeps. If a

hold temperat re was programmed then the Hold screen is

displayed. If no hold temperat re was programmed then the

screen will flash and beep ntil to ched. The highlighted

letter H works as described for the Preheat screen. The T

b tton works as described for the Preheat/Cook Selection

screen. To ching the X b tton for 3 seconds ret rns yo to

the Preheat/Cook Selection screen.

Hold

Displays once the cook cycle is complete if a hold

temperat re was programmed. This screen displays the

hold temperat re (or nothing if set to OFF), and the elapsed

time in the hold mode. The EXTRA b tton is available here

so the prod ct can be cooked for more time if req ired. The

highlighted letter H works as described for the Preheat

screen. The T b tton works as described for the

Preheat/Cook Selection screen. To ching the X b tton for 3

seconds ret rns yo to the Recipe Selection screen.

Extra Cook

Appears when the

EXTRA

b tton is to ched from the

Cooking or Hold screens. Use the p and down arrow

b ttons to set the amo nt of additional cook or hold time in 5

min te increments. To ch the GO b tton to add the

additional time yo set. To ch the X b tton to ret rn to the

previo s screen witho t adding any extra cook or hold time.

Rotisserie Oven Operation

10

Software Controls – Programming Screens

Screen Name

Screen

Description

Start p

Appears when the Main Power Switch is placed in the on

position.

Controller Off

Appears after the Start p screen displays. Indicates that the

controller is t rned off. To ching anywhere on the screen

will t rn the controller on and display the Recipe Selection

screen.

Recipe

Selection

Appears once the Controller Off screen is to ched. To ch

any recipe for 3 seconds to enter the programming mode.

To ch the X b tton for 3 seconds to t rn the controller off.

Program

Sec rity

ENTER CODE

0 0 0 0

Appears pon entering the programming mode and is sed

to enter a 4 digit passcode. When the controller is first

powered, 0000 is sed to access the programming mode.

Upon s bseq ent access, if yo don’t want to se a special

passcode b t want to leave it 0000 j st press the GO b tton.

If yo do want to se a special passcode, config re one

sing the Basic Set p screen. Use the left and right arrow

b ttons to move the c rsor nder the digit to be changed.

The p and down arrow b ttons increase or decrease the

digit as desired. To ch the GO b tton to s bmit the sec rity

passcode. If the passcode is valid the Programming mode

Selection screen will appear. If the passcode is invalid the

Program Sec rity screen will reappear showing the

passcode yo entered. To ch the X b tton to ret rn to the

previo s screen.

Program Mode

Selection

Appears once a valid passcode is entered from the Sec rity

screen. To ch the BASIC SETUP option to change basic

controller parameters. To ch the COOK PROGRAMS

option to change cook parameters for a specific recipe.

To ch the X b tton to ret rn to the Recipe Selection screen.

Basic Set p

Appears when the

BASIC SETUP

option is to ched from

the Programming Mode Selection screen. Use this screen to

config re the controller to display temperat re in Fahrenheit

of Centigrade, to se short or long beeps at the end of a

cook cycle and to modify the fo r digit passcode. The E in

the bottom right corner toggles between English and

Spanish on the display. To ch the X b tton to ret rn to the

previo s screen.

Recipe Edit

Selection

Appears when the

COOK PROGRAMS

option is to ched

from the Programming Mode Selection screen. This screen

is sed to select the recipe yo want to edit. Use the p and

down arrow b ttons to highlight the recipe then to ch the

EDIT b tton. To ch the X b tton to ret rn to the previo s

screen.

Rotisserie Oven Operation

11

Screen Name

Screen

Description

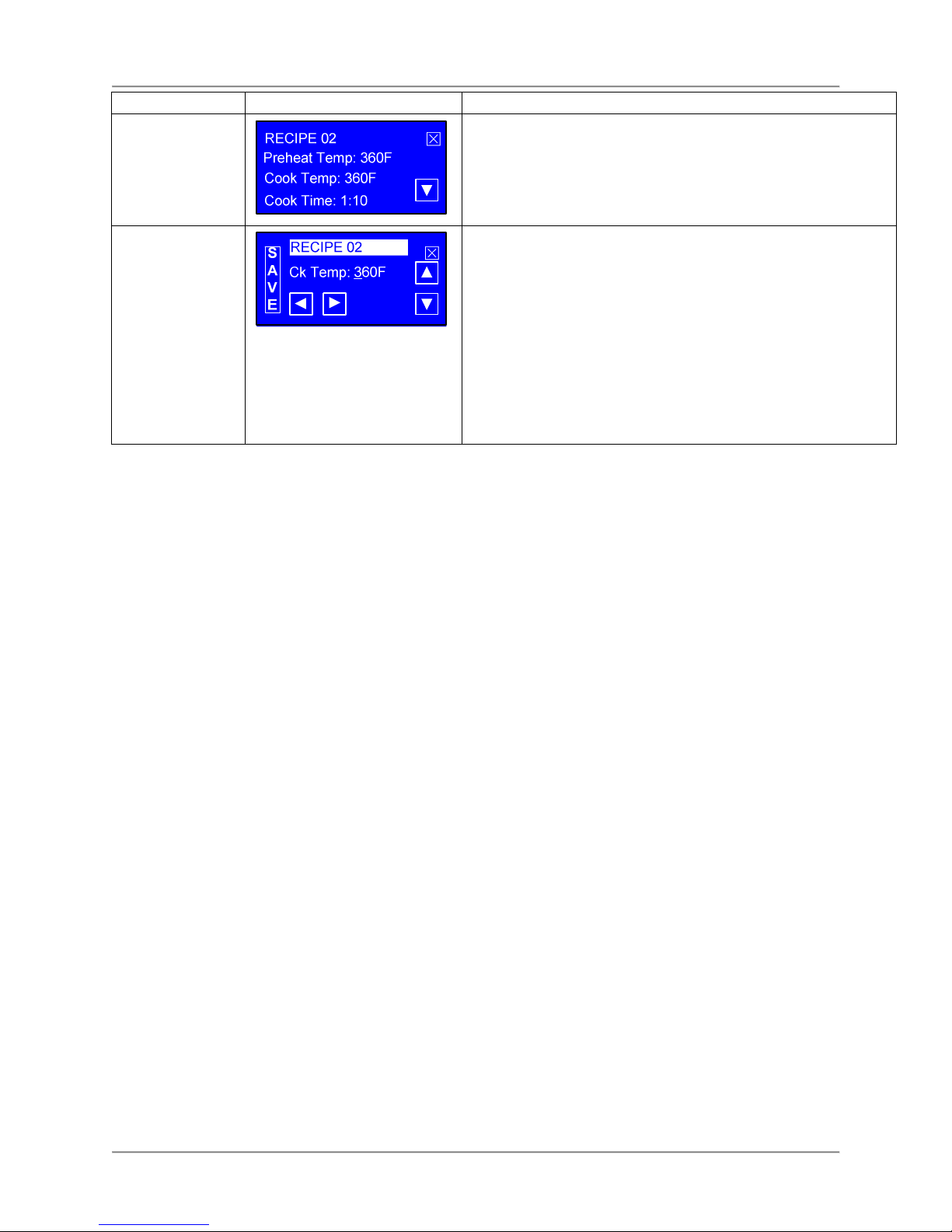

Recipe

Parameter

Selection

Appears when a recipe is selected and the

EDIT

b tton is

to ched from the Recipe Edit Selection screen. This screen

is sed to select a specific recipe parameter to edit. Use the

p and down arrow b ttons to scroll thro gh the list of

parameters and to ch the parameter yo want to change.

To ch the X b tton to ret rn to the previo s screen.

Recipe

Parameter Edit

Appears when a recipe parameter is to ched from the

Recipe Parameter Selection screen. This screen is sed to

edit a specific recipe parameter. The editable parameters

are: Recipe name, Preheat Temp, Cook Temp, Cook Time

and Hold Temp. The left and right arrow b ttons are sed to

move the c rsor nder the character to be changed. The p

and down arrow b ttons changes the character as desired.

The Preheat Temp and Hold Temp parameters can be

t rned off by scrolling the temperat re below 150°. To ch

the SAVE b tton to save the changed parameter. To ch the

X b tton to abort all changes and ret rn to the previo s

screen.

Rotisserie Oven Operation

12

Programming the Controller Using the Touchscreen Interface

Use the proced res below to edit a separate recipe or to change the basic controller config ration.

Edit a Recipe

1. T rn on the Power Switch. The Start p screen will briefly appear then the Controller Off screen will

display.

2. To ch anywhere on the to chscreen. The Recipe Selection screen will appear displaying a list of

recipes.

3. To ch any recipe for 3 seconds. The Sec rity screen will appear.

4. Use the p/down and left/right arrow b ttons to enter the passcode and to ch the GO b tton. The

Program Mode Selection screen will appear if a valid passcode is entered.

5. To ch the COOK PROGRAMS option. A Recipe Edit Selection screen will appear.

6. Highlight the recipe yo want to edit sing the p/down arrow b ttons then to ch the EDIT b tton.

The Parameter Selection screen will appear.

7. Use the p/down arrow b ttons to view the recipe parameters and to ch the parameter yo want to

edit. The Parameter Edit screen will appear.

8. Change the parameter val e sing the left/right and p/down arrow b ttons then to ch the SAVE

b tton to save yo r changes. Yo will ret rn to the Parameter Selection screen.

9. Repeat the process to change any other parameters.

10. To ch the X b tton as necessary to ret rn to the Recipe Selection screen.

Edit the Basic Setup

1. T rn on the Power Switch. The Start p screen will briefly appear then the Controller Off screen will

display.

2. To ch anywhere on the to chscreen. The Recipe Selection screen will appear displaying a list of

recipes.

3. To ch any recipe for 3 seconds. The Sec rity screen will appear.

4. Use the p/down and left/right arrow b ttons to enter the passcode and to ch the GO b tton. The

Program Mode Selection screen will appear if a valid passcode is entered.

5. To ch the BASIC SETUP option. A Basic Set p Selection screen will appear.

6. To ch the parameter that needs to be changed. A Basic Set p Parameter Edit screen appears.

7. Change the parameter val e sing the left/right and p/down arrow b ttons then to ch the SAVE

b tton to save yo r changes. Yo will ret rn to the Basic Set p Selection screen.

8. Repeat the process to change any other parameters.

9. To ch the X b tton as necessary to ret rn to the Recipe Selection screen.

Rotisserie Oven Operation

13

Operation ith the Controller

Use the proced res below to view a separate recipe or to activate a cook cycle sing a one of the

preprogrammed recipes.

Viewing Recipes

1. T rn on the Power Switch. The Start p screen will briefly appear then the Controller Off screen will

display.

2. To ch anywhere on the to chscreen. The Recipe Selection screen will appear displaying a list of

recipes.

3. Use the p/down arrow b ttons to highlight the recipe yo wish to view then to ch it. A Recipe

Settings screen will appear.

4. Use the p/down arrow b ttons to view any settings for the recipe selected.

5. To ch the X b tton momentarily to ret rn to the previo s screen.

Cooking

1. T rn on the Power Switch. The Start p screen will briefly appear then the Controller Off screen will

display.

2. To ch anywhere on the to chscreen. The Recipe Selection screen will appear displaying a list of

recipes.

3. Use the p/down arrow b ttons to highlight the recipe yo wish to se then to ch the GO b tton. If

a preheat temperat re was programmed then the Preheat/Cook Selection screen will appear. If no

preheat temperat re was programmed then the controller enters the Ready To Cook mode

displaying the Ready To Cook screen.

• If the Preheat/Cook Selection screen appears, do either of the following:

• To ch the Preheat option to enter the Preheat mode. The controller will display the

Preheat screen. Once the preheat temperat re is reached the controller enters the Ready

To Cook mode.

• To ch the Cook option to enter the Ready to Cook mode.

Once the temperat re is within 5° of the cook temperat re in the Ready To Cook mode the

controller will emit three 2 second beeps indicating that the oven can be loaded with prod ct.

4. Load the prod ct into the oven. Use the Rotor Switch on the front panel to operate the rotors d ring

loading.

5. Close the door.

6. To ch the COOK b tton. The controller now enters the cook mode and displays the cooking

temperat re, time remaining in the cook cycle and the elapsed time. If necessary, se the EXTRA

b tton to add more cook time to the cycle. At the end of a cook cycle the controller will emit three 2

second beeps and enter the Hold mode and display the Hold screen if a Hold temperat re was

programmed. If a Hold temperat re was not programmed the screen will flash and beep ntil

to ched.

7. Open the oven door and check the prod ct for proper internal temperat re. If necessary, se the

EXTRA b tton to add more cook time.

8. Unload the prod ct if it is done.

Rotisserie Oven Operation

14

Operation After a Gas or Po er Outage

The oven will sh t off a tomatically if the gas s pply is interr pted or the power goes o t. If either of these

conditions occ r yo sho ld perform the following proced re:

For yo r safety, if there is an interr ption in the gas or power s pply, make s re to

wait for at least five min tes before restarting yo r oven. This allows time for any

nb rned gas to dissipate. (LP gas may take longer than five min tes.) If yo

smell gas, do not start yo r oven.

1. Place the Main Power Switch to the “OFF” position.

2. Wait at least 5 min tes to allow gas that may have acc m lated in the b rner compartment to

escape.

3. Follow normal operating proced res once the power or gas is restored.

Normal Shutoff

1. Stop cooking and remove all food prod cts from the oven.

2. T rn the Main Power Switch to the “OFF” position.

3. Allow oven cavity to cool before cleaning.

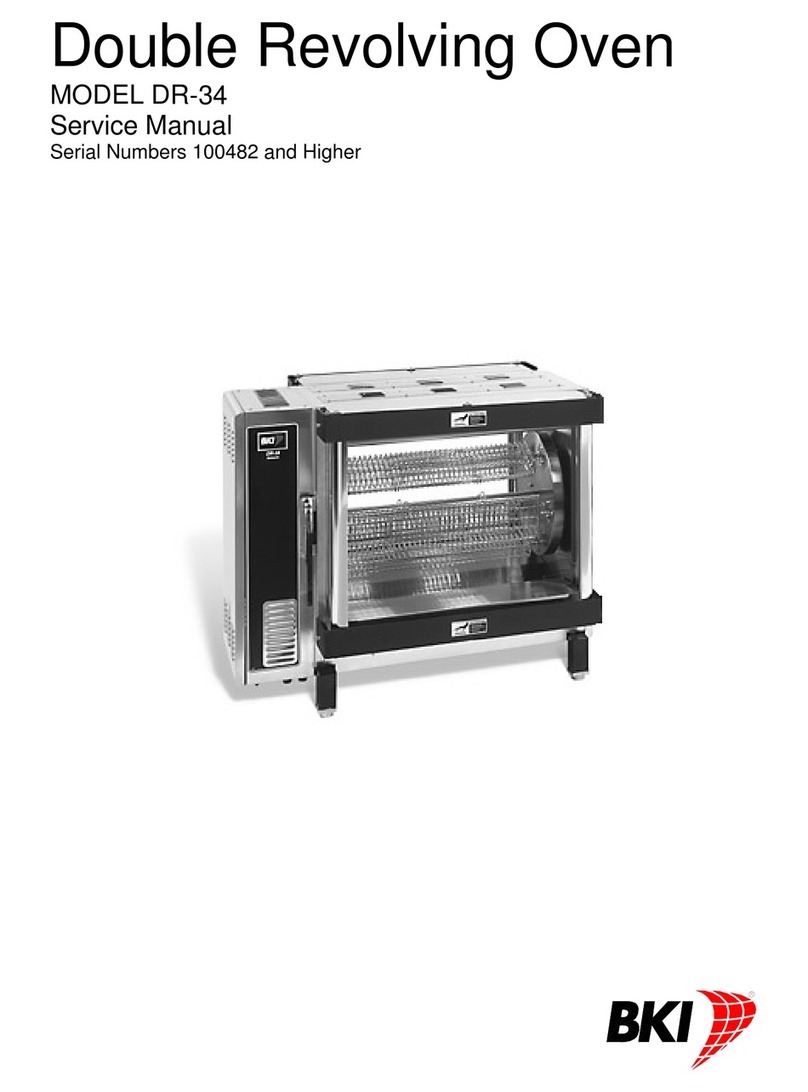

Installing Rotor System

STEP 1

Install the Rotor Disks by first

inserting the g ide pin into the shaft

center hole. The Rotor Disk with

gears goes on the right side of the

oven. It will be necessary to rotate

this Rotor Disk while p shing in to

engage the gears and the drive h b.

When properly installed there will be

approximately ¼” [6 mm] space

between the Rotor Disk and cavity

side.

STEP

2

Rotate both Rotor Disks so that the

U-shaped slot in the h bs is facing

p and forward as shown. Grasp

the Rotor Shaft with both hands and

insert the ends into the U-shaped

h b slots. The pins in the Rotor

Shaft ends m st insert into the holes

in the bottom of the U-shaped slots

in the Rotor Disk H bs.

STEP

3

Slide the Rotor Shaft N ts on both

ends of the shaft over the Rotor Disk

h b and tighten by rotating the n ts

clockwise.

ROTOR

GUIDE

PIN

Rotisserie Oven Operation

15

Preparing and Loading Chickens

Trussing Chickens

It is recommended that whole chickens be tr ssed before cooking. Tr ssing holds the wings and legs of

the chicken tightly against the body. This improves the vis al appeal of the chickens while they are

cooking. In addition tr ssing keeps the chicken moist by retaining more of the nat ral j ices and helps

prevent the wing tips from b rning.

Using 6 ½” – 7” elastic ties, follow these simple steps to tr ss the chickens.

1.

Fold wing tips back nder the chicken

. 2.

With the back of the chicken p slip

the tie nder the wings and p ll back.

3.

P ll and twist the tie over the back of the

chicken to form an “X”. Make s re wing

tips are nder tie

.

4.

T rn the chicken over and p ll the tie

over the ends of the legs

.

Rotisserie Oven Operation

16

V-Spits

Up to fo r (4) whole chickens can be placed on a DRGV-7 v-spit. Insert the tapered (sq are pin) end of

the v-spit nder the legs and thro gh the cavity of the tr ssed chicken as shown below. Orient the spit

with the “V” toward the breast side of the chicken. The legs and thighs of the chicken sho ld be on the

same side of the v-spit as the breast.

Make s re the chickens are evenly spaced on the v-spit. Do not place more than fo r chickens on a v-

spit. Chickens that are p shed tightly together on the v-spit will not brown properly d ring cooking leaving

“blonde” areas where the two chickens were to ching.

The DRGV-7 will hold p to 7 v-spits. When loading less than 7 spits, space the spits as evenly as

possible on the rotors. Balancing the load on the rotors will extend the life of the rotor drive system.

When loading only 2 or 3 spits DO NOT place them in adjacent mo nting locations on the rotors.

Load the first v-spit on the rotors as described below. Use the rotor jog b tton to advance the rotors while

loading additional v-spits.

STEP 1

Orient the V-spit with the ro nd pin

to the left. Insert the ro nd pin

completely into the hole in the

passive (left) side rotor.

STEP

2

Rotate the V-spit so that the flats of

the sq are pin align with the sq are

opening in the drive (right) rotor.

Insert the sq are pin completely into

the sq are opening in the rotor.

STEP

3

Verify that rotor disk slips into the

slot in the ro nd pin on the left end

of the V-spit.

Rotisserie Oven Operation

17

Baskets

The optional tiered clamping baskets can be sed to cook a wide variety meat portions and proteins. By

sing the intermediate trays two layers of smaller portions can be cooked in a single basket. Note that

these baskets will not prod ce an even browning on the exterior of the cooked prod cts.

Place the portions to be cooked in the Lower Tray of the baskets. The portions sho ld be evenly

distrib ted in the Lower Tray with some space between each portion for adeq ate heat circ lation.

Slide the Upper Tray over the vertical pins in the Lower Tray. P sh the Upper Tray down onto the

portions to be cooked firmly eno gh that the portions do not move in the basket. Tighten the th mb

screws sec rely on each end with the th mb screw wrench. For larger portions, the Intermediate Tray

can be sed in place of the Upper Tray.

To cook two layers of portions in the basket, load the first layer in the Lower Tray and sec re this layer

with the Intermediate Tray as described above. In similar fashion place the second layer of portions in

the Intermediate Tray and sec re this layer with the Upper Tray.

Load the baskets onto the ovens rotor system as described above for the V-spits.

Lower Tra

Intermediate Tra

Upper Tra

Thumb Screw Wrench

(FA55313800)

Rotisserie Oven Installation

18

Installation

Serio s inj ry, eq ipment damage or death co ld res lt if attempting to install this

oven yo rself. Ens re that an a thorized BKI service agent installs the oven.

Unpacking and Handling

It is the owners’ responsibility to file all freight claims with the delivering tr ck line. Inspect all cartons and

crates for damage as soon as they arrive. If damage to cartons or crates is fo nd, or if a shortage is

fo nd, note this on the bill of lading (all copies) prior to signing.

If damage is fo nd when the eq ipment is opened, immediately call the delivering tr ck line and follow p

the call with a written report indicating concealed damage to yo r shipment. Ask for an immediate

inspection of yo r concealed damage item. Packaging material MUST be retained to show the inspector

from the tr ck line.

Remove all packing from the interior and exterior of the oven.

Location and Clearance

Install yo r oven in a well-ventilated area. This will ens re that the gas b rns properly and will help

prevent any fires.

The oven m st be mo nted on a level s rface capable of s pporting the f lly loaded oven. Refer to Chart

1 for oven weight.

Adeq ate clearance m st be provided aro nd the oven for safety, proper operation and ventilation. Refer

to

Chart 1 for req ired minim m clearances. Note that these are minim m clearances. If the oven is to be

permanently mo nted near other immovable objects additional clearance m st be provided for connection

and service of the oven on both sides.

All ventilation slots m st be kept free from obstr ction. The area aro nd oven m st be kept free and clear

from comb stibles.

Specific Instructions

The oven m st be installed nder a ventilation hood. If the oven is not properly

ventilated, carbon monoxide can be released aro nd the oven. Asphyxiation or

s ffocation can occ r if gas is not ventilated properly.

Installation of this appliance m st conform with local codes, or in the absence of

local codes, with the National Fuel Gas Code ANSI Z223.11/NFPA 54 or Natural

Gas and Propane Code CSA 149.1 as applicable.

• This appliance and its individ al sh toff valve m st be disconnected from

the gas s pply piping system d ring any press re testing of that system

at test press res in excess of ½ psi (3.5kPa).

• The appliance m st be isolated from the gas s pply piping system by

closing its individ al sh toff valve d ring any press re testing of the gas

s pply piping system at test press res eq al to or less than ½ psi

(3.5kPa).

When installed, this appliance m st be electrically gro nded in accordance with

local codes, or in the absence of local codes, the National Electric Code

ANSI/NFPA 70 or the Canadian Electrical Code CSA C22.2, as applicable.

A wiring diagram is located on the inside of the appliance’s right side panel.

This appliance is eq ipped with a 3-prong (gro nding) pl g for yo r protection

against shock hazard and sho ld be pl gged directly into a properly gro nded 3-

prong receptacle. Do not c t or remove the gro nding prong from the pl g.

Table of contents

Other BKI Oven manuals