TABLE OF CONTENTS

1. INTRODUCTION..............................................................................................................4

2. CHECKLIST ......................................................................................................................5

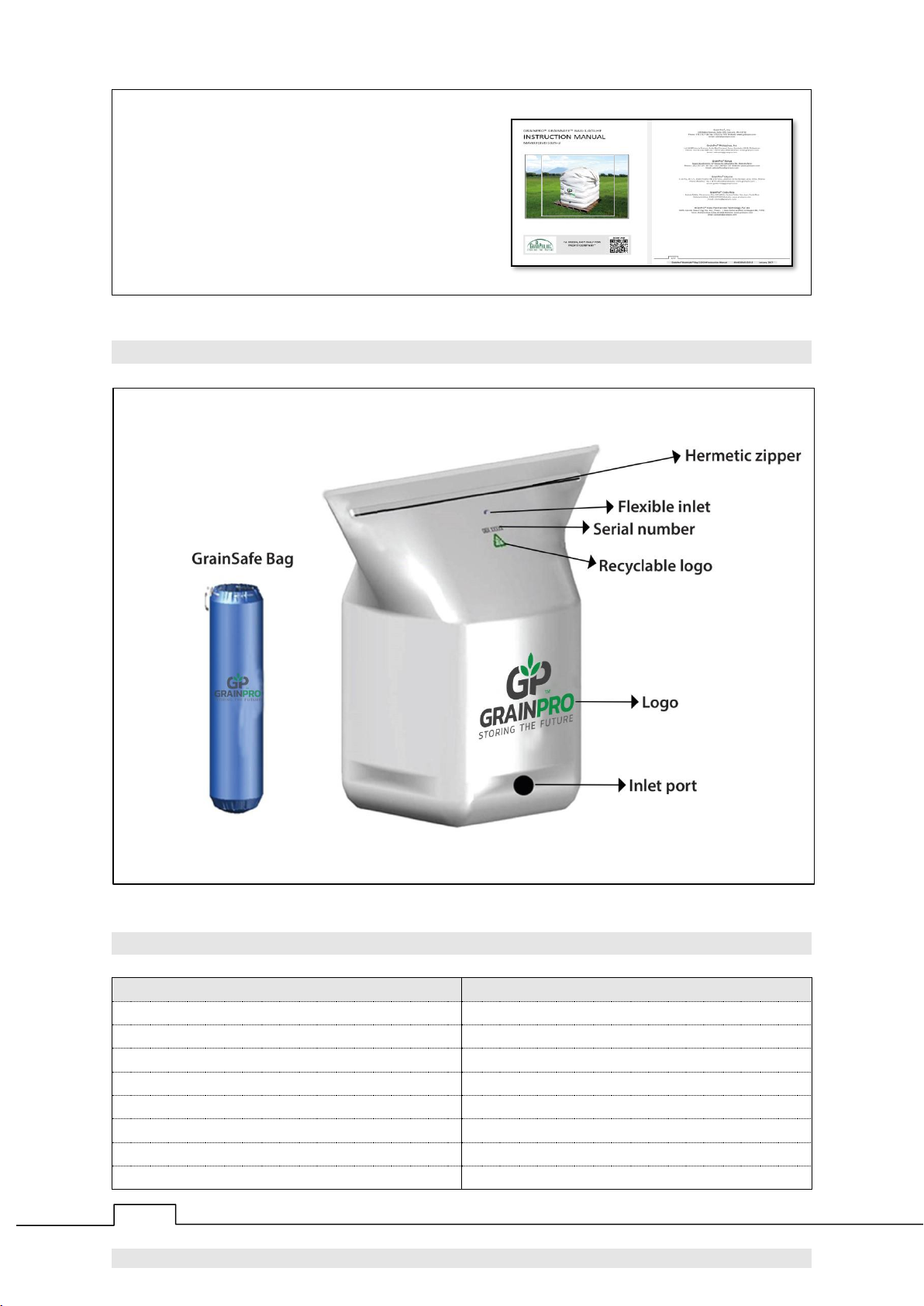

3. COMPONENTS................................................................................................................6

4. SPECIFICATIONS .............................................................................................................6

5. INSTALLATION................................................................................................................7

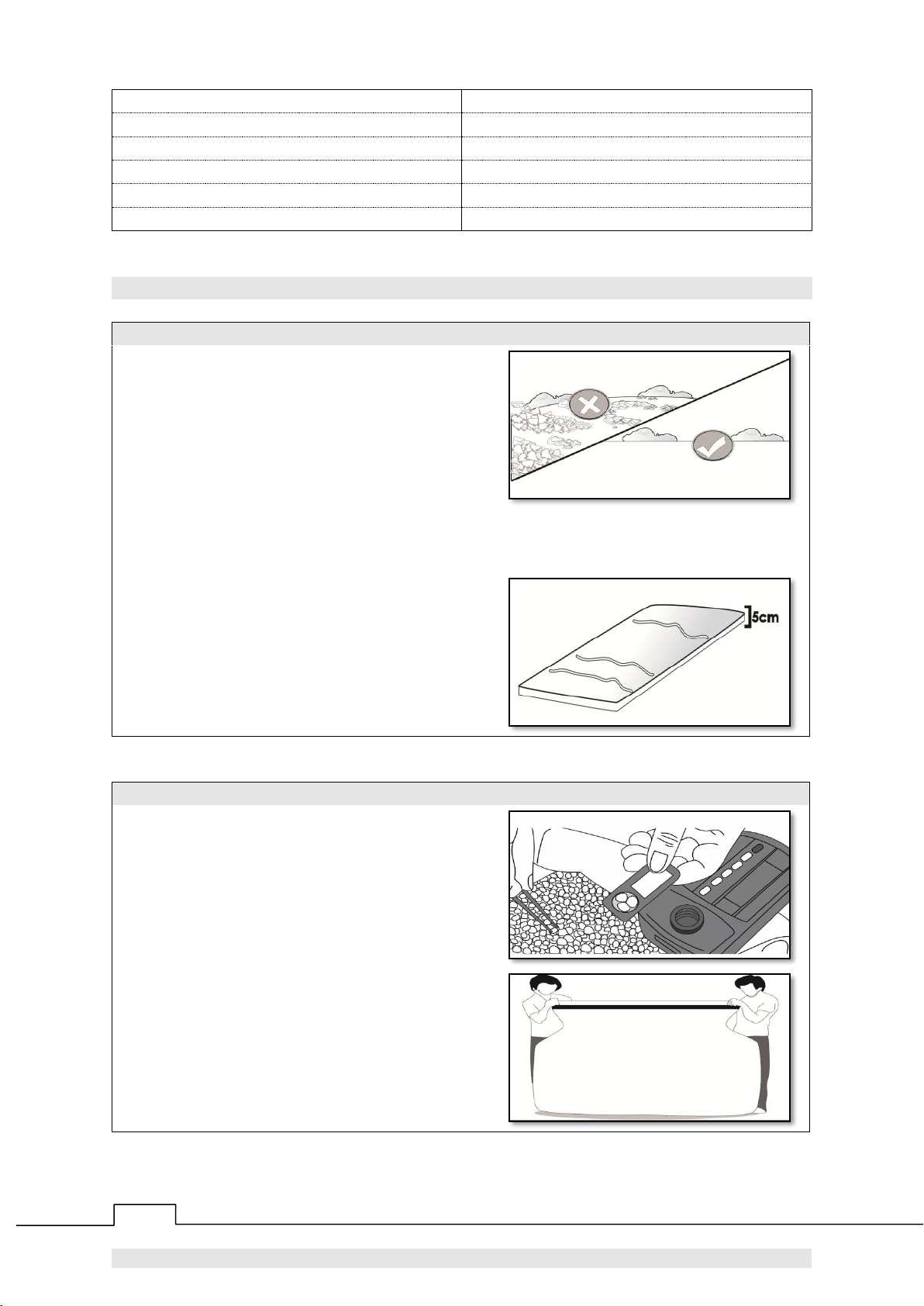

Site selection .............................................................................................................7

Loading ...................................................................................................................... 7

