BKT Elektronik BKT AL200 User manual

BKT Elektronik - Headquarter

Poland, Lochowska 69 Str.

86-005 Biale Blota

Phone: +48 52 36 36 750

e-mail: export@bkte.pl

www.bkte.pl

BKT AL200

Electronic locking & monitoring swinghandle with

mechanical override

- user manual

Version 2

© 2021 BKT Elektronik

AL200 swinghandle manual

2

Table of contents

1Introduction................................................................................................................................................................................................3

1.1 General information ........................................................................................................................................................................3

1.2 Device characteristics ......................................................................................................................................................................3

2Technical specifications ...............................................................................................................................................................................3

3Assembly.....................................................................................................................................................................................................4

3.1 Package Contents............................................................................................................................................................................4

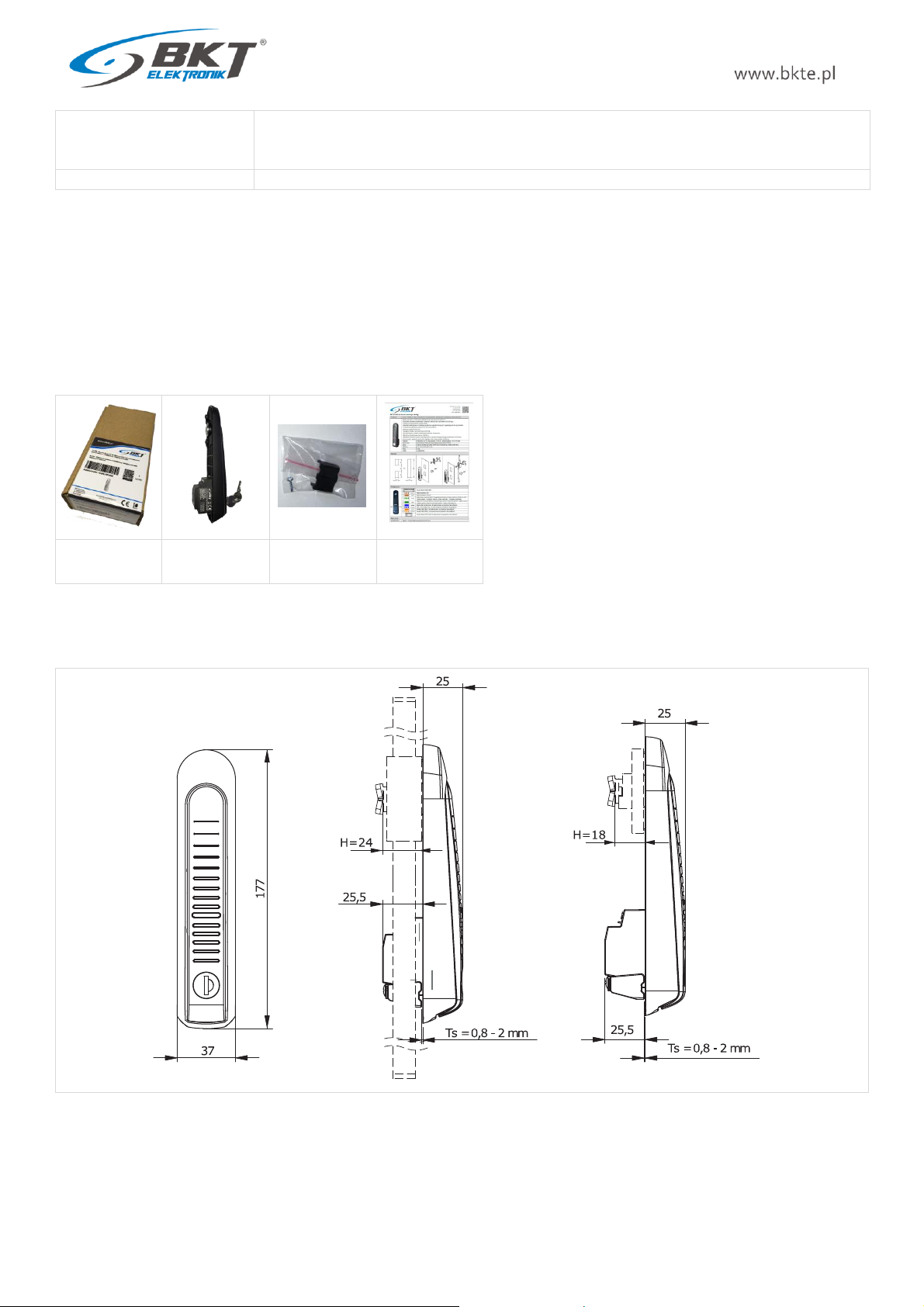

3.2 Dimensions......................................................................................................................................................................................4

