BLU-JET AT6020 User manual

Manual Number

0606020

Rev. 2-19-18 $20.00 Net.

Assembly

and Operators

Manual

TM

AT6020

Commercial Fertilizer Injection Applicator

Thurston Manufacturing Company •1708 H Ave •Box 218 • Thurston, Nebraska, 68062-0218

Design specications and features as described are subject to change without notice. BLU-JET is a registered trademark of Thurston Manufacturing Company, Thurston NE.

/BLU-JET @BLU-JET01 /SIronWorks @SIronWorks

1

AT6020

Table of Contents Introduction------------------------------------------------------------------------------------------------------- 1

Deliver--------------------------------------------------------------------------------------------------------------- 4

To The Owner----------------------------------------------------------------------------------------------------- 5

Warranty------------------------------------------------------------------------------------------------------------ 6

Safety--------------------------------------------------------------------------------------------------------------- 7

Operating Instructions---------------------------------------------------------------------------------------- 11

Anhydrous Ammonia Operating Instructions--------------------------------------------------------- 19

Coupler Operation---------------------------------------------------------------------------------------------- 22

Parts----------------------------------------------------------------------------------------------------------------- 23

Emergency Fresh Water Tank--------------------------------------------------------------------------------- 23

Operational Guide For Various Residue Situations BLU-JET StripTill Implement--------------- 24

Center Section Bundle 66000103 Parts List--------------------------------------------------------------- 35

Primary Wing Right-hand Bundle 66000103--------------------------------------------------------------- 40

Primary Wing Left-hand Bundle 66000103----------------------------------------------------------------- 42

Center Section Bundle 66000103 Exploded Views------------------------------------------------------- 44

Center Section Bundle 66000103 Depth Control Parts-------------------------------------------------- 48

Secondary Wing Right-hand With Hydraulic Gauge Wheel Bundle 66000107-------------------- 50

Secondary Wing Left-hand With Hydraulic Gauge Wheel Bundle 66000107---------------------- 52

Dual Wheel Lift Bundle 66000105---------------------------------------------------------------------------- 54

Pin Adjust Gauge Wheel Bundle 55000100---------------------------------------------------------------- 56

48’ and 60’ Complete Toolbar Drawings--------------------------------------------------------------------- 57

Hydraulics 60’------------------------------------------------------------------------------------------------------ 58

Hydraulics 48’------------------------------------------------------------------------------------------------------ 63

Third Wing Bundle 66000108 Left Side--------------------------------------------------------------------- 70

Third Wing Bundle 66000108 Right Side------------------------------------------------------------------- 72

Stagger Brackets Offset 6 x 6 Mounting-------------------------------------------------------------------- 74

Stagger Bracket 40 x 48 Double, (AAM2125)------------------------------------------------------------- 75

Offset Stagger Bracket (AAM2136)-------------------------------------------------------------------------- 76

Super 1200 Flex Coulter and Shank------------------------------------------------------------------------- 77

Nurse Tank Hitch Assembly PKG00234--------------------------------------------------------------------- 78

Nurse Tank Hitch Assembly, Low Mounting PKG00247------------------------------------------------- 79

Auto-Lok Nurse Tank Hitch (AAM2831)-------------------------------------------------------------------- 80

Blades---------------------------------------------------------------------------------------------------------------- 82

SealPro ll and SealPro SKF------------------------------------------------------------------------------------ 83

Hitches--------------------------------------------------------------------------------------------------------------- 90

Jack------------------------------------------------------------------------------------------------------------------ 91

Shanks-------------------------------------------------------------------------------------------------------------- 92

Row Clamps------------------------------------------------------------------------------------------------------- 93

Manual Holder----------------------------------------------------------------------------------------------------- 96

Impellicone Mounting Hardware------------------------------------------------------------------------------ 97

SuperShooter------------------------------------------------------------------------------------------------------ 98

SuperShooter III Add-on Parts (66000136) Single Assembly------------------------------------------ 100

SuperShooter III Add-on Parts (66000137) Dual Assembly------------------------------------------- 102

GDI With Pump Distribution (Rear Mount) (Bundle 20200119)---------------------------------------- 104

Heat Exchanger (CCP2755)----------------------------------------------------------------------------------- 107

GDI WithTwin Pump Distribution (Rear Mount)(Bundle 20200121)---------------------------------- 112

Meter Assembly Impellicone Manifolds--------------------------------------------------------------------- 121

MaxPac AR700 Parts and Assembly------------------------------------------------------------------------ 131

MaxPac Basket Mount Arm------------------------------------------------------------------------------------ 132

Coulter Extension Kit (9-7/8”)----------------------------------------------------------------------------------- 133

MaxPac Assembly------------------------------------------------------------------------------------------------- 134

Torsion Arm Basket Parts---------------------------------------------------------------------------------------- 136

Torsion Arm Assembly-------------------------------------------------------------------------------------------- 137

Torsion Arm Mounting Bracket Rigid Fertilizer Row------------------------------------------------------ 138

Basket Mount Flat With Hardware---------------------------------------------------------------------------- 139

Decals---------------------------------------------------------------------------------------------------------------- 140

StripTill Residue Manager Parts------------------------------------------------------------------------------- 141

Coulter Shank Extensions Brackets-------------------------------------------------------------------------- 142

StripTill Residue Manager Assembly------------------------------------------------------------------------- 143

Light Kit/Slow Moving Vehicle--------------------------------------------------------------------------------- 149

Light Kit/Slow Moving Vehicle 20” Row Spacing---------------------------------------------------------- 151

GDI Lift Kit---------------------------------------------------------------------------------------------------------- 153

Hub and Spindle Assembly------------------------------------------------------------------------------------- 154

Hydraulic Repair Kit---------------------------------------------------------------------------------------------- 160

Tie-rod Cylinder Disassembly-Assembly Procedure----------------------------------------------------- 161

Torque Specications-------------------------------------------------------------------------------------------- 162

Specications------------------------------------------------------------------------------------------------------ 163

Assembly................................................................................................................................ 165

Main Frame and Primary Wings------------------------------------------------------------------------------ 165

Secondary Wings------------------------------------------------------------------------------------------------- 166

Dual Wheel Lift----------------------------------------------------------------------------------------------------- 168

Primary Wing Gauge Wheels----------------------------------------------------------------------------------- 171

Center Section Wheel Lift Linkage--------------------------------------------------------------------------- 175

Tongue Mounting------------------------------------------------------------------------------------------------- 177

Tongue Linkage--------------------------------------------------------------------------------------------------- 178

Bolt-on Cylinder Lug--------------------------------------------------------------------------------------------- 181

Primary Wing Cable Release---------------------------------------------------------------------------------- 182

Hitch and Safety Chain------------------------------------------------------------------------------------------ 183

Jack------------------------------------------------------------------------------------------------------------------ 184

Hose Holder and Hose Tender-------------------------------------------------------------------------------- 185

Turnbuckle Wrench----------------------------------------------------------------------------------------------- 186

Hitch Storage------------------------------------------------------------------------------------------------------ 187

Manual Holder----------------------------------------------------------------------------------------------------- 188

Stagger Brackets-------------------------------------------------------------------------------------------------- 189

Primary Wing Linkage------------------------------------------------------------------------------------------- 190

Secondary Wing Linkage--------------------------------------------------------------------------------------- 191

Third Wing Linkage----------------------------------------------------------------------------------------------- 193

Secondary Wing Latch Standard Wing---------------------------------------------------------------------- 194

Hose Holder Placement 60’------------------------------------------------------------------------------------- 195

Hydraulics 60’ Assembly------------------------------------------------------------------------------------------ 196

Depth Control Parts and Assembly---------------------------------------------------------------------------- 201

Hydraulic Hoses 60’ Assembly--------------------------------------------------------------------------------- 210

Hose Holder Placement 48’------------------------------------------------------------------------------------- 218

Hydraulics 48’ Assembly----------------------------------------------------------------------------------------- 220

Hydraulics Hoses 48’ Assembly------------------------------------------------------------------------------- 222

Nurse Tank Hitch Single PKG00234------------------------------------------------------------------------- 234

Nurse Tank Hitch Single Low Mounting PKG00247------------------------------------------------------ 236

SuperShooter III Add-on Parts (66000136) Single Assembly------------------------------------------ 238

SuperShooter III Add-on Parts (66000137) Dual Assembly------------------------------------------ 242

Swing Adjust Gauge Wheel------------------------------------------------------------------------------------ 246

Coulter--------------------------------------------------------------------------------------------------------------- 247

Shank---------------------------------------------------------------------------------------------------------------- 249

Spring Cushion---------------------------------------------------------------------------------------------------- 251

Light Kit & Slow Moving Vehicle------------------------------------------------------------------------------ 253

Light Kit & Slow Moving Vehicle 20” Row Spacing------------------------------------------------------- 258

Safety Tank--------------------------------------------------------------------------------------------------------- 261

Depth Collars------------------------------------------------------------------------------------------------------ 262

Decals--------------------------------------------------------------------------------------------------------------- 263

Hydraulic System Charging------------------------------------------------------------------------------------ 265

Folding Tool Bar--------------------------------------------------------------------------------------------------- 266

Row Spacing Layout------------------------------------------------------------------------------------------- 267

Manual Number:

0606020

Rev. 2-19-18

2

AT6020

Welcome to Thurston Manufacturing Company. Our goal is to provide

quality products and services to our customers. The company’s BLU-JET

products have a reputation for quality, excellence in design and proven

durability. Energetic, resourceful and continuous improvement goals in

Environmental, Safety, Quality, Production and Engineering keep our

rm at the cutting edge of technology.

We hope your BLU-JET equipment will give you years of service.

Introduction

Read this manual carefully. It will instruct you on how to operate and

service your machine safely and correctly. Failure to do so could result

in personal injury and/or equipment damage.

SAFETY INFORMATION

Indicates an imminently hazardous situation that, if

not avoided, will result in death or serious injury.

The sign will have the color combination of red and

white.

Indicates a potentially hazardous situation that, if

not avoided, could result in death or serious injury.

The sign will have the color combination of orange

and black.

Indicates a potentially hazardous situation that, if

not avoided, may result in minor or moderate injury.

The sign will have the color combination of yellow

and black.

NOTE: Indicates a special point of information.

Carefully read and follow all safety signs. Reinstall safety signs that

are damaged or missing.

Right-hand and left-hand sides of the implement are determined by

facing in the direction the implement will travel when going forward.

DANGER

WARNING

CAUTION

3

AT6020

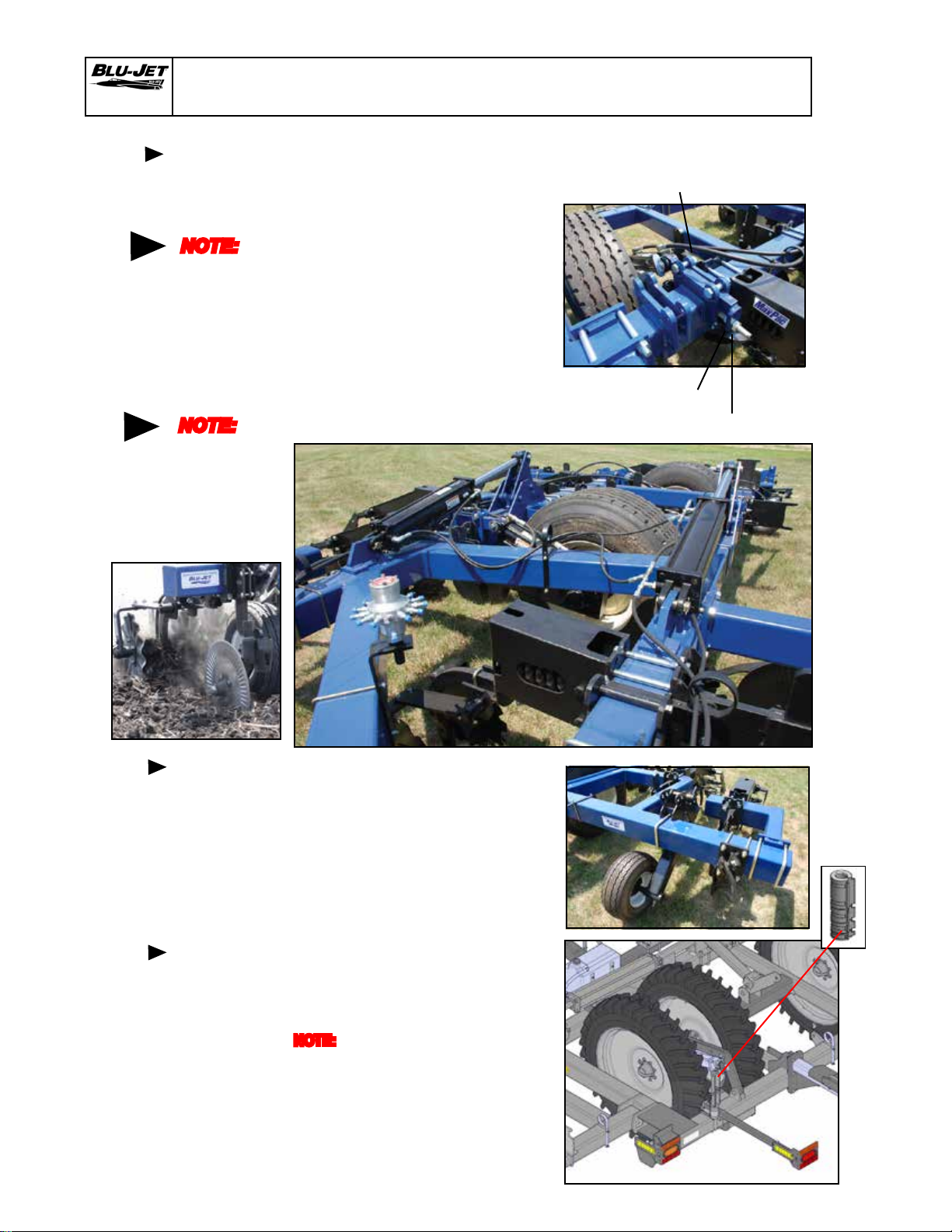

Tractor side

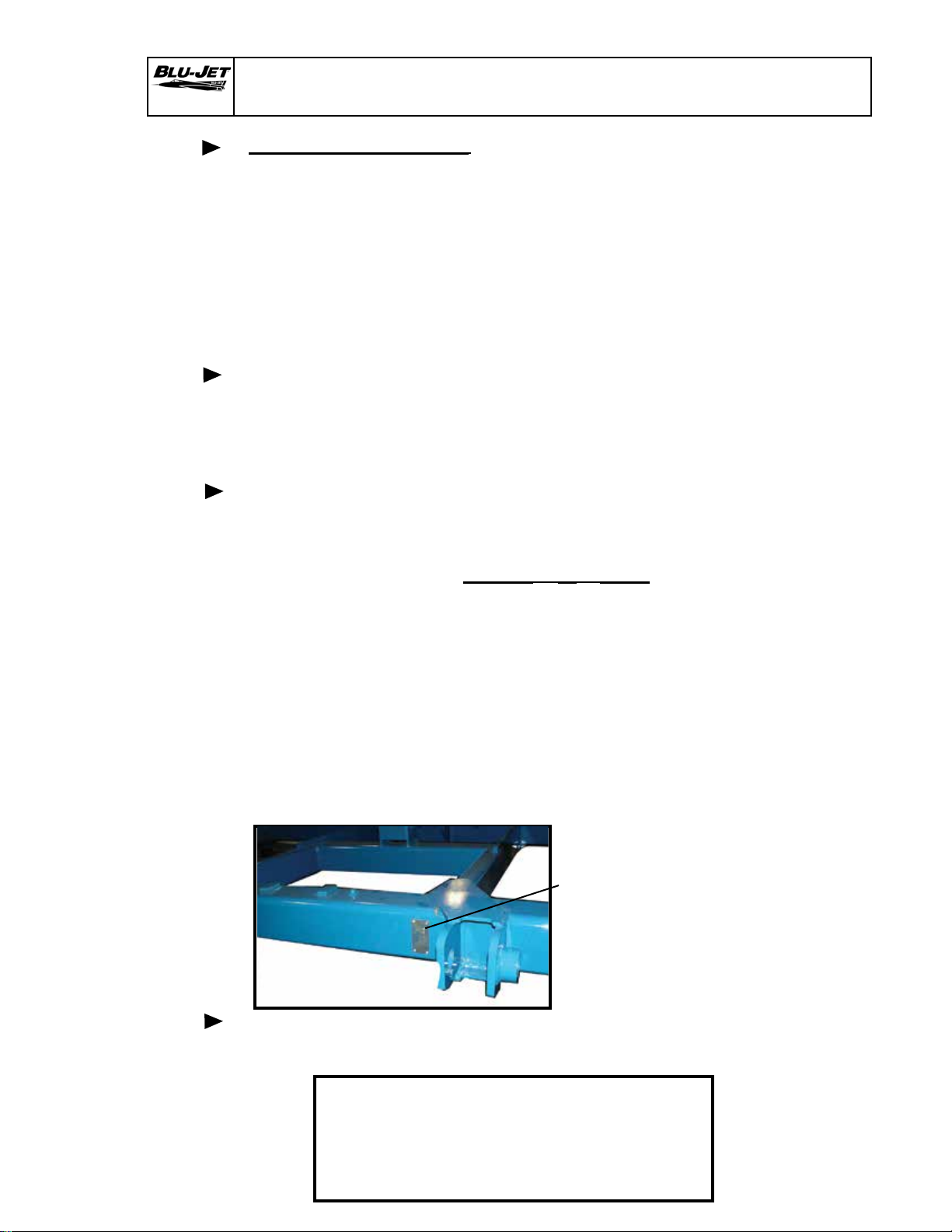

The Serial Number

is located from the

rear of the tool bar

on the right-hand

side behind the

tongue pull plate.

Introduction

For your convenience we have four easy ways to register your warranty.

•Call our toll free number and ask for warranty registration.

1-800-658-3127

•Register on-line at: www.BLU-JET.com

•Complete and mail this Product Registration form to:

Attn: Thurston Manufacturing Company

Product Registration

PO Box 218

Thurston, NE. 68062

• Email a copy to: [email protected]

Thurston Manufacturing Company Warranty does not cover the following:

1) Cleaning, transporting, mailing and service call charges.

2) Depreciation or damage caused by normal wear, accidents,

improper protection or improper use.

MODEL NO.__________________________

SERIAL NO.__________________________

DATE PURCHASED___________________

Record your implement model and serial number in the space provided below.

Your dealer needs this information to give you prompt, efcient service when

you order parts.

General Information:

The BLU-JET AT6020 Commercial Class Fertilizer Injection Applicator

achieves a new performance dimension for high acre, high rate applications.

The BLU-JET AT6020 can easily be congured for a number of operations

including Pre-Plant, Side-Dress, and StripTill applications with anhydrous,

liquid, dry, or dual placement fertilizer injection.

The AT6020 was designed to be used in combination with BLU-JET’s

Super 1200 Coulter, MaxPac 700 AutoReset shank mounting, residue managers,

SealPro disc sealers, torsion arm rming baskets and BLU-JET’s complete

line of shank mountings.

