Standen POWAVATOR 150 User manual

POWAVATOR 150

Standen Engineering Limited.

Hereward Works,

Station Road, Ely,

Cambridgeshire.

CB7 4BP

England.

Tel: 01353 661111 www.standen.co.uk Fax: 01353 662370

POWAVATOR 150

IMPORTANT

• This operators handbook should be regarded as part of the machine. Suppliers of both new

and second-hand machines are advised to retain documentary evidence that this handbook

was supplied along with the machine.

• On installation of the machine (i.e. starting off in the field), the New Machine Installation

Record Card should be completed by the dealer/distributor and be countersigned by the

customer. The document is proof that the correct procedures have been followed.

• The New Machine Installation Record Card should be returned to Standen Engineering

Limited within 7 days of installation. Failure to do so may invalidate the machine warranty.

On delivery, check that the machine is as ordered and has not been damaged in transit.

Please report any shortfall to your STANDEN dealer.

The contents of this handbook, although correct at the time of publication, may be subject to

alteration by the manufacturers without prior notice.

Standen Engineering Limited operate a policy of continual product development. Therefore,

some illustrations and/or text within this publication may differ from your machine.

The copyright of this handbook is the property of Standen Engineering Limited,

Hereward Works, Station Road, Ely, Cambridgeshire. CB7 4BP. This handbook is issued on the

condition that it must not be used, copied or exhibited without their written permission.