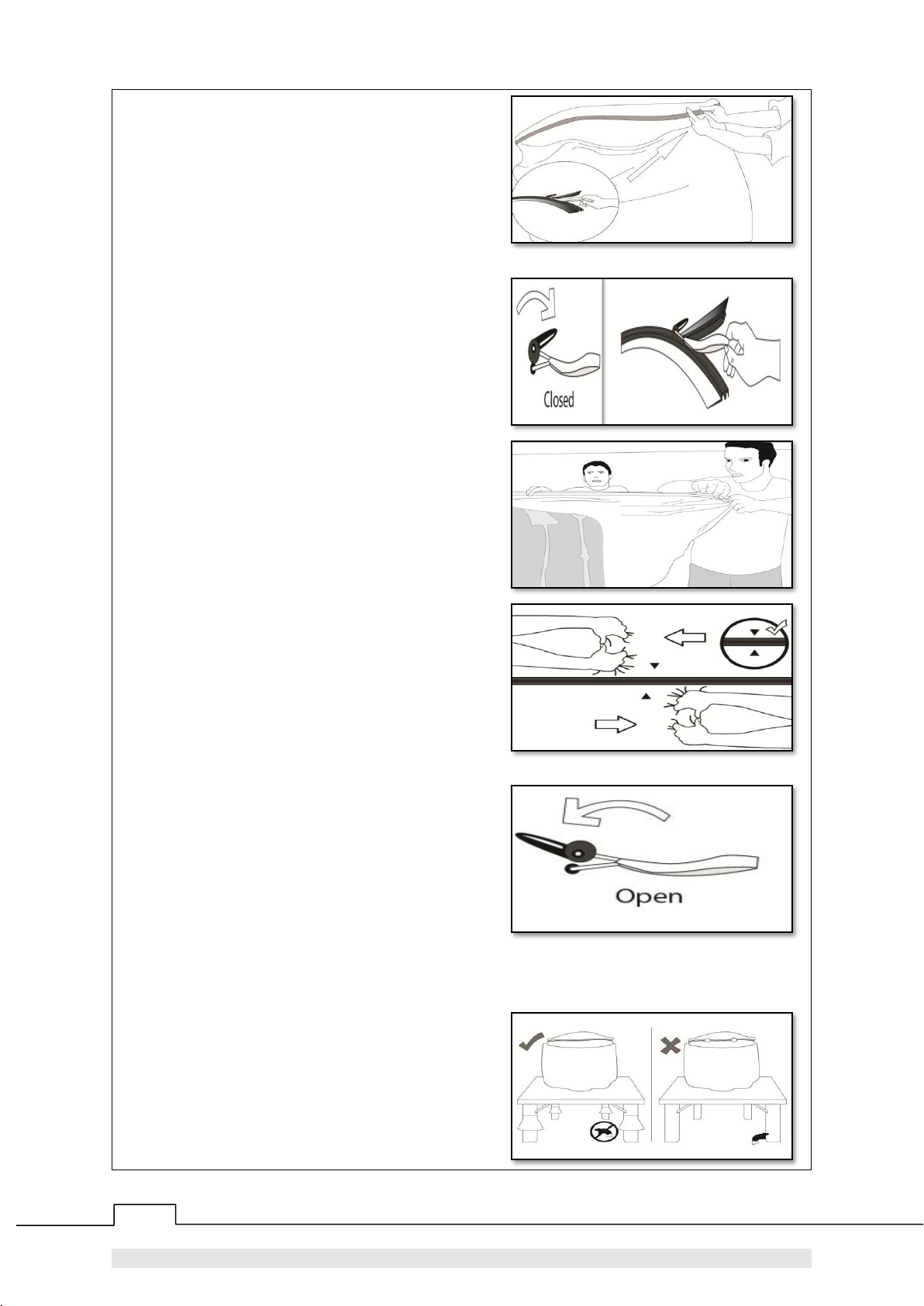

Zipping.......................................................................................................................8

Pressure decay test .................................................................................................10

Installation of rodent guard ....................................................................................10

Outdoor installation................................................................................................11

Procedure for purging carbon dioxide....................................................................11

Monitoring the oxygen level ...................................................................................14

Dismantling .............................................................................................................15

6. PREVENTING CONDENSATION ....................................................................................15

Why does condensation occur................................................................................15

Moisture content requirement for safe storage..................................................... 15

7. MAINTENANCE AND CARE ...........................................................................................16

Regular examination ...............................................................................................16

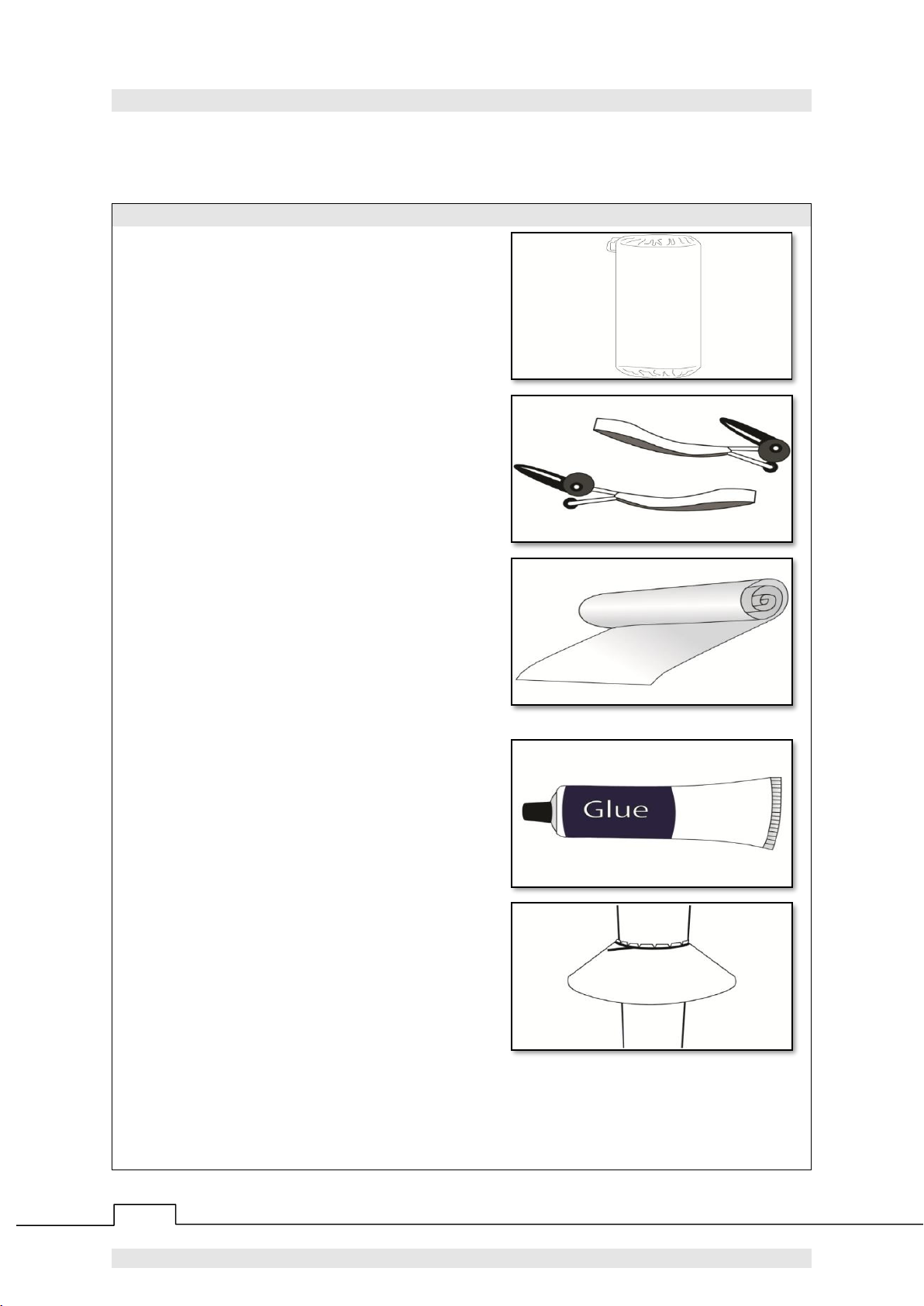

Repairing punctures and other damages................................................................ 16

Recommended weekly monitoring.........................................................................16

Cleaning................................................................................................................... 17

Safekeeping.............................................................................................................17

Prohibited item not allowed to ship .......................................................................17

Recycling.................................................................................................................. 17

8. FREQUENTLY ASKED QUESTIONS AND ANSWERS .......................................................17

9. WARRANTY CLAUSE .....................................................................................................19