BLU-JET GALAXY User manual

$20.00 Net

TM

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

GALAXY • GALAXY • GALAXY • GALAX

• GALAXY • GALAXY • GALAXY • GA

Assembly

and Operators

Manual

3-point StripTill

Implement With

Lift Assist

Manual Number: 08000105

Rev. 11-16-16

GALAXY

84001630, 16 Row 30

16 Row 30

Thurston Manufacturing Company •1708 H Ave •Box 218 • Thurston, Nebraska, 68062-0218

Design specications and features as described are subject to change without notice. BLU-JET is a registered trademark of Thurston Manufacturing Company, Thurston NE.

/BLU-JET @BLU-JET01 /SIronWorks @SIronWorks

1

GALAXY Table of Contents

16 Row 30”

Introduction......................................................................................................... 2

Delivery................................................................................................................ 4

To The Owner...................................................................................................... 5

Warranty............................................................................................................... 6

Safety.................................................................................................................... 7

Operating Instructions........................................................................................... 9

Operational Guide For Various Residue Situations............................................... 14

Storage.................................................................................................................. 25

Specications........................................................................................................ 26

Parts

16Row30”............................................................................................................ 27

16Row30”RowSpacingLayouts........................................................................ 31

LightKit,LiftAssist(41000027)............................................................................. 33

Frame,(80410005)Galaxy,Center...................................................................... 35

Wings.................................................................................................................... 36

Bolt-On3-PointWithLiftAssist.............................................................................. 40

PrimaryWing4”x24”Cylinders(PKG00224).......................................................44

SecondaryWing,4”x24”Cylinders(PKG00224).................................................46

NurseTankHitchLiftAssist(80410031)................................................................ 49

NurseTankHitchAuto-Lok(AAM2870)................................................................. 50

SafetyTank(AAM2426)6”x4”.............................................................................. 51

ManualHolder........................................................................................................ 52

Super1200Coulters.............................................................................................. 53

FlatbackCenteredCoulterAssembly7”x7”(AAM2821)...................................... 55

HubandSpindle(AAM2707)................................................................................. 56

StraddleHub(AAM2714)...................................................................................... 57

Assembly

Frame.................................................................................................................... 58

PrimaryWings.......................................................................................................59

PrimaryWingCylinders........................................................................................60

SecondaryWings..................................................................................................61

SecondaryWingLinkages....................................................................................62

VerticalPinAdjustGaugeWheelsAngled............................................................. 63

3-PointwithLiftAssist........................................................................................... 65

NurseTankHitchwithLiftAssist(80410031)........................................................ 75

LightKit(41000027).............................................................................................. 76

PrimaryFoldCylinders(PKG00224)..................................................................... 83

SecondaryFoldCylinders(PKG00224)................................................................ 87

OffsetStaggerBrackets........................................................................................ 92

Coulters................................................................................................................ 95

StripTillResidueManagerPartsandAssembly(70210646)................................. 97

SealProIIDiscSealersParts(AAM2856)............................................................. 105

Blades................................................................................................................... 107

SealerSpringAdd-onKit(AAM2857).................................................................... 108

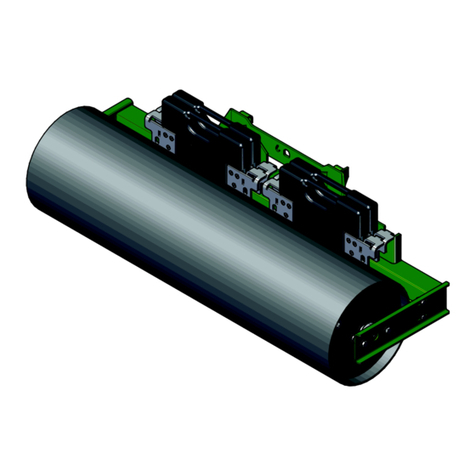

MaxPacParts(AAM2743)..................................................................................... 110

MaxPacBasketMountArm(AAM2623)................................................................ 111

MaxPacandBasketMountAssembly................................................................... 112

RigidShankMount(AAM2137)............................................................................. 114

RigidTorsionBasketMount(70210648)............................................................... 115

RigidShankandBasketMountAssembly............................................................. 116

TorsionArmandBasketAssembly(70210641)..................................................... 118

ManualHolder....................................................................................................... 120

SafetyTank........................................................................................................... 121

Decals................................................................................................................... 123

HydraulicCylindersandParts............................................................................... 124

Tie-rodCylinderDisassembly-AssemblyProcedure........................................... 125

TorqueSpecications............................................................................................ 126

Manual Number: 08000105

Rev. 11-16-16

2

Welcome to Thurston Manufacturing Company. Our goal is to provide

quality products and services to our customers. The company’s BLU-JET

products have a reputation for quality, excellence in design and proven

durability. Energetic, resourceful and continuous improvement goals in

Environmental, Safety, Quality, Production and Engineering keep our

rm at the cutting edge of technology.

We hope your BLU-JET equipment will give you years of service.

Introduction

Read this manual carefully. It will instruct you on how to operate and

service your machine safely and correctly. Failure to do so could result

in personal injury and/or equipment damage.

SAFETY INFORMATION

Indicates an imminently hazardous situation that, if

not avoided, will result in death or serious injury.

The sign will have the color combination of red and

white.

Indicates a potentially hazardous situation that, if

not avoided, could result in death or serious injury.

The sign will have the color combination of orange

and black.

Indicates a potentially hazardous situation that, if

not avoided, may result in minor or moderate injury.

The sign will have the color combination of yellow

and black.

NOTE: Indicates a special point of information.

Carefully read and follow all safety signs. Reinstall safety signs that

are damaged or missing.

Right-hand and left-hand sides of the implement are determined by

facing in the direction the implement will travel when going forward.

DANGER

WARNING

CAUTION

3

For your convenience we have four easy ways to register your warranty.

• Call our toll free number and ask for warranty registration. 1-800-658-3127

• Fax completed warranty registration form. Fax: 402-385-3043

• Register on-line in warranty page at www.blu-jet.com

• Complete and return registration form.

Thurston Manufacturing Company Warranty does not cover the following:

1) Cleaning, transporting, mailing and service call charges.

2) Depreciation or damage caused by normal wear, accidents,

improper protection or improper use.

See complete Warranty for details.

MODEL NO.__________________________

SERIAL NO.__________________________

DATE PURCHASED___________________

Record your implement model and serial number in the space provided below.

Your dealer needs this information to give you prompt, efcient service when

you order parts.

Serial Number

location

General Information:

The BLU-JET Galaxy unit is one of the most versatile machines you can own.

With the Galaxy toolbar, you can till or place fertilizer (dry, liquid, anhydrous ammonia

and dual placement) in one pass or separately, depending on your requirements.

You can adjust the Galaxy’s row spacings to match your requirements for

fertilizer placement, and StripTill.

The Galaxy was designed to be used in combination with BLU-JET’s

Super 1200 Coulter, MaxPac 700 AutoReset shank mounting, residue managers,

SealPro II disc sealers, and torsion arm rming baskets.

Warranty is provided for customers who operate and maintain their equipment

as described in this manual. Warranty registration is accomplished by the

dealer completing and forwarding the WARRANTY REGISTRATION FORM to

Thurston Manufacturing Company. It is in your best interest to ensure that

this has been done.

Introduction

Folding Frame Rigid Frame

4

1. All hardware properly tightened

2. Lubrication of grease ttings

3. All decals properly located and readable

4. Other adjustments for machine level height, etc.

5. Overall condition (touch up any scratches, clean and

polish)

6. Operator’s manual

DATE SET UP_______________________________

SIGNATURE________________________________

PRE-DELIVERY CHECKLIST

Dealer Checklist

To The Dealer:

Inspect the implement thoroughly after assembly to be certain it is

functioning properly before delivering it to the customer. The following

checklist is a reminder of points to cover. Check off each item as it is

found satisfactory or after proper adjustment is made.

DELIVERY

Review the operator’s manual with the customer. Explain

the following:

1. Safe operation and service

2. Correct machine installation and operation

3. Daily and periodic lubrication and maintenance

4 Daily and periodic inspections

5. Troubleshooting

6. Storing machine

7. Thurston Manufacturing Company parts and service

8. Have the customer write the machine model and serial

number in space provided in manual introduction.

9. Give customer the operator’s manual and encourage

the customer to read the manual carefully.

10. Completion and mailing of warranty registration

form.

DATE DELIVERED__________________________

SIGNATURE_______________________________

MODEL NO.________________________________

SERIAL NO.________________________________

5

To The Owner

Thank you for your recent purchase of a new BLU-JET

implement. The primary objective of Thurston Manufacturing

Company is to build and provide you with a quality product.

However, in the event that a problem does occur, it is

imperative that your warranty registration is on le in order to

accurately respond to your specic service circumstances.

For your convenience we have four easy ways to register

your warranty:

•Call our toll free number and ask for

warranty registration.

1-800-658-3127

•Fax your completed warranty

registration form.

1-402-385-3043

•Register on-line at:

www.blu-jet.com

•Complete and mail the warranty

registration form.

This manual has been prepared to assist you in the assembly

of your new machine and contains information pertaining to

safety, operation and all of its parts. Our personnel in sales

and service are always available to assist you when

questions arise concerning the assembly or operation of

your tool bar.

When ordering parts, please refer to part numbers and

descriptions as listed throughout this book. All parts and

whole goods will be shipped FOB Thurston, Nebraska, or

FOB your regional distributor. Always check merchandise

immediately upon receipt for damage or shortage. Note any

discrepancy on carrier’s bill of lading and notify Sender within

10 days. Returned goods will be subject to a 15% restocking

charge. Thurston Manufacturing Company reserves the right

to make improvements and modications on equipment

without obligation to change previously built equipment. All

prices are subject to change without notice.

Register

Warranty

One of

Four Ways

6

Thurston Manufacturing Company warrants each new BLU-JET machine

primary framework to be free from defects in material and workmanship for a period

of ve (5) years, normal wear of wearing parts excepted. Thurston Manufacturing

Company further warrants each new BLU-JET product to be free from defects in

material and workmanship, normal wear of wearing parts excepted, for a period

of one (1) year. All accessories purchased and resold by Thurston Manufacturing

Company will be warranted according to their respective manufacturer. Tires on

BLU-JET equipment are warranted through their respective tire manufacturers and

their network of dealers in your local area.

Warranty begins from date of delivery to the original purchaser and applies

to all new BLU-JET products that have not been altered and are being used for the

intended purpose. Negligence, abuse or modication of equipment manufactured

by or purchased and resold by Thurston Manufacturing Company will void this

warranty.

The obligation of Thurston Manufacturing Company to honor this warranty

is limited to the repair or replacement of defective merchandise, to the original

purchaser, subject to inspection of equipment in question by an authorized Thurston

Manufacturing Company sales or service technician. In the USA, freight of warranty

replacement parts including main frame centers and wings will be prepaid for a

period of one (1) Year by Thurston Manufacturing Company. Shipments of repaired

or replaced parts including main frame centers and wings after one year will be paid

by the customer.

Return of defective goods must be made within thirty (30) days of failure to

Thurston Manufacturing Company, Thurston, Nebraska USA or to the nearest

authorized BLU-JET Distributor or Rep Sales and service outlet.

Thurston Manufacturing Company will not be held responsible for any repair

charges made by customers without prior written consent and prior equipment

inspection by an authorized Thurston Manufacturing Company sales or service

technician.