POWAVATOR 150

CONTENTS

SECTION 1 SECTION 4

INTRODUCTION SETTING INSTRUCTIONS

1:1 Warranty 4:1 Attaching the Powavator to the Tractor

1:2 Replacement Parts 4:2 Removing the Powavator from the Tractor

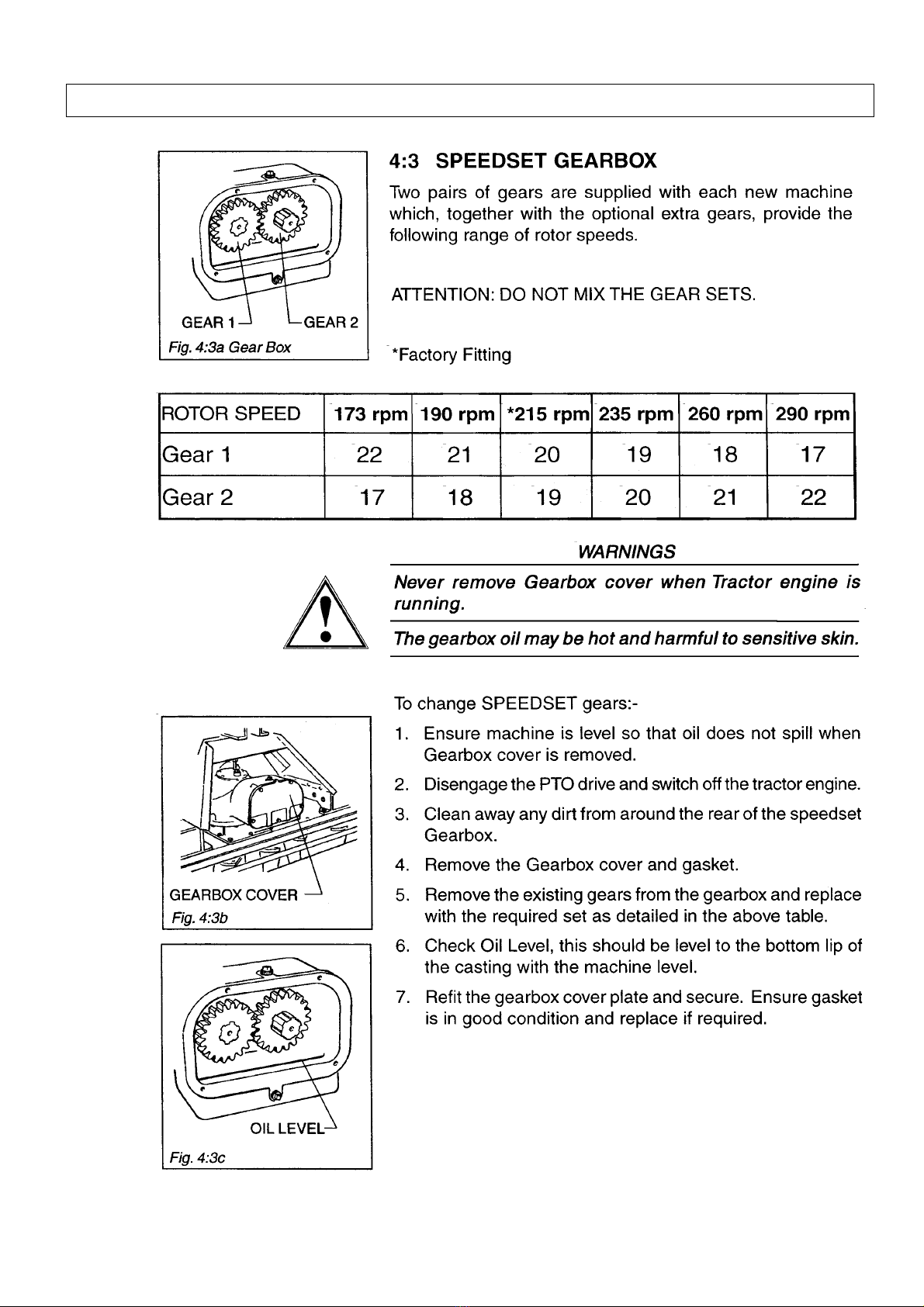

1:3 Machine Layout 4:3 Speedset Gearbox

1:4 Introduction to the Manual 4:4 Overload Clutch Unit

1:5 Copyright 4:5 Depth Control

4:6 Weed Cutter Blades

4:7 Trailing Shields

SECTION 2

SAFETY

SECTION 5

OPERATING INSTRUCTIONS

2:1 Noise Levels

2:2 Personnel Safety 5:1 Checks Before Operation

2:3 Safety in Operation 5:2 Working Instructions

2:4 Safety in Transit 5:3 Operators Check List

2:5 Safety in Maintenance

2:6 Safety in Lifting SECTION 6

