16 17Well-designed, quality tools and equipment | farmersfriendllc.com (931) 583-0397 | support@farmersfriendllc.com

BasicO peratingInstructions

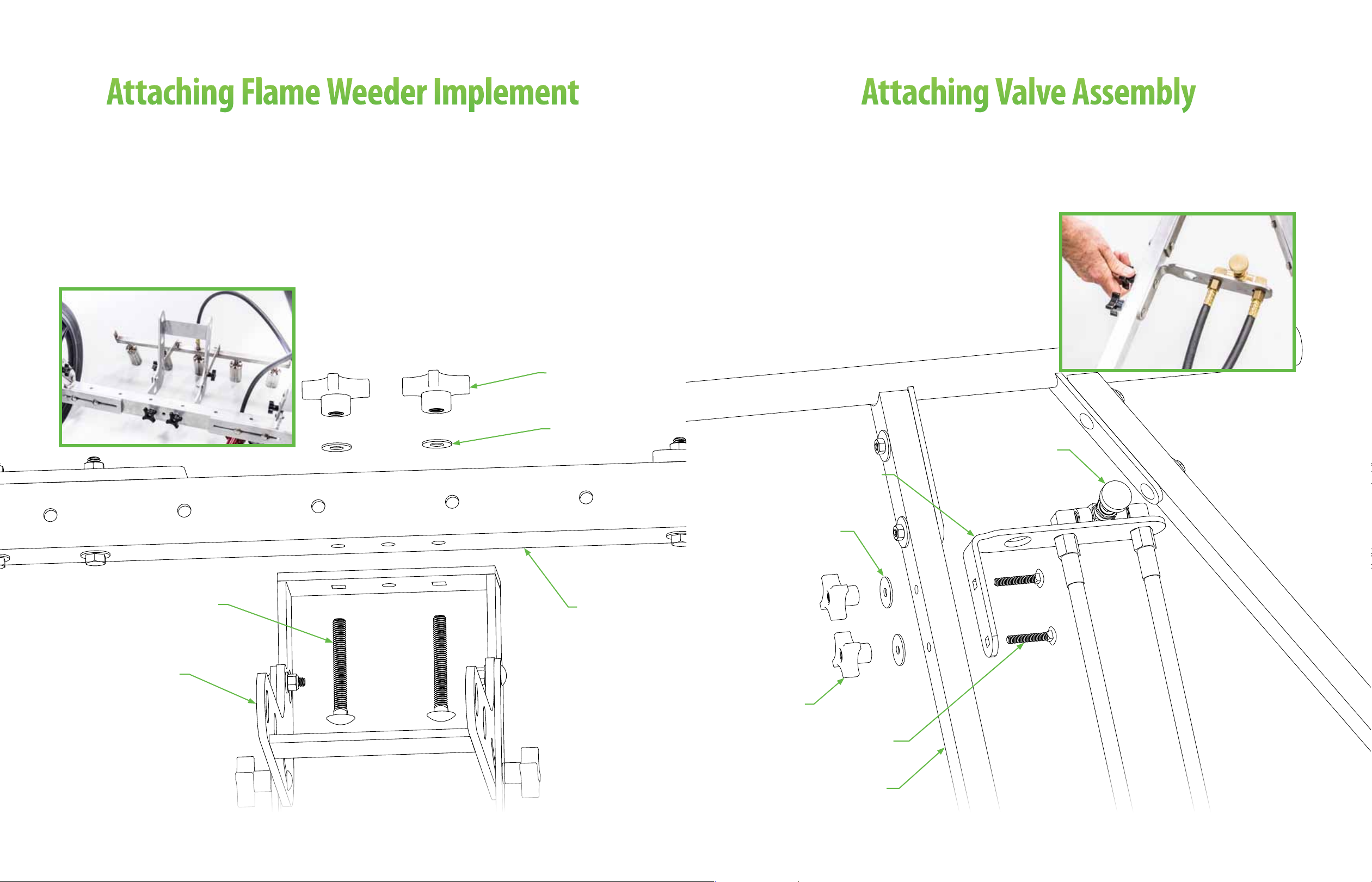

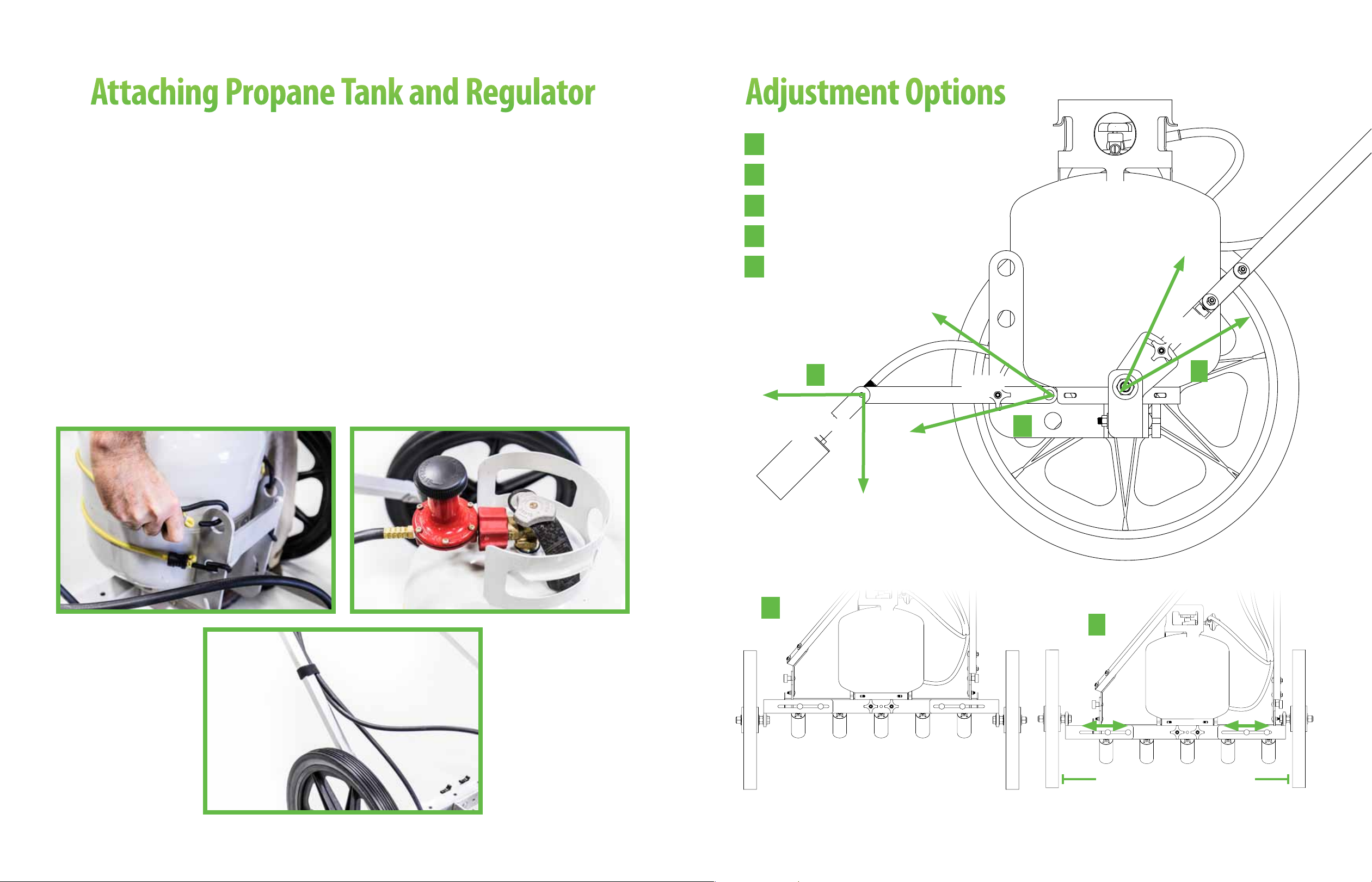

1. The Pyroweeder is equipped with a high-

capacity Quick Connect Coupler (QCC) that

connects the regulator to the propane tank

valve; it has a red plastic coupling nut. The

QCC is equipped with an excess ow check

valve. This safety feature may be acciden-

tally activated—severely limiting propane

ow—if proper startup procedures are not

followed. When this happens, close the tank

valve, bleed o all pressure, and then close

the control valve (the one near the handle)

before re-opening the tank valve.

2. We recommend that you try 20–25 psi as

a starting propane pressure; later, you may

nd that you can achieve acceptable results

with a lower pressure.

3. To light your Pyroweeder, start with both

the tank valve and control valve completely

closed. To avoid accidentally activating the

excess ow check valve, open the tank

valve rst. Then open the control valve just

enough to hear the propane gas escaping.

Then use your striker to light one of the

outside burners. Once one burner is lit,

open the valve up and lower the burners

until the burner heads are almost touching

the ground. This should disperse the ame

enough to light the other burners.

4. Try to ame when the weeds are less

than 2" tall. Larger annual weeds and all