This warranty shall not be interpreted to render liability for injury or damages

of any kind, direct, consequential or contingent to person or property. This warranty

does not extend to loss of crops, economic and/or commercial loss, loss because

of delay in crop production or any expense incurred for labor, supplies, substitute

machinery, rental or for any other reason. This warranty is subject to any existing

condition of supply, which may directly affect Thurston Manufacturing Company’s

ability to obtain materials of manufacture and delivery of replacement parts.

Thurston Manufacturing Company reserves the right to make improvements

in design and changes in specications at any time without incurring any obligation

to owners of units previously sold.

No one is authorized to alter, modify or enlarge this warranty nor its exclusions,

limitations and reservations. Thurston Manufacturing Company makes no

representations or warranties, expressed or implied (including implied warranties

of merchantability and tness), except for those set forth in Thurston Manufacturing

Company’s current applicable published warranty policies and procedures.

Layton W. Jensen, President 022398\mgmt

Limited Warranty

7

Safety

RECOGNIZE SAFETY INFORMATION

• This is the safety-alert symbol. When you see his symbol

on your machine or in this manual, be alert to the

potential for personal injury. Follow recommended

precautions and safe operating practices.

FOLLOW SAFETY INSTRUCTIONS

• Carefully read all safety messages in this manual and

on your machine safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs.

• Learn how to operate the machine and how to use

controls properly.

• Do not let anyone operate without instruction.

• Keep your machine in proper working condition.

• Unauthorized modication to the machine may

impair the function and/or safety and affect machine life.

PROTECT CHILDREN AND BYSTANDERS

• Before you back, LOOK CAREFULLY behind for

children.

• Clear area of children, pets and bystanders.

HIGHWAY AND TRANSPORT OPERATIONS

Adopt safe driving practices:

• Keep the brake pedals latched together at all times.

NEVER USE INDEPENDENT BRAKING WITH MACHINE

IN TOW AS LOSS OF CONTROL AND/OR UPSET OF

UNIT CAN RESULT.

• Always drive at a safe speed relative to local

conditions and ensure that your speed is low enough

for a emergency stop to be safe and secure. Keep

speed to a minimum.

• Reduce speed prior to turns to avoid the risk of

overturning.

• Avoid sudden uphill turns on steep slopes.

• Always keep the tractor or towing vehicle in

gear to provide engine braking when going downhill.

Do not coast.

• Do not drink and drive.

• Comply with state and local laws governing highway

safety and movement of farm machinery on public roads.

• Use approved accessory lighting and necessary

warning devices to protect operators of other vehicles

on the highway during daylight and nighttime transport.

• The use of ashing amber lights is acceptable in most

localities. However, some localities prohibit their use.

Local laws should be checked for all highway lighting

and marking requirements.

• When driving the tractor and equipment on the road

or highway under (20 mph max.) (32 kmph max.) at night or

during the day, use ashing amber warning lights

and a slow moving vehicle (SMV) identication emblem.

8

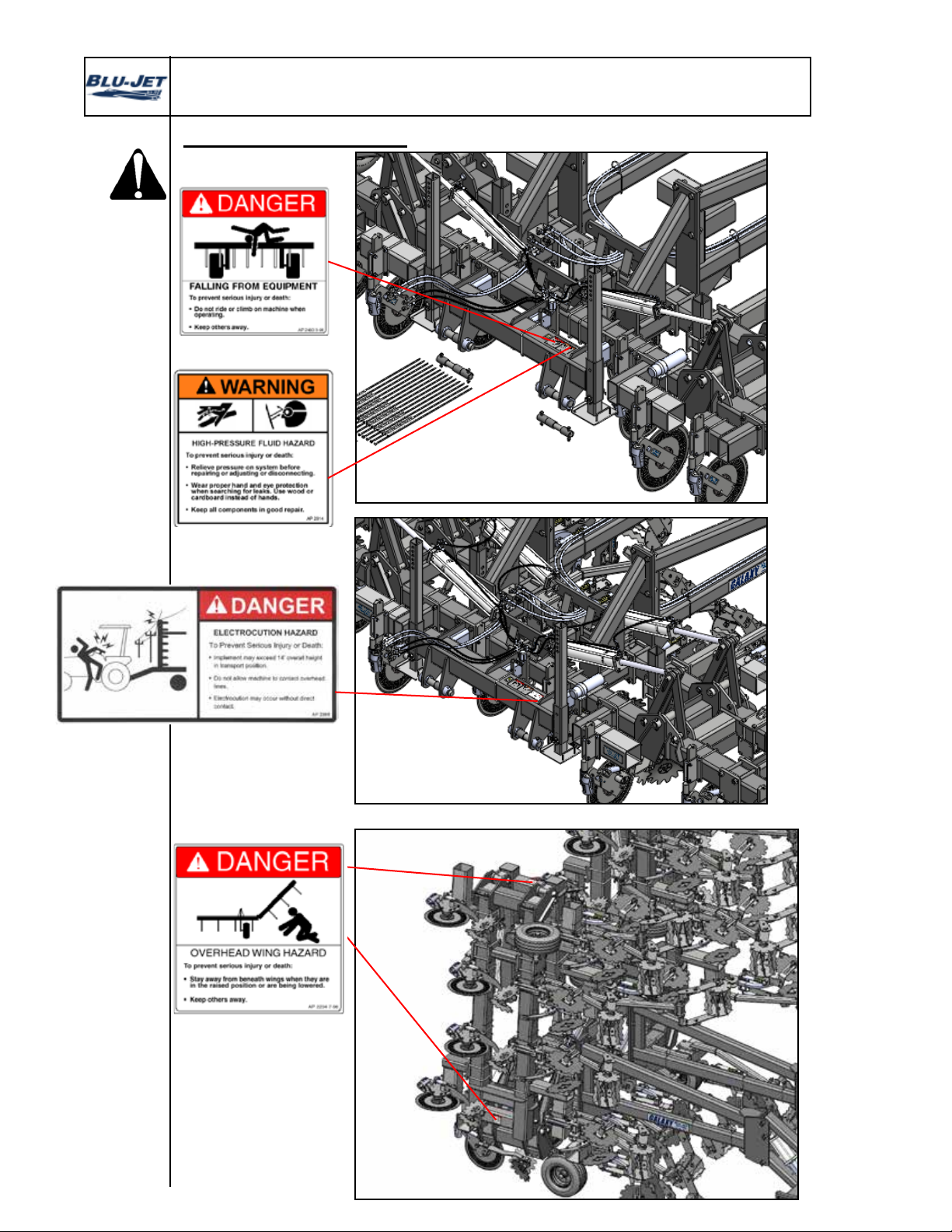

Safety

AP 2483-8-98

AP 2914

Observe Safety Signs

Folding Frame

AP 2234-7-98

AP 2988

9

Operating Instructions

Task Procedures Illustrations

3-Point

adjustments

1. Measure tractor linkages on

pullarms toinsureequal length

for level operation as viewed

across the rear of the tractor.

Check tractor tire pressure for

equal ination. Be certain that

the proper pins are used in

either CAT. IIl or CAT. IV

hookup.

2. Mount implement with pull

pin kit. Connect hydraulic

hoses.

3. Attach 7 pin electrical harness.

4. Raise park stands.

5. Check lights for proper operation.

Mounting

implement

Checking

lights

10

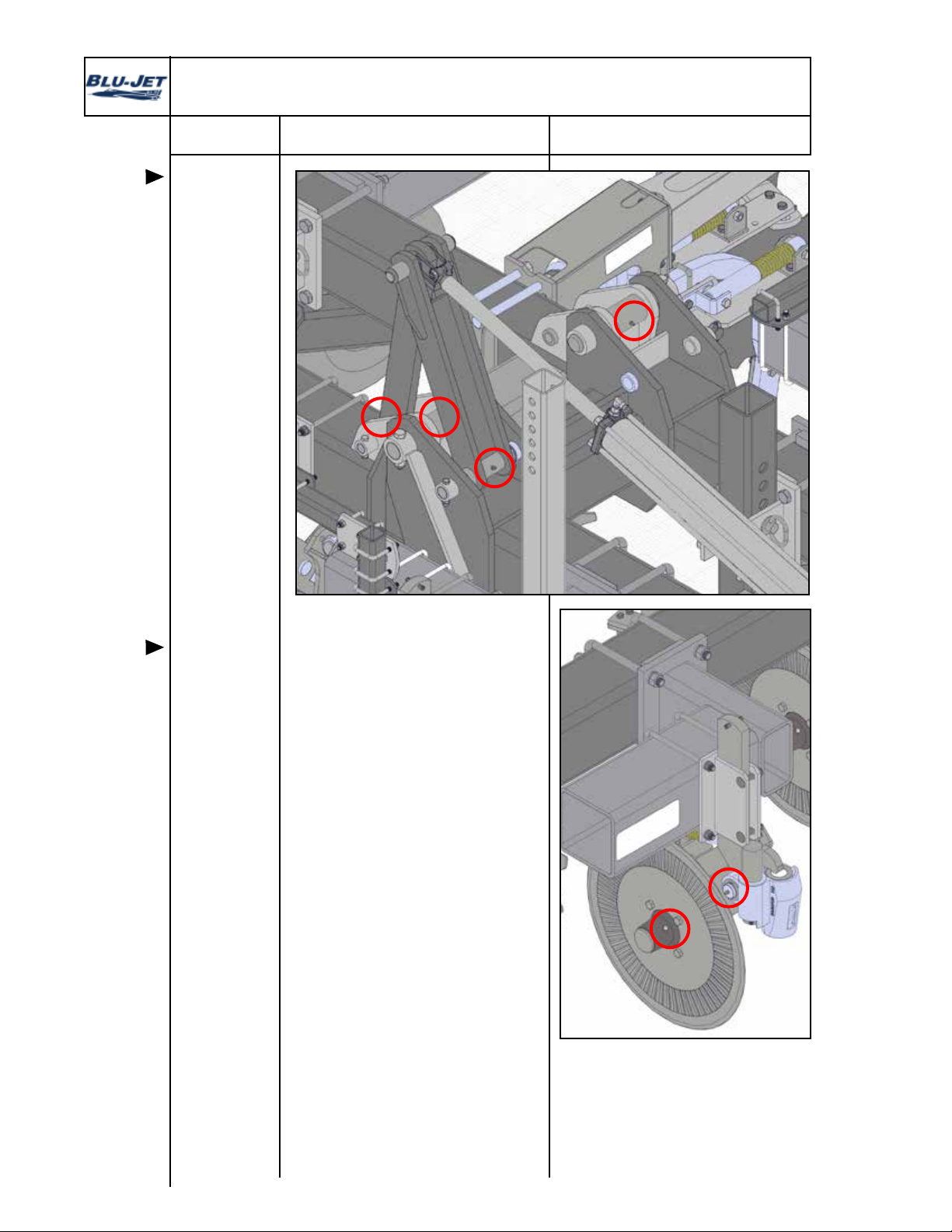

Task Procedures Illustrations

Lubrication

wing hinges

and wing

linkages

6. Grease all zerks daily.

7. Grease coulter arm pivots

daily.

8. Grease all coulter arm pivots

The plug on the coulter hub

can be removed. A zerk can be

installed. Hub and spindle

assembly should be greased

twice seasonally.

Operating Instructions

Coulter

lubrication

11

Task Procedures Illustrations

Lubricate

nurse tank

hitch latch

daily

Operating Instructions

Pinch point

To prevent Injury

Keephandsclear

whenextendingor

retractingtheswing

slide insert

WARNING

9. Nurse tank hitch can be

retracted and moved from

side to side for easy hookup.

Hitch will automatically lock

in the extended position.

NOTE:

Periodically

checkLatch

mechanismto

ensure proper

latchinginthe

extended

position.