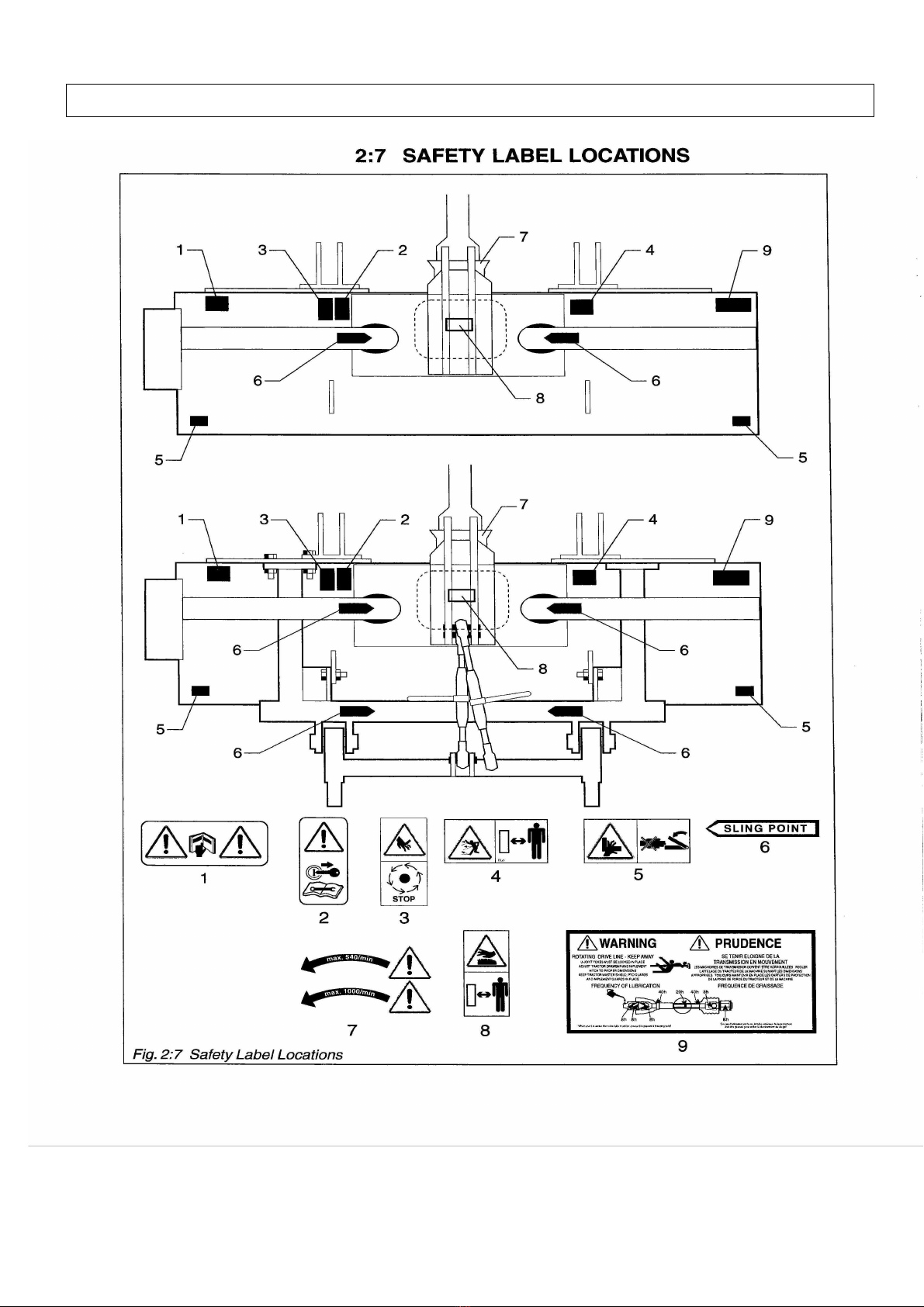

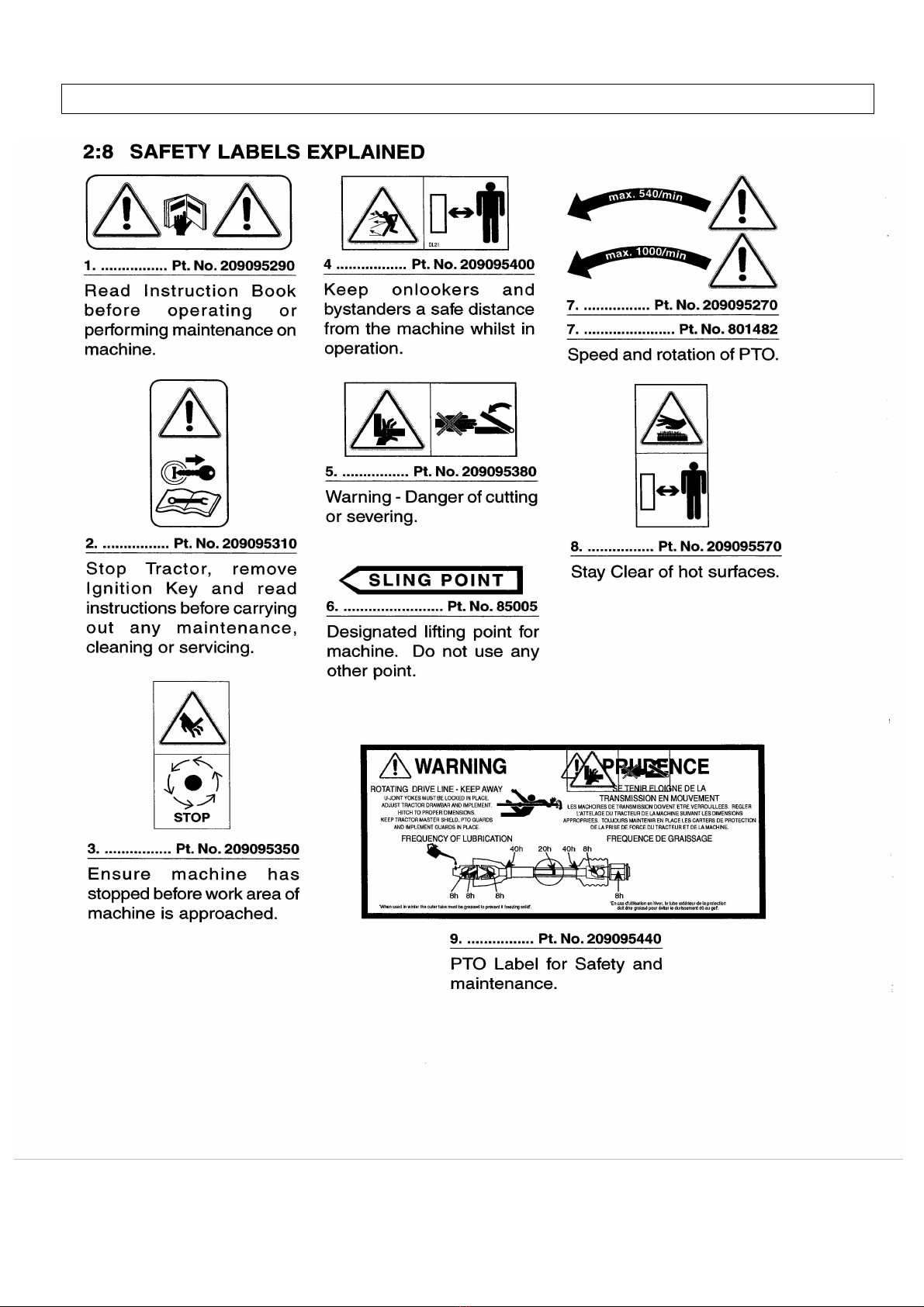

2:7 Safety Label Locations MAINTENANCE

2:8 Safety Labels Explained 6:1 Lubrication

6:2 Preliminary Maintenance

SECTION 3

6:3 Service Schedule

TECHNICAL INFORMATION 6:4 Wear Skids

3:1 Description

6:5 Rotor Blades

3:2 Specifications 6:6 Spike Removal/Fitting

3:3 Dimensions

3:4 Tractor Suitability SECTION 7

3:5 Tractor Tyres SUPPLEMENTS

7:1 Bedformer Kit

7:2 Fitting the Frame

POWAVATOR 150

SECTION 1 INTRODUCTION

1:1 WARRANTY

Should defective material and/or workmanship used in

Manufacture give rise to failure, the products themselves or

The components and sub-assemblies affected, will be

Replaced or repaired free of charge during the first 12 months.

The fitting of non Standen parts, or repairs, or modifications

Carried out by unauthorised persons may invalidate the

Warranty. No major work is to be undertaken without prior

consultation with Standen Engineering Limited.

Save to the extent covered by the warranty, the Company

Shall not be liable in any circumstances for any loss, injury

Or expense, whether direct or indirect, which may arise for any

reason whatsoever from any defect in or otherwise in connection with

any goods supplied or work done by the Company.

1:2 REPLACEMENT PARTS

Use only genuine STANDEN spares, which have the full

Warranty. Refer to the parts section for information on ordering

spares.