3.2.1 Swinghandle dimensions ...................................................................................................................................................4

3.2.2 Cut out dimensions............................................................................................................................................................5

3.2.3 Cogwheel dimensions........................................................................................................................................................5

3.2.4 Cam dimensions................................................................................................................................................................5

3.3 Single point assembly ......................................................................................................................................................................6

3.4 Multi-point assembly.......................................................................................................................................................................6

3.5 Connection......................................................................................................................................................................................7

4Operation....................................................................................................................................................................................................7

4.1 Electrical opening ............................................................................................................................................................................7

4.2 Handle position indication ...............................................................................................................................................................8

4.3 Working status indication ................................................................................................................................................................8

5Accessories .................................................................................................................................................................................................8

6Document revisions.....................................................................................................................................................................................9

AL200 swinghandle manual

3

1Introduction

1.1 General information

Warning:

This is a Class A product. In a domestic environment this product may cause radio interference in which case the user may be required to take

adequate measures.

The specification is owned and copyrighted by BKT Elektronik Sp. z o.o. Information contained herein may be changed at owner’s discretion

without any notice. BKT Elektronik may not be held liable for any possible inaccuracies and discrepancies in this document.

1.2 Device characteristics

The AL200 is an electronic swinghandle for ICT cabinets. It allows opening of cabinet doors in a standard way and by electrical remote control. It

can operate with any access control system. The device has a handle position indication. Thanks to the installed cylinder, it is also possible to

open it with a key.

Basic features:

It allows the remote opening from any external access control systems.

Equipped with the optical sensor of the handle position.

Two multi-pin connectors providing control and status signals of the handle.

Three-color LED signalling the operation status of the swinghandle.

Emergency key override.

Available inserts for the master key system.

For use with indoor cabinets.

Installation in a standard 150x25mm cut out.

Can be installed in a single and multi-point locking system (requires additional elements - cam or cogwheel mechanism, which should

be ordered separately).

2Technical specifications

Parameter

Value

Power supply voltage

Nominal 12V DC, allowed 10-24V DC, recommended power supply 12V DC ≥500mA

Quiescent current consumption

110 mA at 10 V

90 mA at 12 V

60 mA at 24 V

Maximal current consumption

when opening/closing (200ms)

300 mA at 10 V

250 mA at 12 V

150 mA at 24 V

Connectors

Type 53047-0810 8-pin connector, type 53047-0410 4-pin connector

Dimensions

177 x 37 x 51mm (H x W x D)

Weight

150g

Packaging dimensions

200 x 100 x 50 mm (W x D x H)

Packaging weight

200g

Operating conditions

Temperature: 0°C - 50°C, Humidity: 0% - 90% RH (without condensation)

Storage conditions

Temperature: -10°C - 60°C, Humidity: 0% - 95% RH (without condensation)

Enclosure material

Glass fibre reinforced polyamide PA6 GF30

Enclosure colour

Black, RAL 9005

Enclosure protection degree

IP30

Compliance with directives

2014/30/EU (EMC), 2011/65/EU (RoHS)

Compliance with standards

EN 61000-4-2:2009 Electrostatic discharge immunity test.

EN 61000-4-3:2007 Radiated, radio-frequency, electromagnetic field immunity test

EN 61000-4-4:2012 Electrical fast transient/burst immunity test.

EN 61000-4-5:2014 Surge immunity test.

AL200 swinghandle manual

4

EN 61000-4-6:2014 Immunity to conducted disturbances, inducted by radio-frequency fields.

EN 61000-6-4:2007/A1:2011 Electromagnetic compatibility (EMC) –Emission standard for industrial

environments.