Nurse tank

hitch

12

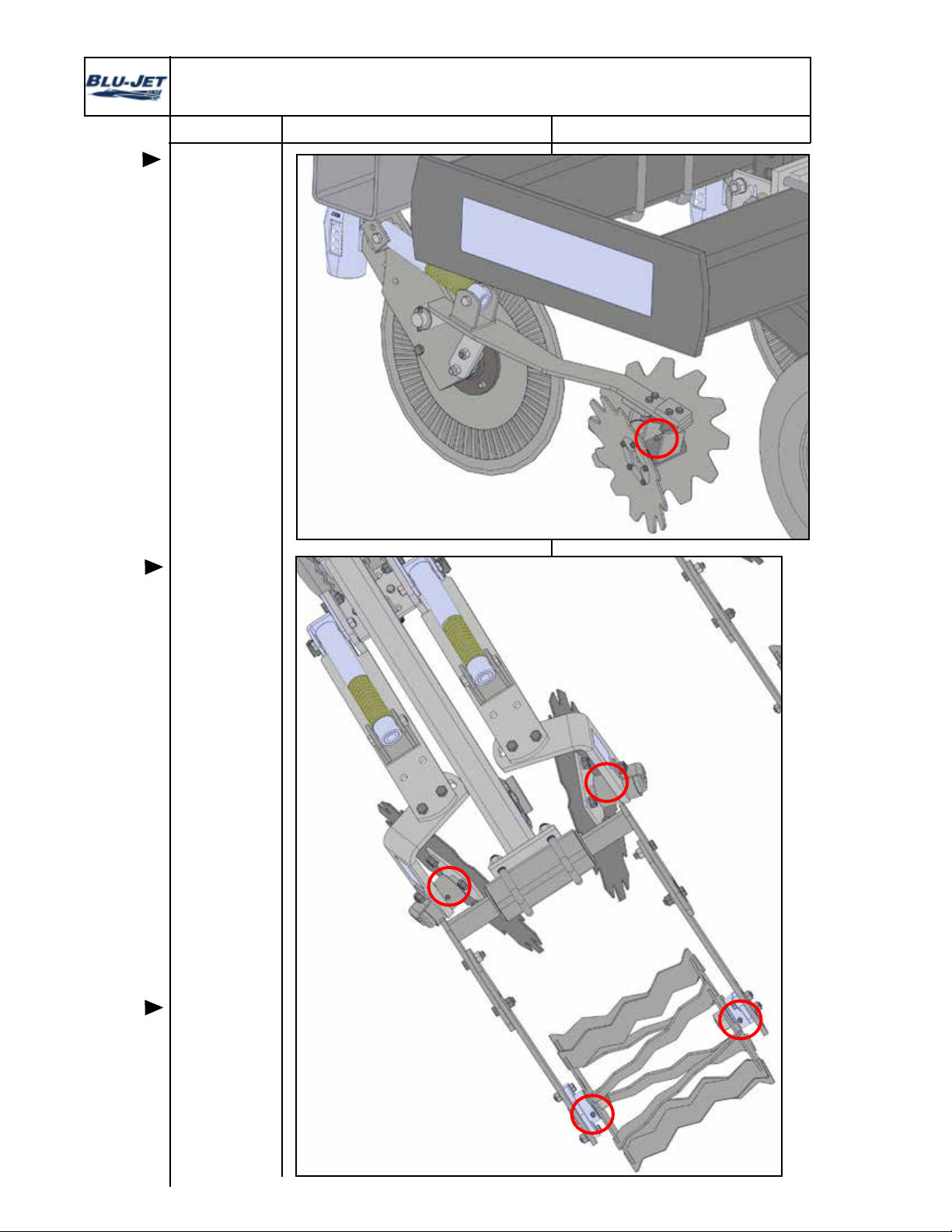

Task Procedures Illustrations

Operating Instructions

Lubricate

Residue

Managers

daily

Lubricate

SealPro

hubs

daily

Lubricate

basket

bearings

daily

13

Task Procedures Illustrations

Operating Instructions

10. Locate nine-gallon

emergency water tank/toolbox.

Change water daily to provide

fresh clean water to ush

exposed skin or eyes.

Drain water daily in cold

temperatures to prevent

freezing and bursting tank.

11. In case of exposure to fertilizer,

open faucet or pull top

end of hose loose to ush

exposed part of body.

Remove contaminated

clothes as soon as possible.

Emergency

water tank

operation

and

maintenance

14

Operational Guide For Various Residue Situations

BLU-JET StripTill Implement

Coulter Blades

•3”-4”Deep(makesurehubisnotrunningintheground).

•Ifbladesareneworbeingusedforthersttimeinaseason,

orifresidueishairpinning,sharpeningeachbladewillassist

incuttingduringtherstfewacresofoperation.Afterthe

rstfewacres,bladeswillself-sharpen.

Residue Managers–Lightpressuresetting(particularlyinlightsoils).

Shank depth–Minimum4”deepfromgroundlevel(optimumdepth

forfertilizerplacementis6”-8”).

Sealer Blade Position –Frontholesonthesealerarm.

Sealer Blade Pitch–Determinedbysoiltypeandseasoninsoybean

residue.

Sealer Blade Down Pressure–Determinedbysoiltypeandseason

inthisresidue.

Basket Pressure–Determinedbysoiltypeandseasoninthisresidue.

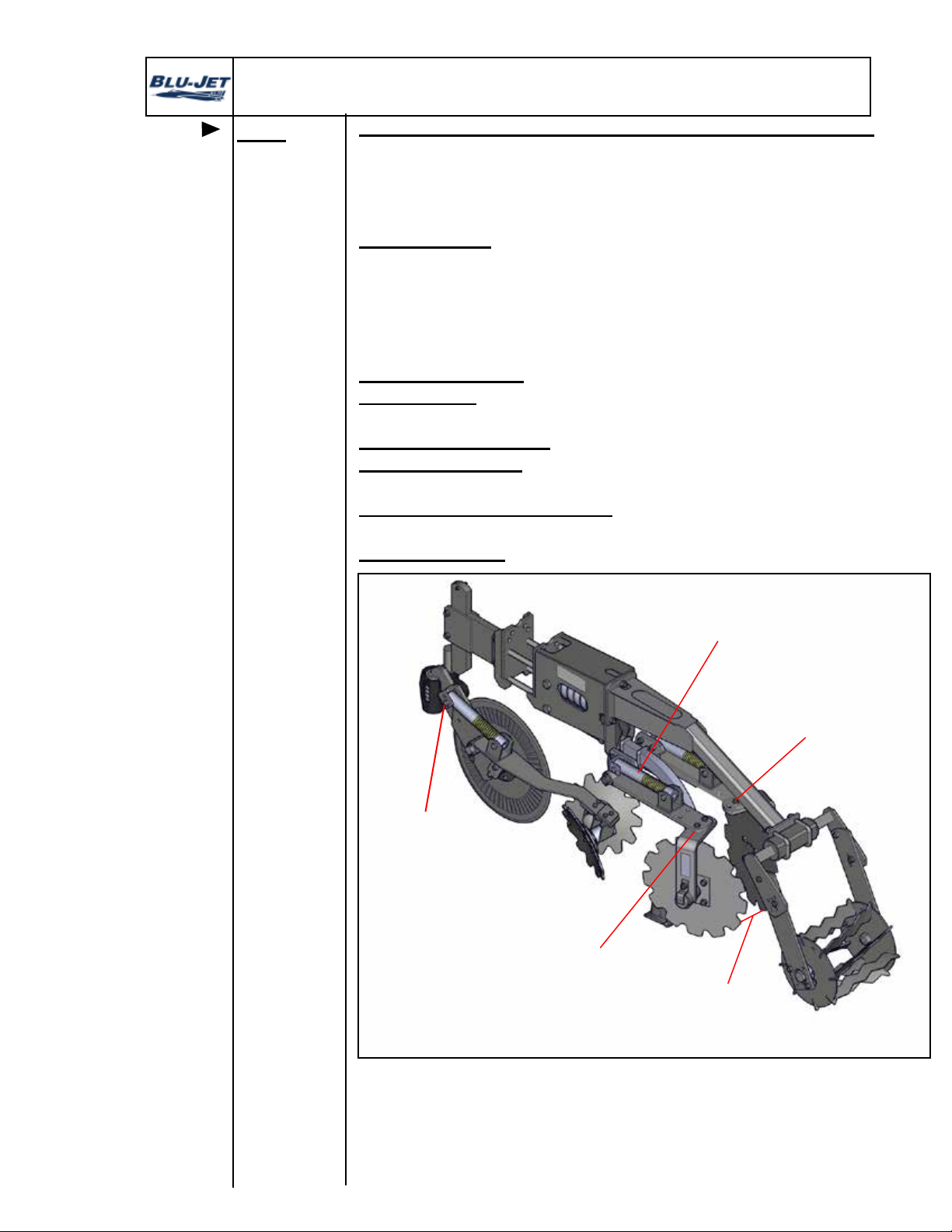

Beans

(Soy or

Pinto)

ResidueManagers

Sealers

Torsion

Basket

LightPressure

Setting

Frontholes

Frontholes

Left-hand

Right-hand

Frontholes

15

For best results follow these operating recommendations:

•Leavingstandingstalksintheeldwhenharvesting(about

kneehigh)ispreferabletoshreddingtheresidue.

•Rowunitsonthemachineshouldbeoperatedbetweenlast

year’scornrows(splitlastyear’srows).

Coulter Blades

•3”-4”Deep(makesurehubisnotrunningintheground).

•Ifbladesareneworbeingusedforthersttimeinaseason,

orifresidueishairpinning,sharpeningeachbladewillassist

incuttingduringtherstfewacresofoperation.Aftertherst

fewacres,bladeswillself-sharpen.

Residue Managers–Heavypressuresetting.

Shank depth –Minimum4”deepfromgroundlevel(optimum

depthforfertilizerplacementis6”-8”).

Sealer Blade Position–Rearholesonthesealerarm.

Sealer Blade Pitch–Bladesshouldbeeveninpitchandbacksof

thebladesshouldbeatleast8”apart.

Sealer Blade Down Pressure–Determinedbysoiltypeandseason

inthisresidue.

Basket Pressure–Determinedbysoiltypeandseasoninthisresidue.

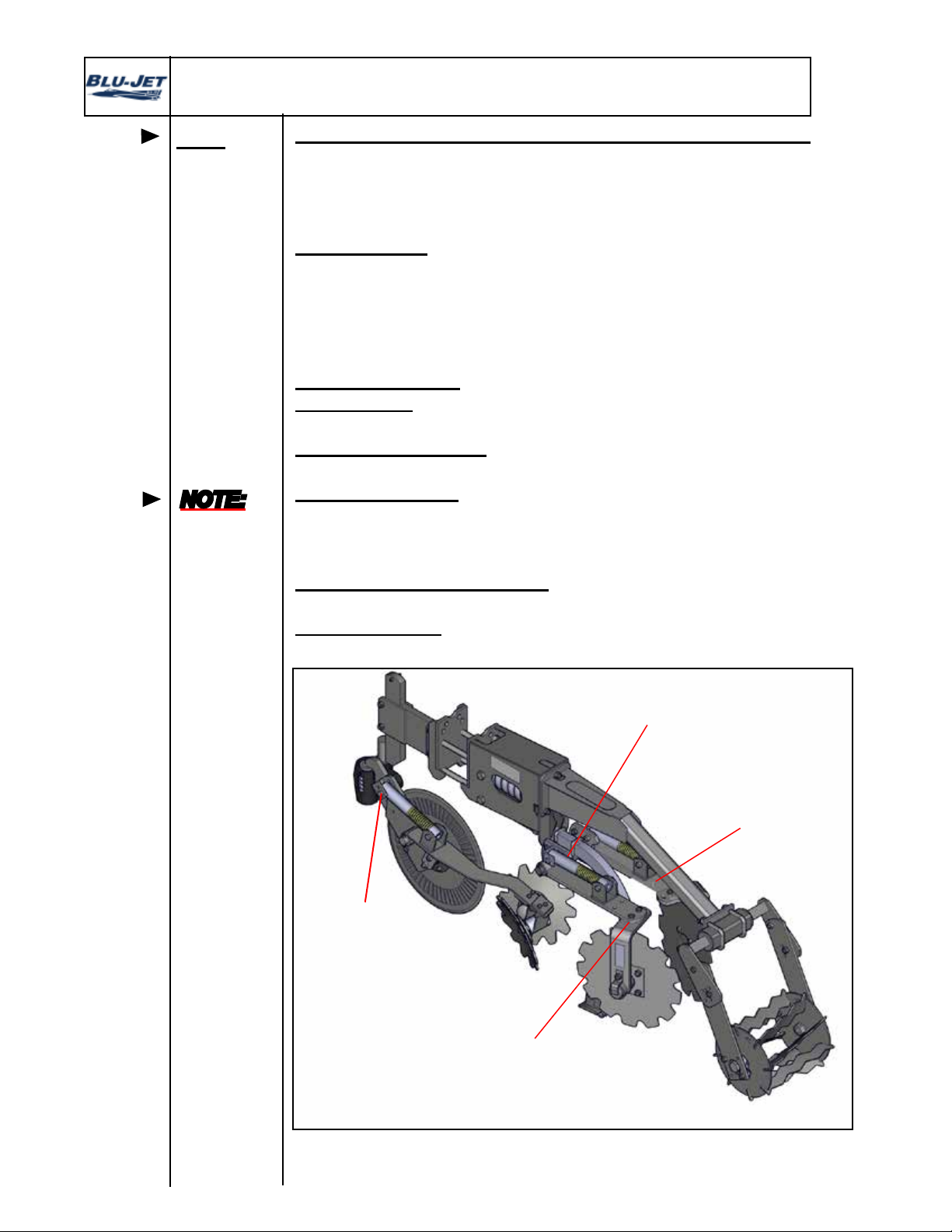

Corn

Grain under

250 bushel

(in one year

corn/bean

rotation or

corn/corn/

bean rotation

if not Strip-

Tilling beans)

Operational Guide For Various Residue Situations

BLU-JET StripTill Implement

ResidueManagers

Sealers

Torsion

Basket

HeavyPressure

Setting

Rearholes

Rearholes

Left-hand

Right-hand

Rearholes

AdjustSealers

8”apart

DownPressureKit

16

For best results follow these operating recommendations:

•Leavestandingstalksdonotshredtheresidueintheeldwhen

harvesting(aboutkneehigh).

•Rowunitsonthemachineshouldbeoperatedbetweenlast

year’scornrows(splitlastyear’srows).

Coulter Blades

•3”-4”Deep(makesurehubisnotrunningintheground).

•Ifbladesareneworbeingusedforthersttimeinaseason,

orifresidueishairpinning,sharpeningeachbladewillassist

incuttingduringtherstfewacresofoperation.Aftertherst

fewacres,bladeswillself-sharpen.

Residue Managers–Heavypressuresetting.

Shank depth –Minimum4”deepfromgroundlevel(optimum

depthforfertilizerplacementis6”-8”).

Sealer Blade Position–Offset(leftbladeinrearholesandright

bladeinfrontholes).

Sealer Blade Pitch –

•Leftbladeshouldbesetatnearlymaximumpitch.

•Rightbladeshouldbesetatabouthalfpitchwhencomparedto

theleftblade.

Sealer Blade Down Pressure–DownPressureKitsarerecommended

forthisresiduesituation.

Basket Pressure–Runningabasketisrecommendedforthisresidue

situation.