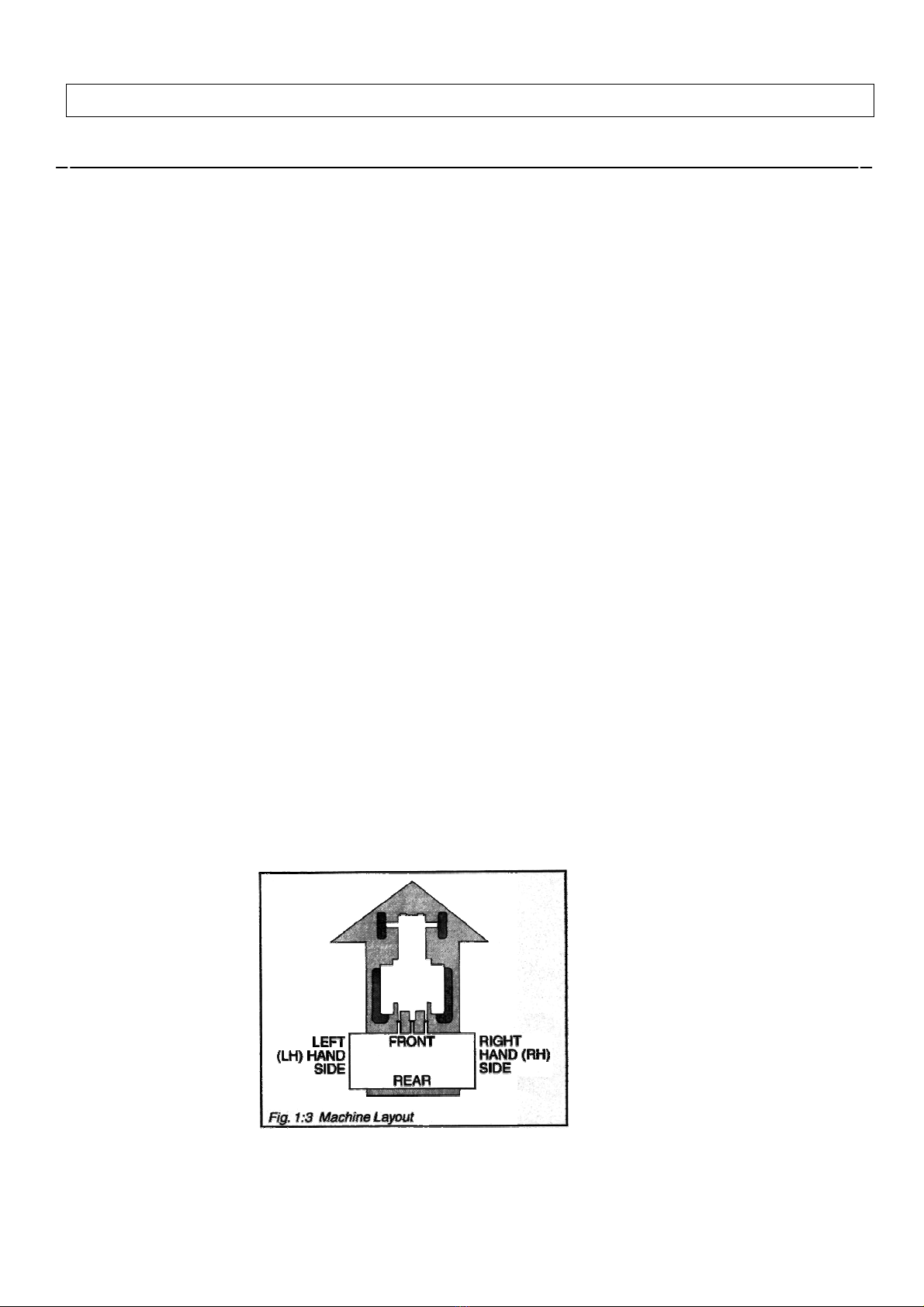

1:3 MACHINE LAYOUT

Fig. 1:3 (below) shows the Left, Right, Front and Rear terminology as

used throughout this manual.

POWAVATOR 150

1:4 INTRODUCTION TO THE MANUAL

Standen products comply with the Machinery Directive

89/392/EEC, as amended by Directive 91/368/EEC, 99/44,

99/68.

This manual has been written and provided to enable users

Of the Standen products to :-

1. Understand how the machine operates.

2. Be able to operate the machine safely and without hazard to

either the operator or persons in the vicinity.

3. Be able to use the machine to its full potential.

The operator must read all of the manual and fully understand its

contents before attempting to operate, adjust or service the machine.

The contents of this manual are intended as a guide to the

operation and servicing of the machine. It is not a training

manual.

Whilst all care and attention has been taken in the design and

production of all Standen products, as with all machinery there

remains a certain amount of risk to personnel whilst the machine is in

use.

It is strongly recommended that operators take all possible

precautions to ensure both their own safety and the safety of others

that may be in the vicinity.

POWAVATOR 150

1:5 COPYRIGHTS

Standen Engineering Limited

Hereward Works Station Road,

Ely, Cambridgeshire. CB74BP

This handbook is issued on the condition that it must not be

used, copied or exhibited without their written permission.

POWAVATOR 150

SECTION 2 SAFETY

2:1 NOISE LEVELS

In accordance with the Supply of Machinery (Safety) Regulations

1992 the equivalent continuous A-weighted sound pressure level at

the drivers seat does not exceed 70 dB(A).

2:2 PERSONNEL SAFETY

The STANDEN machine has been designed and constructed to

comply with current Safety Regulations. However, as with all

machinery, there will be inherent dangers whilst operating and

carrying out maintenance on the Implement.

Safety is the responsibility of persons working with the machine.

Think ‘SAFETY’ at all times. Read and remember the contents of this

handbook.

The following list of precautions should be brought to the attention of

all persons operating or working on the machine and should be

complied with at all times.

