Blancett 1100 Series Service manual

8635 Washington Avenue

Racine, Wisconsin 53406

Toll Free: 800.235.1638

Phone: 262.639.6770 •Fax: 262.417.1155

www.blancett.com

Model 1100

Turbine Flow Meter

INSTALLATION & INSTRUCTION

MANUAL

Form No. B110-001 08/10 3

TABLE OF CONTENTS

Introduction ................................................................................................4

Operating Principle..................................................................................4

Specications..............................................................................................6

Installation...................................................................................................7

Operational Start-up............................................................................10

Troubleshooting.....................................................................................11

Part Number Information..................................................................12

Repair Kit Information.........................................................................13

Statement of Warranty........................................................................14

NOTE: Blancett reserves the right to make any changes or improvements

to the product described in this manual at any time without notice.

4 Form No. B110-001 08/10

INTRODUCTION

The Model 1100 Turbine Flow Meter is designed to withstand the demands

of the most rigorous ow measurement applications. Originally developed

for the secondary oil recovery market, the Model 1100 is an ideal meter for

liquid ow measurement on or o the oil eld.

The meter features a rugged 316 stainless steel housing and rotor

support assemblies, CD4MCU stainless steel rotor, and abrasive-resistant

tungsten carbide rotor shaft and journal bearings. Model 1100 maintains

measurement accuracy and mechanical integrity in the corrosive and

abrasive uids commonly found in oil eld water ood projects and many

industrial applications.

OPERATING PRINCIPLE

Fluid entering the meter passes through the inlet ow straightener which

reduces its turbulent ow pattern and improves the uid’s velocity prole.

Fluid then passes through the turbine, causing it to rotate at a speed

proportional to the uid velocity. As each turbine blade passes through

the magnetic eld at the base of the transducer, an AC voltage pulse is

generated in the pick-up coil. See Figure 1. These pulses produce an

output frequency proportional to the volumetric ow through the meter.

The output frequency is used to represent ow rate and/or totalization of

uid passing through the turbine ow meter.

Figure 1

Schematic illustration of electric signal

generated by rotor movement

Form No. B110-001 08/10 5

Figure 2

Typical cross-section of B110-375 through

B111-121 turbine ow meter

MAGNETIC PICK-UP

RETAINING RING

GROOVE

METER BODY

RETAINER PINS

CONDUIT ADAPTOR

* RETAINING

RING

* UPSTREAM

ROTOR SUPPORT

* DOWNSTREAM

ROTOR SUPPORT

* BEARING

* THRUST BALL

NOTE: * INDICATES PARTS CONTAINED IN REPAIR KITS

* ROTOR AND

ROTOR SHAFT

6 Form No. B110-001 08/10

SPECIFICATIONS

MATERIALS of CONSTRUCTION:

Body: 316 Stainless Steel

Rotor: CD4MCU Stainless Steel

Rotor Support: 316 Stainless Steel

Rotor Shaft and Bearings: Tungsten Carbide

OPERATING LIMITATIONS:

Temperature: -150 °F to +350 °F (-101 °C to +177 °C)

The meter should not be subjected to temperatures

above +350 °F (+177 °C), or below -150 °F (-101 °C)

or the freezing point of the metered liquid. High

temperatures will damage the magnetic pick-up, while

lower temperatures will limit the rotation of the rotor.

Pressure: Maximum pressure ratings as follows:

5,000 psi − all NPT meters up to 2”

2,000 psi − 3” male NPT

1,500 psi − 4” male NPT

1,000 psi − 6” male NPT

800 psi − all grooved end meters

Note: Consult factory for pressure ratings for anged

meters.

Accuracy: ±1.0% of reading for ¾”and larger meters

±1.0% of reading over the upper 70% of the measuring

range for ” and ½” meters

Repeatability: ±0.1%

Calibration: Water (NIST Traceable Calibration)

Corrosion: All Blancett Model 1100 turbine meters are constructed

of stainless steel and tungsten carbide. The operator must

ensure that the operating uid is compatible with these

materials. Incompatible uids can cause deterioration

of internal components and cause a reduction in meter

accuracy.

WARNING: Pressure in excess of allowable rating may cause the housing to

burst and cause serious personal injury.

AVERTISSEMENT: La pression au-dessus de l’estimation permise peut faire

éclater et causer le logement le dommage corporel sérieux.

Form No. B110-001 08/10 7

Pulsation and

Vibration: Severe pulsation and mechanical vibration will aect

accuracy and shorten the life of the meter.

Filtration: If small particles are present in the uid, Blancett

recommends that strainer be installed upstream

of the meter (see Table 1 on page 8 for ltration

recommendations).

REPAIR KIT:

The Model 1100 Turbine Flow Meter Repair Kit is designed for easy eld

service of a damaged ow meter, rather than replacing the entire ow

meter. See Appendix C on page 13 for repair kit information. Repair

parts are constructed of stainless steel alloy and tungsten carbide and

are factory calibrated to ensure accuracy throughout the entire ow

range. Each kit is complete and includes the calibrated K-factor which

is used to recalibrate the ow monitor or other electronics to provide

accurate output data.

INSTALLATION INSTRUCTIONS

Prior to installation, the ow meter should be checked internally for foreign

material and to ensure the turbine rotor spins freely. Fluid lines should also

be checked and cleared of all debris.

The ow meter must be installed with the ow arrow, etched on the exterior

of the meter body, pointing in the direction of uid ow. Though the meter

is designed to function in any position it is recommended, where possible,

to install horizontally with the magnetic pick-up facing upward.

The liquid being measured should be free of any large particles that may

obstruct rotation of the rotor. If particles are present, a mesh strainer

should be installed upstream before operation of the ow meter. See

Table 1 on page 8.

8 Form No. B110-001 08/10

Part Number Strainer Mesh Clearance Filter Size

B110-375 60 × 60 .0092 260 Micron

B110-500 60 × 60 .0092 260 Micron

B110-750 60 × 60 .0092 260 Micron

B110-875 60 × 60 .0092 260 Micron

B111-110 60 × 60 .0092 260 Micron

B111-115 20 × 20 .0340 .86mm

B111-120 10 × 10 .0650 1.6mm

B111-121 20 × 20 .0340 .86mm

B111-130, B311-004 8 × 8 .0900 2.3mm

B111-140, B311-084 10 × 10 .0650 1.6mm

B111-160, B311-085 4 × 4 .1875 4.8mm

B111-180 8 × 8 .0900 2.3mm

B111-200 4 × 4 .1875 4.8mm

Table 1

Filtration recommendations

The preferred plumbing setup is one containing a by-pass line that

allows meter inspection and repair without interrupting flow. If a by-

pass line is not utilized, it is important that all control valves be located

downstream of the flow meter. See Figures 3 and 4 on page 9.

This is true with any restriction in the ow line that may cause the liquid

to ash. If necessary, air eliminators should be installed to ensure that the

meter is not incorrectly measuring entrained air or gas.

It is recommended that a minimum length of straight pipe, equal to ten

(10) pipe diameters, be installed on the upstream side and ve (5) pipe

diameters on the downstream side of the ow meter. Otherwise, meter

accuracy may be aected. Piping should be the same size as the meter bore

or threaded port size.

CAUTION: Damage can be caused by striking an empty meter with a high

velocity ow stream.

ATTENTION: Des dommages peuvent être provoqués en frappant un mètre

vide avec un jet d’écoulement de vitesse élevée.

Form No. B110-001 08/10 9

Do not locate the ow meter or connection cable close to electric motors,

transformers, sparking devices, high voltage lines, or place connecting

cable in conduit with wires furnishing power for such devices. These devices

can induce false signals in the ow meter coil or cable, causing the meter

to read inaccurately.

If problems arise with the ow meter and monitor, consult Appendix A

(Troubleshooting Guide) on page 11. If further problems arise, consult the

factory.

If the internal components of the turbine ow meter are damaged beyond

repair, turbine meter repair kits are available. Information pertaining to the

turbine meter repair kits is referenced in Appendix C on page 13.

Figure 3

Meter installation utilizing a by-pass line

Figure 4

Meter installation without utilizing a by-pass line

10 Form No. B110-001 08/10

OPERATIONAL START-UP

The following steps should be followed when installing and starting the

meter.

1. After meter installation, close the isolation valves and open the by-

pass valve. Flow liquid through the by-pass valve for sucient time to

eliminate any air or gas in the ow line.

2. Open upstream isolating valve slowly to eliminate hydraulic shock

while charging the meter with the liquid. Open the valve to full open.

3. Open downstream isolating valve to permit meter to operate.

4. Close the by-pass valve to a full closed position.

5. Adjust the downstream valve to provide the required ow rate through

the meter.

NOTE: The downstream valve may be used as a control valve.

WARNING: Make sure that uid ow has been shut o and pressure in the

line released before attempting to install the meter in an existing system.

CAUTION: High velocity air or gas may damage the internal components

of the meter.

AVERTISSEMENT: Assurez-vous que le ux de uide a été coupé et de la

pression dans la ligne a été libérée avant d’essayer d’installer le mètre dans

un système actuel.

ATTENTION: L’air ou le gaz de vitesse élevée peut endommager les

composants internes du mètre.

Form No. B110-001 08/10 11

APPENDIX A

TROUBLESHOOTING GUIDE

Trouble Possible Cause Remedy

Meter indicates higher

than actual ow rate

•Cavitation

•Debris on rotor support

•Build up of foreign material

on meter bore

•Gas in liquid

•Increase back pressure

•Clean meter

•Clean meter

•Install gas eliminator ahead

of meter

Meter indicates lower

than actual ow rate

•Debris on rotor

•Worn bearing

•Viscosity higher than

calibrated

•Clean meter and add lter

•Install new repair kit

•Recalibrate monitor

Erratic system

indication, meter alone

works well (remote

monitor application

only)

Ground loop in shielding Ground shield one place

only. Look for internal

electronic instrument

ground. Reroute cables away

from electrical noise.

Indicator shows ow

when shut o

•Mechanical vibration causes

rotor to oscillate without

turning

•Electrical noise

•Isolate meter

•Install a 2.2K , ¼W leaded

resistor across output of

magnetic pick-up

No ow indication,

full or partial open

position

Fluid shock, full ow into

dry meter or impact caused

bearing separation or broken

rotor shaft

Rebuild meter with repair

kit and recalibrate monitor.

Move to location where

meter is full on start-up

or add downstream ow

control valve.

Erratic indication at low

ow, good

indication at high ow

Rotor has foreign material

wrapped around it

Clean meter and add lter

No ow indication Faulty pick-up Replace pick-up

System works perfect,

except indicates lower

ow over entire range

By-pass ow, leak Repair or replace by-pass

valves, or faulty solenoid

valves

Meter indicating high

ow, upstream piping

at meter smaller than

meter bore

Fluid jet impingement on

rotor

Change piping

Opposite eects of

above

Viscosity lower than

calibrated

Change temperature, change

uid or recalibrate meter

12 Form No. B110-001 08/10

APPENDIX B

PART NUMBER INFORMATION

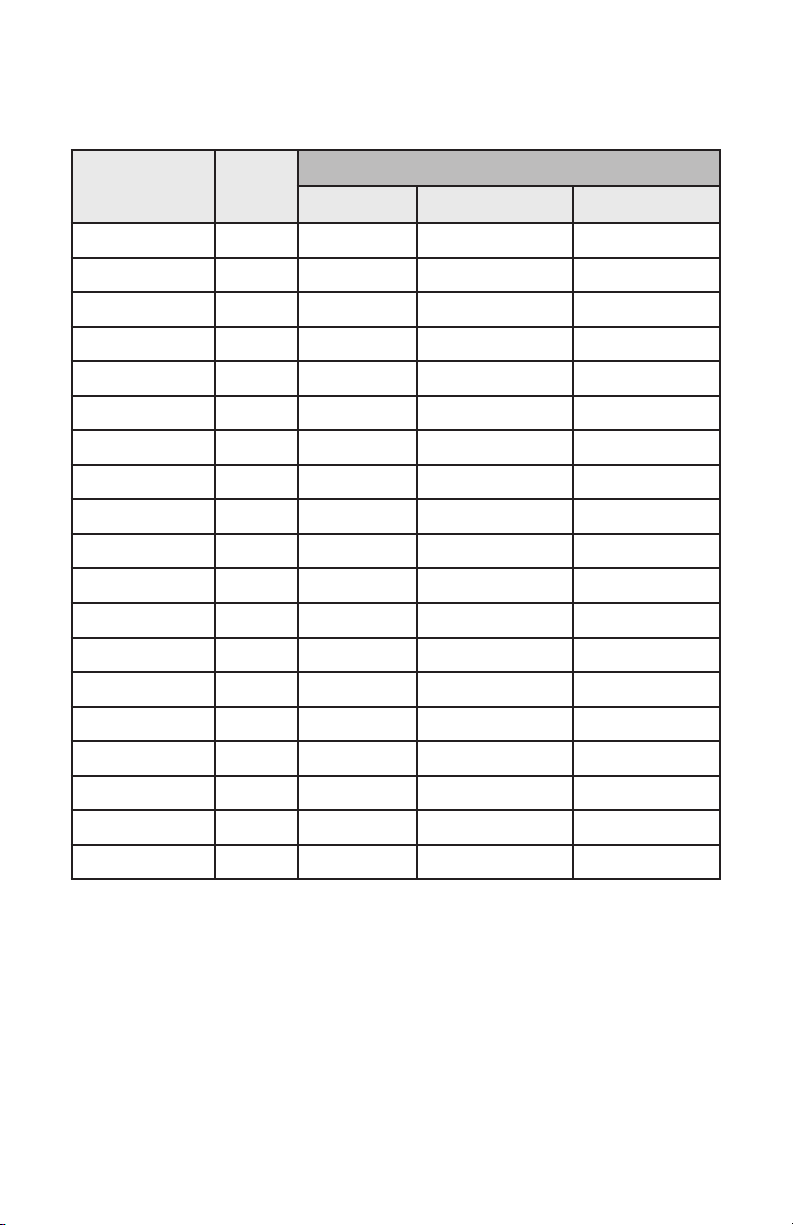

Part

Number

Meter

Size

Flow Ranges

GPM BPD M³/D

B110-375-1/2 ” 0.6 - 3 20 - 100 3.3 - 16

B110-500-1/2 ½” 0.75 - 7.5 25 - 250 4.1 - 41

B110-750-1/2 ¾” 2 - 15 68 - 515 10.9 - 81.75

B110-375 ” 0.6 - 3 20 - 100 3.3 - 16

B110-500 ½” 0.75 - 7.5 25 - 250 4.1 - 41

B110-750 ¾” 2 - 15 68 - 515 10.9 - 81.75

B110-875 ” 3 - 30 100 - 1,000 16 - 160

B111-110 1” 5 - 50 170 - 1,700 27.25 - 272.5

B111-115 1-½” 15 - 180 515 - 6,000 82 - 981

B111-121 2” Low 15 - 180 515 - 6,000 82 - 981

B111-120 2” 40 - 400 1,300 - 13,000 218 - 2,180

B111-130 3” 60 - 600 2,100 - 21,000 327 - 3,270

B111-140 4” 100 - 1,200 3,400 - 41,000 545 - 6,540

B311-004 4” NPT 100 - 1,200 3,400 - 41,000 545 - 6,540

B110-160 6” 200 - 2,500 6,800 - 86,000 1,090 - 13,626

B311-084 6” NPT 200 - 2,500 6,800 - 86,000 1,090 - 13,626

B110-180 8” 250 - 3,500 12,000 - 120,000 1,363 - 19,076

B311-085 8” NPT 250 - 3,500 12,000 - 120,000 1,363 - 19,076

B110-200 10” 500 - 5,000 17,000 - 171,000 2,725 - 27,252

Form No. B110-001 08/10 13

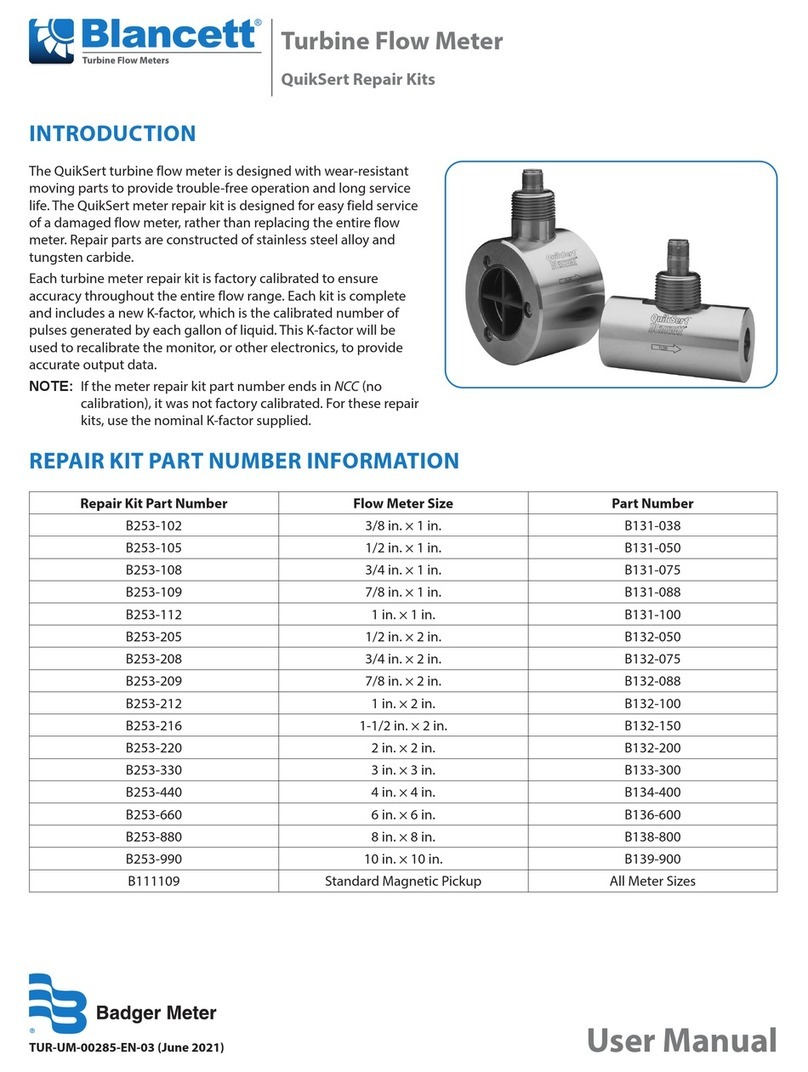

APPENDIX C

REPAIR KIT INFORMATION

Flow Meter Size Repair Kit Fits

Meter Part Number

Repair Kit

Part Number

” B110-375, B110-375-1/2 B251-102

½” B110-500, B110-500-1/2 B251-105

¾” B110-750, B110-750-1/2 B251-108

” B110-875 B251-109

1” B111-110 B251-112

1-½” B111-115 B251-116

2” Low B111-121 B251-116

2” B111-120 B251-120

3” B111-130, B311-004 B251-131

4” B111-140, B311-084 B251-141

6” B111-160, B311-085 B251-161

8” B111-180 B251-181

10” B111-200 B251-200

Standard Magnetic Pick-up All Meter Sizes B111109

Figure 5

Typical turbine meter component directory

FLOW

FLOW DIRECTION

ARROW

ROTOR

ASSEMBLY

UPSTREAM

ROTOR SUPPORT

RETAINING

RING

MAGNETIC

PICK-UP

RETAINING RING

GROOVE

FLOW DIRECTION

ARROW

FLOW DIRECTION

ARROW

FLOW METER

BODY

RETAINING

RING

RETAINING RING

GROOVE

FLOW DIRECTION

ARROW

DOWNSTREAM

ROTOR SUPPORT

14 Form No. B110-001 08/10

STATEMENT OF WARRANTY

Blancett Flow Meters, Division of Racine Federated Inc. warrants to the

end purchaser, for a period of one year from the date of shipment from

the factory, that all ow meters manufactured by it are free from defects

in materials and workmanship. This warranty does not cover products

that have been damaged due to defects caused by misapplication,

abuse, lack of maintenance, modied or improper installation. Blancett’s

obligation under this warranty is limited to the repair or replacement of

a defective product, at no charge to the end purchaser, if the product is

inspected by Blancett and found to be defective. Repair or replacement

is at Blancett’s discretion. A return goods authorization (RGA) number

must be obtained from Blancett before any product may be returned

for warranty repair or replacement. The product must be thoroughly

cleaned and any process chemicals removed before it will be accepted

for return.

The purchaser must determine the applicability of the product for its

desired use and assumes all risks in connection therewith. Blancett

assumes no responsibility or liability for any omissions or errors

in connection with the use of its products. Blancett will under no

circumstances be liable for any incidental, consequential, contingent or

special damages or loss to any person or property arising out of the

failure of any product, component or accessory.

All expressed or implied warranties, including the implied warranty of

merchantability and the implied warranty of tness for a particular

purpose or application are expressly disclaimed and shall not apply

to any products sold or services rendered by Blancett.

The above warranty supersedes and is in lieu of all other warranties,

either expressed or implied and all other obligations or liabilities. No

agent or representative has any authority to alter the terms of this

warranty in any way.

8635 Washington Avenue • Racine, Wisconsin 53406

Toll Free: 800.235.1638

Phone: 262.639.6770 •Fax: 262.417.1155

www.blancett.com •info@blancett.com

BLANCETT is a registered trademark of Racine Federated Inc.

UL is a registered trademark of Underwriters Laboratories.

© 2010 Racine Federated Inc.

Printed in USA

Form No. B110-001 08/10

Other manuals for 1100 Series

2

Table of contents

Other Blancett Measuring Instrument manuals

Blancett

Blancett B2800 Standard User manual

Blancett

Blancett QuikSert B131-038 User manual

Blancett

Blancett 1100 Series User manual

Blancett

Blancett B253-102 User manual

Blancett

Blancett B1750 User manual

Blancett

Blancett B1750 Service manual

Blancett

Blancett QUIKSERT User manual

Blancett

Blancett B2800 Standard User manual

Blancett

Blancett FloClean Service manual

Blancett

Blancett B1500 User manual