Warranty is provided for customers who operate and maintain their equipment

as described in this manual. Warranty registration is accomplished by

the dealer completing and forwarding the WARRANTY REGISTRATION FORM

to Thurston Manufacturing Company. It is in your best interest to ensure that

this has been done.

4

AT6020

1. All hardware properly tightened

2. Lubrication of grease ttings

3. All decals properly located and readable

4. Other adjustments for machine level height, etc.

5. Overall condition (touch up any scratches, clean and

polish)

6. Operator’s manual

DATE SET UP_______________________________

SIGNATURE________________________________

PRE-DELIVERY CHECKLIST

Dealer Checklist

To The Dealer:

Inspect the implement thoroughly after assembly to be certain it is

functioning properly before delivering it to the customer. The following

checklist is a reminder of points to cover. Check off each item as it is

found satisfactory or after proper adjustment is made.

DELIVERY

Review the operator’s manual with the customer. Explain

the following:

1. Safe operation and service

2. Correct machine installation and operation

3. Daily and periodic lubrication and maintenance

4 Daily and periodic inspections

5. Trouble shooting

6. Storing machine

7. Thurston Manufacturing Company parts and service

8. Have the customer write the machine model and serial

number in space provided in manual introduction.

9. Give customer the operator’s manual and encourage

the customer to read the manual carefully.

10. Completion and mailing of warranty registration

form.

DATE DELIVERED__________________________

SIGNATURE_______________________________

MODEL NO.________________________________

SERIAL NO.________________________________

5

AT6020

To The Owner

Thank you for your recent purchase of a new BLU-JET

implement. The primary objective of Thurston Manufacturing

Company is to build and provide you with a quality product.

However, in the event that a problem does occur, it is imperative

that your warranty registration is on le in order to accurately

respond to your specic service circumstances.

For your convenience we have four easy ways to register

your warranty:

For your convenience we have four easy ways to register your warranty.

•Call our toll free number and ask for warranty registration.

1-800-658-3127

•Register on-line at: www.BLU-JET.com

•Complete and mail this Product Registration form to:

Attn: Thurston Manufacturing Company

Product Registration

PO Box 218

Thurston, NE. 68062

• Email a copy to: [email protected]

This manual has been prepared to assist you in the assembly

of your new machine and contains information pertaining to

safety, operations and all of its parts. Our personnel in sales

and service are always available to assist you when questions

arise concerning the assembly or operations of your tool bar.

When ordering parts, please refer to part numbers and

descriptions as listed throughout this book. All parts and

whole goods will be shipped FOB Thurston, Nebraska. Or

FOB your regional distributor. Always check merchandise

immediately upon receipt for damage or shortage. Note any

discrepancy on carrier’s bill of lading and notify Sender within

10 days. Returned goods will be subject to a 15% restocking

charge. Thurston Manufacturing Company reserves the right

to make improvements and modications on equipment

without obligation to change previously built equipment. All

prices are subject to change without notice.

6

AT6020

Thurston Manufacturing Company warrants each new BLU-JET machine

primary framework to be free from defects in material and workmanship for a period

of ve (5) years, normal wear of wearing parts excepted. Thurston Manufacturing

Company further warrants each new BLU-JET product to be free from defects in

material and workmanship, normal wear of wearing parts excepted, for a period

of one (1) year. All accessories purchased and resold by Thurston Manufacturing

Company will be warranted according to their respective manufacturer. Tires on

BLU-JET equipment are warranted through their respective tire manufacturers and

their network of dealers in your local area.

Warranty begins from date of delivery to the original purchaser and applies

to all new BLU-JET products that have not been altered and are being used for the

intended purpose. Negligence, abuse or modication of equipment manufactured

by or purchased and resold by Thurston Manufacturing Company will void this

warranty.

The obligation of Thurston Manufacturing Company to honor this warranty

is limited to the repair or replacement of defective merchandise, to the original

purchaser, subject to inspection of equipment in question by an authorized Thurston

Manufacturing Company sales or service technician. In the USA, freight of warranty

replacement parts including main frame centers and wings will be prepaid for a

period of one (1) Year by Thurston Manufacturing Company. Shipments of repaired

or replaced parts including main frame centers and wings after one year will be paid

by the customer.

Return of defective goods must be made within thirty (30) days of failure to

Thurston Manufacturing Company, Thurston, Nebraska USA or to the nearest

authorized BLU-JET Distributor or Rep Sales and service outlet.

Thurston Manufacturing Company will not be held responsible for any repair

charges made by customers without prior written consent and prior equipment

inspection by an authorized Thurston Manufacturing Company sales or service

technician.

This warranty shall not be interpreted to render liability for injury or damages

of any kind, direct, consequential or contingent to person or property. This warranty

does not extend to loss of crops, economic and/or commercial loss, loss because

of delay in crop production or any expense incurred for labor, supplies, substitute

machinery, rental or for any other reason. This warranty is subject to any existing

condition of supply, which may directly affect Thurston Manufacturing Company’s

ability to obtain materials of manufacture and delivery of replacement parts.

Thurston Manufacturing Company reserves the right to make improvements

in design and changes in specications at any time without incurring any obligation

to owners of units previously sold.

No one is authorized to alter, modify or enlarge this warranty nor its exclusions,

limitations and reservations. Thurston Manufacturing Company makes no

representations or warranties, expressed or implied (including implied warranties

of merchantability and tness), except for those set forth in Thurston Manufacturing

Company’s current applicable published warranty policies and procedures.

Layton W. Jensen, President 022398\mgmt

Limited Warranty

7

AT6020 Safety

RECOGNIZE SAFETY INFORMATION

• This is the safety-alert symbol. When you see his symbol

on your machine or in this manual, be alert to the

potential for personal injury. Follow recommended

precautions and safe operating practices.

FOLLOW SAFETY INSTRUCTIONS

• Carefully read all safety messages in this manual and

on your machine safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs.

• Learn how to operate the machine and how to use

controls properly.

• Do not let anyone operate without instruction.

• Keep your machine in proper working condition.

• Unauthorized modication to the machine may

impair the function and/or safety and affect machine life.

PROTECT CHILDREN AND BYSTANDERS

• Before you back, LOOK CAREFULLY behind for

children.

• Clear area of children, pets and bystanders.

HIGHWAY AND TRANSPORT OPERATIONS

Adopt safe driving practices:

• Keep the brake pedals latched together at all times.

NEVER USE INDEPENDENT BRAKING WITH MACHINE

IN TOW AS LOSS OF CONTROL AND/OR UPSET OF

UNIT CAN RESULT.

• Always drive at a safe speed relative to local

conditions and ensure that your speed is low enough

for a emergency stop to be safe and secure. Keep

speed to a minimum.

• Reduce speed prior to turns to avoid the risk of

overturning.

• Avoid sudden uphill turns on steep slopes.

• Always keep the tractor or towing vehicle in

gear to provide engine braking when going downhill.

Do not coast.

• Do not drink and drive.

• Comply with state and local laws governing highway

safety and movement of farm machinery on public roads.

• Use approved accessory lighting and necessary

warning devices to protect operators of other vehicles

on the highway during daylight and nighttime transport.

• The use of ashing amber lights is acceptable in most

localities. However, some localities prohibit their use.

Local laws should be checked for all highway lighting

and marking requirements.

• When driving the tractor and equipment on the road

or highway under (20 mph max.) (32 kmph max.) at night or

during the day, use ashing amber warning lights

and a slow moving vehicle (SMV) identication emblem.

8

AT6020

HIGHWAY AND TRANSPORT OPERATIONS

• Plan your route to avoid heavy trafc.

• Be a safe and courteous driver. Always yield to oncoming

trafc in all situations, including narrow bridges,

intersection, etc.

• Be observant of bridge loading ratings. Do not cross

bridges rated lower than the gross weight at which you

are operating.

• Always operate equipment in a position to provide

maximum visibility at all times. Makes allowances for

increased length and weight of the equipment when

making turns, stopping the unit, etc.

TRANSPORT SAFETY

• A safety chain will help control drawn equipment

should it accidentally separate from the drawbar.

• Attach the chain to the tractor drawbar support or

other anchor location. Provide only enough slack in

the chain to permit turning.

• Use hydraulic cylinder transport lockup during road

transportation.

•Maximum road speed is 20 m.p.h.

AVOID HIGH PRESSURE FLUIDS

• Escaping uid under pressure can penetrate the skin

causing serious injury.

• Avoid the hazard by relieving pressure before

disconnecting hydraulic or other lines. Tighten

all connections before applying pressure.

• Search for leaks with a piece of cardboard.

• Protect hands and body from high pressure uids.

• If an accident occurs, see a doctor immediately.

DISPOSE OF FLUIDS PROPERLY

• Improperly disposing of uids can harm the

environment and ecology. Before draining any

uids, contact your local environmental agency

for the proper waste disposal methods.

• Use proper container when draining uids. Do

not use food or beverage containers that may

mislead someone into drinking from them.

• DO NOT pour oil into the ground, down a drain, or

into a stream, pond, or lake. Observe relevant

environmental protection regulations when disposing

of oil and other harmful waste.