2:3 SAFETY IN OPERATION

1. Untrained personnel or children must never operate the

Implement.

2. The tractor must be of a suitable size to be able to operate the

Implement safely.

3. Always check that the Implement has been correctly mounted

to the tractor before moving off.

4.

Normal safe working procedures should be adopted at all

times. Reduce speed when moving across sloping ground and

when turning. Do not work on ground where there is a

possibility of overturning or across steep slopes.

5.

Before carrying out any work on the machine, make sure the

Machine is lowered to the ground, switch off the tractor

engine, apply the handbrake and remove the ignition key.

POWAVATOR 150

6. Never work on, or under the machine when it is in a raised

position without suitable blocks/props being used to fully

support the weight of the Implement.

7. The Implement should only be used for the purpose for which

it was designed and as per the instructions in the operators

manual.

8. Wear substantial or proper footwear. Wear gloves when

handling the Implement or parts with sharp edges.

9.

In low light conditions, a sufficient level of artificial light should

be made available to ensure safe working conditions.

2:4 SAFETY IN TRANSIT

1. Only transport the machine at a speed suitable to the

prevailing conditions

2. Be aware of the weight and overall size of the machine at all

times.

3. When travelling on the highway in restricted light or at night, a

suitable lighting board should be attached to the rear of the

machine.

POWAVATOR 150

2:5 SAFETY IN MAINTENANCE

1. Lubricate the Implement as per section 6 of this manual.

2. Check the tightness of all nuts and bolts regularly.

3. Never work on or under the machine when it is in a raised

position without suitable blocks/props being used to fully

support the weight of the Implement.

4. Beware of pinch and trap points. Lock moving parts as

required before working in the vicinity.

5. Wear substantial or proper footwear. Wear gloves when

handling the Implement or parts with sharp edges.

6. Always use mechanical or additional help when lifting heavy

parts.

7.

Use only genuine STANDEN replacement parts.

2:6 SAFETY IN LIFTING

1. Ensure lifting equipment is fully tested and has a rated lifting

capacity capable of lifting the Implement.

2. The machine should only be lifted using nylon straps or

similar. Only fix straps to the main chassis and hitch.

3. Lifting without total care and attention can cause damage to

the machine and may cause injury to personnel.

For weight of machine – refer to 3:2 Technical Specifications

POWAVATOR 150

POWAVATOR 150

POWAVATOR 150

SECTION 3 TECHNICAL INFORMATION

3:1 DESCRIPTION

The Powavator 150 series is ideally suited for either primary or

secondary cultivation’s and will produce seedbeds, control

weeds, incorporate chemicals, trash and sterilising agents.

The implement has an option of Soil Blades or Spikes that are

driven from the tractor PTO. A substantial bevel gearbox with

interchangeable gear sets, enables speed change to suit soil

conditions. An overload clutch unit provides protection to the

machine.

All width versions are suitable for category 2 or 3 mounting in

the central position only. Depth of cultivation is maintained by

side mounted wheels or a rear mounted roller.

3:2 SPECIFICATIONS

Model

70

90

100

120

140

Power

65 – 112kW (90 – 150 HP)

PTO rpm

540 or 1000

TRACTOR

Three point

Linkage

Category 2 or Category 3

MACHINE

WIDTH

Overall

(maximum)

Cultivating

(approx.)

1270mm

(90”)

1780mm

(70”)

2800mm

(110”)

2250mm

(90”)

3050mm

(120”)

2550mm

(100”)

3550mm

(140”)

3050mm

(120”)

4060mm

(160”)

3560mm

(140”)

WEIGHT

Standard

Spec. Kg

850Kg

1100Kg

1200Kg

1450Kg

1700Kg

Cultivating

Depth

Up to 200mm (8”)

Control

Device

Side mounted wheels or Rear mounted Roller

190,215,235 and 260 rpm with standard Gears Supplied

ROTOR

Speed

(approx.)

173 and 290 rpm with ‘optional’ gears

POWAVATOR 150

3:3 DIMENSIONS

See table 3:2

3:4 TRACTOR SUITABILITY

Power requirement – up to 112kW – 150 HP

The tractor must be of a suitable size to suit land conditions

and to handle and lift the implement safely.