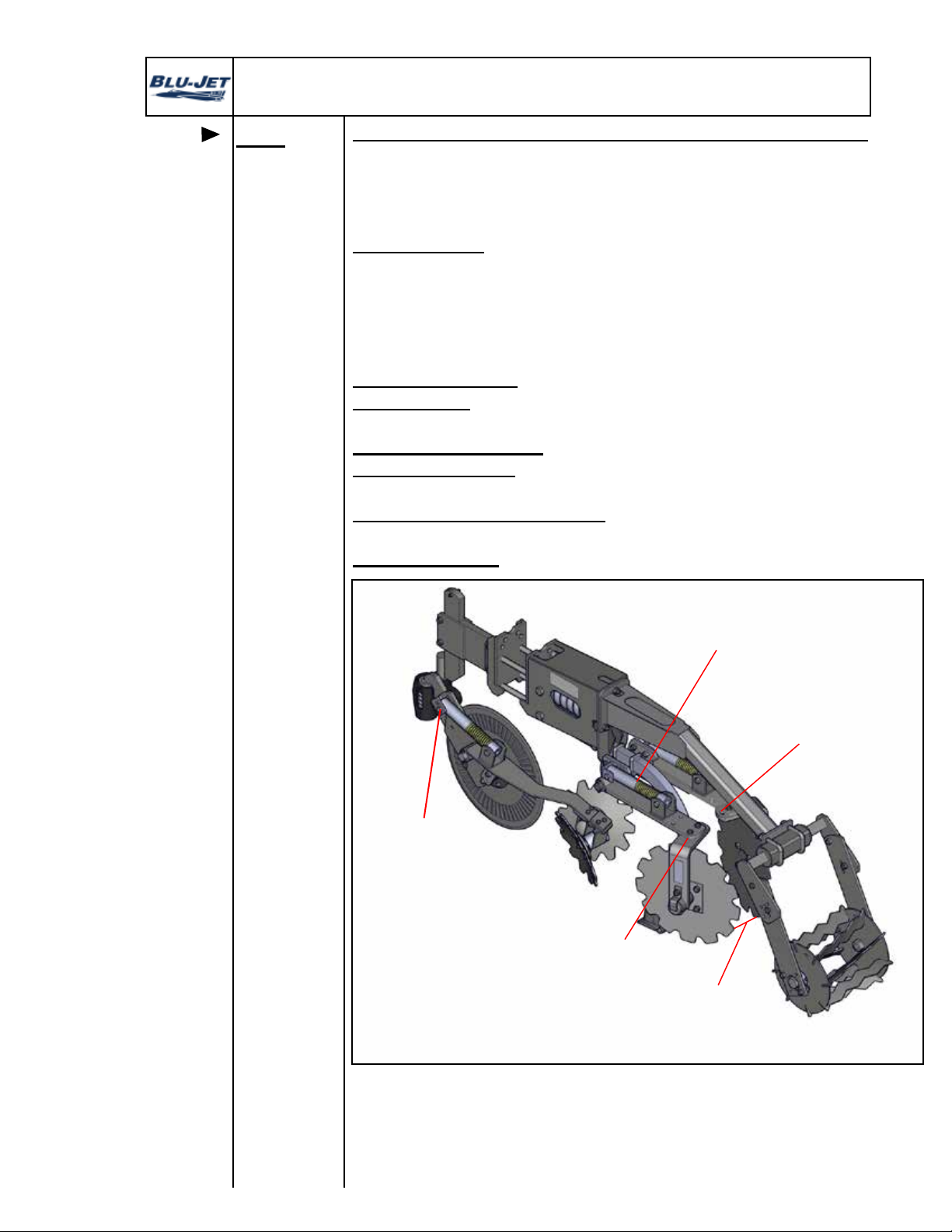

Corn

Grainover

250bushel

(inoneyear

corn/bean

rotation)

ResidueManagers

Sealers

Torsion

Basket

HeavyPressure

Setting

Rearholes

Maximum

Pitch

Operational Guide For Various Residue Situations

BLU-JET StripTill Implement

NOTE:

Left-hand

and

right-hand

as viewed

from the

rear

Left-hand

Right-hand

Frontholes

HalfPitch

DownPressureKit

17

Operational Guide For Various Residue Situations

BLU-JET StripTill Implement

For best results follow these operating recommendations:

•Leavestandingstalksdonotshredtheresidueintheeldwhen

harvesting(aboutkneehigh).

•Rowunitsonthemachineshouldbeoperated7.5”tooneside

oflastyear’scornrow(RTKguidancerecommended).

Coulter Blades

•3”-4”Deep(makesurehubisnotrunningintheground).

•Ifbladesareneworbeingusedforthersttimeinaseason,

orifresidueishairpinning,sharpeningeachbladewillassist

incuttingduringtherstfewacresofoperation.Aftertherst

fewacres,bladeswillself-sharpen.

Residue Managers–Heavypressuresetting.

Shank depth –Minimum4”deepfromgroundlevel(optimum

depthforfertilizerplacementis6”-8”).

Sealer Blade Position–Rearholesonthesealerarm.

Sealer Blade Pitch–Bladesshouldbeeveninpitchandbacksof

thebladesshouldbeatleast10”apart.

Sealer Blade Down Pressure–DownPressureKitsarerecommended

forthisresiduesituation.

Basket Pressure–Determinedbysoiltypeandseasoninthisresidue.

Corn

Grain under

250bushel

(in2+years

cornrotation)

ResidueManagers

Sealers

Torsion

Basket

HeavyPressure

Setting

Rearholes

EvenPitch AdjustSealers

10”apart

Left-hand

Right-hand

DownPressureKit

Rearholes

EvenPitch

18

For best results follow these operating recommendations:

•Leavestandingstalksdonotshredtheresidueintheeldwhen

harvesting(aboutkneehigh).

•Rowunitsonthemachineshouldbeoperated7.5”tooneside

oflastyear’scornrow(RTKguidancerecommended).

Coulter Blades

•3”-4”Deep(makesurehubisnotrunningintheground).

•Ifbladesareneworbeingusedforthersttimeinaseason,

orifresidueishairpinning,sharpeningeachbladewillassist

incuttingduringtherstfewacresofoperation.Aftertherst

fewacres,bladeswillself-sharpen.

Residue Managers–Heavypressuresetting.

Shank depth –Minimum4”deepfromgroundlevel(optimum

depthforfertilizerplacementis6”-8”).

Sealer Blade Position–Offset(leftbladeinrearholesandright

bladeinfrontholes).

Sealer Blade Pitch –

•Leftbladeshouldbesetatnearlymaximumpitch.

•Rightbladeshouldbesetatabouthalfpitchwhencomparedto

theleftblade.

Sealer Blade Down Pressure–DownPressureKitsarerecommended

forthisresiduesituation.::

Basket Pressure–Runningabasketisrecommendedforthisresidue

situation.Consult:Setting the Implement for eld

operation: pages

Corn

Grainover

250bushel

(in2+years

cornrotation)

Operational Guide For Various Residue Situations

BLU-JET StripTill Implement

ResidueManagers

Sealers

Torsion

Basket

HeavyPressure

Setting

Rearholes

Maximum

Pitch

Left-hand

Right-hand

Frontholes

HalfPitch

DownPressureKit

NOTE:

Left-hand

and

right-hand

as viewed

from the

rear

Table of contents

Other BLU-JET Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Horizont

Horizont TRAPPER N8 instruction manual

horsch

horsch Maestro 12 SV Translation of the original operating instructions

Avantco

Avantco A37064 Operator's manual

LELY

LELY ASTRONAUT Operator's manual

GrainPro

GrainPro GRAINSAFE 1.0/GHF instruction manual

Farmers Friend

Farmers Friend Pyroweeder Assembly and instruction manual