perennial weeds may require multiple

passes over time in order to achieve a

complete kill. Grass is also harder to kill

than broadleaf weeds.

5. Flaming when the weeds are wet will require

you to walk a little slower. The water has to

evaporate o the leaves before the ame

will kill the weeds. Dusk is an ideal time to

ame since there is less chance of dew (and

it is easier to see your ame).

6. Your goal with aming is not to actually

incinerate the weeds, but just to expand the

water in the weeds’ cells enough to burst the

cell walls. According to Eliot Coleman, this

only takes a second at 160º F to do (usually

accomplished at a slow walking speed).

The only visible indication of “kill” is a slight

wilting. To test if you have achieved kill, lightly

press a leaf between two ngers. If the leaf

surface shows a dark green ngerprint, you

have accomplished your goal. The weeds will

appear obviously dead within a few hours.

7. In order to have the cleanest seedbed for

your crops, prepare your beds for seeding at

least 10 days ahead of time. Irrigate and use

oating row cover (during the cooler months)

to encourage weed seed germination. Flame

your beds once or twice (or more) before

seeding. If you are careful, you can seed

your crop and let it germinate; just before

emergence, you can ame one nal time and

have your crop come up into a weed-free

bed (see Eliot Coleman’s New Organic Grower

pp.168 & 169 for a more detailed explana-

tion). One little trick for carrots is to seed

some beet seeds with your carrots. When the

beets emerge, it is time to ame.

8. Because of the high output of the burners,

you will eventually freeze up your propane

tank if you burn for extended periods. After

about a half-hour you may notice the pres-

sure beginning to drop and ice forming on

the tank. Extinguish the ame and allow the

tank to thaw out before resuming operation.

Tip: Have a second tank on hand and just

replace the tank if you have a lot of aming

to do. Once the second tank begins to freeze

up, your rst one should be thawed out.

9. Although there are screens in the pressure

regulator and also in the manifold, there is

still the unlikely possibility that one of your

burners could get plugged with some type

of foreign matter. A bread bag twisty tie is

the perfect size to unclog the orice (take

o the plastic and just use the bare wire). If

you still have problems with the burner, you

can use an ⁄" socket with an extension to

unscrew the pipe cap inside the obstructed

burner and clean it out from the inside.

10. Remember that aming is not weed spe-

cic. It will kill benecial plants as easily as it

does weeds!

11. Be very careful not to ame poison oak,

poison ivy, or any other poisonous plant.

The vapor or smoke from these can cause

irritation to skin and lungs.

Although there is lots of information on ame weeding available

from other sources, we are summarizing the main points here for

your convenience and reference: