BLACK STAR APOLLO Series User manual

Blaclc.

♦

Star

APOLLO

SERIES

OF

UNIVERSAL COUNTER TIMERS

APOLLO

10

APOLLO 100

APOLLO

100

UNIVERSAL

COUNTER-TIMER

APOLLO 10X

APOLLO 100X

~Bla~ck

♦

~Star~~~~~~~~

INPUT&-

rNPUTA-

=

cc.~-

llC,tDOWNo-

Service

Manual

SPECIFICATION

INTRODUCTION

FUNCTIONAL DESCRIPTION

CIRCUIT DESCRIPTION

VOLTAGE CONVERSION

CALIBRATION

TROUBLE SHOOTING

AND

FAULT FINDING GUIDE

PARTS LIST

DIAGRAMS:

INDEX

MECHANICAL

ASSEMBLY

FUNCTIONAL BLOCK

DIAGRAM

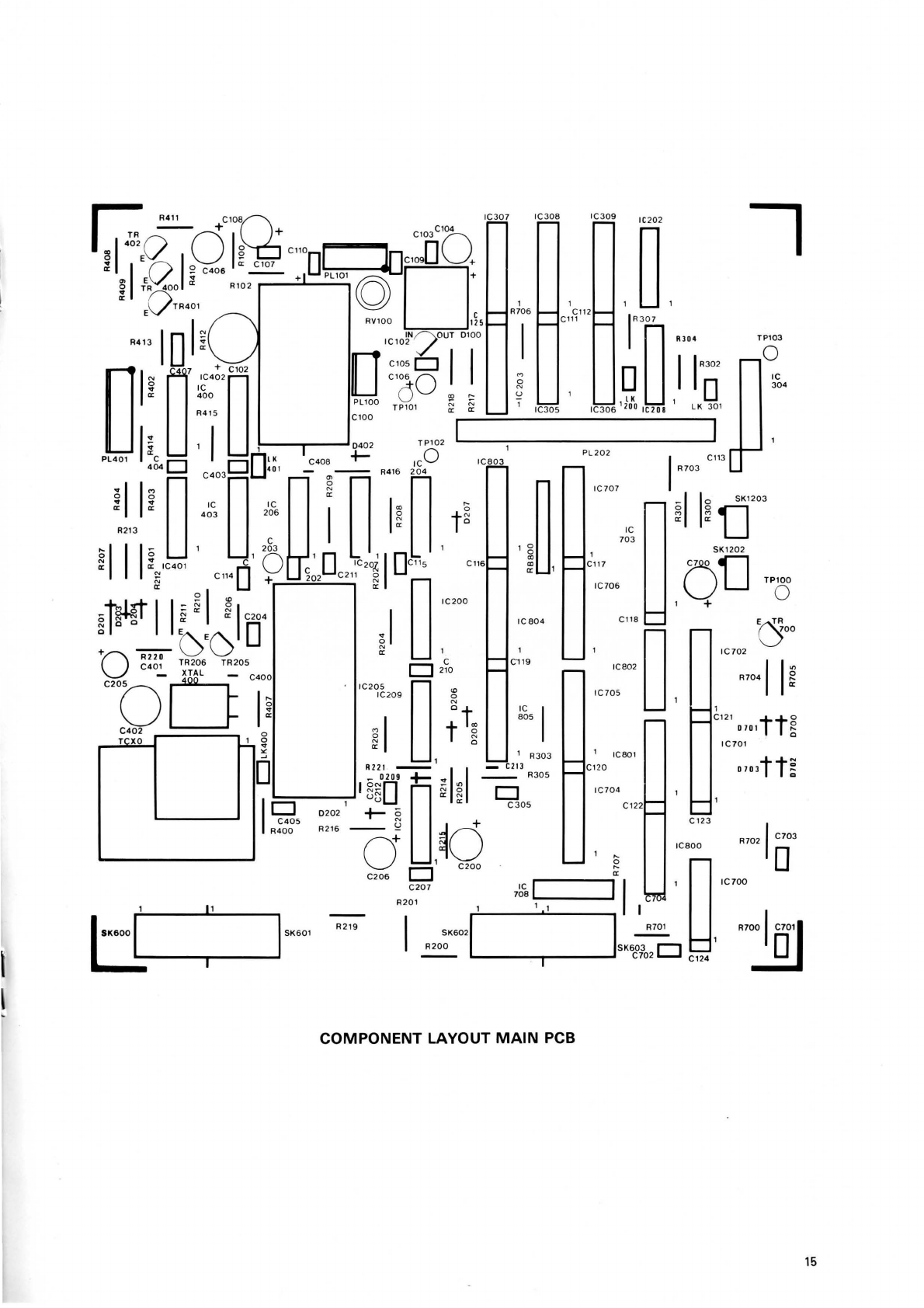

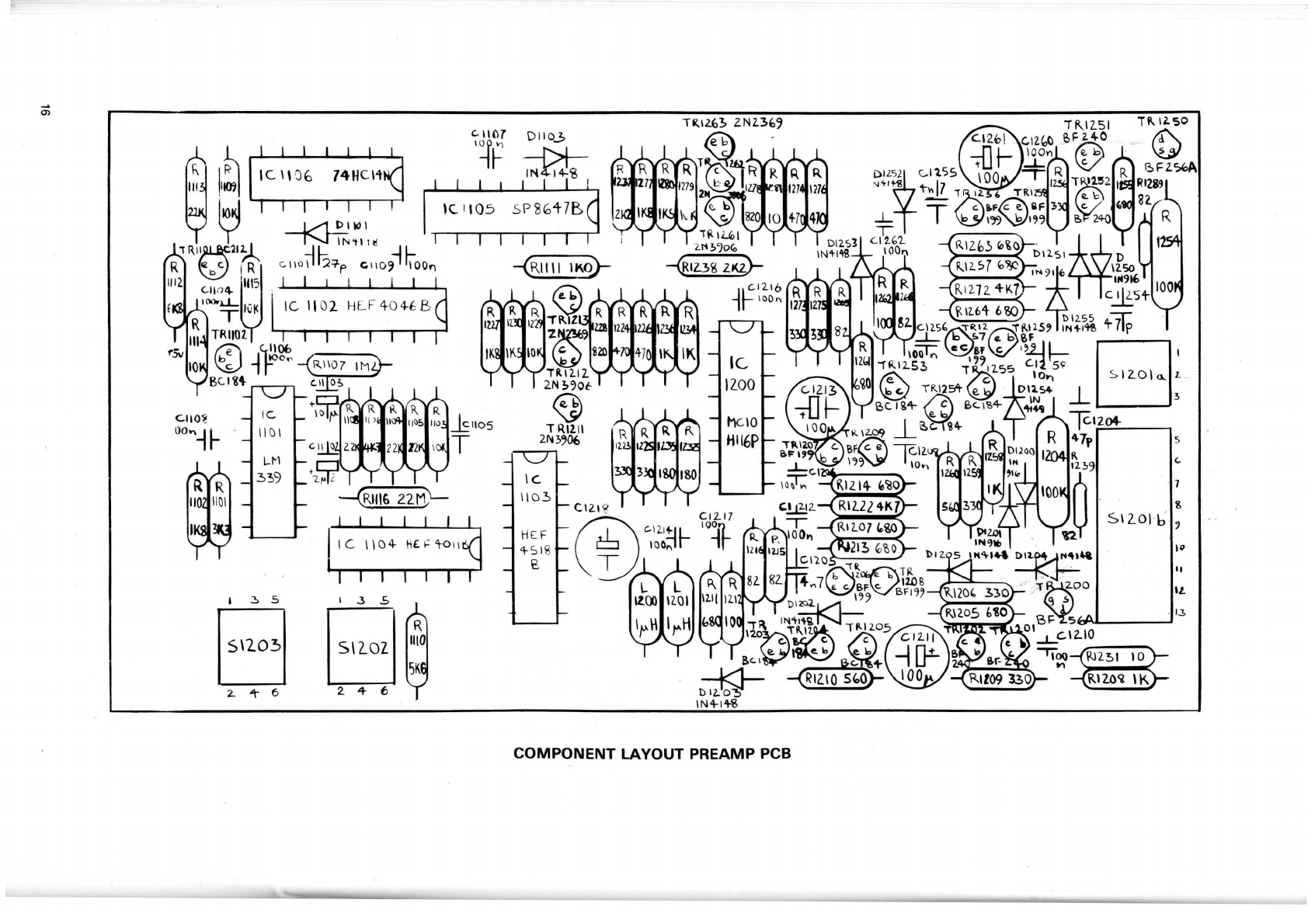

COMPONENT

LAYOUT

MAIN PCB

COMPONENT

LAYOUT

PREAMP

PCB

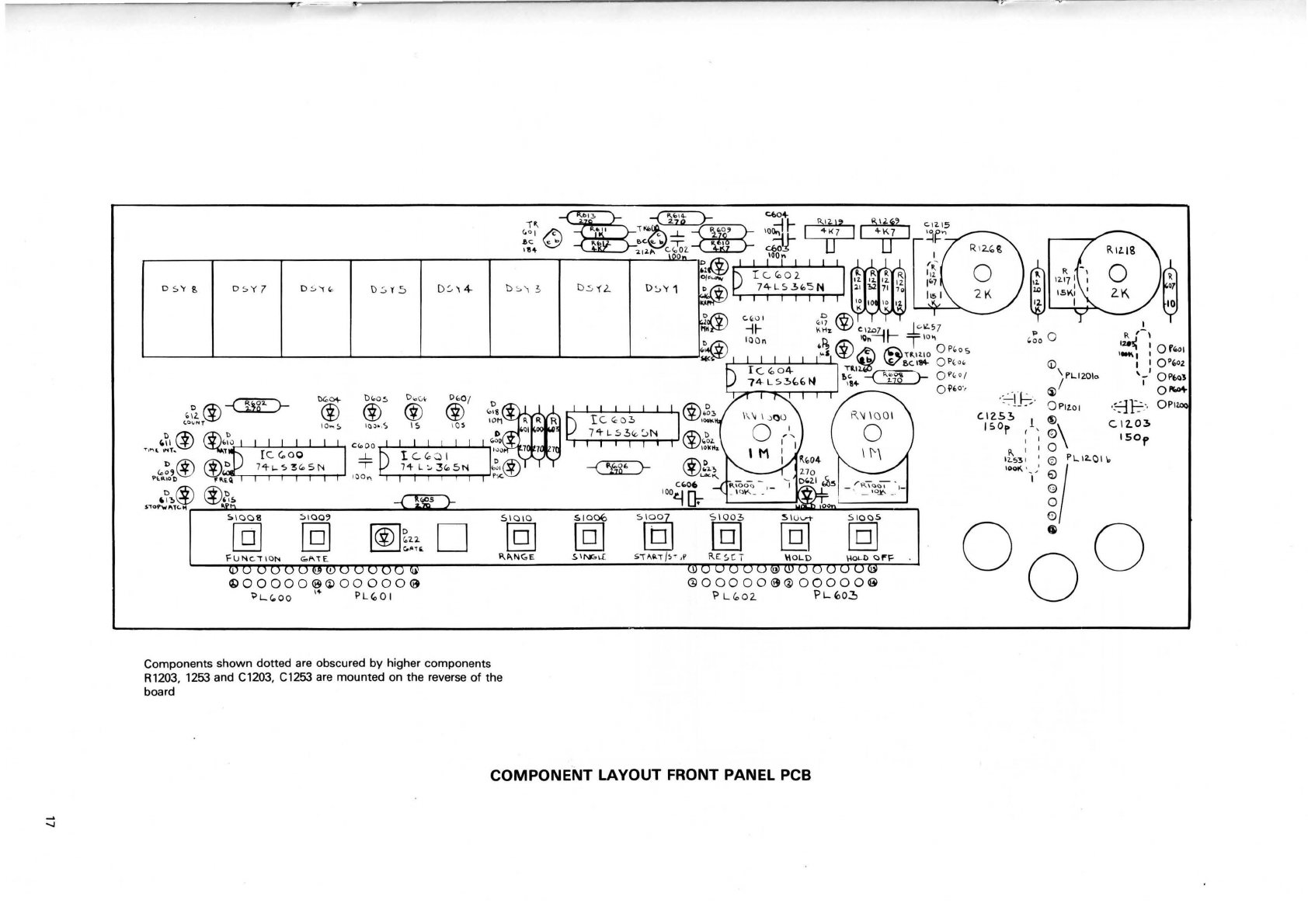

COMPONENT

LAYOUT

FRONT PANEL

PCB

COMPONENT

LAYOUT

SUB BOARD

PCB

1

2

2

5

8

9

10

11

3

4

15

16

17

18

CIRCUIT

DIAGRAMS

1 POWER SUPPLY

19

©

1986

BLACK STAR

2 PRE-AMPLIFIER 20

3 FREQUENCY MULTIPLIER

21

PR

ES

CALER

4 INPUT SELECTOR 22

STOPWATCH

START/STOP

GATING

5 SLOPE CONTROLS 23

HOLD-OFF

SINGLE MEASURE PRIMING

TRIGGER L.E.D. CONTROL

RESET

DISPLAY HOLD

MAIN

COUNTER I.C.

6 SYSTEM CLOCK 24

RPM PRESCALER

7 FRONT PANEL SWITCH LOGIC 25

8 DISPLAY MULTIPLEXERS 26

RANDOM LOGIC

9 FRONT PANEL DISPLAYS 27

10

MISCELLANEOUS SWITCHING 28

TIMEBAS

E

Crystal Oscillator Frequency

Time

between

measurements

Aging

Setability

Temperature

Stability

INPUT

A

Bandwidth

/

Sensitivity

Coupling

and

Input

Impedance

Low

Pass Fitter

Maximum Input Voltage

Triggering

Attenuat

or

INP

UT

B

B

andwidth

/Sensitivity

Coupling and

Input

Impedance

Low

Pass Filter

Maximum

Input

Voltage

Triggering

Attenuator

F

REQU

EN

CY

A

Gate

Tim

es

Ranges/Resoluti

on

Accuracy

FREQU

ENCY

RA

T

IO

A TO B

Frequency

Maximum

Ratio Averaged Over

Resoluti

on

Ac

cu

ra

cy

PERIOD

A

Measurement Type

Per

io

d Range

Display

Period Averaged Over

Resol

uti

on

Ac

curacy

TIM

E

INTERVA

L A TO B

Range

Display

Minimum

Pulse Wi

dth

Maximum

Frequency

Time Interval Averaged Over

Resolution

Accuracy

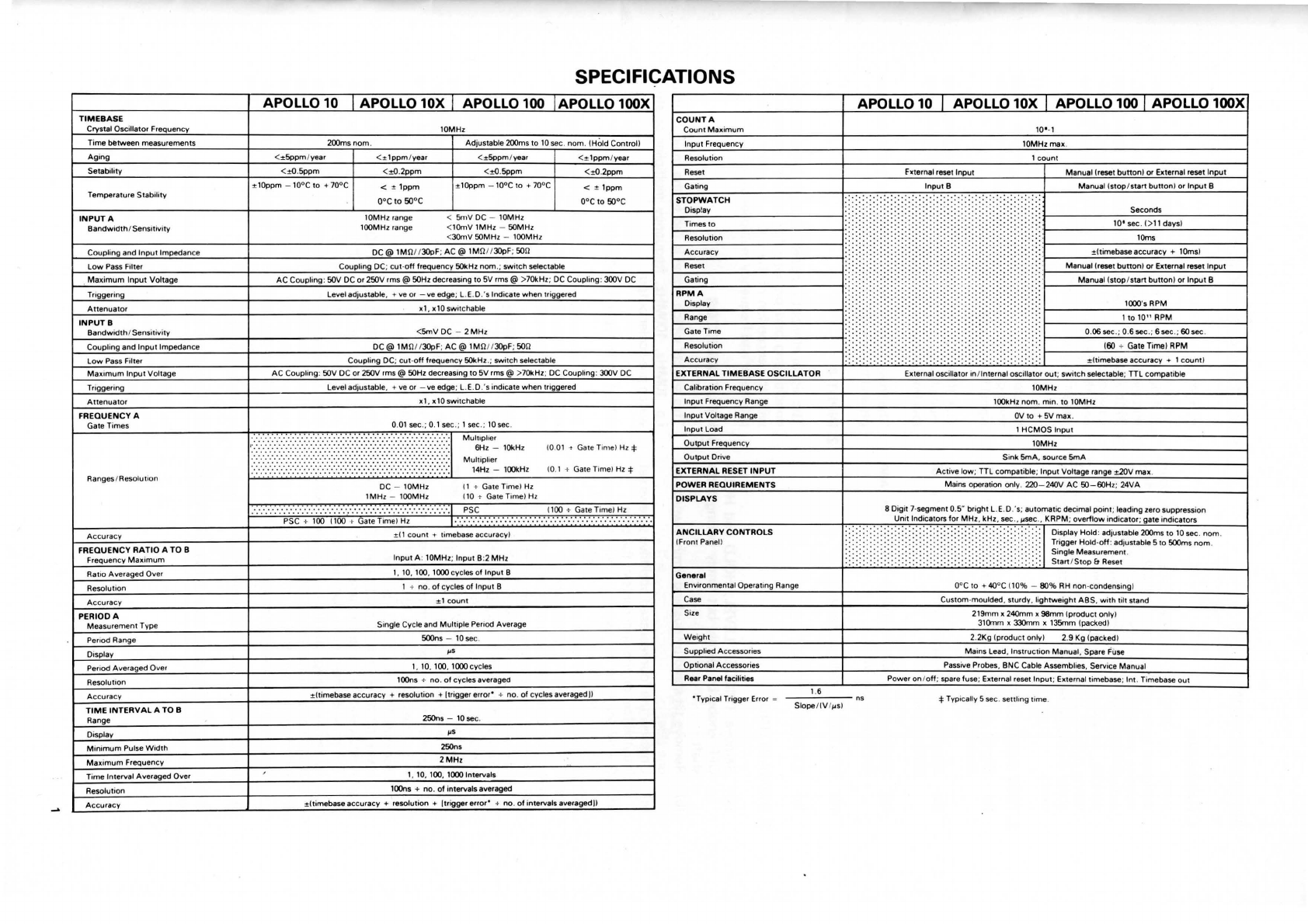

SPECIFICATIONS

APOLLO 10 APOLLO

10X

APOLLO 100 APOLLO 100X

10MHz

200ms nom.

Adjustable

200ms to

10

sec.

nom

. (HOid

Contrell

<::t

5ppm

/year <::t

lppm

/

year

<::t

5Ppm

/

year

<:t

lppm

/year

<.0

.Sppm

<~

.2ppm

<.O

.Sppm

<:0

.2ppm

::t

10ppm -10°C

to

+ 70°C < z

lppm

::t

l()ppm -10°C to + 70°C <

::t

lppm

0°c

to

so

0c

0°c

to

so

0c

10MHz range <

SmV

DC -

10MHz

100MHz

range

<10mV 1MHz -00MHz

<

30mV

50MH

z - 100MHz

DC@

1

MU

//

30pF;

AC@

1M

{l

/ /30pF ;

SOU

Coupling DC; c

ut

-

off

frequency

S()kHz

nom

.;

switch

selectable

AC

Coupling

: 50V DC

or

250V

rm

s@

50Hz

decreasing

to

5V

rms@

>70kHz; DC

Coupling

: 300V DC

Level adjustable, + ve or

-ve

edge; L.E.D.·s Indicate

when

triggered

xl,

xl0

switchable

<SmV DC - 2 MHz

DC@

1M

{l

/ /30pF;

AC@

1MQ/ /30pF;

son

Coupling DC; c

ut

-

off

frequency

SOie.Hz

.; switch selectable

AC Coupling: 50V DC or 250V

rms@

50Hz decreasing to 5V

rms@

>70kHz; DC Coupling:

JOOV

DC

Level adjustable, +ve or -ve edge; L.E.D.'s indicate

when

triggered

xl

,

xl0

switchable

0.

01

sec.; 0.1sec .; 1sec. ;

10

sec.

·: ·::.·.·:::.·::.

·:::

·:

·::::

:::

:

Mult1pl1

er

6Hz - 10kHz

10

.

01

+ Gate Time)

Hz*

Mult

iplier

·::

14Hz -100kHz

10

.1 + Gate TimeI

Hz*

DC -10MHz (1 + Gate Time)

Hz

1MHz -100MHz I

10

+ Gate Time) Hz

..

...

..

.•:•:•

.

·.·.·

.

·.·.·.·.•.•:

·.

·

.·.

·

.·

.

·.·

.·

.·

.

·.·.·

.

-:·:·:

·:

·.

·.

I PSC (1()() +

Ga1e

Time) Hz

.... .

..

.

..

...

.

PSC +

100

1100

r Gate Time/

Hz

1

•·:·

·:

··

····

·

·············

·

··

·

·······

···

··::.·.·.

·..·.

·.·.·.·

.

·.·.·.·

.

·.·.·.·

.

·.·.·.

:t(1co

unl

+ timebase accuracy)

Input A: 10MHz; Input 8:2 MHz

1,

10

,

100,

1()))

cycles of Input B

1 +

no

.

of

cycles

of

Input

8

:tl

count

Single Cycle and Multiple Period Average

5(X)ns

- 10 sec.

-·

1,

10,

100,

1()))

cycles

100ns +

no

.

of

cycles averagect

:tltim

ebase accuracy + resolution + ltrigger error• +

no

.

of

cycles averagedI)

250ns -

10

sec.

-·

250ns

2 M

Hz

1, 10, 100, 1

()))

Intervals

lOOns

+

no

.

of

intervals averaged

:t(timebase accuracy + resolution + Itrigger

error•

+

no

.

of

intervals averagedII

APOLLO 10 I APOLLO 10X APOLLO 100 I APOLLO

100X

C

OUNT

A

Count

Maximum

Input Frequency

Resolution

Reset

Gating

S

TOPW

AT

CH

Display

Times

to

Resolution

Accuracy

Reset

Gating

RP

MA

Display

Range

Gate Time

Resolution

Accuracy

EXTE

RNAL

TI

ME

BASE OS

CILLA

TOR

Calibration Frequency

Input Frequen

cy

Range

Input Voltage Range

Input Load

Output

Frequency

Output

Drive

EXTE

RNAL

RESET

INPU

T

PO

W

ER

REQUIRE

MEN

TS

DI

SPLA

YS

ANCIL

LARY

C

ON

TROLS

(Front Panel)

Gene

ral

Environmental Operating Range

Case

Size

Weight

Supplied Accessories

Optional Accessories

Rear P

antH

facilities

1.6

•Typical Trigger Error = -

----

-ns

Slope/

(V

/

µsl

10•-1

10MHzmax

.

1

count

Fvternal reset Input Manual !reset

button)

or

External reset

Input

Input B Manual (stop/start

button

) or I

nput

B

. . . . . . . . ·. ·.

___

• Seconds

. , .

...

.;.::::

·:

::·:·... :.

..

:

._

____

_

,_o_•_••-~

-;.,,-1>_

~_,

_

da

_v_s_l

--------1

.·,·

•.

·..

t-

--

----

- -

---

-------1

:t(timebase accuracy + 10ms)

.........

..

..

. : : : . . . :

..

:-:

-

.·

.

Man

ual (reset

button)

or

External reset

Input

. : ·,· . .

,•

..·...

>------

-

----

---~--

Manual (stop/start

button)

or

I

nput

B

. .. . . .

.

,:,

.

:,

.

....

-:

-. . .:

.·

.

..

' , '

. : : . . . : : : : : . . . . . . .

~.

!:

~.

l()X)'s RPM

..

·,· . 1

to

10

11 RPM

..

·.• ·.·. .

...

.

..·

.•,•

.•,:-:-:: : :·: :

:-·

,•

0.06

se

c.; 0.6 sec.; 6 sec.;

6()

sec.

(60

+ Gate Time) RPM

..

:tltimebase accuracy + 1

count)

External oscillator in/Internal oscillator

out

;

swit

ch selectable;

TT

L compatible

10MHz

lOOkHz

nom

. min.

to

10MHz

0V

to

+ 5V max.

1HCMOS

Input

10MHz

Sink SmA, source SmA

Active

low

; TTL compatible; Input Voltage range

~V

max.

Mains operation only.

220

-240V AC

50-60Hz

; 24VA

8 Digit 7-segment

0.5'

' bright L.E.D.'s;

automati

c decimal

point

; leading zero suppression

Unit Indicators for MHz. kHz.

se

c ., µsec., KRPM;

overflow

indicator; gate i

ndi

cators

:: \ Display Hold: adjustable 200ms

to

10

sec.

nom

.

:!; :;; Trigger Hold-o

ff

: adjustable 5 to 500ms

nom

.

\

::>;:'.:'.

:;

:

~~:~~s~i=~r;::~t.

0°C

to

+ 40°C I

10

% - 80%

RH

non

-condensing)

Custom-moulded, sturdy,

lightweight

ABS

.

with

tilt stand

219mm x 240mm x 98mm (product only)

310mm x 330mm x 135mm (packed)

2.2Kg (produ

ct

only) 2.9 Kg (packed)

Mains Lead, Instruction Manual, Spare Fuse

Passive Probes. BNC Cable Assemblies, Service Manual

Power on/

off;

spare fuse; External reset Input; External timebase;

lnt

. Timebase

out

* Typi

ca

lly

5sec

. settling time.

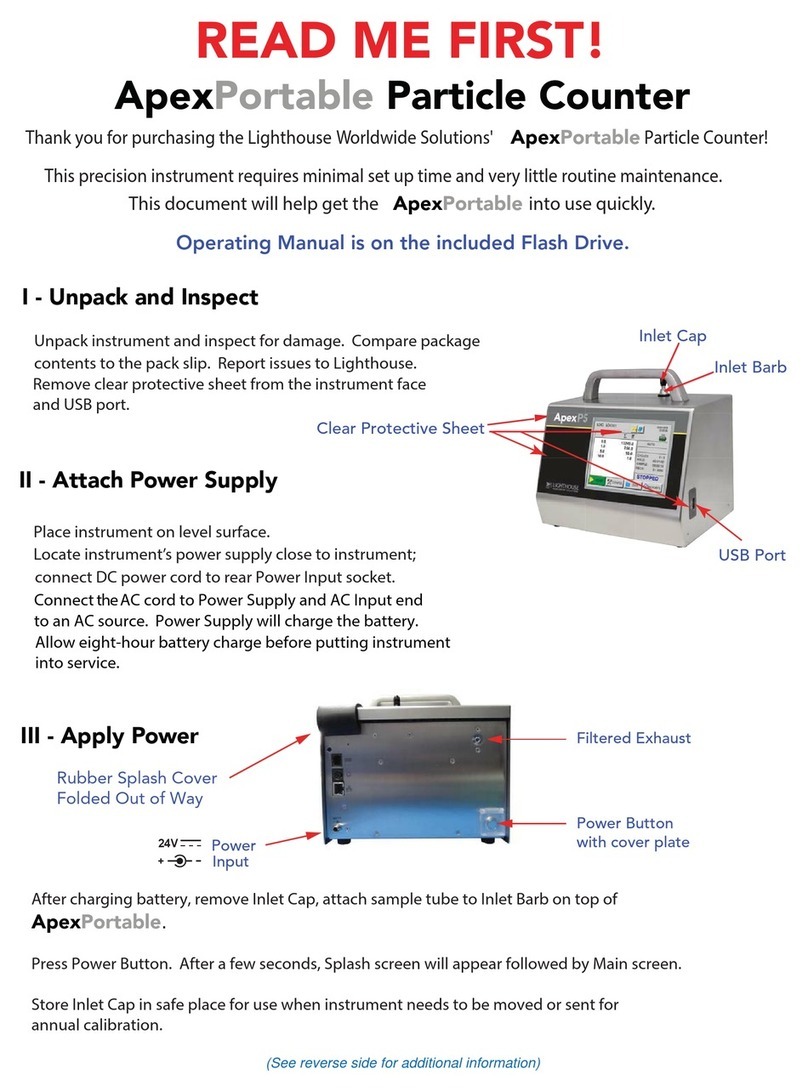

INTRODUCTION

1.

HANDLING

While the APOLLO counter timers have been

designed

to

be

rugged, severe shocks can

be

des-

tructive and should

be

avoided. Do

not

expose

to

radiant heat, including direct sunlight

for

long

periods, or excessively high humidity. When ser-

vicing suitable precautions should

be

taken against

static discharge

as

the

unit

contains CMOS compo-

nents.

2.

TEST

EQUIPMENT

(a) Signal generators 2Hz

to

100MHz

with

cali-

brated output.

(bi

(cl

(d)

Frequency standard

with

an accuracy

of

0.05ppm or better.

Oscilloscope

with

100MHz bandwidth and

5mV

/div

sensitivity.

x10, 10M 01oscilloscope probe.

(el 3½ digit multimeter.

3.

DISMANTLING

(a) Remove TRIGGER LEVEL, HOLD and HOLD

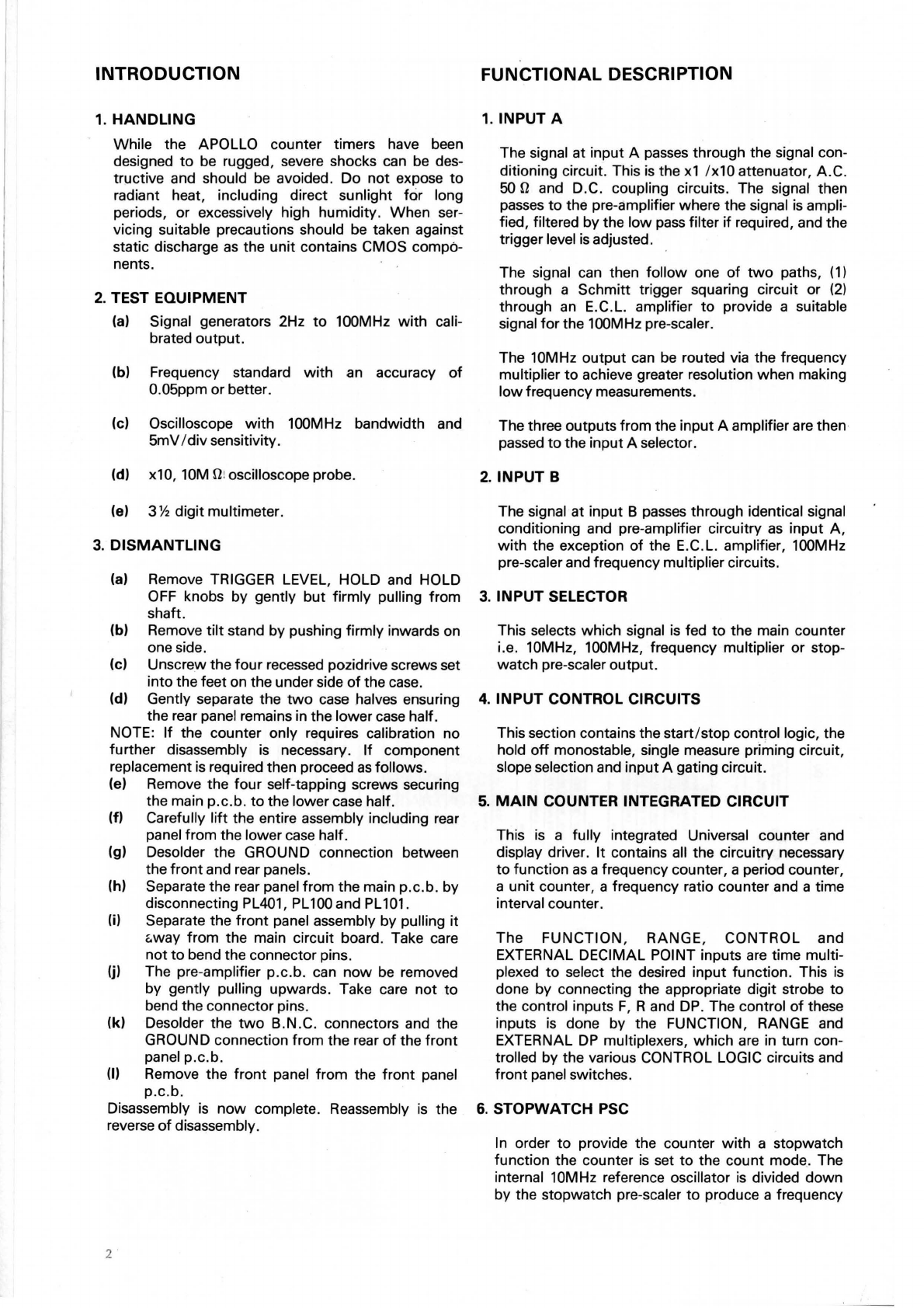

FUNCTIONAL DESCRIPTION

1.

INPUT

A

The signal at input A passes through the signal con-

ditioning circuit. This

is

the

x1

/x10 attenuator, A.C.

50

n and D.

C.

coupling circuits. The signal then

passes

to

the pre-amplifier where the signal

is

ampli-

fied, filtered by the

low

pass filter

if

required, and the

trigger level

is

adjusted.

The signal can then

follow

one

of

two

paths, (

1)

through a Schmitt trigger squaring circuit or

(2)

through an E.C.L. amplifier

to

provide a suitable

signal

for

the 100MHz pre-scaler.

The 10MHz

output

can

be

routed via the frequency

multiplier

to

achieve greater resolution when making

low

frequency measurements.

The three outputs from the input A amplifier are then

passed

to

the input A selector.

2.

INPUT

B

The signal at input B passes through identical signal

conditioning and pre-amplifier circuitry

as

input A,

with

the exception

of

the E.C.

L.

amplifier, 100MHz

pre-scaler and frequency multiplier circuits.

OFF

knobs by gently

but

firmly pulling

from

3.

INPUT

SELECTOR

shaft.

(b) Remove

tilt

stand by pushing firmly inwards on

one side.

(cl Unscrew the

four

recessed pozidrive screws set

into the feet on the underside

of

the case.

(di Gently separate the

two

case halves ensuring

the rear panel remains in the lower case half.

NOTE: If the counter only requires calibration no

further disassembly

is

necessary.

If

component

replacement

is

required then proceed

as

follows.

(e) Remove the four self-tapping screws securing

the main p.c.b.

to

the lower case half.

(f) Carefully

lift

the entire assembly including rear

panel from the lower case half.

(gl Desolder the GROUND connection between

the

front

and rear panels.

(h) Separate the rear panel from the main p.c.b. by

disconnecting PL401, PL100 and PL101.

(i) Separate the

front

panel assembly by pulling it

c.way

from

the main circuit board. Take care

not

to

bend the connector pins.

(j) The pre-amplifier p.c.b. can

now

be

removed

by gently pulling upwards. Take care

not

to

bend the connector pins.

(kl

Desolder the

two

B.N.C. connectors and the

GROUND connection from the rear

of

the

front

panel p.c.b.

(I) Remove the

front

panel

from

the

front

panel

p.c.b.

Disassembly

is

now

complete. Reassembly

is

the

reverse

of

disassembly.

2

This selects which signal

is

fed

to

the main counter

i.

e.

10MHz, 100MHz, frequency multiplier or stop-

watch pre-scaler output.

4.

INPUT

CONTROL CIRCUITS

This section contains the

start/stop

control logic, the

hold

off

monostable, single measure priming circuit,

slope selection and input A gating circuit.

5.

MAIN

COUNTER INTEGRATED CIRCUIT

This

is

a fully integrated Universal counter and

display driver. It contains all the circuitry necessary

to

function

as

afrequency counter, a period counter,

a unit counter, a frequency ratio counter and a time

interval counter.

The

FUNCTION,

RANGE,

CONTROL

and

EXTERNAL DECIMAL POINT inputs are time multi-

plexed

to

select the desired input function. This is

done by connecting the appropriate digit strobe

to

the control inputs

F,

Rand

DP

. The control

of

these

inputs

is

done by the FUNCTION, RANGE and

EXTERNAL

DP

multiplexers, which are in turn con-

trolled by the various CONTROL LOGIC circuits and

front

panel switches.

6.

STOPWATCH PSC

In

order

to

provide the counter

with

a stopwatch

function the counter

is

set

to

the count mode. The

internal 10MHz reference oscillator

is

divided

down

by the stopwatch pre-scaler

to

produce a frequency

ov

z

~

0

er

Q)

GREEN /YELLOW

WHITE

I

WHIT

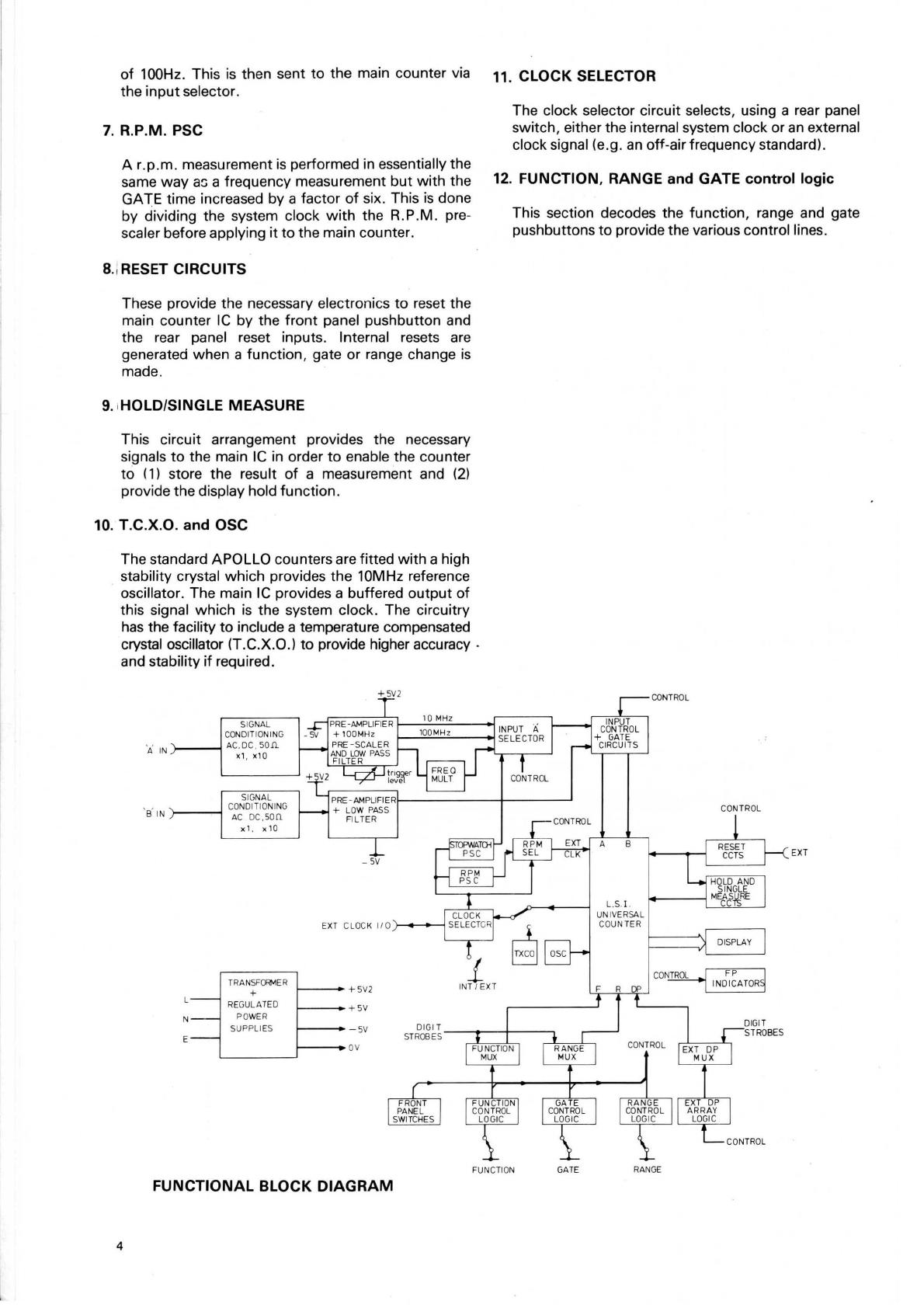

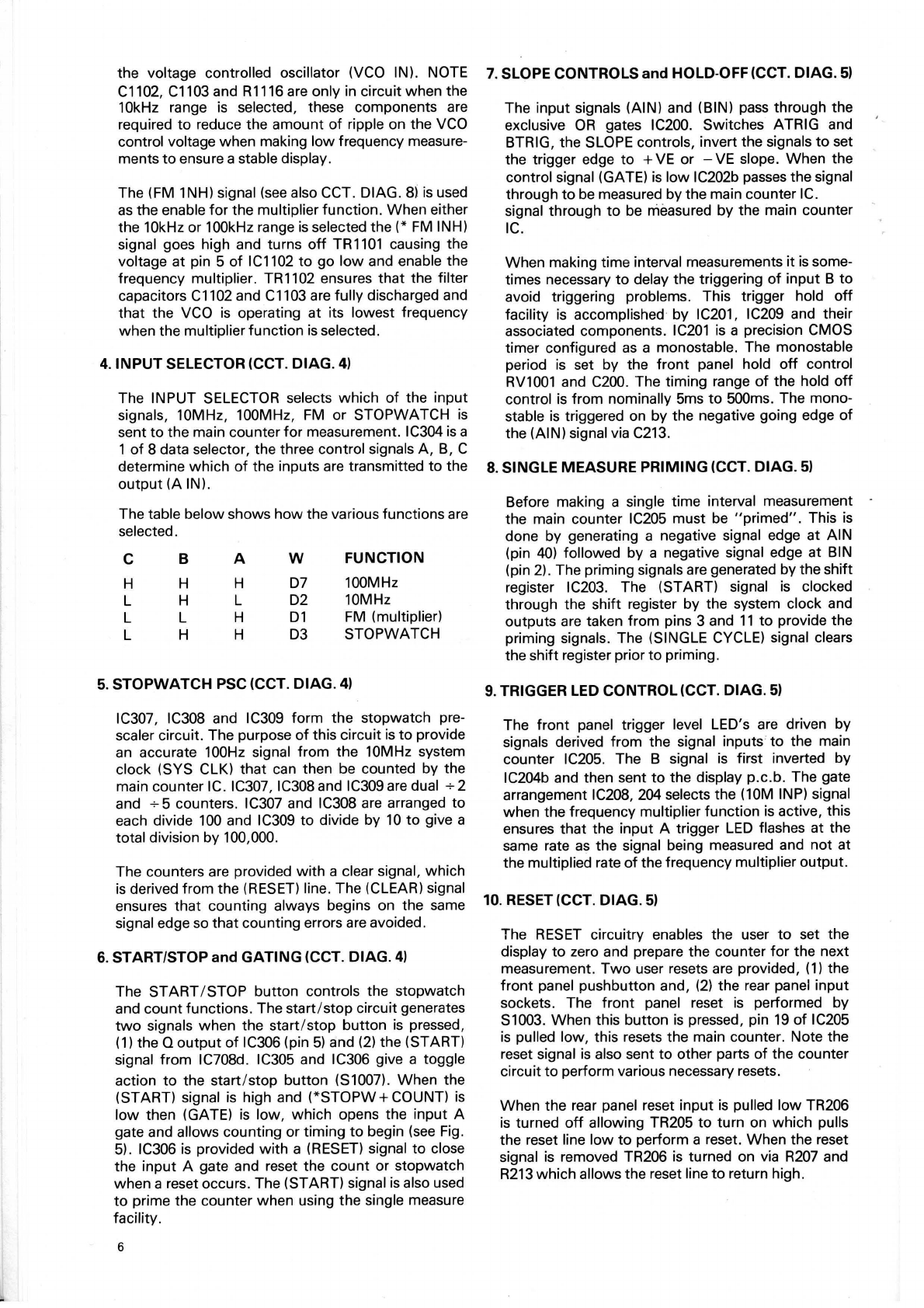

MECHANICAL ASSEMBLY

LJ

LJ

SK12O3 SK12O2

MAIN

P.

C. B.

I

PRE -AMP PRESCALER

ANO FREQUENCY

MULTIPLIER

P.C

.B.

C4O2

G)

TC.XO

.

ADJUST

LJ'

PL12O1la)

PL12O1lb)

al

u

a.:

...J

UJ

z

rt

I-

z

0

er

u.

R1269

.L

of

100Hz. This

is

then sent

to

the main counter via

the

input

selector.

7. R.P.M. PSC

A r.

p.m.

measurement

is

performed in essentially the

same

way

as

a frequency measurement

but

with

the

GATE time increased by a

factor

of

six. This

is

done

by dividing the system clock

with

the R.P.M. pre-

scaler before applying

it

to

the main counter.

8.

;RESET

CIRCUITS

These provide the necessary electronics

to

reset the

main counter

IC

by the

front

panel pushbutton and

the rear panel reset inputs. Internal resets are

generated when a

function

, gate or range change

is

made.

9.

1HOLD/SINGLE

MEASURE

This circuit arrangement provides the necessary

signals

to

the main

IC

in order

to

enable the counter

to

(

1)

store the result

of

a measurement and

(2)

provide the display hold

funct

ion.

10. T.C.X.O. and OSC

The standard APOLLO counters are fitted

with

a high

stability crystal

which

provides

the

10MHz reference

oscillator. The main

IC

provides a buffered

output

of

this signal

which

is

the system clock. The circuitry

has the facility

to

include a temperature compensated

crystal oscillator (T.C.X.O.)

to

provide higher accuracy .

and stability

if

required.

SIGNAL

CO

NDITIONING

'

t{,

IN

------1

AC.DC,

50.fl

x1

, x10

+5V2

11. CLOCK SELECTOR

The clock selector circuit selects, using a rear panel

switch, either the internal system clock or an external

clock signal

(e

.g.

an

off-airfrequency standard).

12.

FUNCTION,

RANGE and GATE control logic

This section decodes the

function,

range and gate

pushbuttons

to

provide the various control lines.

INPUT

CO

NTROL

+ GATE

CIRCUITS

CO

NTR

OL

SIGNAL

,8, IN

-----<

CONDITIONING

AC

oc,

son

X1. X 10

PR

E- AMPLIFIER

f--------+-----'

4

TRANSFCJR,,1ER

+

REGULATED

N POWER

SUPPLIES

E

+

LO

W

PASS

F

IL

TER

- 5V

EXT

CLOC

K

1/0

......,

..........

_

+5V2

+sv

-s

v

ov

DIGI T

STROBES

F

RON

T

PA

NE

L

SWITC

HE

S

FUNCTIONAL

BLOCK

DIAGRAM

FUNCT

IO

N GATE

A B

L.S.

l.

UNIVERSAL

CO

UNTER

RANGE

CO

NTR

OL

DISP

LAY

DIGIT

STROBES

CONTROL

EX

T

CIRCUIT DESCRIPTION

The following description applies

to

the APOLLO

100

counter timer. Certain sections

are

not applicable

to

the

APOLLO

10.

Refer

to

circuit diagrams for the differ-

ences. NOTE control signals marked with

a'

*' are active

low

e.g. (*

FREQ)

.

1.

POWERSUPPLY(CCT. DIAG.1)

Three separate voltages

are

generat

ed

by the power

supply circuit. These voltages

are

provided by mono-

lithic integrated circuit regulators IC100,

101,

102

and

their associated components. The +5V2, and the

-

5V

supplies

are

used by the pre-amplifier, pre-

scaler and frequency multiplier circuits. The +5V2

supply

is

adjusted by RV100

to

5.2V ±0.05V so that

the

ECL

circuits operate at their optimum voltage.

The +

5V

supply

is

used by the main logic circuits.

Test points TP100,

TP101

, TP102 and TP103

are

pro-

vided for convenient monitoring

of

the power

supplies. All three voltage supplies have built in short

circuit protection. The mains transformer T100 pro-

vides the necessary voltage conversion and isolation

of

the mains supply voltage. Transformer taps are

provided

to

enable conversion

to

110/120V

operation.

Fuse

F100

provides protection against

fault currents. SW100

is

the instrument ON/OFF

switch arid

is

mounted on the rear panel.

2.

PRE-AMPLIFIERS (CCT. DIAG.

2)

S1200 selects the input coupling mode AC,

50

n,

DC

or LPF.

With

the switch in the

50

n position

C1201

and

R1200

terminate the input

with

nominally

50

n,

(the input

is

DC

coupled in this position).

With

DC

selected the input signal

is

directly coupled

to

the

pre-amplifier.

R1201

sets the input impedance

to

1

Mn.

With

S1201

in

the x10 position the input signal

passes through the x10 attenuator,

R1202

and

R1203

perform the voltage division and C1202 and

C1203

provide frequency compensation.

The pre-amplifier

is

protected from excessive input

voltage by

R1204

,

R1239

,

C1204

, D1200, and D1201.

The input coupling components are situated on the

front

panel sub-board, which

is

mounted between

the

front

panel and the

front

panel p.c.b.

01200, 01201 and 01202 form a high input impe-

dance, wide bandwidth voltage follower. The high

input impedance

is

necessary

to

avoid loading the

input coupling and attenuator circuits.

The next stage

of

the pre-amplifier consists

of

two

differential amplifiers 01208, 01209 and 01206,

01207. Amplifier 01206, 01207

is

operative when the

LPF

(low pass filter)

is

selected. Amplifier 01208,

01209

is

operative when AC,

500

or

DC

is

selected.

Normally 01205

is

biased on so that the current

source 01203

is

connected

to

the emitters

of

01208,

01209, so that this amplifier

is

operative. Alterna-

tively

if

the

LPF

is

selected 01204

is

biased on and

01205

is

biased

off

so that the current source

is

con-

nected

to

the emitters

of

01206 and 01207. This

amplifier

is

then operative and the inputsignal passes

through the

low

pass network

R1213

and

C1205

before amplification. The filter components values

are

calculated

to

give a cut

of

frequency

of

nominally

50kHz.

The variable resistor

R1218

is

the front panel

TRIGGER

LEVEL

control and sets the working point

of

the differential amplifiers. Resistor

R1219

is

adjusted during calibration

to

take account

of

com-

ponent tolerances. The emitter follower 01210

applies the working point voltage

to

the

base

of

01206, 01207, 01208, 01209. Diodes D1204 and

D1205

provide temperature compensation

for

the

trigger level control.

The antiphase outputs from the differential amplifier

provide the input

to

IC1200(b). IC1200(b) forms the

main gain stage

of

the pre-amplifier, this

IC

is

an

ECI

differential line driver biased

to

operate

in

the linear

mode

to

provide higher gain. The output from

IC1200(b) feeds

two

circuits

(1)

a Schmitt trigger

ECL

to

TTL converter, 01211, 01212 and 01213. 01213

is

a high speed switcliing transistor

to

ensure the

fastest possible

rise

time. Overall feedback around

this amplifier

is

provided by

R1229

.

(2)

IC1200(c)

buffers the output

of

IC1200(b)

to

provide asignal for

the 100MHz pre-scaler

(see

CCT. DIAG. 3).

3.

FREQUENCY MULTIPLIER

AND

PRE-SCALER

CIRCUITS (CCT. DIAG.

3)

IC1105

is

a +

10

or +

11

pre-scaler.

D1103

pulls pins 2

and 3 high

to

set the pre-scaler

to

the

+-10

mode.

The 10MHz

output

from the pre-scaler

is

inverted by

the Schmitt trigger IC1106(b) and sent

to

the input

selector

(see

CCT. DIAG. 4).

Channel A output from 01213

(see

CCT. DIAG.

3)

is

inverted by IC1106(f) and sent

to

the input selector.

The channel B signal from the pre-amplifier

is

passed

through IC1106(a,c) and sent

to

the Gating and Input

B circuits

(see

CCT. DIAGS.

4and

5).

IC1101

performs level shifting for the input signals

to

the frequency multiplier circuit. This

is

necessary

as

the frequency multiplier circuit operates from dual

supplies. The frequency multiplier function

is

per-

formed by IC1102, IC1103, IC1104 and associated

components, which form a frequency multiplying

PHASE LOCKED LOOP. IC1102

is

a phase locked

loop integrated circuit, containing

two

phase com-

parators, a voltage controlled oscillator (VCO) and a

source follower. IC1103

is

a

two

stage counter which

divides the VCO output by either

10

or

100

and sends

the signal

to

the phase comparator input pin

3.

The

two

multiplier ranges

are

selected by the control lines

(* 100kHz) and (* 10kHz). When the 10kHz range

is

selected the gate IC1104(a)

is

enabled and the divide

by

100

output

of

IC1103

is

sent

to

the phase com-

parator input of IC1102

to

provide a multiplication

factor

of

100.

When the 100kHz range

is

selected the

gate IC1104(b)

is

enabled and the divide by

10

output

from IC1103

is

sent

to

phase comparator input of

IC1102

to

provide amultiplication factor of

10.

The phase comparator

output

(PC

OUT)

is

smoothed

by the filtering components

R1107, R1108,

R1116

,

C1102

and

C1103

to

provide the control voltage for

5

the voltage controlled oscillator (VCO IN). NOTE

C1102, C1103 and R1116 are only in circuit when the

10kHz range is selected, these components are

required

to

reduce the

amount

of

ripple on the VCO

control voltage when making low frequency measure-

ments

to

ensure a stable display.

The (FM 1NH) signal

(see

also CCT. DIAG.

8)

is

used

as

the enable

for

the multiplier function. When either

the 10kHz or 100kHz range

is

selected

the(*

FM INH)

signal goes high and turns

off

TR1101 causing the

voltage at pin 5

of

IC1102

to

go

low

and enable the

frequency multiplier. TR1102 ensures

that

the filter

capacitors C1102 and C1103 are fully discharged and

that

the VCO

is

operating

at

its lowest frequency

when the multiplierfunction

is

selected.

4.

INPUT

SELECTOR (CCT. DIAG.

4)

The INPUT SELECTOR selects

which

of

the input

signals, 10MHz, 100MHz, FM

or

STOPWATCH

is

sent

to

the main counter

for

measurement. IC304

is

a

1

of

8 data selector, the three control signals A,

B,

C

determine

which

of

the inputs are transmitted to the

output

(A IN).

The table below shows

how

the various functions are

selected.

C

H

L

L

L

B

H

H

L

H

A

H

L

H

H

w

07

02

01

03

FUNCTION

100MHz

10MHz

FM (multiplier)

STOPWATCH

5.

STOPWATCH

PSC (CCT. DIAG.

4)

IC307, IC308 and IC309

form

the stopwatch pre-

scaler circuit. The purpose

of

this circuit

is

to

provide

an accurate 100Hz signal

from

the 10MHz system

clock (SYS CLK)

that

can then be counted by the

main counter

IC

. IC307, IC308 and IC309

are

dual + 2

and + 5 counters. IC307 and IC308 are arranged

to

each divide

100

and IC309

to

divide by

10

to

give a

total division by 100,000.

The counters are provided

with

a clear signal, which

is

derived

from

the (RESET) line. The (CLEAR) signal

ensures

that

counting always begins on the same

signal edge so

that

counting errors are avoided.

6.

START/STOP and

GATING

(CCT. DIAG.

4)

The

START

/STOP

button

controls the stopwatch

and

count

functions. The start/stop circuit generates

two

signals when the start/stop

button

is

pressed,

(

1)

the Q

output

of

IC306 (pin

5)

and

(2)

the (START)

signal

from

IC708d. IC305 and IC306 give a toggle

action

to

the start/stop

button

(S1007). When the

(START) signal

is

high and

(*STOPW

+ COUNT)

is

low

then (GATE)

is

low,

which opens the input A

gate and allows counting or timing

to

begin (see Fig.

5)

. IC306

is

provided

with

a (RESET) signal

to

close

the input A gate and reset the

count

or stopwatch

when a reset occurs. The (START) signal

is

also used

to

prime the counter when using the single measure

facility.

6

7. SLOPE CONTROLS and HOLD-OFF (CCT. DIAG.

5)

The input signals (AIN) and (BIN) pass through the

exclusive

OR

gates IC200. Switches ATRIG and

BTRIG, the SLOPE controls, invert the signals

to

set

the trigger edge

to

+

VE

or -

VE

slope. When the

control signal (GATE)

is

low

IC202b passes the signal

through

to

be measured

by

the main counter IC.

signal through

to

be measured by the main counter

IC.

When making time interval measurements

it

is

some-

times necessary

to

delay the triggering

of

input B to

avoid triggering problems. This trigger hold

off

facility

is

accomplished by IC201, IC209 and their

associated components.

IC201

is

a precision CMOS

timer configured

as

a monostable. The monostable

period

is

set by the

front

panel hold

off

control

RV1001

and C200. The timing range

of

the hold

off

control

is

from nominally 5ms

to

500ms. The mono-

stable

is

triggered on by the negative going edge

of

the (AIN) signal via

C213

.

8.

SINGLE MEASURE

PRIMING

(CCT. DIAG.

5)

Before making a single time interval measurement

the main counter IC205 must

be

"primed".

This

is

done by generating a negative signal edge at AIN

(pin

40)

followed by a negative signal edge

at

BIN

(pin 2). The priming signals are generated by the shift

register IC203. The (START) signal

is

clocked

through the shift register by the system clock and

outputs are taken

from

pins 3 and

11

to

provide the

priming signals. The (SINGLE CYCLE) signal clears

the shift register prior

to

priming.

9.

TRIGGER LED CONTROL(CCT. DIAG.

5)

The

front

panel trigger level LED's are driven by

signals derived from the signal inputs;

to

the main

counter IC205. The B signal

is

first inverted by

IC204b and then sent

to

the display p.c.b. The gate

arrangement IC208, 204 selects the (10M INP) signal

when the frequency multiplier function

is

active, this

ensures

that

the input A trigger

LED

flashes

at

the

same rate

as

the signal being measured and

not

at

the multiplied rate

of

the frequency multiplier output.

10. RESET (CCT. DIAG.

5)

The RESET circuitry enables the user

to

set the

display

to

zero and prepare the counter

for

the next

measurement.

Two

user resets are provided, (

1)

the

front

panel pushbutton and,

(2)

the rear panel input

sockets. The

front

panel reset

is

performed by

S1003.

When

this button

is

pressed, pin

19

of

IC205

is

pulled

low

, this resets the main counter. Note the

reset signal is also sent

to

other parts

of

the counter

circuit

to

perform various necessary resets.

When

the rear panel reset input

is

pulled

low

TR206

is

turned

off

allowing TR205

to

turn on

which

pulls

the reset line

low

to

perform a reset. When the reset

signal is removed TR206

is

turned on via

R207

and

R213

which

allows the reset line

to

return high.

Protection up

to

± 20V

is

provided by D201,

D203

an

D204,

with

the input current limited by R207.

An

internal reset

is

generated by the

front

panel

switch logic, this resets the counter whenever a

range

of

function change

is

made.

11.

DISPLAY HOLD (CCT. DIAG.

5)

The display hold "freezes" the last measurement

made on the display.

Two

separate functions are

available (

1)

a variable display hold and

(2)

an

indefi-

nite display hold. The variable hold

is

performed by

the monostable IC201.

After

the main

IC

has per-

formed and displayed the result

of

a measurement,

the STORE

output

of

IC205 goes

low

and triggers the

mon,ostable. The Q

output

of

IC201

passes via the

NOR

gate IC206 and sets the following

RS

latch

IC206(a,b)

output

high, this causes IC205

to

"freeze"

the display.

At

the end

of

the monostable timing

period the

RS

latch is reset and the counter makes

the next measurement. RV1000 and C206 adjust the

HOLD time between nominaly200ms and

10s.

When the

front

panel HOLD button

is

pressed the

RS

latch

output

is

set high and thedisplay

is

held indefi-

nitely. When the single measure

button

is

depressed

the monostable

output

sets the

RS

output

high and

causes IC205

to

"freeze"

the display until the counter

is

reset.

12.

MAIN

COUNTER IC (CCT. DIAG.

5)

IC205

is

a fully integrated universal counter and dis-

play driver. It contains all the circuitry necessary

to

function

as

a frequency counter, a

unit

counter, a

frequency ratio counter and a time interval counter.

The FUNCTION, RANGE, CONTROL and EXTER-

NAL

DECIMAL POINT inputs are time multiplexed

to

select the desired input function. This

is

done by

connecting the appropriate digit strobe (01

to

D8)

to

the control inputs. The control

of

these inputs

is

achieved by the function, range and external decimal

point multiplexers

(see

CCT. DIAG. 8), which are in

turn controlled by the various control and logic cir-

cuitryand

front

panel switches.

A display test facility

is

provided, which

is

activated

by connecting together pins 1 and 2

of

PL202. PL202

is

situated on the main p.c.b. The display test illumi-

nates all the display segments and all decimal points

except decimal point8.

13.

FRONT PANEL

SWITCH

LOGIC ,(CCT. DIAG.

7)

Resistors

R701

to

R703

and capacitors

C701

to

703

in

conjunction

with

IC708(a,b,c) ensure that the set up

times

of

the following

J-K

flip flops are met.

IC701

and IC702

are

clocked by the (SLO CLK) and produce

a single pulse

of

1ms duration each time FUNCTION,

FREQ

or GATE buttons are pressed. Diodes D701,

D702, D703 and TR700 form a three input

NOR

gate

which generates a reset whenever the FUNCTION,

RANGE or GATE

button

is

pressed. The next stage

of

the circuit

is

the Programmable Array Logic (PAL).

IC703. This

IC

is

a fusible link

AND

-

OR

gate array,

and

is

used

to

perform the complex logic functions

necessary

to

decode the FUNCTION, RANGE and

GATE switches. The advantage

of

using this device

is

that it replaces many discreet IC's and therefore

allows a more compact design.

The function

of

IC703 can

be

divided into three

sections (

1)

the FUNCTION logic,

(2)

the RANGE

logic and

(3)

the GATE logic.

The FUNCTION outputs 014, 013,

012

of

IC703

is

a

3 bit binary code which increments by one each time

the FUNCTION button

is

pressed. IC704

is

a 3

to

8

line decoder which decodes the PAL outputs

to

provide the seven function control lines: (*FREQ),

(*RATIO), (*TIME INT), (*COUNT), (*RPM),

(*STOPWATCH) and (*PERIOD).

The RANGE outputs 019, 018,

017

are

decoded by

IC705

to

give the five frequency range control lines:

(*10M), (*100M), (*10kHz), (PSC) and (*100kHz).

The GATE outputs

015

and

016

are decoded by

IC706

to

provide the four GATE control lines:

(*1SEC), (*10SEC), (*100ms) and (*10ms).

Note that when either the stopwatch or count func-

tions are selected the control lines from IC706 are

inhibited by the (*STOPW+COUNT) control line.

The PAL has its

own

"power

up reset" circuit

R705,

C700

and D700. This ensures that when the counter

is

first switched on the RANGE

is

set

to

10MHz, the

GATE

is

set

to

1sec and the FUNCTION set

to

FRE-

QUENCY.

IC707 provides the correct decimal point positioning

for

all possible combinations

of

selected function

range and gate time. IC707

is

a fusible link ROM

(read only memory)

with

its address lines connected

to

the PAL outputs. The ROM data lines are the deci-

mal point control signals (DPC), (DPD), (DPC).

14.

RANDOM

LOGIC and DISPLAY MULTIPLEXERS

(CCT. DIAG.

8)

The random logic circuitry generates various control

signals from the 1

of

8 decoders IC704, IC705, IC706.

One example

is

the (*FM INH) signal which

is

used

to

enable the frequency multiplier circuit when either

the 10kHz or 100kHz frequency range

is

selected.

As described in section

12

the FUNCTION and

RANGE selection

is

accomplished by connecting the

appropriate digit drive

to

the control inputs

of

the

main counter IC. IC804 and IC805 perform this

function.

IC804 and IC805 are 8 channel analog multiplexers

which form digitally controlled single pole 8-way

switches which are controlled by the switch function

logic control signals.

See

over

for

table showing the functions selected by

each digit

for

the control input.

7

FUNCTION

Frequency

Period

Function Frequency Ratio

Pin

4 Time Interval

Unit Counter

Oscillator Frequency

0.01

Sec/ 1 Cycle

Range Input

0.1

Sec/10 Cycles

Pin

21

1 Sec/

100

Cycles

10

Sec/1k Cycles

Pin

31

Enable External Range

Input

Display

Off

Display Test

Control Input 1MHz Select

Pin 1 External Oscillator

Enable

External Decimal Point

Enable

DIGIT

D1

D8

D2

D5

D4

D3

D1

D2

D3

D4

D5

D4

and

Hold

D8

D2

D1

D3

External Decimal point output

is

for same digit

Decimal Point that

is

connected

to

this input

Input, Pin

20

15.

SYSTEM CLOCK and R.P.M. PRE-SCALER

(CCT. DIAG.

6)

In the standard model the 10MHz system clock

is

provided by the crystal oscillator circuit XTAL

400,

C400,

C401,

C402

and

R407.

Frequency adjustment

is

provided by trimmer capacitor

C401.

The clock signal

for

IC205

is

not provided directly by

the on chip oscillator but

via

the EXT

OSC

IN, this

allows for the provision

of

a T.C.X.

O.

(Temperature

Compensated Crystal Oscillator) or an externally con-

nected oscillator via the rear panel B.N.C. connector.

The gate arrangement

IC401

(a,b,

c)

selects either the

BUFF OSC OUT signal via IC401(d)

OR

the externally

applied oscillator signal EXT

OSC

IN. The output

from pin 6 of

IC401

is

pre-scaled by the divide by six

counter IC402

to

give a frequency

of

1.6667MHz

necessary for the

RPM

function. IC403 selects either

the 10MHz signal from pin 6

of

IC401

or the pre-

scaled output

of

IC402 which provides the clock

inputfor IC205.

The 10MHz

output

from

IC401

pin 3

is

buffered by

IC400 which then drives the switching transistor

TR401. The 4 gates

in

IC400 are connected

in

parallel

to

ensure that there

is

adequate drive for

TR401

. To

set the rear panel B.N.C. socket

to

an

output the rear

panel INT/EXT switch

is

set

to

the INT position, this

turns on the current mirror formed by TR402 and

TR400 which provides collector current for TR401.

To set the B.N.

C.

socket

to

an

input the switch

is

set

to

the

EXT

position, this turns

off

TR401

by pulling

the collector

of

TR402 high

via

R403

and

R410.

Gate

IC401

(a)

is

closed and Gate

IC401

(c)

is

opened allow-

ing

an

externally applied signal

to

be routed

to

the

main counter

IC

.

8

MIP output; this

output

from the main counter IC205

is

used to drive the front panel GATE

LED

and indi-

cates that a measurement

is

in

progress.

When using the STOPWATCH or COUNT mode or

if

the input signal

is

gated by input B then the (GATE)

signal controls the GATE

LED

which then illuminates

when counting or timing

is

in

progress. IC207(b,c)

and associated components form a pulse stretching

circuit that ensures that the GATE

LED

is

visible even

when the measurement cycle

is

short.

16

. FRONT PANEL DISPLAY SECTION (CCT. DIAG.

9)

IC's

600

,

601,

602

and

603

provide buffering

for

the

various control signals

to

drive the front panel LED's.

TR600 and

TR601

drive the overflow

LED.

17.

CONVERTING FROM 220/240V

to

110/120V

OPERATION

IMPORTANT -Disconnect Mains

Lead

Referring

to

DISMANTLING Section

3,

page

2,

disas-

semble up

to

Section 3(d).

Referring

to

MECHANICAL ASSEMBLY DIAGRAM,

page

3:

1.

On

transformer primary terminals, remove 0V

to

120V

link.

2.

Using 16/0.1 insulated wire, connect the

two

0V

terminals together, and connect the

two

120V

terminals together.

3.

Replace 250mA anti-surge fuse with 315mA

anti-surge fuse (and replace spare).

4.

Fit label

to

back panel indicating voltage and

fuse type.

CALIBRATION

1.

In order

to

calibrate the APOLLO series

of

counter

timers

it

is

first necessary

to

dismantle the

case

(see

Introduction p. 2).

2.

POWER SUPPLY

The first step in calibrating the instrument

is

to

ensure

that

the + 5V2 supply

is

set

to

within its

design limits

of

±0.05V.

If adjustment

is

required,

use a digital voltmeter and adjust RV100 until the

supply

is

within the required limits.

3.

TRIGGER LEVEL calibration (see diagram p.

3)

(a)

Centre both TRIGGER LEVEL controls

as

accurately

as

possible.

(b) Set both ATTENUATION switches

to

x1

.

(c) Set both COUPLING switches

to

A.C.

(d) Carefully adjust

R1219

until both input A trigger

LED's are illuminated.

(e) Carefully adjust

R1269

until both input B trigger

level LED's are illuminated.

4.

CRYSTAL CLOCK calibration (standard model)

Calibration

of

the crystal oscillator becomes

necessary

is

crystal

drift

exceeds requirements.

(a) Switch on the instrument and allow at least a

30

minute warm

up

period before proceeding.

(b) Set INPUT A COUPLING

to

AC.

(c) Set INPUT A ATTENUATION

to

x1.

(cl Set FUNCTION

to

FREQ.

(e)

Set GATE time

to

1s.

If) Set RANGE

to

10MHz.

(g) Connect a frequency standard

of

known

accuracy (0.1ppm or better)

to

INPUT A.

Typically a 10MHz off-air standard would

be

used.

(hi

Adjust TRIGGER LEVEL control until a stable

reading

is

displayed.

(i) Adjust

C401

for

a reading

of

10,000000 ± 5

digits.

5.

T.C.X.O. calibration

(a) Proceed

as

section 3 steps

(a)

to

(f).

(b) Connect a frequency standard

of

known

accuracy (0.05ppm or better)

to

INPUT A.

Typically a 10MHz off-air standard would

be

used.

(cl Adjust a TRIGGER LEVEL control until a stable

reading

is

displayed.

(d) Adjust T.X.C.O.

for

a reading

of

10.000000 ± 2

digits.

9

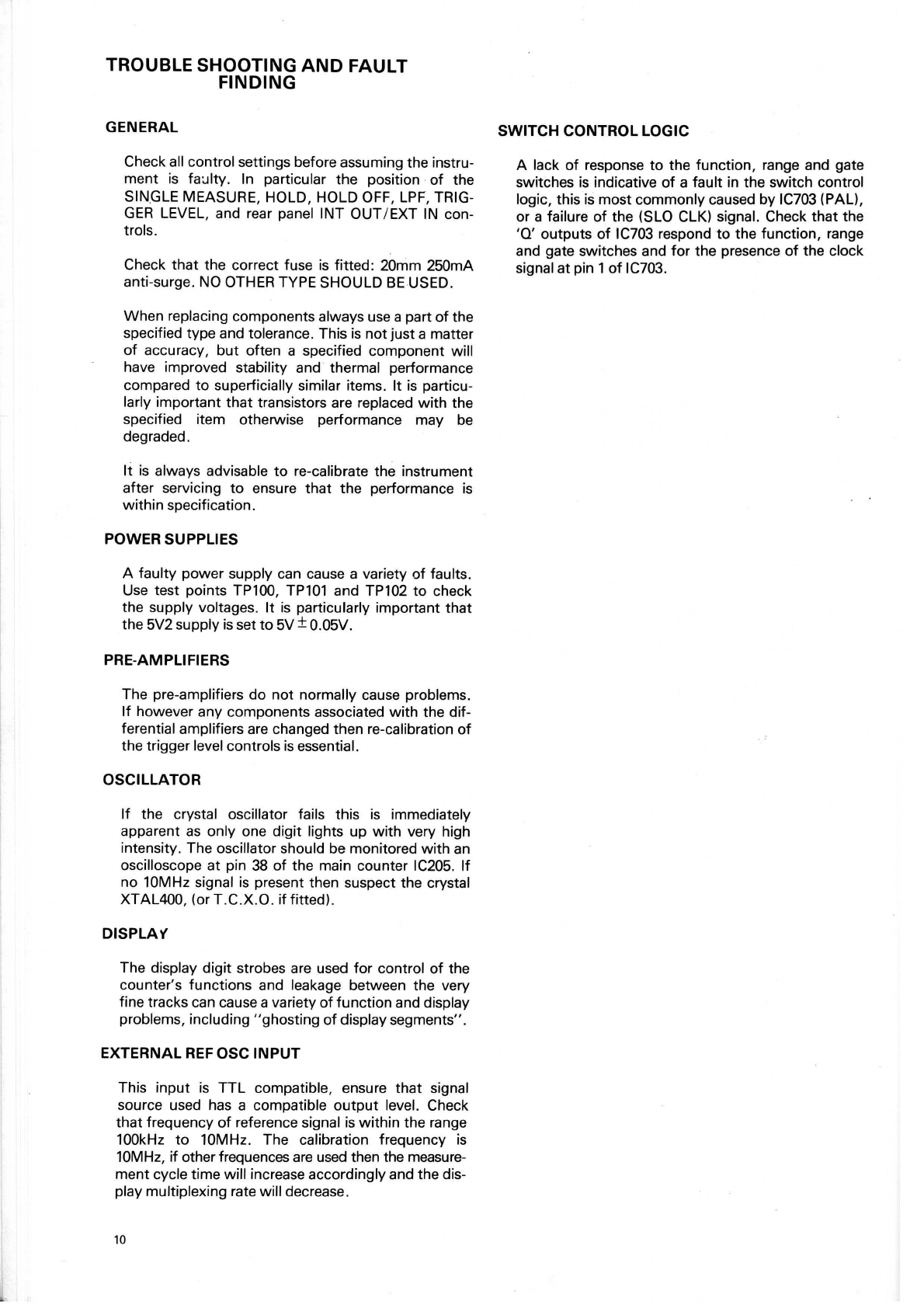

TROUBLE SHOOTING

AND

FAULT

FINDING

GENERAL

Check all control settings before assuming the instru-

ment

is

fa:..ilty. In particular the position

of

the

SINGLE MEASURE, HOLD, HOLD OFF, LPF, TRIG-

GER

LEVEL, and rear panel INT OUT

/EXT

IN

con-

trols.

Check

that

the correct fuse

is

fitted: 20mm 250mA

anti-surge. NO OTHER TYPE SHOULD

BE

USED.

When

replacing components always use a part

of

the

specified type and tolerance. This

is

not

just a matter

of

accuracy,

but

often a specified component will

have improved stability and thermal performance

compared

to

superficially similar items.

It

is

particu-

larly important

that

transistors are replaced

with

the

specified item otherwise performance may be

degraded.

It

is

always advisable

to

re-calibrate the instrument

after servicing

to

ensure

that

the performance

is

within

specification.

POWER SUPPLIES

A faulty

power

supply can cause a variety

of

faults.

Use test points TP100,

TP101

and TP102

to

check

the supply voltages.

It

is

particularly important

that

the 5V2 supply

is

set

to

5V ±0.05V.

PRE-AMPLIFIERS

The pre-amplifiers

do

not

normally cause problems.

If

however any components associated

with

the dif-

ferential amplifiers are changed then re-calibration

of

the trigger level controls

is

essential.

OSCILLATOR

If

the crystal oscillator fails this

is

immediately

apparent

as

only one digit lights up

with

very high

intensity. The oscillator should be monitored

with

an

oscilloscope at pin

38

of

the main counter IC205.

If

no 10MHz signal

is

present then suspect the crystal

XTAL400,

(orT.C.X.O.

if

fitted).

DISPLAY

The display digit strobes are used

for

control

of

the

counter's functions and leakage between the very

fine tracks can cause a variety

of

function

and display

problems, including

"ghosting

of

display segments".

EXTERNALREFOSCINPUT

This

input

is

TTL

compatible, ensure

that

signal

source used has a compatible

output

level. Check

that

frequency

of

reference signal

is

within

the range

100kHz

to

10MHz. The calibration frequency

is

10MHz, if other frequences

are

used then the measure-

ment cycle time will increase accordingly and the dis-

play multiplexing rate will decrease.

10

SWITCH CONTROL LOGIC

A lack

of

response

to

the function, range and gate

switches

is

indicative

of

a fault in the switch control

logic, this

is

most commonly caused by IC703 (PAL),

or a failure

of

the (SLO CLK) signal. Check

that

the

'Q'

outputs

of

IC703 respond

to

the function, range

and gate switches and

for

the presence

of

the clock

signal

at

pin 1

of

IC703.

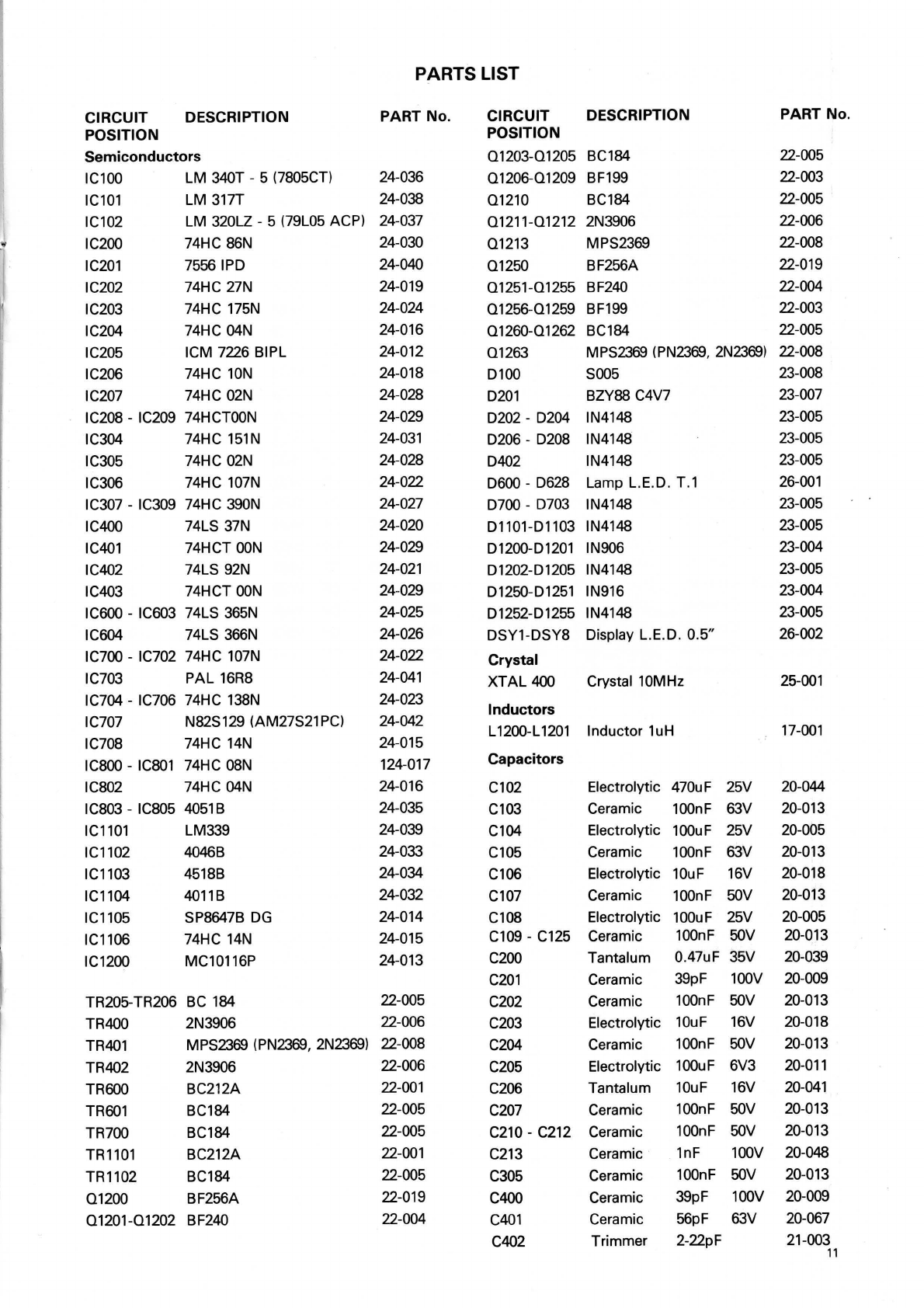

PARTS LIST

CIRCUIT DESCRIPTION PART No. CIRCUIT DESCRIPTION PART No.

POSITION POSITION

Semiconductors 01203-01205 BC184 22-005

IC100

LM

340T - 5 (7805CT) 24-036 01206-01209 BF199 22-003

IC101

LM

317T 24-038 01210 BC184 22-005

IC102

LM

320LZ - 5 (79L05 ACP) 24-037 01211-01212 2N3906 22-006

y IC200 74HC 86N 24-030 01213 MPS2369 22-008

IC201

7556 IPD 24-040 01250 BF256A 22-019

IC202 74HC 27N 24-019 01251-01255 BF240 22-004

IC203 74HC 175N 24-024 01256-01259 BF199 22-003

IC204 74HC 04N 24-016 01260-01262 BC184 22-005

IC205 ICM 7226 BIPL 24-012 01263 MPS2369 (PN2369, 2N2369) 22-008

IC206 74HC 10N 24-018 D100 S005 23-008

IC207 74HC 02N 24-028

D201

BZY88 C4V7 23-007

IC208 -IC209

74HCTOON

24-029 D202 -D204 IN4148 23-005

IC304 74HC 151N 24-031 D206 -D208 IN4148 23-005

IC305 74HC 02N 24-028 D402 IN4148 23-005

IC306 74HC 107N 24-022 D600 -D628 Lamp L.E.D. T.1 26-001

IC307 -IC309 74HC 390N 24-027 D700 -D703 IN4148 23-005

IC400 74LS 37N 24-020 D1101-D1103 IN4148 23-005

IC401 74HCT

OON

24-029 D1200-D1201 IN906 23-004

IC402 74LS 92N 24-021 D1202-D1205 IN4148 23-005

IC403 74HCT

OON

24-029 D1250-D1251 IN916 23-004

IC600 -IC603 74LS 365N 24-025 D1252-D1255 IN4148 23-005

IC604 74LS 366N 24-026

DSY1-DSY8

Display L.E.D.

0.5"

26-002

IC700 -IC702 74HC 107N 24-022 Crystal

IC703

PAL

16R8 24-041

XTAL

400 Crystal 10MHz 25-001

IC704 -IC706 74HC 138N 24-023 Inductors

IC707 N82S129 (AM27S21PC) 24-042 L1200-L1201

Inductor

1uH 17-001

IC708 74HC 14N 24-015

ICBOO

-IC801 74HC 08N 124-017 Capacitors

IC802 74HC 04N 24-016 C102 Electrolytic 470uF 25V 20-044

IC803 -IC805

4051

B 24-035 C103 Ceramic 100nF 63V 20-013

IC1101 LM339 24-039 C104 Electrolytic 100uF 25V 20-005

IC1102 4046B 24-033 C105 Ceramic 100nF 63V 20-013

IC1103 4518B 24-034 C106 Electrolytic 10uF 16V 20-018

IC1104 4011B 24-032 C107 Ceramic 100nF 50V 20-013

IC1105 SP8647B DG 24-014 C108 Electrolytic 100uF 25V 20-005

IC1106 74HC 14N 24-015 C109 -C125 Ceramic 100nF 50V 20-013

IC1200 MC10116P 24-013 C200 Tantalum 0.47uF 35V 20-039

C201

Ceramic 39pF 100V 20-009

TR205-TR206 BC 184 22-005 C202 Ceramic 100nF 50V 20-013

TR400 2N3906 22-006 C203 Electrolytic 10uF 16V 20-018

TR401 MPS2369 (PN2369, 2N2369) 22-008 C204 Ceramic 100nF 50V 20-013

TR402 2N3906 22-006 C205 Electrolytic 100uF 6V3

20-011

TR600 BC212A 22-001 C206 Tantalum 10uF 16V 20-041

TR601 BC184 22-005 C207 Ceramic 100nF 50V 20-013

TR700 BC184 22-005 C210 -C212 Ceramic 100nF 50V 20-013

TR1101 BC212A 22-001 C213 Ceramic 1nF 100V 20-048

TR1102 BC184 22-005 C305 Ceramic 100nF 50V 20-013

01200

BF256A 22-019 C400 Ceramic 39pF 100V 20-009

01201-01202

BF240 22-004

C401

Ceramic 56pF 63V 20-067

C402

Trimmer

2-22pF 21-003

11

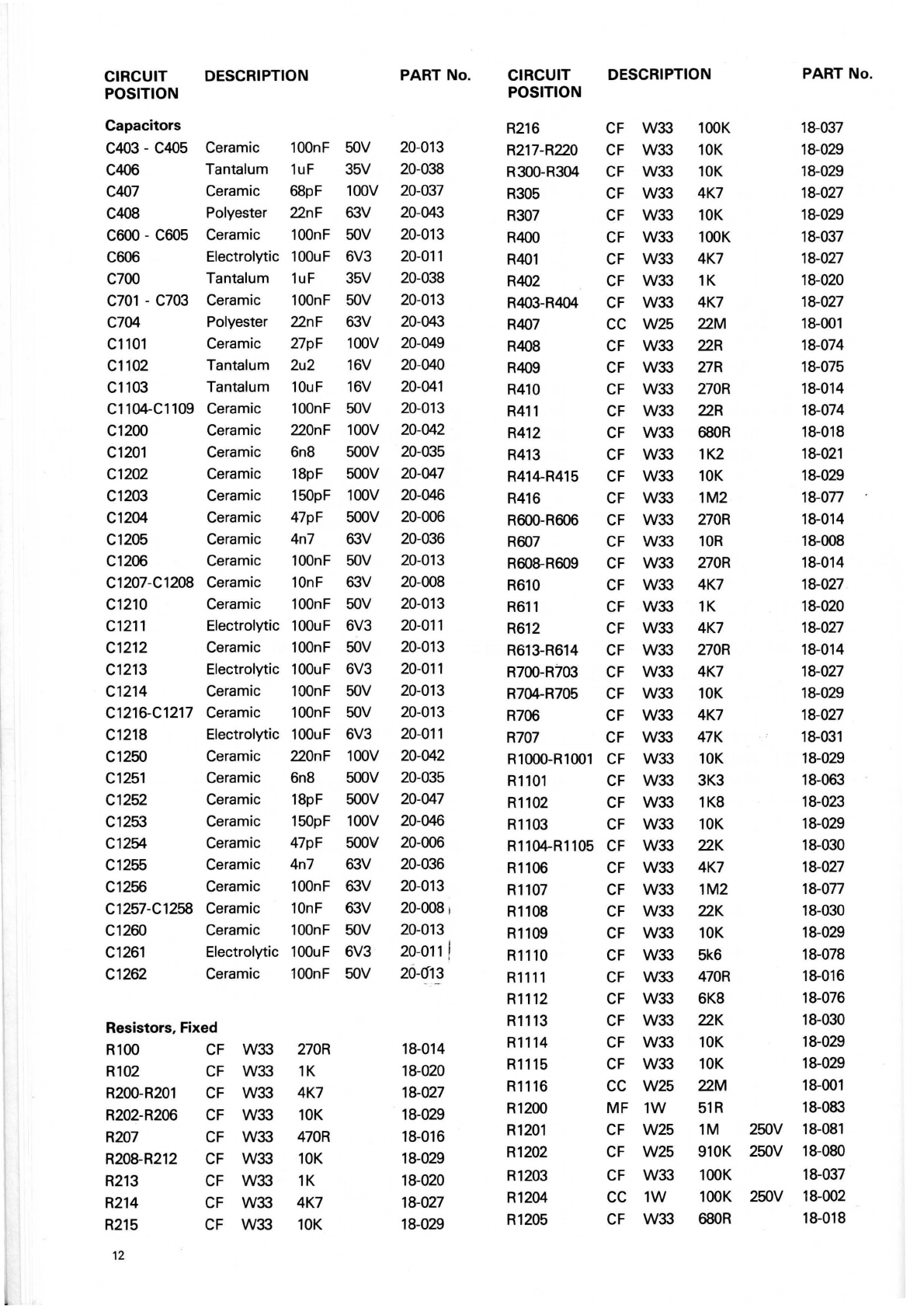

CIRCUIT DESCRIPTION PART No. CIRCUIT DESCRIPTION PART No.

POSITION POSITION

Capacitors R216

CF

W33

100K 18-037

C403 -C405 Ceramic 100nF 50V 20-013 R217-R220 CF

W33

10K 18-029

C406

Tantalum

1uF 35V 20-038 R300-R304 CF

W33

10K 18-029

C407 Ceramic 68pF 100V 20-037 R305

CF

W33

4K7 18-027

C408 Polyester 22nF 63V 20-043 R307 CF

W33

10K 18-029

C600 -C605 Ceramic 100nF 50V 20-013 R400 CF

W33

100K

18

-037

C606 Electrolytic 100uF 6V3 20-011

R401

CF

W33

4K7 18-027

C700

Tantalum

1uF 35V 20-038 R402 CF

W33

1K 18-020

C701

-C703 Ceramic 100nF 50V 20-013 R403-R404

CF

W33

4K7 18-027

C704 Polyester 22nF 63V 20-043 R407 cc

W25

22M 18-001

C1101 Ceramic 27pF 100V 20-049 R408 CF

W33

22R 18-074

C1102

Tantalum

2u2 16V 20-040 R409

CF

W33

27R 18-075

C1103

Tantalum

10uF 16V 20-041 R410

CF

W33

270R 18-014

C1104-C1109 Ceramic 100nF 50V 20-013

R411

CF

W33

22R 18-074

C1200 Ceramic 220nF 100V 20-042 R412 CF

W33

680R 18-018

C1201 Ceramic 6n8 500V 20-035 R413

CF

W33

1K2 18-021

C1202 Ceramic 18pF 500V 20-047 R414-R415

CF

W33

10K 18-029

C1203 Ceramic 150pF 100V 20-046 R416

CF

W33

1M2

18-077

C1204 Ceramic 47pF 500V 20-006 R600-R606 CF

W33

270R 18-014

C1205 Ceramic 4n7 63V 20-036 R607

CF

W33

10R

18-008

C1206 Ceramic 100nF 50V 20-013 R608-R609 CF

W33

270R 18-014

C1207-C1208 Ceramic 10nF 63V 20-008 R610

CF

W33

4K7

18

-027

C1210 Ceramic 100nF 50V 20-013

R611

CF

W33

1K 18-020

C1211 Electrolytic 100uF 6V3 20-011 R612 CF

W33

4K7 18-027

C1212 Ceramic 100nF 50V 20-013 R613-R614 CF

W33

270R 18-014

C1213 Electrolytic 100uF 6V3 20-011 R700-R703

CF

W33

4K7 18-027

C1214 Ceramic 100nF 50V 20-013 R704-R705

CF

W33

10K 18-029

C1216-C1217 Ceramic 100nF 50V 20-013 R706 CF

W33

4K7 18-027

C1218 Electrolytic 100uF 6V3 20-011 R707 CF

W33

47K 18-031

C1250 Ceramic 220nF 100V 20-042 R1000-R1001 CF

W33

10K 18-029

C1251 Ceramic 6n8 500V 20-035

R1101

CF

W33

3K3 18-063

C1252 Ceramic 18pF 500V 20-047 R1102 CF

W33

1K8 18-023

C1253 Ceramic 150pF 100V 20-046 R1103 CF

W33

10K 18-029

C1254 Ceramic 47pF 500V 20-006 R1104-R1105 CF

W33

22K 18-030

C1255 Ceramic 4n7 63V 20-036 R1106 CF

W33

4K7 18-027

C1256 Ceramic 100nF 63V 20-013 R1107 CF

W33

1M2

18-077

C1257-C1258 Ceramic 10nF

63V

20-008 1 R1108 CF

W33

22K 18-030

C1260 Ceramic 100nF 50V 20-013 R1109 CF

W33

10K 18-029

C1261 Electrolytic 100uF

6V3

20-011 I

Rl

110 CF

W33

5k6 18-078

C1262 Ceramic 100nF 50V

20-Cf13

R1111

CF

W33

470R 18-016

R1112 CF

W33

6K8

18-076

Resistors, Fixed R1113

CF

W33

22K

18-030

R100

CF

W33

270R 18-014 R1114 CF

W33

10K 18-029

R102 CF

W33

1K 18-020 R1115

CF

W33

10K 18-029

R200-R201 CF

W33

4K7 18-027 R1116 cc

W25

22M 18-001

R202-R206 CF

W33

10K 18-029 R1200

MF

1W

51R 18-083

R207

CF

W33

470R 18-016

R1201

CF

W25

1M

250V 18-081

R208-R212 CF

W33

10K 18-029 R1202

CF

W25

910K 250V 18-080

R213

CF

W33

1K 18-020 R1203 CF

W33

100K 18-037

R214 CF

W33

4K7 18-027 R1204 cc

1W

100K 250V 18-002

R215 CF

W33

10K 18-029 R1205 CF

W33

680R 18-018

12

CIRCUIT DESCRIPTION PART No. CIRCUIT DESCRIPTION PART No.

POSITION POSITION

Resistors, Fixed

R1275

CF

W33

330R

18-015

R1206

CF

W33

330R

18-015

R1276

CF

W33

470R

18-016

R1207

CF

W33

680R

18-018

R1277

CF

W33

1K8

18-023

R1208

CF

W33

1K

18

-

020

R1278

CF

W33

820R

18-019

R1209

CF

· W33

330R

18

-

015

R1279

CF

W33

10K

18-029

R1210

CF

W33

560R

18-017

R1280

CF

W33

1K

18-020

R1211

CF

W33

680R

18-018

R1281

CF

W33

10R

18-008

R1212

CF

W33

100R

18-012

R1289

MF

W5

82R

18-087

R1213-R1214

CF

W33

680R

18-018

RB800

Block SIL 8 x

4K7

18-082

R1215-R1216

CF

W33

82R

18-038

Resistors, Variable

R1217

CF

W33

15K

18-036

R1220

CF

W33

12K

18-065

R101

Open

preset Hor. W2

100R

19-004

R1221

CF

W33

10K

18-029

R1218

Variable Pot. linear

2K

19-001

R1222

CF

W33

4K7

18-027

R1219

Open

preset Vert W2

4K7

19-011

R1223

CF

W33

330R

18

-

015

R1268

Variable Pot. linear

2K

19-001

R1224

CF

W33

470R

.

18

-

016

R1269

Open

preset Vert W2

4K7

19-011

R1225

CF

W33

330R

18-015

RV1000-

R1226

CF

W33

470R

18-016

RV1001

Variable Pot. linear 1M

19-003

R1227

CF

W33

1K8

18-023

Switches

R1228

CF

W33

820R

18

-

019

S400

Slide 2P2W

16-001

R1229

CF

W33

10K

18-029

S1001-S1002

Slide 2W2W

16-006

R1230

CF

W33

1K

18-020

S1003-S1010

Push

8 position

16-009

R1231

CF

W33

10R

18-008

S1008-S1010

Push

3 position

16-010

R1232

CF

W33

100R

18-012

S1200

Slide 2P4W

16-007

R1233

CF

W33

180R

18

-

062

S1201

Slide 2P2W

16-006

R1234

CF

W33

1K

18-020

S1250

Slide 2P4W

16-007

R1235

CF

W33

180R

18-062

S1251

Slide 2P2W

16-006

R1236

CF

W33

1K

18-020

SW100 Mains,

on/off

rocker

16-011

R1237-R1238

CF

W33

2K2

18-024

Sockets/Connectors/Pins

R1239

MF W5

82R

18-087

SK100

Socket housing 4 way

14-029

R1250

MF 1W

51R

18-083

SK101

Socket housing 6 way

14-031

R1251

CF

W25

1M

250V

18-081

SK102

Socket mains I.E.C.

14-017

R1252

CF

W25

910K

250V

18-080

SK401

Socket housing 8 way

14-033

R1253

CF

W33

100K

18-037

SK200

Socket

4mm

red

14-023

R1254

cc 1W

100K

250V

18-002

SK200

Socket 4mm black

14-022

R1255

CF

W33

680R

18-018

SK400

Socket

BNC

50

Ohm

14-002

R1256

CF

W33

330R

18-015

SK600-SK603 Socket P.C.B.

14-025

R1257

CF

W33

680R

18-018

SK1200

Socket

BNC

50

Ohm

14-002

R1258

CF

W33

1K

18-020

SK1201a

Socket P.C.B.

14-026

R1259

CF

W33

330R

18-015

SK1201b

Socket P.C.B.

14-027

R1260

CF

W33

560R

18-017

SK1202

Socket P.C.B.

14-014

R1261

CF

W33

680R

18-018

SK1203

Socket P.C.B.

14-026

R1262

CF

W33

100R

18-012

SK1250

Socket

BNC

50

Ohm

14-002

R1263

-

R1264

CF

W33

680R

18-018

TP100-TP103

Test pins

14-005

R1265

-

R1266

CF

W33

82R

18-038

PL100

Plug

4 way

14-028

R1267

CF

W33

15K

18-036

PL101

Plug

6 way

14-030

R1270

CF

W33

12K

18-085

PL401

Plug

8 way

14-032

R1271

CF

W33

10K

18-029

R1272

CF

W33

4K7

18-027

R1273

CF

W33

330R

18-015

R1274

CF

W33

470R

18-016

13

DESCRIPTION

Miscellaneous

Socket I.C.

40

pin O.1.L.

(3)

Socket I.C.

20

pin O.1.L.

Socket I.C.

16

pin O.1.L.

Socket I.C.

14

pin

O.1.L.

Spacer P.V.C. (L.E.O.)

(29)

Tag, Solder (B.N.C.)

(3)

Sleever, Rubber H15

(13)

Shroud, mains

Pin, P.C.B.

(8)

Pin, P.C.B.

(62)

Fuse

, 20mm 250mA anti-surge

(2)

P.C.B. (main)

P.C.B. (Front panel)

P.C.B. (Pre-amp)

P.C.