Safety

9

AT6020 Safety

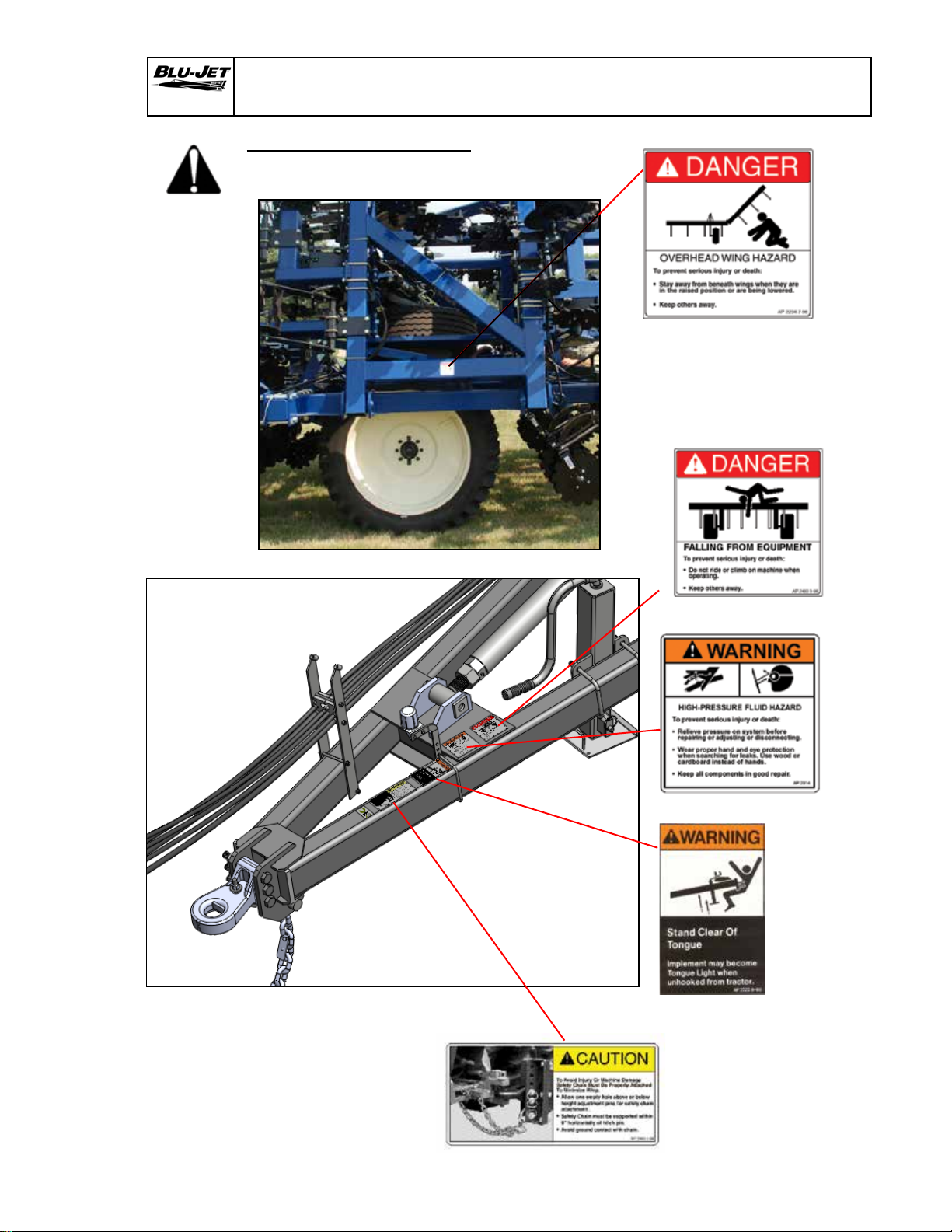

Observe Safety Signs

AP 2469-7-98

AP 2483-8-98

AP 2234-7-98

AP 222 8-90

AP 2914

10

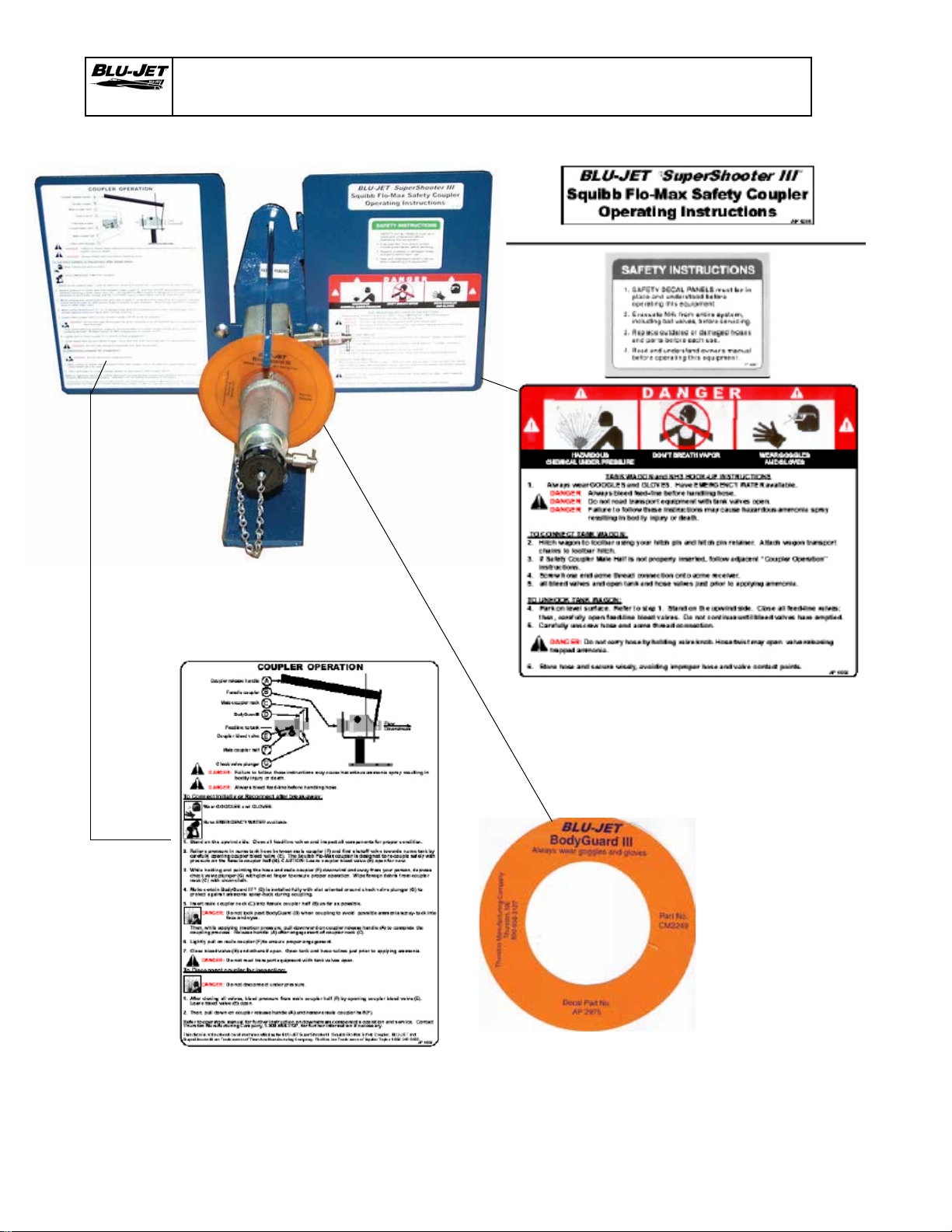

AT6020 Safety Decals

AP2973

AP2975

AP2974

AP2227

AP2972

11

AT6020 Operating Instructions

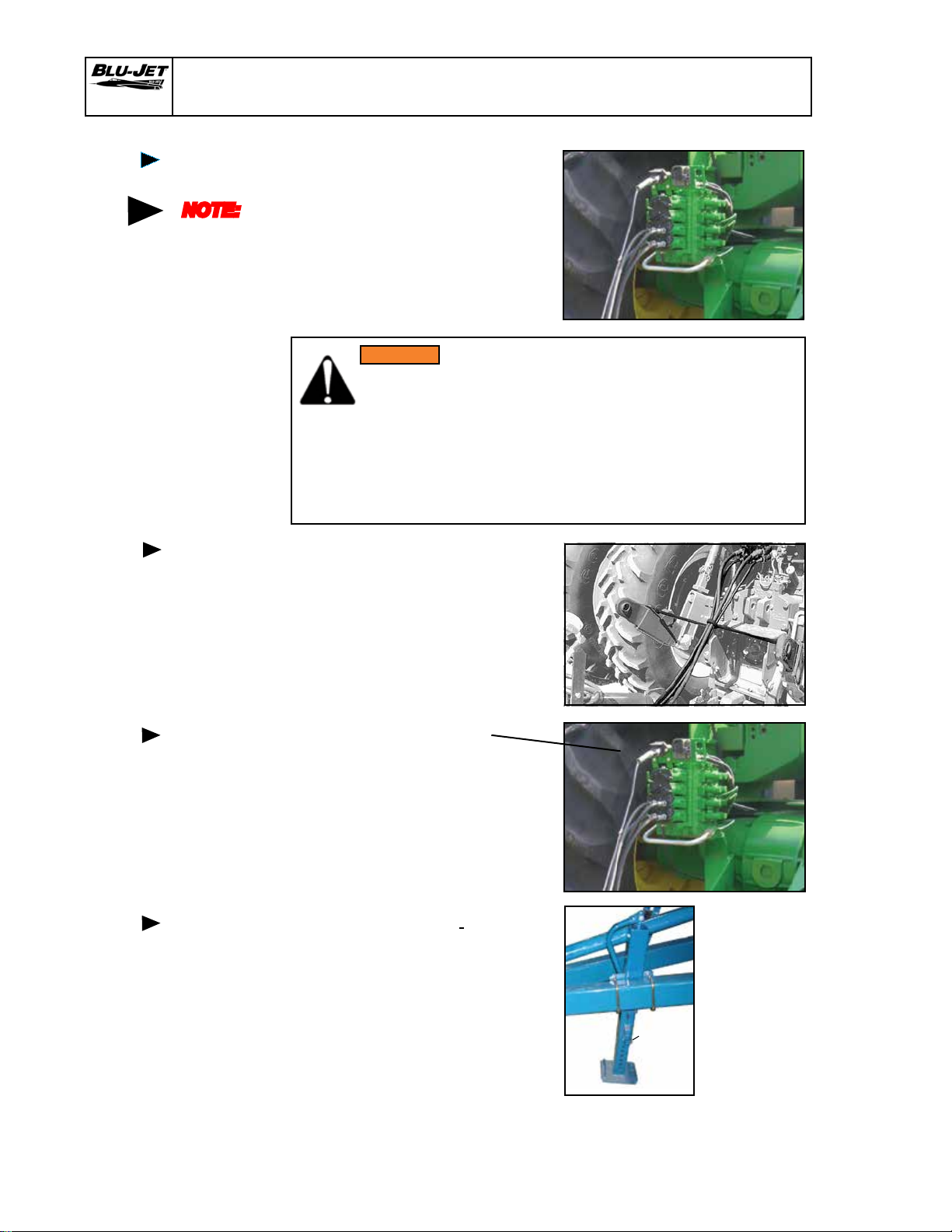

Hitch 1. The tractor must be equipped

with a drawbar and a draw-

bar safety chain clevis. For

rigid frame tractors equipped

with swinging drawbar, the

drawbar must be located in a

xed position in the center of

the tractor. Refer to your

tractor operators manual for

drawbar adjustment and

drawbar operating instructions.

NOTE:

Implement

hitch weights

are designed

to match

tractor size

ranges.

Check the

following

chart to

conrm your

particular

implement

specication.

WARNING: Tractor drawbar must be in a xed position before

transporting implement. Implement will sway or slam against

tractor resulting in equipment damage or injury to personnel.

WARNING: In case the tractor hitch pin is lost during transport-

ing. The safety chain must be attached between the implement

and tractor to prevent separated implement from running freely

and causing damage or injury.

WARNING: Do not move articulated tractor steering wheel

until everyone is clear of the equipment. Moving the steering

wheel can swing or move attached equipment which could

cause serious personal injury.

Tractor to

tool bar

connection

2. Before connecting the tool bar to the tractor drawbar, raise the

tractor three point hitch (if equipped) to prevent interference

between the implement and the tractor.

Connect the tool bar to tractor drawbar ONLY. DO NOT connect

the tool bar to any other part of the tractor. Connect the tool bar

clevis to the tractor drawbar with hitch pin. Install the safety

chain through the tractor drawbar support bracket.

3. Always use a safety hitch pin of the correct diameter. Make sure

that the hitch pin is locked in place with a safety type lock pin or

other locking device.

4. Always use a safety chain between the toolbar and the tractor.

Install the chain to the tractor drawbar support bracket. Support

the center of the chain with a clevis installed to the tractor

drawbar.

Safety

hitch pin

Safety

chain

Generic Photo

Engine

HP Range

Drawbar

Vertical Load Pounds

Category

I

II

III

IV

20

40

80

100

47

133

227

400

731

1,236

2,248

4,777

1,405

3,597

5,957

10,341

WARNING

WARNING

WARNING

12

AT6020 Operating Instructions

Remote

hydraulic

5. Connect the toolbar hydraulic

hoses to the tractor remote

couplers. The 1/2” hoses

supply oil to the toolbar lift

cylinders. The 3/8” hoses

supply oil to the wing fold

cylinders.

NOTE:

Always

connect the

hoses so

the toolbar

raises when

the tractor

remote con-

trol lever is

moved rear-

ward and

lowers when

the lever

is moved

forward.

6. It may be necessary to tie

the hydraulic hoses up to

keep them away from the

hitch area. A tarp strap

around the hoses and

between the two point arms

works well.

7. Attach 7 pin electrical

harness before road

transport.

8. Lower the jack and pull

ring on drop leg jack

plunger and raise the sand

pad off the ground. Secure

plunger in holes.

I

MPORTANT: Always lower the

jack stand to the ground before

disconnecting the tool bar from the

tractor.

Remote

hydraulic

Attaching

electrical

harness

Jack stand

Ring

WARNING: Hydraulic uid escaping under pressure can have

enough force to penetrate the skin. Hydraulic uid may also

infect a minor cut or opening in the skin. If injured by escaping

uid, see doctor at once. Serious infection or reaction can result

if medical treatment is not given immediately. Make sure all

connections are tight and that hoses and lines are in good

condition before applying pressure to the system. Relieve all

pressure before disconnecting the lines or performing other work

on the hydraulic systems.

WARNING

13

AT6020 Operating Instructions

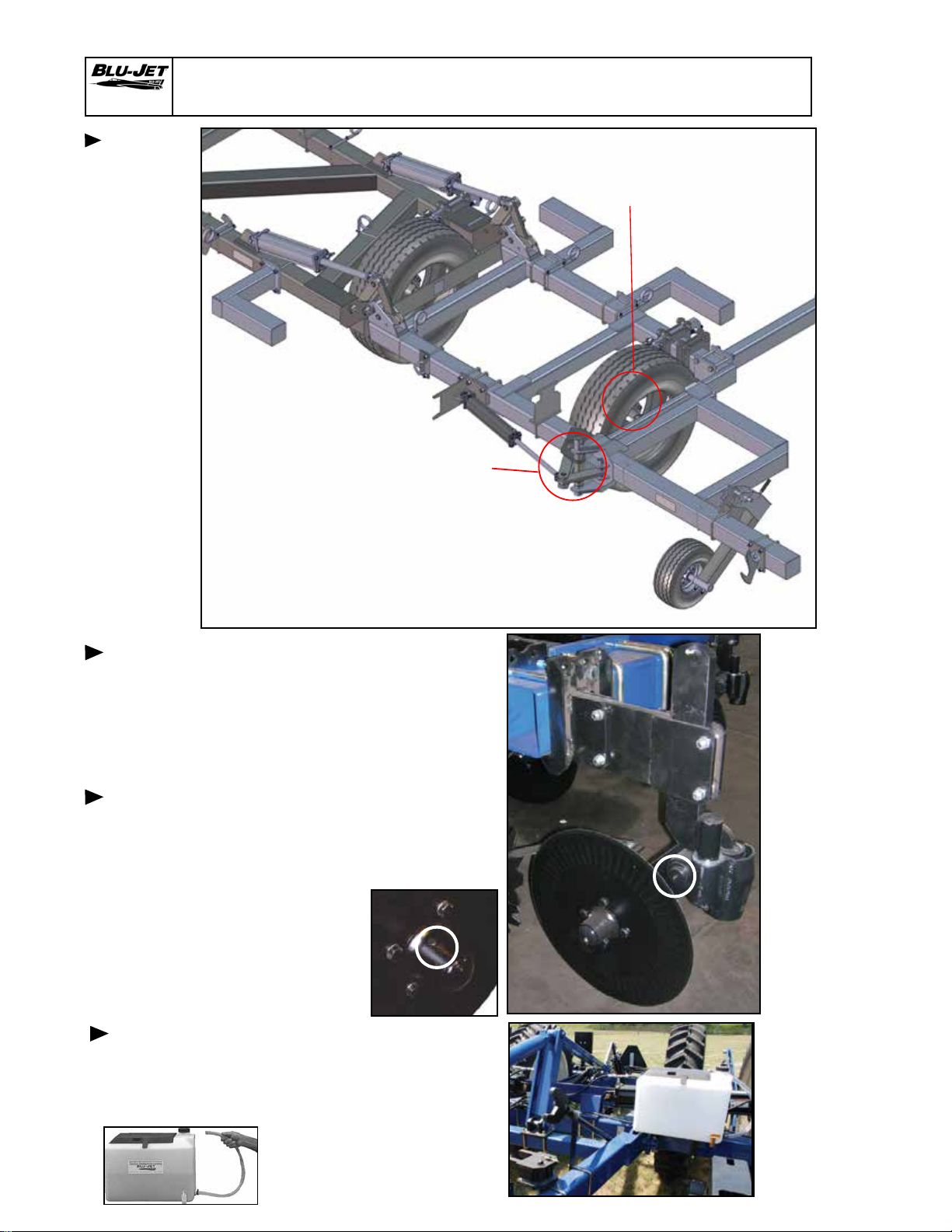

9. Before leveling the machine

the tire pressure should be

checked.

Inate center section lugged

tractor tires to 56 P.S.I. Maximum

Truck tires 95 P.S.I. Maximum

Before beginning operation of

this machine the main frame

must be level.

Place tool bar on level surface.

Use the turnbuckle wrench to

loosen the lower turnbuckle

jam nut. Adjust turnbuckle with

wrench until the main frame is

level front to back. After making

the necessary adjustment,

lock turnbuckle with jam nut.

Leveling

Machine

Main Frame

10. Unlatch primary wing latch

with the cable release located

on the front of the tool bar

before unfolding tool bar.

CAUTION: To prevent serious accident or injury

do not remove wing latch cable release mecha-

nism. Wing fall may result during road transport.

NOTE: Cable must be free. Do not place

hydraulic hoses, EVA hoses or ties around

the cable.

Jam Nut

CAUTION

14

AT6020

Tighten one inch

hex nuts after

wheel adjustment.

Leveling

adjustable

gauge

wheels

One Inch hex nut

Cylinder lug adjust

11. Check tire pressure before

adjusting.

Loosenthetwo1”x4” Hexbolts

at the top of the adjust linkage.

Loosen 1” hex nut on inside of

threaded rod. Turn 1” hex nut

on outside clockwise to lower

wingand counter clockwise to

raisewing. Secure bothnuts on

threaded rod against cylinder

lug adjust. Tighten

1” x 4” hex cap screws after

wheel adjustment.

NOTE:

Adjust until

tool bar is

level

across the

entire bar

12. Adjust pin adjust gauge wheel

to level position with the

hydraulic gauge wheel.

Operating Instructions

Pin adjust

gauge

wheel

13. Install equal lengths of cylinder

depth collars to the right and left

hand center section wheel lift

cylinders.

NOTE: Unequal depth collar installation

may result in wheel lift linkage damage.

Depth

collars

NOTE:

Coulter will

require

nal

working

depth

adjustment

in the eld.

15

AT6020

DEPTH ADJUSTMENT

1. One complete revolution equals 1/2” of

depth increase.

LOCKING DEPTH ADJUSTMENT

LINKAGE

1. Rotate depth control adjuster latch

over handle and lock in place with

(27) (BP3376) 1/4” x 2” wire retaining

pin.

LOCKED POSTION

Operating Instructions

16

AT6020

Pinch point

To prevent Injury

Keep hands clear

when extending or

retracting the swing

slide insert

WARNING

14. Nurse tank hitch can be

retracted and moved from

side to side for easy hookup.

Hitch will automatically lock

in the extended position.

NOTE:

Periodically

check Latch

mechanism to

ensure proper

latching in the

extended

position.

Nurse tank

hitch

Secondary

wing latch

Cylinder rod

maintenance

Operating Instructions

15. Mechanism must swing

freely in order to operate

properly. Installed position

must be squared with frame

to allow maximum freedom

of movement. Keep soil and

debris from area to allow

maximum movement.

NOTE: After seasonal storage,

check wing latch for freedom of

movement.

16. All exposed cylinder rods

should be greased before

seasonal storage to prevent

rusting.

Remove depth collars and

lubricate exposed cylinder

rods.

Latch in open position

before wing is folded

17

AT6020

Zerks On Wing Gauge

Wheel Pivot

(Torque 100 ft./lbs.)

Zerk

Wing Hinges

17. Lug nut Torque

1. Check every hour rst four

hours.

2. Check every four hours to

rst twenty hours.

3. Check once every fty hours

thereafter.

Lug Nut

Torque

Lubrication

Zerk

Under

Hitch

Lift Wheel Pivot Zerk

(Torque 150-180 ft. lbs.)

Operating Instructions

17. Lubrication

• Grease all zerks daily

• Grease coulters daily

Zerk

Zerks

Zerk

Wing Linkage

Zerk

Wing Linkage

18

AT6020

Zerks On Linkage

And Hinge

Operating Instructions

Lubrication

Zerks On Wing Gauge

Wheel Pivot

(Torque 100 ft./lbs.)

18. Grease all coulter arm pivots.

19. The plug on the coulter hub

can be removed. A zerk can

be installed. Hub and spindle

assembly should be greased

twice seasonally.

20. emergency water tank/toolbox.

Change water daily to provide

fresh clean water to ush

exposed skin or eyes.

Drain water daily in cold

temperatures to prevent

freezing and bursting tank.

Coulter

pivot shaft

lubrication

Coulter

hub

lubrication

Emergency

water tank

operation

and

maintenance

Table of contents

Other BLU-JET Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Anderson

Anderson Double stretcher Operator's manual

GrainPro

GrainPro TRANSAFELINER BULK instruction manual

UNIA

UNIA MX user guide

MASSEY FERGUSON

MASSEY FERGUSON Combines MF 7340 Workshop service manual

sitrex

sitrex MX 8 Assembly, use and maintenance

Quattro

Quattro Titanium EGO400 Installation guide and user information