Part number

122AL002000

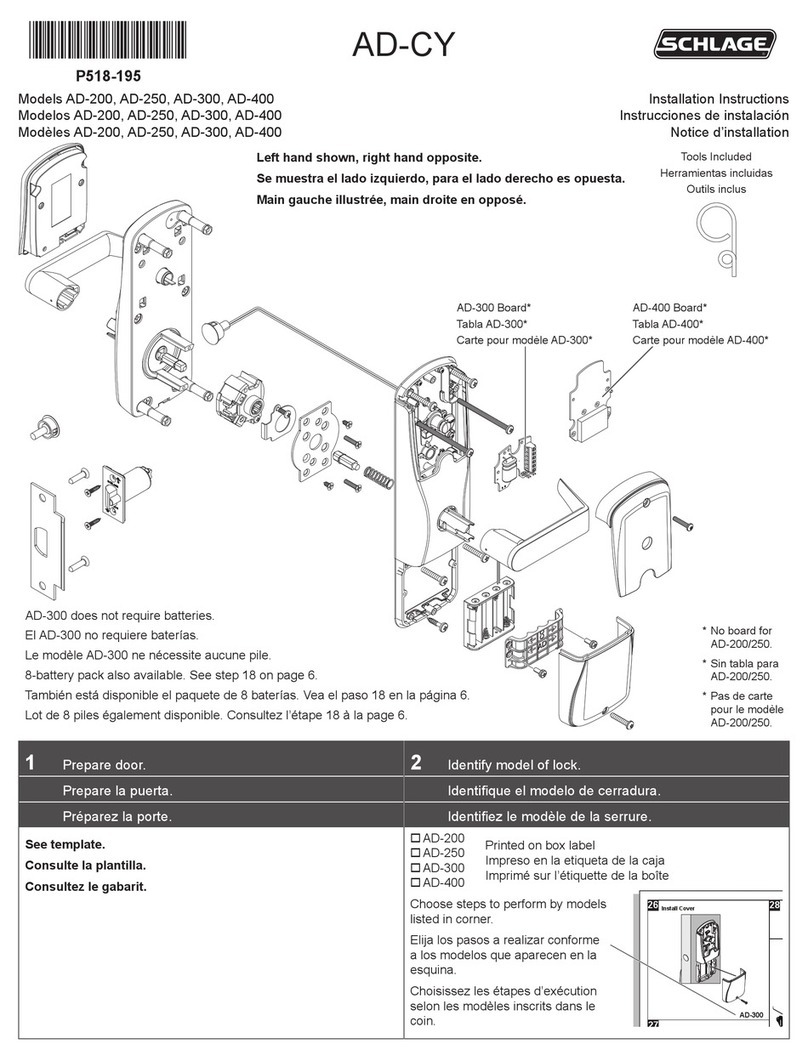

3Assembly

The swinghandle can work in a single-point system (only with a cam) or a multi-point system (with a cogwheel mechanism and a cam). The

package does not contain all the mounting elements. Additional mounting elements dedicated to the respective cabinet must be ordered

separately.

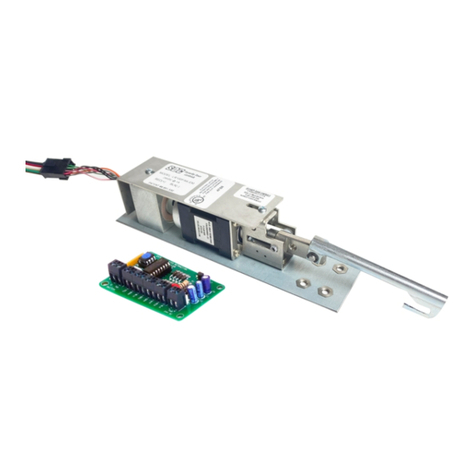

3.1 Package Contents

Packaging

AL200 swinhandle

Fastening element

with screw

Quick Start Guide

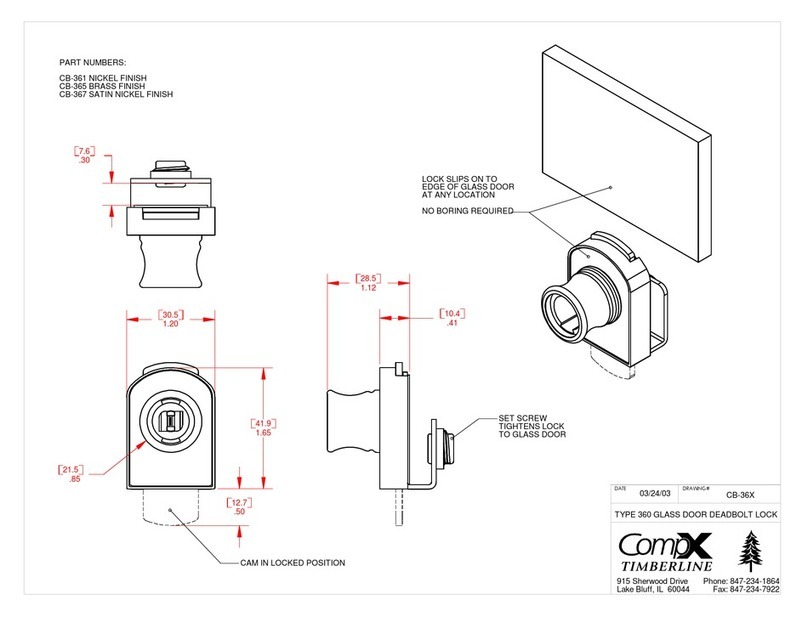

3.2 Dimensions

3.2.1 Swinghandle dimensions

AL200 swinghandle manual

5

3.2.2 Cut out dimensions

3.2.3 Cogwheel dimensions

3.2.4 Cam dimensions

or

AL200 swinghandle manual

6

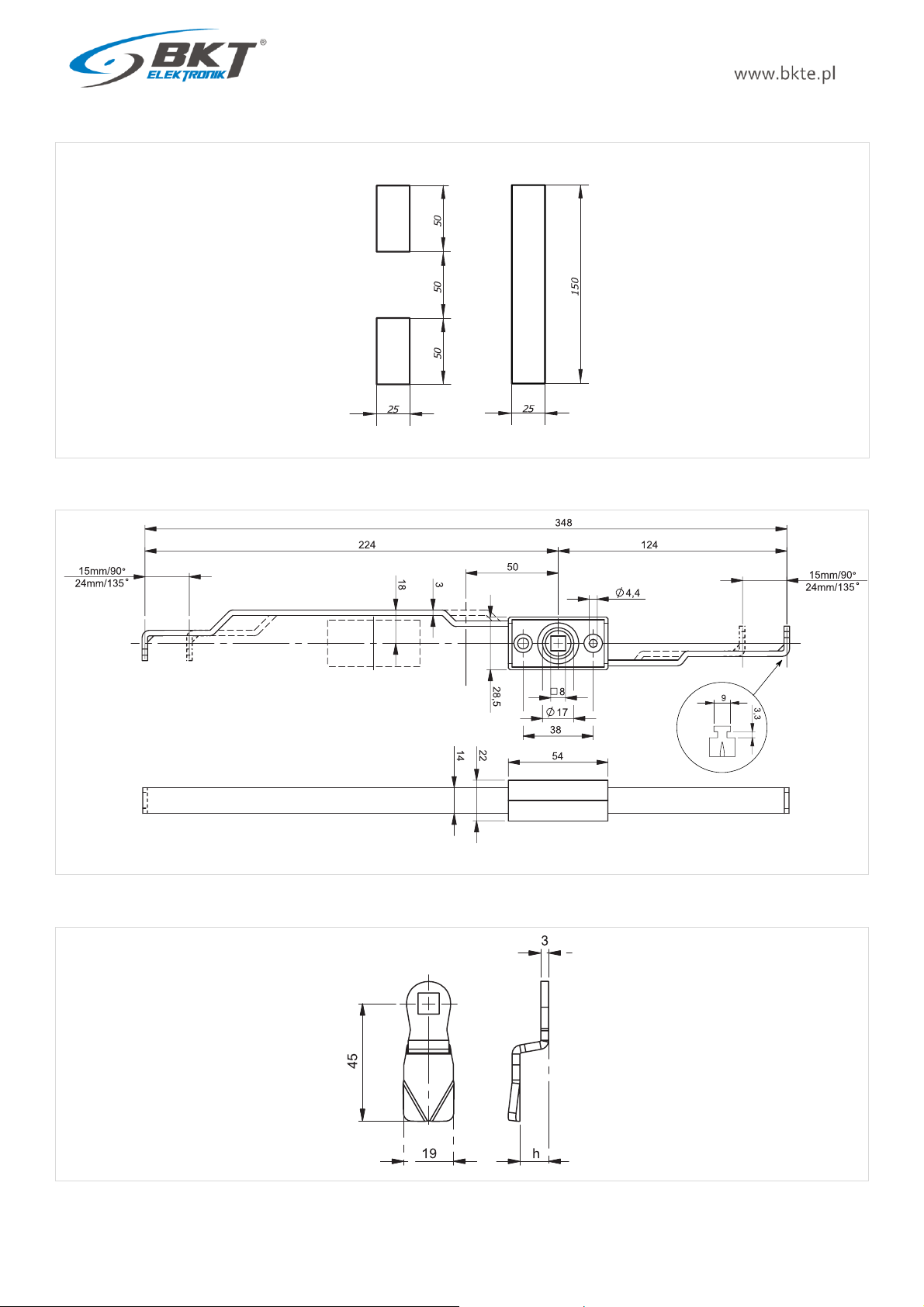

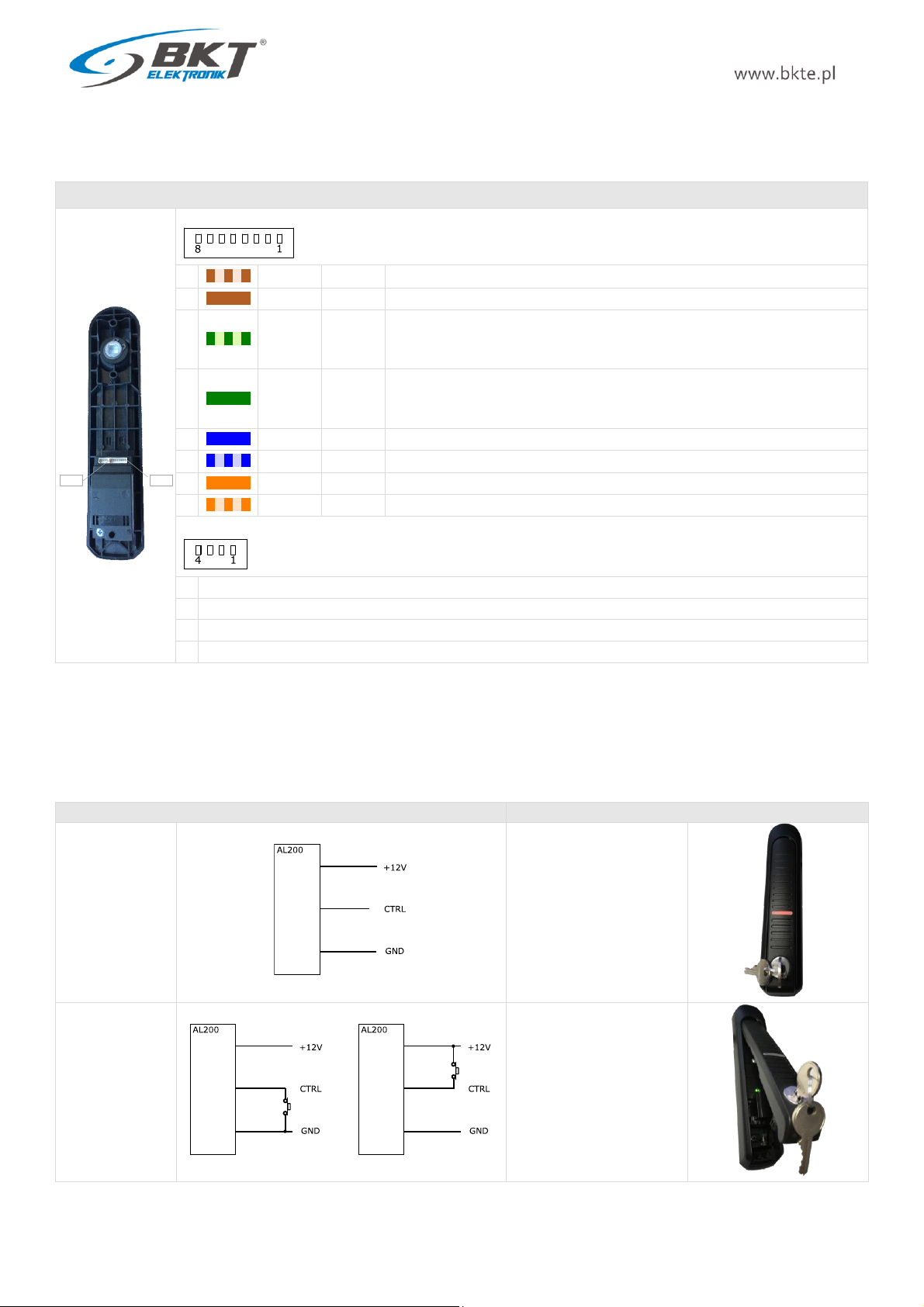

3.3 Single point assembly

1

122AL002000

AL200 swinghandle

2

Fastening element with screw

3

122AM002021

Cap

4

122AM002022

Cap adapter

5

122AM002023

Cap screw F4.1x12

6

122AM002024

Cam bolt M6x8

7

122AM002100

Cam h=0mm (locking height H=18mm)