B.

(Switch)

Front panel printed (Apollo

10)

Front panel printed (Apollo

100)

Case

upper (inserts)

Case

lower (drilled)

Expansion strip

(2)

Foot A

(2)

Foot B

(2)

Leg

Screw M3 x

70

(4)

Pad,

foot

(4)

Rear Panel, printed

Knob, grey

(4)

Knob cap blue

(4)

Knob cap green

(2)

Stand-off washer B.N.C.

(2)

Insulator B.N.

C.

(2)

Button, grey

(8)

Washer, Mic

(2)

Screw 6BA x

½"

Pozi

PN

HO

(2)

Nut

6BA

(2)

Washer 6BA

(2)

Washer, shakeproof M3

(5)

Insulator, top hat T0220

(2)

Screw M3 x

12

Tamper proof

Screw M3 x

10

Pozi C/S

(2)

Screw No. 4 x ¼" Pozi

(4)

Nut

M3

(3)

Screw M4 x

12

Pozi

PN

HO

(27

Screw M4 x

12

Pozi

PN

HO

(2)

Nut M4

(2)

Solder tag 5BA

(2)

Screw M2.5 x 0.45 x 5 Pozi

PN

HO

(2)

M4 Shakeproof washer

(2)

Poly bag 12" x 16"

Poly bag 7" x

9"

(2)

14

PART No.

14-013

14-036

14-016

14-037

13-030

14-003

15-004

15-005

14-024

14-015

33-002

30-006

30-007

30-008

30-009

28

-

007

28-008

27-001

27-002

27-003

27-004

27-005

27-008

13-003

27-009

28-010

29-011

29-013

29-012

13-020

15-002

29-007

13-028

13-021

13-009

13-007

13-018

15-003

13-022

13-023

13-010

13-019

13-024

13-025

14

-

035

13-026

13-027

31-010

31-011

DESCRIPTION

Manual, instruction

Guarantee card (U.K.)

Mains lead (U.K., Euro or USA)

Polystyrene end cap

(2)

Carton

Heatsink

Transformer 24VA

PART No.

31-038

31-009

As appro-

priate

31-004

31-006

38-002

40-002

I

~

C

G

O"'

o+c11

0

R;

-=---

C103C1O04

IC307 IC308

i1

40

1\ Q IO

~

C1

07

Cl10

ol

J[]

c1~ +

a, E

;;

C406

-+ PL101 0

□

+

j TA

400

cc

R102

0

()

TR40

1 1 1

E c

R7

06

C112

I

Rv100

12

5

crn

I RJ

01

ID

~

IN

?O

UT

D100

IC

3

09

IC202

M

a:

400

0

~~

~

□

PU00

;;; ;;; 1 1 l K 1

R415

c100

TP

101

cc

,....

cc

---==-----

'cJ

_

os

_

20

_0

,

_c

2_oa_ L_K 301

I; 1 I 1

D4

02

TP10

2

...__

________

___.

7

TP103

0

IC

304

CC

□

+- 0

PL202

PL4

01

C D D

lK

C408

IC

IC803

I C113

0

~u:M

~

,::~

n

::

--

,

rn"i'~

~

't~ }

,c,o,~~

;1

°'

1

~.tr

~

11

I•

-'""

[]

0

IT

,

□

""l

ID'

"'

"'"

:U,

,

..

, L)

1J

~~

ii

~

i

(ii

□

:

,,,

,,,.

'.

1n

'""

"'"

,ooo • + "O

+O~DD

~

lJ

1 1

C401

TR206

TR205

D C C119

"'OD

T;

·"'l1,,.

~

\

C402

g 81 t

~

~ ~

C

~

1

R303

□

R221

_,

11

-C21J

_ D2

D9

+-

,.

-

R305

,

2~

0

~

N

:g

D

.___

_

___,

UN

C[

N

ID

1 u

cc

C305

D

202

+- o

C405

N +

C123

rr

xo

..!.

IC

I

805

C118 G

700

.

"""

D

IC702

R704

I

,~

1

C705

1 1

c,2,

D701 tt~

IC701

, IC801

c120

omtt~

IC704

c~

cc

C207

IC

,---1

--1

I 1

IC

700

708..._

__

__,_

1

:·

R201

1

t:!.

ISK601

R219

I SK6021

R200

1

:

1 I

~

1

R70][]1

C701

SK603

D

□

--

.

____

_.

C702

C1

24

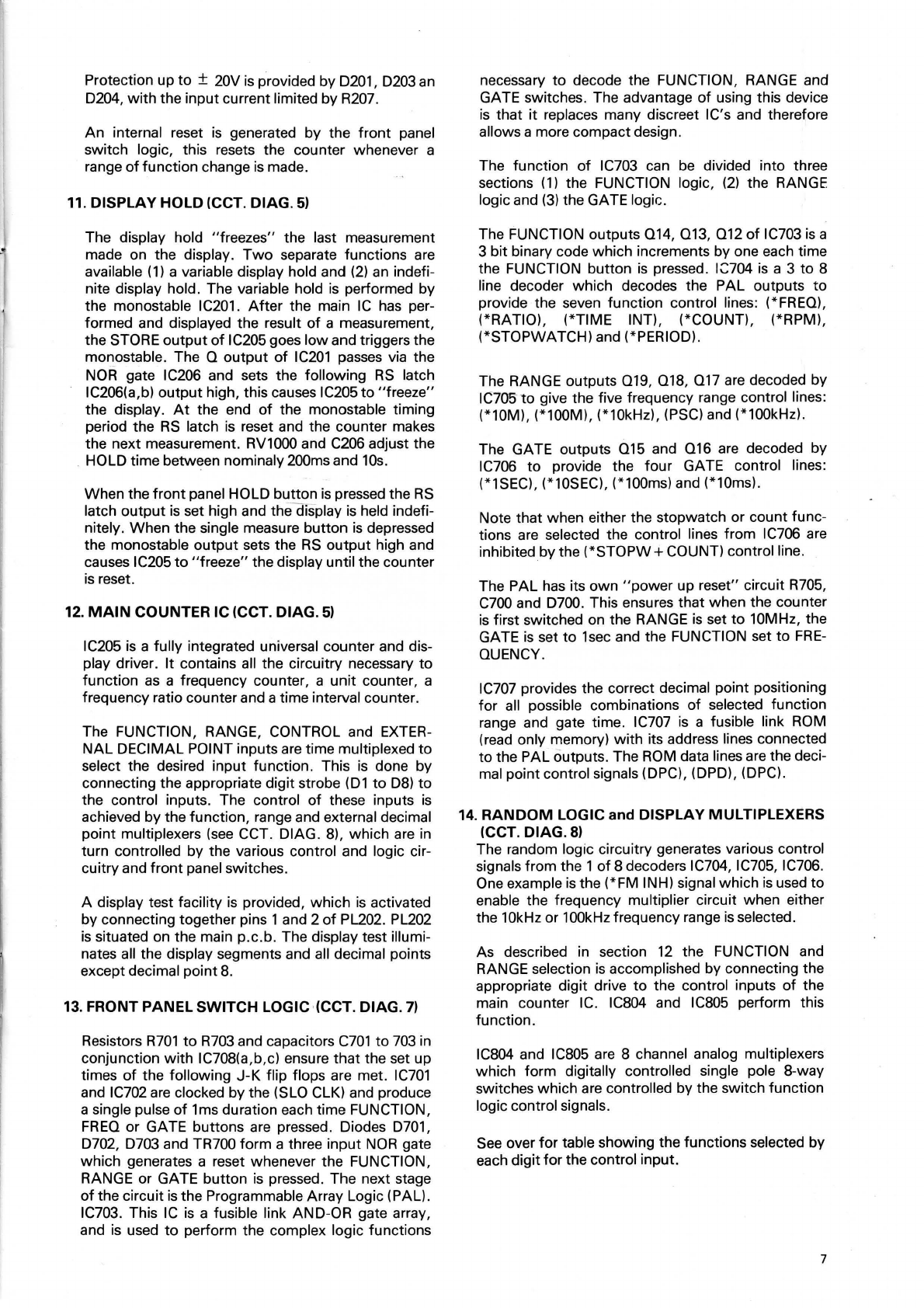

COMPONENT

LAYOUT

MAIN

PCB

15

c.

1107

·~F

IC.

1105

IC

\1

02 H

E.F

40 4-6B

~1105

T

I

~

S I .3 .S

I

S11031

I

SILOl1

·~

2. "\" 6

2.

4 t,

DII0..3,

~

S

P%

47B

e.

b

TRZ

2 '

Rl21

N

~~

~

T

A.12I1

2N~'.'06

.......

-~

I

c.

\\0

~

H.12.E,3,

ZNBb~

@

C.12-1

'?

HEF

4 S l8

E,

~

~~

~jl--

T

ll.00

12.

I

1-\

I

COMPONENT

LAYOUT PREAMP PCB

g

I"

IL

.--------

-------------

--rc

r -

D

S'r

!!,

D~Y

7

\).'.,Y

S

~~

'D<oO,!i

D..,

u~

DS

O/

"~

© @ @ @

"''

'

,o

r,

~

I\ R

10

...

!>

IQ~

•-S

I$

IQ > "

0\

c

<ooo

..,

,

I.JO 7 7 7

...L

!i(

!)

T

1

00~

'"

51010

□

[g]

1\

11.N

(,,E

®000

00

@

~00000

G

°l>

L.G.

00

1"

PL

"OI

Components

shown

dotted are

ob

scured

by

higher components

R1203, 1253 and C1203, C1253 are mounted on the reverse

of

the

board

r-'---'--'--'--'-----'-----'-~-~

-~:!,

Ic«o:!> W,-.

7'\-~S3c,,'..,

N

@

000

0 0 @

@0

0

000

@

? L

"oz.

PL.M~

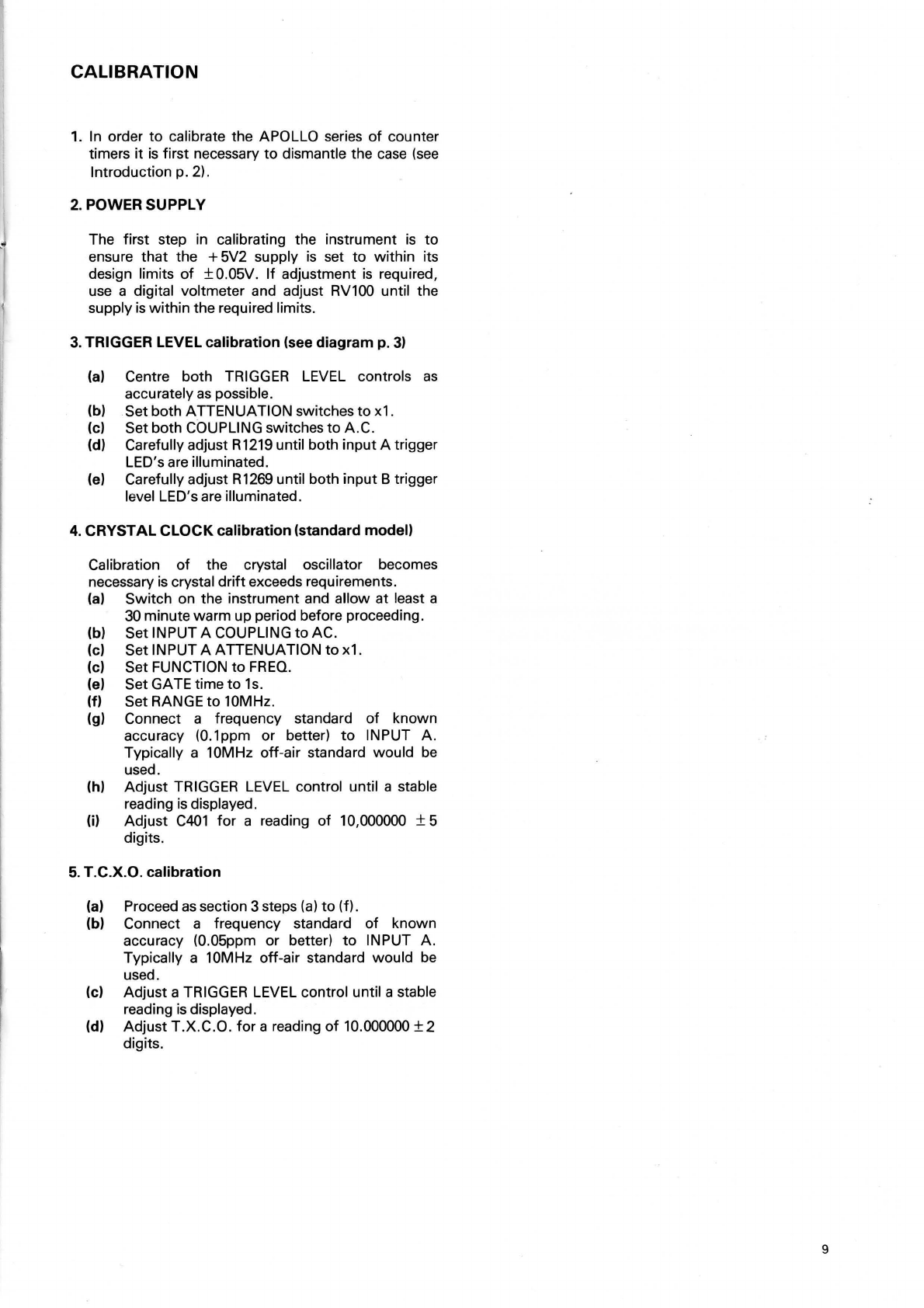

COMPONENT

LAYOUT FRONT PANEL PCB

0PI

C\2.0J.

ISOf'

Df.27

"05S I OOl S IC) 0 I

Pb0

6

II

IIII

II

11111111

D R R

1251

[i]

12.0I

N>Z6

IM

61

Sl251

o

Pi201

5.120

I

11111111

I C

a'.

C

11111111

1252

1200

I

8p

220n

512.50

m

512..00

11111111

m

11111111

l!i

R\250

51

!ill

~

PL

1201

b

COMPONENT LAYOUT SUB BOARD

PCB

18

PGOlg

IPWl(Q)

~03