3:5 TRACTOR TYRES

Ensure that all tractor tyres are at the manufacturers

recommended pressures and that left and right hand side

tyres are identical and state of wear is approximately the

same.

POWAVATOR 150

SECTION 4 SETTING INSTRUCTIONS

4:1 ATTACHING THE POWAVATOR TO THE

TRACTOR

The Powavator 150 Series is suitable for either category 2 or 3

three point linkage, it must be mounted in the central position

only. (See fig.4:1a)

Fig. 4:1a Lower Mounting Brackets

To determine the correct mounting position :-

1. With the Powavator on a firm level surface, adjust the

depth control device until the machine gearbox input shaft

is horizontal.

2. Reverse the tractor up to the machine to give 150mm

(6 ins) minimum engagement of the male half of the PTO

drive shaft in the female tube when connected to the

tractor. The safe working length between centres of the

cross journals is 660-870mm (26-34 inches).

3. Position the tractor lower link ball ends in line with the

machine lower mounting brackets.

POWAVATOR 150

4. APPLY THE TRACTOR HANDBRAKE AND SWITCH

OFF THE ENGINE

5. Insert the mounting pins through the brackets and the

tractors lower link ball ends. Secure using clip pins.

6. Adjust the tractor top link length and fit to the machine

using the mounting pin supplied. Secure using a clip pin.

7. Fit and adjust stabiliser bars or chains to limit sway to a

maximum of 50mm (2 inches).

8. Fit the PTO drive shaft to the tractor PTO, ensuring that

the end yoke quick-release pin locates fully in the tractor

PTO shaft groove. Clip the safety check chain to the

tractor.

9. Before engaging the tractor PTO, check that the length of

the PTO drive shaft is within the specified operating range

when the machine is in the horizontal and raised positions.

When raised, the angle on the universal joint must not

exceed 40º or damage may occur (see fig 4:1b).

10.Raise the parking prop and secure in the raised position.

Fig. 4:1b

POWAVATOR 150

4:2 REMOVING THE POWAVATOR FROM THE

TRACTOR

1. Locate and secure the parking prop in the lowered

position. Lower the Powavator to the ground.

2. APPLY THE TRACTOR HANDBRAKE AND SWITCH

OFF THE ENGINE.

3. Disconnect the PTO drive shaft safety guard check

chain from the tractor

4. Depress the quick-release pin on the tractor end yoke

and slide the yoke off the tractor PTO shaft and put it in

the stow position.

5. Disconnect the tractor top link from the machine.

6. Remove the stabiliser bars or chains and then

disconnect the tractor lower links from the machine.