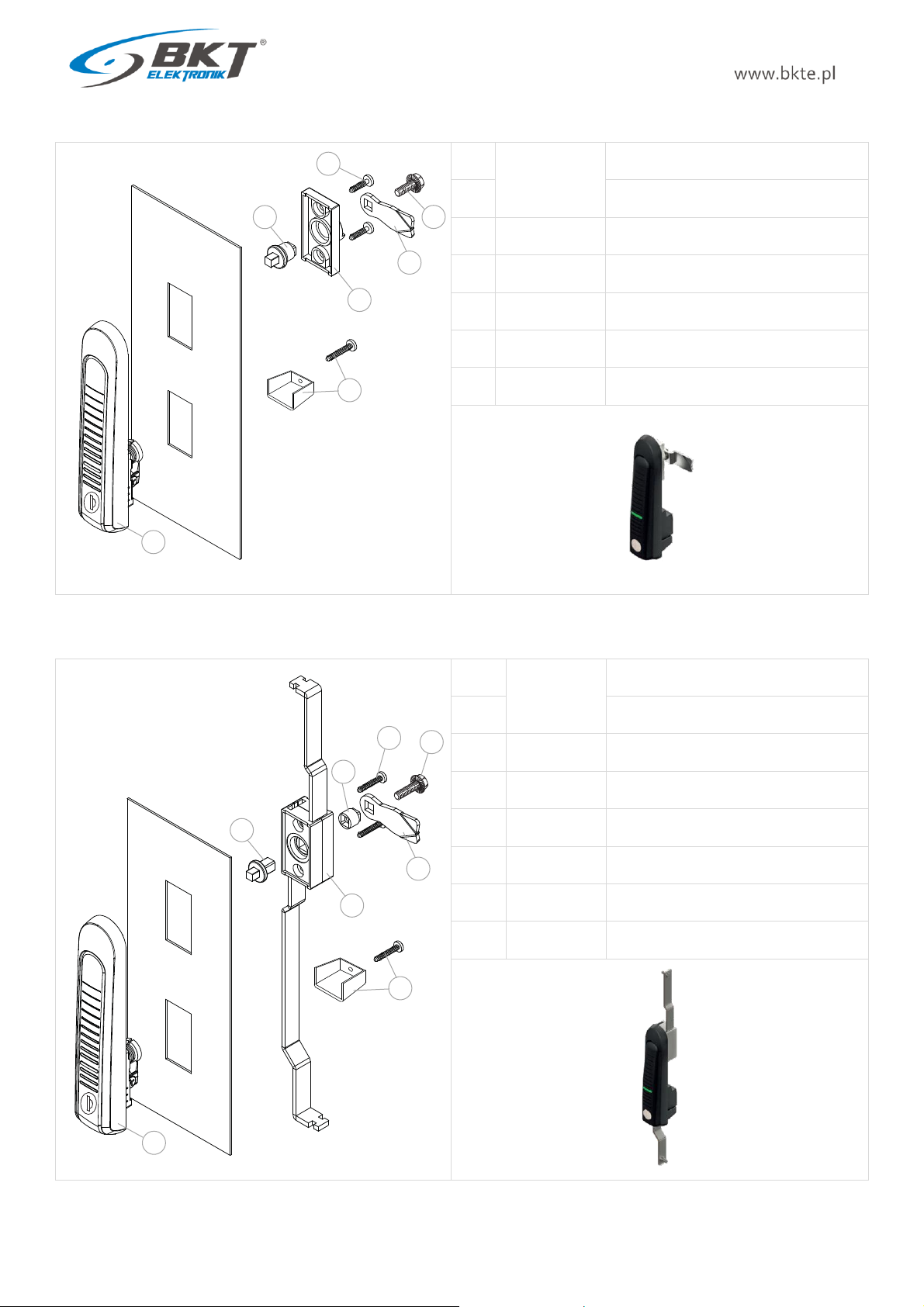

3.4 Multi-point assembly

1

122AL002000

AL200 swinghandle

2

Fastening element with screw

3

122AM002001

Cogwheel mechanism

4

122AM002002

Cogwheel mechanism adapter

5

122AM002003

Bushing for cam

6

122AM002004

Cam bolt M6x16

7

122AM002005

Cogwheel screw F4.1x22

8

122AM002006

Cam h=0mm (locking height H=24mm)

1

2

4

3

5

7

6

1

2

4

3

6

8

7

5

AL200 swinghandle manual

7

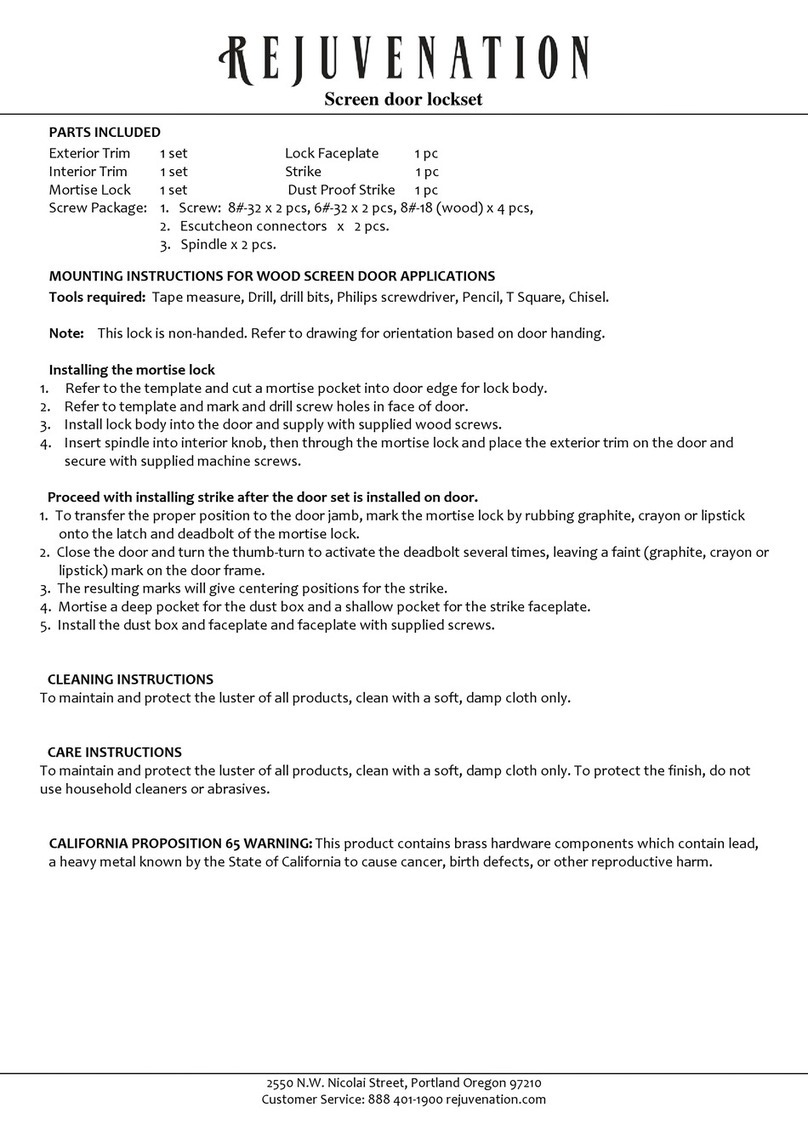

3.5 Connection

To connect the handle to external access control systems, use the AW200 or AW205 cable (see chapter 5 Accessories). The cable can be extended

to a maximum length of 100m using UTP Cat5e cable.

Connectors

Socket type 53047-0810

1

w/brown

GND

Power supply input: GND

2

brown

+12V

Power supply input: +12V DC

3

w/green

STATUS

Open collector output for signalling the position of the handle, IC=50mA, UCE=25V.

Handle open -> NPN transistor open (active)

Handle closed -> NPN transistor closed (inactive)

4

green

CTRL

Input for controlling the swinghandle from an external system.

Opening the handle -> CTRL shorted to GND or +12V

Closing the handle -> CTRL not connected

5

blue

SENSOR

Door sensor input - for the future use. Do not connect.

6

w/blue

GND

GND - for the door sensor - for the future use. Do not connect.

7

orange

CANL

CAN bus interface (CANL) - for the future use. Do not connect.

8

w/orange

CANH

CAN bus interface (CANH) - for the future use. Do not connect.

Socket type 53047-0410 for the future use. Do not connect.

1

For the future use. Do not connect.

2

For the future use. Do not connect.

3

For the future use. Do not connect.

4

For the future use. Do not connect.

4Operation

4.1 Electrical opening

Electric opening is made by shorting the CTRL input to the GND or +12V potential. If the CTRL input is not connected anywhere, then the

swinghandle remains closed.

CTRL input state

Swinghandle lock status

CTRL input not

connected

Lock is closed

CTRL input not

connected to

GND or +12V

Lock is open

PIN 1

PIN 8

or

AL200 swinghandle manual

8

4.2 Handle position indication

The device has an optical sensor of the handle position, thanks to which this information can be transferred to an external access control system.

The state of the STATUS output corresponds to the position of the handle. The STATUS output has overload protection. If the current through

the transistor is greater than 50mA, the output will be turned off. The STATUS output will return tonormal operation after removing the overload

and changing the position of the handle.

Position of the handle

STATUS output state

Handle closed

STATUS output inactive (NPN

transistor closed)

Handle open

STATUS output active (NPN

transistor open)

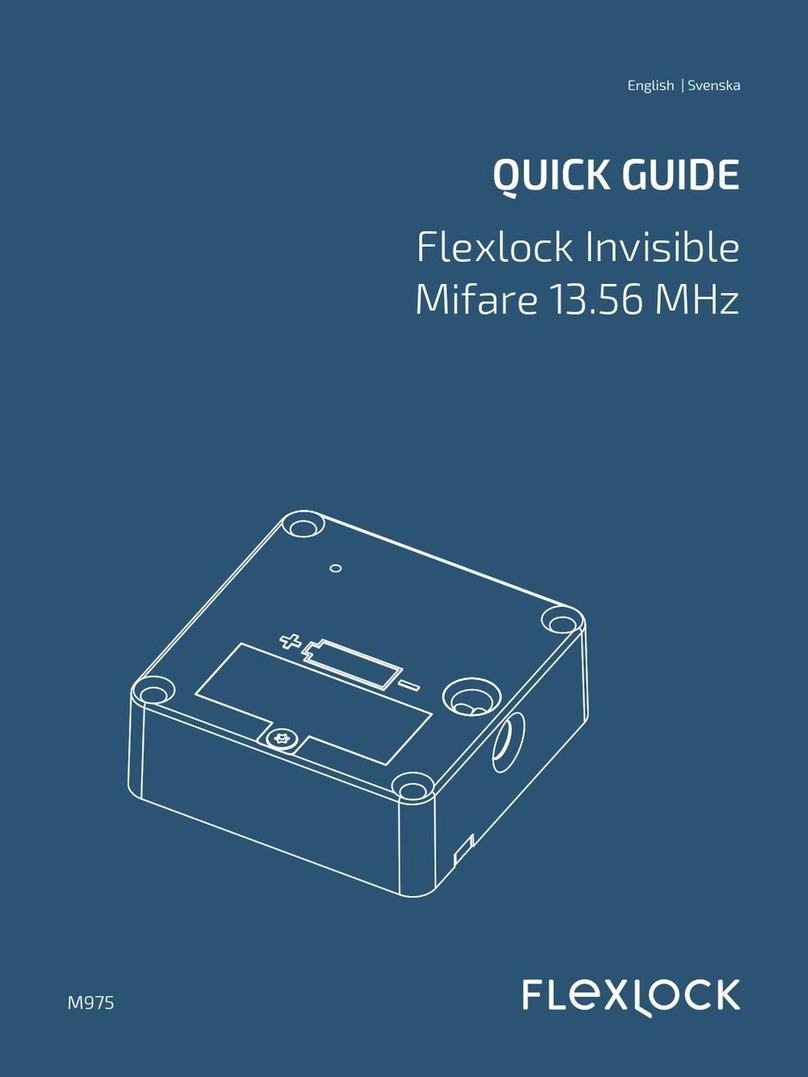

4.3 Working status indication

The swinghandle has a three-color LED indicating the status of its operation.

LED state

Swinghandle working state

Orange is on

The device is in programming mode

Orange blinking

The device is booting (within 3 seconds after connecting the power)

or firmware error (if it blinks for more than 3 seconds)

Red is on

The electric lock of the device is closed (no control on the CTRL input)

Red blinking

The electric lock of the device is closed (no control on the CTRL input), but the

handle is open.

Green is on

The electric lock of the handle is open (controlled on the CTRL input)

5Accessories

Product

Description

Part number

AW200 - AL200 swinghandle connection cable, length 0,5m; connectors: 1-plug, 2-ferrules

122AW002000

AW205 - AL200 swinghandle connection cable, length 5m; connectors: 1-plug, 2-ferrules

122AW002050

LED

AL200 swinghandle manual

9

6Document revisions

Version

Changes

Date

1

Initial version.

March 2021

2

Updated 3.2, 3.3 and 3.4

July 2021

Table of contents

Other BKT Elektronik Lock manuals