TURBINE METER REMOVAL

HIGH PRESSURE LEAKS ARE DANGEROUS AND MAY CAUSE PERSONAL INJURY. MAKE SURE THAT FLUID FLOW HAS

BEEN SHUT OFF AND PRESSURE IN THE LINE RELEASED BEFORE ATTEMPTING TO REMOVE THE METER.

Disassembly

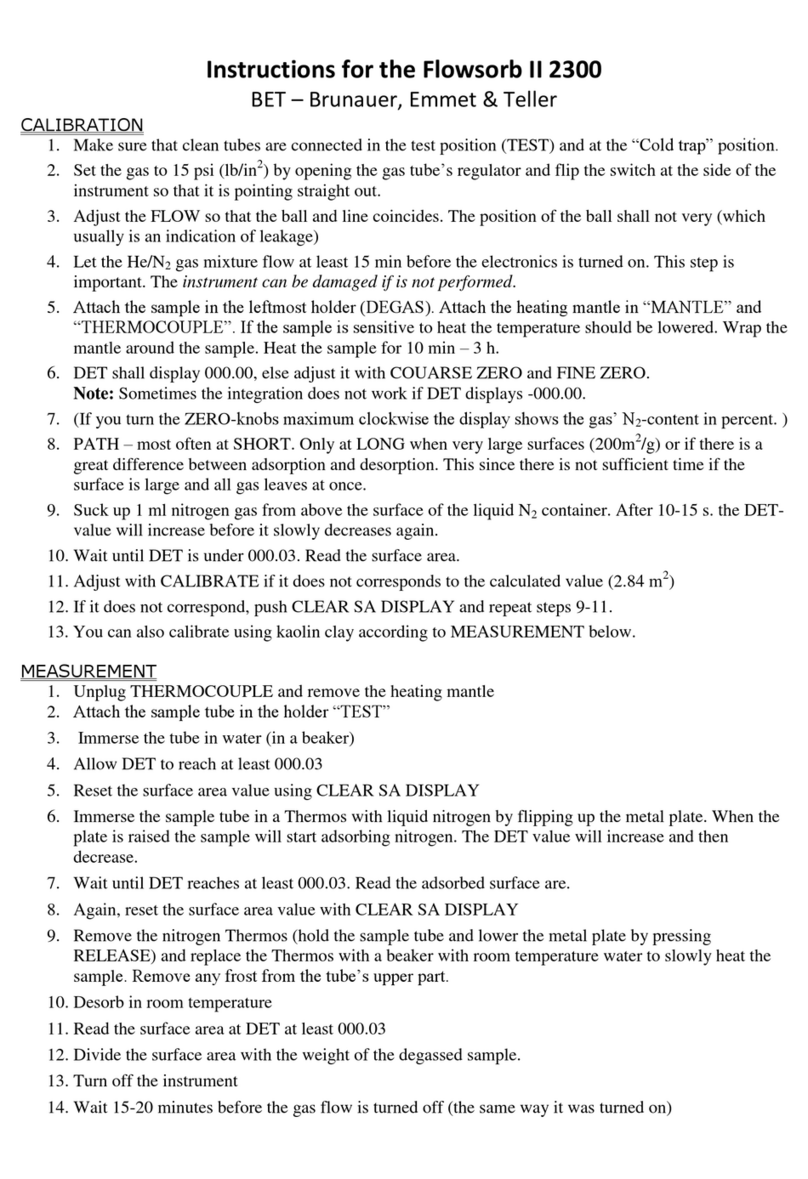

1. See Figure 1 on page 3 and Figure 2 on page 3 for relative positions of repair kit components.

2. Remove the magnetic pickup from the meter body to avoid damage during repair.

3. Remove the retaining ring from one end of the meter.

OTE:N Meters 2 inches and larger have retaining screws.

4. Remove the rotor support from the body. If the rotor support is jammed in the body, use a pair of pliers or vise grips to

break the rotor support free.

5. Remove the rotor.

6. Remove the retaining ring from the opposite side of the meter.

OTE:N Meters 2 inches and larger have retaining screws.

7. Remove the second rotor support.

Installing the New Kit

MPORTANTI

Before reassembly, note that an arrow is cast or engraved on each component (see note below). The arrow indicates the direction of

flow. The meter must be reassembled with arrowheads pointed in the direction of the fluid flow. The arrows are to be oriented in the

UP position on both rotor supports. The magnetic pickup side of the body signifies the UP position. This is the position at which the

repair kit was calibrated. Use this position for meter accuracy.

Figure 1 on page 3 and Figure 2 on page 3 show the proper alignment and orientation of the repair kits.

OTE:N Fractional size (3⁄8 in. , 1/2 in. and 3/4 in.) rotors do not contain a cast or engraved arrow. However, a colored cap is

provided on the downstream side of the rotor shaft to indicate flow direction. Remove this cap before assembly,

noting flow direction.

1. Install one of the rotor supports into the body bore, noting the orientation of the arrow.

2. Secure a retaining ring in the groove provided. Be sure that retaining rings are completely installed in each groove.

OTE:N Meters 2 inches and larger will have retaining screws on both ends of the meter (see Figure 2).

3. Insert the rotor and second rotor support in the opposite side of the body, noting the orientation of the arrow.

4. Secure the second retaining ring in the opposite groove.

OTE:N Meters 2 inches and larger meters will have retaining screws on both ends of the meter (see Figure 2).

5. Check the meter by blowing air through the assembly. If the rotor does not turn freely, disassemble the meter and check

for anything that would obstruct movement of the rotor.

EXCESS AIR PRESSURE MAY DAMAGE THE ROTOR AND BEARINGS BY OVER SPINNING.

6. Install the magnetic pickup.

OTE:N At this time, the electronics will need recalibration. Refer to the product user manual. If you have any questions on

recalibration, contact Badger Meter, Inc. or the manufacturer of the associated electronics.

Turbine Flow Meter, QuikSert Repair Kits

Page 2 June 2021