POWAVATOR 150

POWAVATOR 150

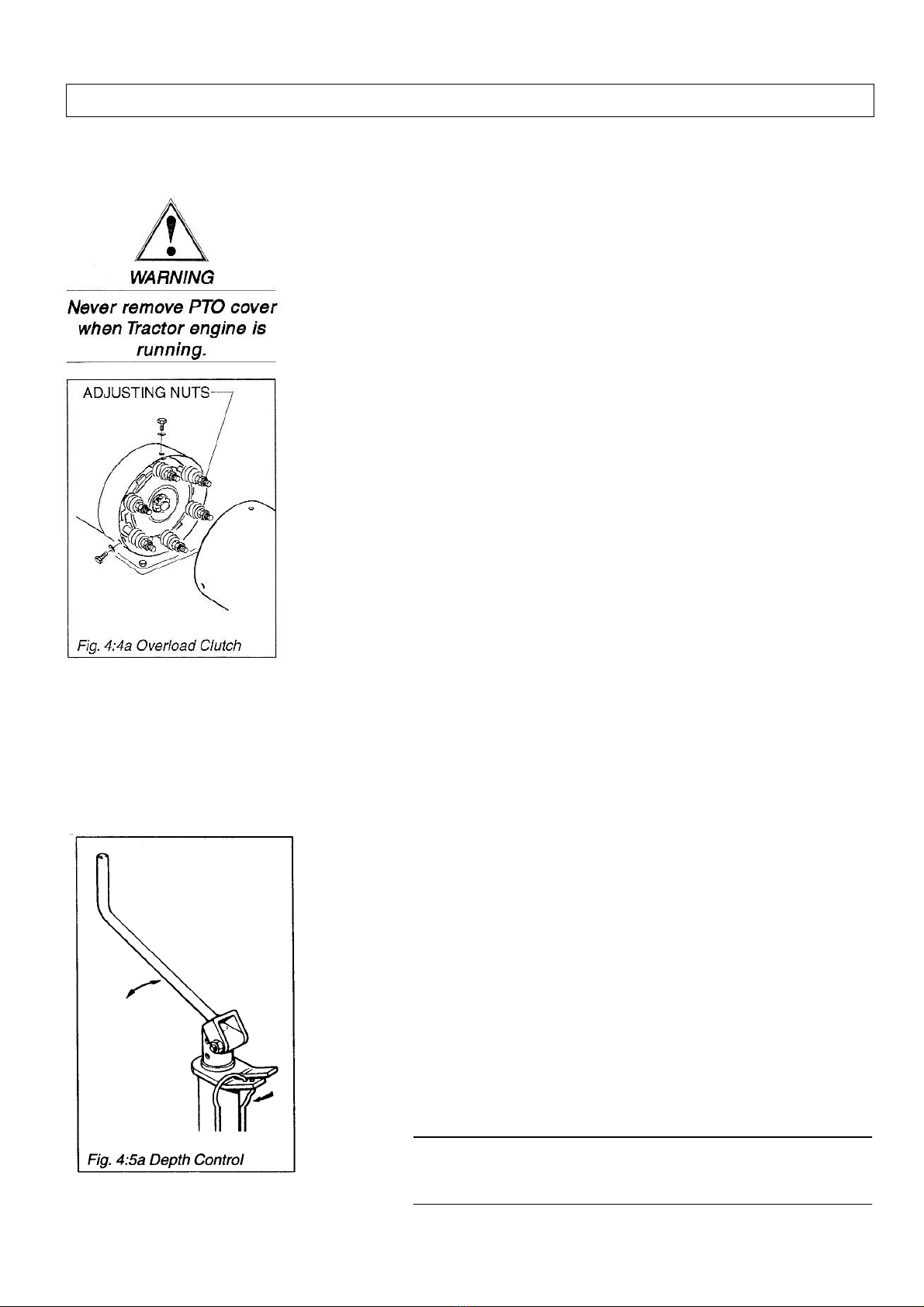

4:4 OVERLOAD CLUTCH UNIT

The overload clutch unit (part of PTO shaft supplied) protects the

machine transmission should the blades encounter an obstruction.

CAM CLUTCH UNIT (machines prior to 2010)

The cam clutch unit is supplier-set and is not adjustable. For any

other information refer to the suppliers literature (supplied with the

machine).

FRICTION CLUTCH UNIT (machines from 2010)

If set too loosely the blades will turn erratically leading to excessive

friction plate wear and poor work finish. If set too tightly it will not

provide the necessary protection.

To adjust the clutch setting:

1. Disengage the PTO drive and switch off the tractor engine.

2. Disconnect the PTO drive shaft safety guard check chain and

remove the clutch guard from the machine.

3. Tighten two opposite nuts until the springs are coil bound as

this will help to centralise the plates.

4. Tighten the other nuts until they just touch the washers , then

tighten each nut an additional 2 1/2 complete turns for 540

rpm, or 1 3/4 turns for 1000 rpm.

5. Slacken off the two coil bound springs and reset the same as

the others.

6. Refit and secure the clutch unit safety gurad and clip the PTO

drive shaft safety guard check chain to the machine.

4:5 DEPTH CONTROL

The depth of cultivation is controlled down to a maximum

of 200mm (8 inches) by means of side mounted wheels

or a rear mounted roller.

To adjust depth :-

1. Unclip the screw adjuster handles and rotate

clockwise to increase depth or anticlockwise to

decrease depth.

2. When correct, fold the handles down and secure

using the clip.

NOTE

Adjustment should be the same on both sides to ensure

even depth of cultivation

Table of contents

Other Standen Farm Equipment manuals

Standen

Standen SP Series User manual

Standen

Standen T2 Service manual

Standen

Standen ZENO Series User manual

Standen

Standen T2 User manual

Standen

Standen POWAVATOR 400 Service manual

Standen

Standen BX Series User manual

Standen

Standen T2 Service manual

Standen

Standen SP Series User manual

Standen

Standen SP Series User manual

Standen

Standen SP Series User manual

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions